Professional Documents

Culture Documents

Design and Fabrication of A Peltier Oper

Uploaded by

Youssef LANDOLSIOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Fabrication of A Peltier Oper

Uploaded by

Youssef LANDOLSICopyright:

Available Formats

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056

Volume: 03 Issue: 03 | Mar-2016 www.irjet.net p-ISSN: 2395-0072

Design and Fabrication of a Peltier Operated

Portable Air Cooling System

Nilesh Varkute, Akshay Chalke, Deepak Ailani, Ritesh Gogade, Ajay Babaria

Mechanical Engineering Department, F.C.R.I.T

Vashi, Navi Mumbai, Maharashtra, India

---------------------------------------------------------------------***---------------------------------------------------------------------

Abstract – Air Conditioning is the science of controlling A.F. Rudd [2] investigated the important parameters that

primarily three parameters of human comfort, temperature, needed to be assessed for achieving thermal comfort.

relative humidity and air quality. Air conditioners, Surrounding temperature and RH were the two most pre-

dehumidifiers and evaporative coolers serve the purpose dominant factors that needed to be considered as per the

however air conditioners are termed expensive and coolers research paper by him based on residential dehumidification.

prove ineffective in humid conditions. The study conducted in The optimum range of RH for human comfort lies between

the work aims at developing a Peltier operated air cooler 50-55% and temperature of 240C were the derived

coupled with a dehumidifier to achieve dual objective of conclusions from this research paper.

dehumidification and sensible cooling. The work aims to Matthew Carl [3], Upendra Kulshreshtha [4] and his research

performance testing of Peltier for indoor cooling. The desired group analyzed various heat exchangers and studied

design is intended to provide a good alternative to Air automobile Heat Exchangers to a great depth. For the

Conditioners which consume sufficiently high power with very selection of appropriate heat exchanger, these references

large initial investment. based on automotive Heat Exchangers were used to get a

brief idea about working of car Heat Exchangers and also to

Key Words: Peltier, Dehumidification, sensible cooling, understand the basic difference between evaporating coils

relative humidity, human comfort, air conditioning. and Heat Exchangers and which one would be more suitable

for the required application. An idea about the coolant flow

through the heat exchanger and air flow over fins for

1. INTRODUCTION convective cooling was understood.

Lewis G Harriman III [5], second edition of Dehumidification

Thermal comfort is the condition of mind that expresses Handbook, was used to understand the key concepts

satisfaction with the thermal environment and is assessed regarding psychometric chart and also for load calculations

by subjective evaluation. Maintaining this standard of based on design conditions. The key fundamentals of

thermal comfort for occupants of buildings or other psychometrics such as difference between dry bulb

enclosures is one of the important goals of HVAC (heating,

temperature and wet bulb temperature, relative humidity

ventilation, and air conditioning) design engineers. Two of

based on percentage of saturation, humidity ratio based on

the most important parameters that are taken into account

while evaluating thermal comfort are rh (Relative Humidity) grains of water vapour, dew point temperature and enthalpy

and ambient temperature. These two parameters are in Btu s per pound of air were studied. Various types of

dependent on n number of factors which vary from person dehumidifiers and their respective applications in HVAC field

to person depending on their metabolism. The best range of are of prime importance. Moisture load calculations due to

rh for human comfort is known to occur from 45-55%. We humans, leakages inside the room, furniture and other things

here consider effects only due to high humidity because of inside the room were studied in detail so as to consider the

Mumbai being a coastal region and rh values here generally appropriate dehumidifier for our use.

being well above 75 %. The project idea was developed based

Umesh V. Sangale [7], Prof. Priyanka Jhavar [7] and

on the following research work published earlier.

Dr.G.R.Seloskar.S [7] made use of thermoelectric modules in a

A. S. Alosaimy [1] studied and also did some research work to unique way by using solar cell powered Peltier junctions for

understand the working of a desiccant based dehumidifier refrigeration purpose. These authors have used 4 Peltier

where solar energy was being used to regenerate the calcium modules for obtaining a refrigeration of one liter capacity.

chloride desiccant. Use of solar energy for regenerating They have used fans to cool the hot junction of Peltier module

desiccant was not very cost effective and also the lack of and we wish to do the same if required.

availability of desiccant based dehumidifiers and their high

Thus the idea was developed to build Peltier cooled water

running costs made compressor based dehumidifiers a better

heat exchanger to condition air.

alternative.

© 2016, IRJET ISO 9001:2008 Certified Journal Page 1801

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056

Volume: 03 Issue: 03 | Mar-2016 www.irjet.net p-ISSN: 2395-0072

2. AIM AND OBJECTIVE 4. Peltier Module – Peltier Module is a 12 V DC device used

to cool the coolant from its cold side.

Objective: To provide an alternative for Air Conditioners as 5. Heat Sink – Heat sink is used to dissipate the heat from

they are deemed too expensive for vast majority of people in the hot side.

India. 6. SMPS (Switched-mode Power Supply) – It is used to

Aim: Design and fabrication of a Peltier Operated Portable power the Peltier Module and the fans used for heat

Air Cooling Unit. dissipation on the heat sink.

3.2 Design Procedure

3. DESIGN LAYOUT, COMPONENT SELECTION AND The air after dehumidification will enter a water cooled

CALCULATIONS condenser (heat exchanger) where it will cool down to

comfort conditions i.e. 240C. The water in this process will

Air conditioning involves dehumidification and cooling of

take the heat from air and its temperature will rise which

air. The process starts with dehumidification. Air at

needs to be cooled using a Peltier device. The temperature

ambient conditions enters the dehumidifier where the

humidity is extracted and collected in a tank. The air after rise of coolant water is calculated as follows:

passing through the dehumidifier is heated up which

requires cooling. The heated air then is passed through 1. Heat Load Calculations:

cross flow heat exchanger. Water is stored in a sump

equipped with a thermoelectric module to maintain the Calculation of temperature rise of coolant in single pass

coolant temperature. Water is circulated through the heat

exchanger where it absorbs heat from the air and flows Volume flow rate of air = 95 x 28.32 x 10-3

m3/min

back into the tank. Thus after rejecting heat to the water

= 2.6904 m3 /min

air is cooled and passed into the room. The process flow is Mass flow rate of air,

shown in figure 1.

mair = 2.6904 x Density of air

= 2.6904 x 1.128

= 3.03 Kg/min

Specific heat capacity of air,

Cair = 1.005 KJ/Kg

Inlet air temperature = 40 0C

Outlet air temperature = 25 0C

Heat loss by air, Qair = mair x Cair x ΔTair

= 3.03 x 1.005 x 15

= 45.67 KJ/min

Volume flow rate of coolant

= 750 L/hr.

= 12.5 L/min

= 12.5 x 10-3 m3/min

Fig -1: Layout of Air Cooling Unit

Mass flow rate of coolant,

3.1 Components of Air Conditioning Unit Mc = 12.5 x 10-3 x Density of coolant

= 12.5 x 10-3 x 1000

1. Dehumidifier - A dehumidifier is a device that removes = 12.5 Kg/min

moisture from an enclosed space and brings down the

relative humidity. Specific heat capacity of air,

2. Cooling Coils - Cooling coils are used to absorb heat of Cc = 4.18 KJ/Kg

the dehumidified air.

Heat lost by air = Heat gain by Coolant

3. Pumps - Pumps are used to pump the coolant in

through the radiator. mair x Cair x ΔTair = mc x Cc x ΔTC

© 2016, IRJET ISO 9001:2008 Certified Journal Page 1802

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056

Volume: 03 Issue: 03 | Mar-2016 www.irjet.net p-ISSN: 2395-0072

Substituting in equation,

ΔTC =

ΔTC = 0.874 0C

h = 19.68 W/m2K

2. Cooling Surface Requirement & Design of Heat Substituting this value in the equation,

Exchanger :

Outlet temperature = Inlet temperature + ΔTC

0C of coolant

The temperature after the dehumidifier is 1 above

= 20 + 0.874

ambient according to manufacturer s data. The ambient = 210C

temperature in Mumbai during summer is 350C Calculating LMTD:

according to weather data which will be nearly 400C LMTD =

after passing through the dehumidifier. The area of heat

exchanger required to cool air from 400C to 250C is

calculated as follows: =

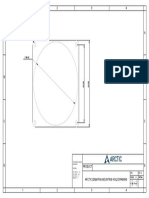

For the heat transfer a fin surface of available condenser = 10.48 0C

is as in figure 2.

Substituting values in the equations,

Q = h x A x LMTD

= 19.68 x A x 10.48

A = 4.05 m2

All the design calculations as shown below in table 1.

Fig -2: Fin surface

Table - 1: Design Dimensions

(eight: . cm

Width: . cm Sr Summary of design calculations

The heat transfer co-efficient for laminar flow over a plate is No. Components Dimensions Quantity

given by:

1 Dehumidifier L = 1

W= .

2 Cooling Coils L = 1

W=

For air at 400 C and for fin surface assuming properties of air

are: 3 Peltier Module L = 4.2 cm 1

W = 4.2 cm

L=0.05 m 4 Heat Sink L = 8 cm 2

= 1.127 kg/m3 W = 8 cm

= 19.12 x 10-6 Ns/m

5 SMPS O/P=12,5A 1

k = 0.0271 W/mk

v = 16.97 x 10-6 m2/s

6 Water Cooling Block L = 4.2 cm 1

Pr = 0.699 = W = 4.2 cm

© 2016, IRJET ISO 9001:2008 Certified Journal Page 1803

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056

Volume: 03 Issue: 03 | Mar-2016 www.irjet.net p-ISSN: 2395-0072

3. Heat sink and Peltier cooling assembly :

The hot water outlet of condenser is fed into the water

cooling block and Peltier assembly as in figure 4 for

cooling the water for its recirculation. The heat taken

from the water by the Peltier and that generated by the

hot junction of the Peltier needs to be rejected. A heat

sink and fan assembly is used to take up the rejected heat.

Proper heat rejection is important or else the cold

junction of Peltier would not reach the required low

temperature.

The methods employed to increase the heat rejection are

as follows:

1. Increase the size of heat sink.

Increasing the size of heat sink increases the heat

rejection area thus allowing the Peltier cold junction to

achieve lower temperatures.

Fig - 4: Heat sink and Peltier block assembly

2. Forced convection over the heat sink

Removal of heat from the heat sink is equally important

which is achieved by heat rejection. A different approach

was used in the design to increase the flow rate of air 4. FABRICATION AND FINAL SETUP

over the heat sink. A diffuser shaped section as in figure 3

was designed and a fan assembly was mounted on the A mobile steel frame supported on castor wheels is fabricated

to hold all components in place. The wheel supported frame

larger opening side and heat sink assembly was placed

fulfills the objective of portability. Specification of final setup

near the smaller opening.

as shown in fig. 5 is as follows.

DIMENSIONS: 38cm X 38cm X 50cm

WEIGHT : 20 kg

The entire unit is mounted on a wheel frame for ease of

portability.

Fig -3: Forced convection over heat sink

By continuity equation:

A1V1 = A2V2

Since A1< A2

V1>V2

Thus higher velocity air and thus higher convection rate

was thus achieved by change in design. The temperature

achieved on water cooling block was 5 0c.

Fig -5: Final fabricated air cooling unit.

© 2016, IRJET ISO 9001:2008 Certified Journal Page 1804

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056

Volume: 03 Issue: 03 | Mar-2016 www.irjet.net p-ISSN: 2395-0072

5. TESTING AND RESULTS 3. CONCLUSIONS

The Air Cooling Unit was tested and the following results 1. The air cooling unit gives a cooling of up to 26°C and

were obtained. Table 2 shows the Temperatures of air and better results are achieved with use of cold water.

water before and during testing. The temperature of air at 2. The Peltier module proves sufficient in air

ambient condition, after the dehumidifier and after the heat conditioning for indoor applications as desired in the

exchanger was noted down. Tests were conducted using above study.

normal tap water and water from refrigerator. The results

obtained were as in Table 2 and Table 3:

ACKNOWLEDGEMENT

We would like to express our regards to Prof. Nilesh Varkute

Table - 2: Effect by using tap water for guiding us thorough the entire BE final year project. We

would also like to thank Dr.T Mathewlal (Head of

Department, Fr. C.R.I.T., Vashi, and (Navi-Mumbai)) for giving

Sr.No. Description Temperat

his valuable time to guide through the project.

ure (0C)

REFERENCES

1 Ambient Air Temperature 25 [1] A. S. Alosaimy, , Application of Evaporative Air

Coolers Coupled With Solar Water Heater for

Dehumidification of )ndoor Air , Mechanical Engineering

Department, Faculty of Engineering, Taif University,

Temperature at the outlet KSA.

2 32

of dehumidifier [2] A.F. Rudd, J.W. Lstiburek, P. Eng, and K. Ueno, 2005,

Residential Dehumidification Systems Research for

Temperature of water in Hot- (umid Climates , Building Science Corporation

3 24 Westford, Massachusetts.

tank before operations

[3] Matthew Carl, Dana Guy, Brett Leyendecker, Austin

Temperature of air Miller and Xuejun Fan, , The Theoretical and

Experimental investigation of the Heat Transfer process

4 coming (in the room) out 26 of an Automobile (eat Exchanger , Department of

of Heat Exchanger Mechanical Engineering Lamar University, PO Box

10028 Beaumont, TX 77710

[4] Upendra Kulshrestha, Gaurav Kumar, Manu Augustine

and Sanjay Mittal, , CFD Analysis of Automobile

Table - 3: Effect by using cold water at 130C Heat Exchanger – A Review , Department of Automobile

Engineering, School of Engineering & tech., Manipal

University, Jaipur, Rajasthan, India.

[5] The Dehumidification Handbook Second Edition ISBN 0-

Sr.No. Description Temperat 9717887-0-7 Copyright 1989 and 2002 © Munters

ure (0C) Corporation, Lewis G. Harriman III, Editor

[6] Ajitkumar N. Nikam, Dr. Jitendra A. (ole, A Review on

use of Peltier Effects , Mechanical Engineering

Department, Rajrashree Shahu College of Engineering,

1 Ambient Air Temperature 36 Pune, India.

[7] Umesh V. Sangale, Prof. Priyanka Jhavar,

Dr.G.R.Seloskar.S, Thermoelectric Refrigeration by

Temperature at the outlet Using Solar Energy for Domestic Appliance , Mechanical

2 40 Engg. Department1, 2, 3, SSSIST, Sehore, Bhopal, M.P.

of dehumidifier

[8] Rajput R.K., Heat and mass transfer, S Chand Publication,

New Delhi

Temperature of water in

3 13 [9] Bosen Qian, Fei Ren, Cooling Performance of

tank before operations Transverse Thermoelectric devices , Department of

Mechanical Engineering Temple University,

Temperature of air Philadelphia, PA 19112, USA.

4 coming (in the room) out 25 [10] Nilesh Varkute, Bipin Mashilkar, Sanjay Rukhande, Akshay

of Heat Exchanger Vengal, Vishal Madhavi, Mayur Karche, Amar Ingle, 2015,

EXPERIMENTATION AND TESTING OF AN OP-AMP

OPERATED SOLAR TRACKING MECHANISM” IRJET

volume 2, issue 7.

© 2016, IRJET ISO 9001:2008 Certified Journal Page 1805

You might also like

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemFrom EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemNo ratings yet

- Mech 1 (Magway)Document5 pagesMech 1 (Magway)Dr. Aung Ko LattNo ratings yet

- Irjet V5i1236 180319101623 PDFDocument6 pagesIrjet V5i1236 180319101623 PDFsuchismita swainNo ratings yet

- Cooling Load CalculationDocument90 pagesCooling Load CalculationmiraqueelaliNo ratings yet

- Awg India IjmeDocument7 pagesAwg India IjmeIwan SetiawanNo ratings yet

- Analysis of An Evaporative Desiccant Cooling System: January 2015Document9 pagesAnalysis of An Evaporative Desiccant Cooling System: January 2015abin brothersNo ratings yet

- Solar-Driven Refrigeration SystemDocument7 pagesSolar-Driven Refrigeration SystemIJAMTESNo ratings yet

- Smt.S.R.Patel College, Dabhi: EngineeringDocument24 pagesSmt.S.R.Patel College, Dabhi: EngineeringPATEL MITKUMAR SHAILESHBHAINo ratings yet

- Design and analysis of a regenerative air coolerDocument6 pagesDesign and analysis of a regenerative air coolerannmaryNo ratings yet

- Design of Chiller For Air Conditioning of Residential BuildingDocument7 pagesDesign of Chiller For Air Conditioning of Residential BuildingEditor IJTSRDNo ratings yet

- Low-Cost Refrigeration Trainer Demonstrates Vapor Compression CycleDocument6 pagesLow-Cost Refrigeration Trainer Demonstrates Vapor Compression CycleEugine BalomagaNo ratings yet

- Design and Development of Vapour Compression Refrigeration System Using Liquid Heat ExchangerDocument4 pagesDesign and Development of Vapour Compression Refrigeration System Using Liquid Heat Exchangersmruti katwaleNo ratings yet

- B037105018 PDFDocument14 pagesB037105018 PDFnavabnavab786No ratings yet

- Activity No. 3: Chiller EfficiencyDocument12 pagesActivity No. 3: Chiller EfficiencyAldrian BarachinaNo ratings yet

- Design and Heat Transfer Analysis of AC Condenser For Different MaterialsDocument7 pagesDesign and Heat Transfer Analysis of AC Condenser For Different MaterialsFawaz IqbalNo ratings yet

- Design, Calculation and Cost Estimation of HVAC System For School BuildingDocument12 pagesDesign, Calculation and Cost Estimation of HVAC System For School BuildingMd KaleemNo ratings yet

- Chapter 1Document39 pagesChapter 1الأردني JordanianNo ratings yet

- Assignment Thermal UiTMDocument26 pagesAssignment Thermal UiTMAmirul 'Pit'No ratings yet

- 4 ACMV SystemsDocument293 pages4 ACMV SystemsMorgan HengNo ratings yet

- Design and Analysis of Central Air-Conditioning System With Air Cooled Chiller of Multi-Storey Office BuildingDocument16 pagesDesign and Analysis of Central Air-Conditioning System With Air Cooled Chiller of Multi-Storey Office BuildingSajjad HasanNo ratings yet

- Assignment Thermal UiTMDocument29 pagesAssignment Thermal UiTMiwe1234No ratings yet

- Module 4Document29 pagesModule 4YUG VARSHNEYNo ratings yet

- The Influence Comparison of The Mass Refrigerant Towards Coefficient of Performance Car Air - Conditioning Systems With Refrigerant R-134ADocument7 pagesThe Influence Comparison of The Mass Refrigerant Towards Coefficient of Performance Car Air - Conditioning Systems With Refrigerant R-134Aanon_630820255No ratings yet

- Design and Performance Analysis of Water Chiller - A ResearchDocument8 pagesDesign and Performance Analysis of Water Chiller - A ResearchDiyar NezarNo ratings yet

- 7 ACMV SystemsDocument270 pages7 ACMV SystemsSK NGNo ratings yet

- IJAIEM Journal Article on Designing an Air Conditioning SystemDocument3 pagesIJAIEM Journal Article on Designing an Air Conditioning SystemAsok AyyappanNo ratings yet

- Geothermal HVAC - : Exceeding ASHRAE Standards at Lowest Life Cycle CostDocument11 pagesGeothermal HVAC - : Exceeding ASHRAE Standards at Lowest Life Cycle CostKagitha TirumalaNo ratings yet

- Irjet V8i3370Document5 pagesIrjet V8i3370Semister 5No ratings yet

- 20 A0188 p.148-162-1 PDFDocument18 pages20 A0188 p.148-162-1 PDFEganNo ratings yet

- Lab 01 RACDocument5 pagesLab 01 RACSaad mubeenNo ratings yet

- "Air Cooler" by Yojit Lokhande Swapnil Kumawat Gurudevkeware Mandar Pawar Swayam Ahire Parth Patil Guide Prof. S.D. MateDocument22 pages"Air Cooler" by Yojit Lokhande Swapnil Kumawat Gurudevkeware Mandar Pawar Swayam Ahire Parth Patil Guide Prof. S.D. MateswapnilNo ratings yet

- Design and Development of Modified Air Cooler Cum Storage SystemDocument7 pagesDesign and Development of Modified Air Cooler Cum Storage SystemPAVIN ENGGNo ratings yet

- Rac Notes (By D Deepak)Document32 pagesRac Notes (By D Deepak)Desh DeepakNo ratings yet

- A Review of Case Study of Room Comfort Analysis If Fan and Exhaust Fan Being UsedDocument4 pagesA Review of Case Study of Room Comfort Analysis If Fan and Exhaust Fan Being UsedEditor IJTSRDNo ratings yet

- Construction of A Radiant Cooling and Control Demonstration Unit For Use in Engineering CoursesDocument14 pagesConstruction of A Radiant Cooling and Control Demonstration Unit For Use in Engineering CoursesAshmin AryalNo ratings yet

- Shell-Tube Heat Exchanger DesignDocument28 pagesShell-Tube Heat Exchanger DesignsachingirNo ratings yet

- Upload 48990ijrdtvlis22 142204 150118011549 Conversion Gate01 PDFDocument5 pagesUpload 48990ijrdtvlis22 142204 150118011549 Conversion Gate01 PDFVignesh VickyNo ratings yet

- Refrigeration Cycles and Systems: A Review: ArticleDocument18 pagesRefrigeration Cycles and Systems: A Review: ArticleSuneel KallaNo ratings yet

- Lab Manual - Refrigeration & Air CONDITIONING (2161908) : January 2018Document47 pagesLab Manual - Refrigeration & Air CONDITIONING (2161908) : January 2018Getachew TikueNo ratings yet

- ReportDocument5 pagesReportabdulNo ratings yet

- Refrigeration and Air Conditioning ThesisDocument4 pagesRefrigeration and Air Conditioning Thesisfc4b5s7r100% (1)

- Refrigeration System Research PaperDocument6 pagesRefrigeration System Research Paperoabmzrznd100% (1)

- Main RefrenceDocument122 pagesMain RefrenceMàñëësh RèddyNo ratings yet

- Performance Assessment of HFC Group Refrigerants in Window Air Conditioning SystemDocument5 pagesPerformance Assessment of HFC Group Refrigerants in Window Air Conditioning SystemAdi PriyantoNo ratings yet

- Proposal Lab Thermo Topic 2 COMPLETEDocument10 pagesProposal Lab Thermo Topic 2 COMPLETEsaperuddinNo ratings yet

- What Is RefrigerationDocument10 pagesWhat Is RefrigerationxyonieNo ratings yet

- CH - 1Document6 pagesCH - 1Mohamed AbdelRazekNo ratings yet

- HVACDocument14 pagesHVACbagi1900No ratings yet

- 14 Mur Jet AamirDocument9 pages14 Mur Jet AamirAkshat RNo ratings yet

- Seminar On RACDocument21 pagesSeminar On RACAditya DeshpandeNo ratings yet

- New Refrigerants and Refrigeration SafetyDocument6 pagesNew Refrigerants and Refrigeration SafetyADITYA S RNo ratings yet

- Group - 1 Refegeration 1 (Marine Refrigeration Cycle)Document16 pagesGroup - 1 Refegeration 1 (Marine Refrigeration Cycle)Jannen V. ColisNo ratings yet

- Simulation Based Interpretation and Recent Trends On Performance Analysis On Automobile Radiator Through Nano Particle FluidsDocument3 pagesSimulation Based Interpretation and Recent Trends On Performance Analysis On Automobile Radiator Through Nano Particle FluidsEditor IJTSRDNo ratings yet

- Investigation On Reciprocating Air ComprDocument6 pagesInvestigation On Reciprocating Air ComprChris VilaNo ratings yet

- On Solar Vapour Absorption Refrigeration System: Seminar ReportDocument16 pagesOn Solar Vapour Absorption Refrigeration System: Seminar ReportlokeshjakharNo ratings yet

- Mec544 11701322Document18 pagesMec544 11701322muath idelNo ratings yet

- Solar Powered Evaporative Air Conditioning SystemDocument12 pagesSolar Powered Evaporative Air Conditioning SystemdineshNo ratings yet

- Inverter Air Conditioner Performance AnalysisDocument26 pagesInverter Air Conditioner Performance Analysissamuel kaluNo ratings yet

- 0.drying Heat Pumps-Part IDocument17 pages0.drying Heat Pumps-Part IDr-Abhijit SinhaNo ratings yet

- Design ConstrutionDocument14 pagesDesign ConstrutionYoussef LANDOLSINo ratings yet

- Day2 9 Nate SAM Intro and OpenSource Slides For Kazakhstan v1 enDocument20 pagesDay2 9 Nate SAM Intro and OpenSource Slides For Kazakhstan v1 enYoussef LANDOLSINo ratings yet

- Electronic Enclosure Cooling Thermoelectric vs. Compressor Based Air Conditioners WhitepaperDocument13 pagesElectronic Enclosure Cooling Thermoelectric vs. Compressor Based Air Conditioners WhitepaperYoussef LandolsiNo ratings yet

- 92mm Fan-Mounting Hole PatternDocument1 page92mm Fan-Mounting Hole PatternYoussef LANDOLSINo ratings yet

- Thermoelectric Assemblies Handbook 1120Document15 pagesThermoelectric Assemblies Handbook 1120Youssef LandolsiNo ratings yet

- Materi Enegry CleanDocument46 pagesMateri Enegry Cleansofta novaNo ratings yet

- Réalise Par:: Institut Supérieur Des Études Technologiques de TataouineDocument13 pagesRéalise Par:: Institut Supérieur Des Études Technologiques de TataouineYoussef LANDOLSINo ratings yet

- Cooling Using Thermoelectric Cooler When Vehicle Is ParkedDocument8 pagesCooling Using Thermoelectric Cooler When Vehicle Is ParkedYoussef LANDOLSINo ratings yet

- Design and Analysis of A Thermoelectric Air-Conditioning SystemDocument12 pagesDesign and Analysis of A Thermoelectric Air-Conditioning SystemYoussef LANDOLSINo ratings yet

- Peltier Cooling ModuleDocument43 pagesPeltier Cooling ModuleVenkatesh MohanNo ratings yet

- Sealed with a Kiss Hit Song from 1962Document1 pageSealed with a Kiss Hit Song from 1962mrmarcoguimaNo ratings yet

- BHEL Doctors - Mobile Number and Email IdDocument11 pagesBHEL Doctors - Mobile Number and Email IdCHANDRAN MAHA100% (1)

- Make Money OnlineDocument9 pagesMake Money OnlineTimiNo ratings yet

- Amelia Wills CV 2021 VDocument4 pagesAmelia Wills CV 2021 Vapi-446566858No ratings yet

- CV HannahDocument3 pagesCV HannahRoxan DosdosNo ratings yet

- Thesis Chapter 123Document15 pagesThesis Chapter 123Chesca Mae PenalosaNo ratings yet

- Lesson Plans by Noman Niaz MaharDocument3 pagesLesson Plans by Noman Niaz MaharNoman Niaz 13No ratings yet

- Science in VedasDocument42 pagesScience in VedasPratyush NahakNo ratings yet

- Harsheen Kaur BhasinDocument20 pagesHarsheen Kaur Bhasincalvin kleinNo ratings yet

- Ky203817 PSRPT 2022-05-17 14.39.33Document8 pagesKy203817 PSRPT 2022-05-17 14.39.33Thuy AnhNo ratings yet

- Dangerous Journeys - Rules (GDW5000)Document418 pagesDangerous Journeys - Rules (GDW5000)DeviousDVS100% (5)

- In The Matter of The Adoption of Elizabeth MiraDocument2 pagesIn The Matter of The Adoption of Elizabeth MiradelayinggratificationNo ratings yet

- UTH homework template for English exercisesDocument8 pagesUTH homework template for English exercisesCinthya Peña de MezaNo ratings yet

- ResMed Case Study AnalysisDocument12 pagesResMed Case Study Analysis徐芊芊No ratings yet

- Chimdesa J. Functional FoodsDocument201 pagesChimdesa J. Functional FoodsChimdesa100% (1)

- Proposal to Enhance Science InstructionDocument4 pagesProposal to Enhance Science InstructionAzzel ArietaNo ratings yet

- Maximizing ROI Through RetentionDocument23 pagesMaximizing ROI Through RetentionSorted CentralNo ratings yet

- Nursing Process & Patient Care ModalitiesDocument6 pagesNursing Process & Patient Care ModalitiesNur SanaaniNo ratings yet

- Soil Penetrometer ManualDocument4 pagesSoil Penetrometer Manualtag_jNo ratings yet

- Module IV StaffingDocument3 pagesModule IV Staffingyang_19250% (1)

- Baltimore County IG ReportDocument35 pagesBaltimore County IG ReportChris BerinatoNo ratings yet

- Business Process AnalysisDocument64 pagesBusiness Process AnalysisPanko MaalindogNo ratings yet

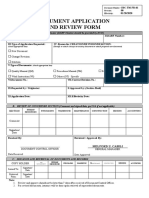

- Document Application and Review FormDocument1 pageDocument Application and Review FormJonnel CatadmanNo ratings yet

- Development Plan-Part IV, 2022-2023Document3 pagesDevelopment Plan-Part IV, 2022-2023Divina bentayao100% (5)

- Edited General English Question Paper Part 1Document12 pagesEdited General English Question Paper Part 1Utkarsh R MishraNo ratings yet

- Bipolar DisorderDocument9 pagesBipolar Disorderapi-306929216No ratings yet

- Module 4 Flexible Learning EnvironmentDocument2 pagesModule 4 Flexible Learning EnvironmentRyan Contratista GimarinoNo ratings yet

- Macroeconomics QuestionnaireDocument5 pagesMacroeconomics Questionnairevikrant vardhanNo ratings yet

- A. Pawnshops 4. B. Pawner 5. C. Pawnee D. Pawn 6. E. Pawn Ticket 7. F. Property G. Stock H. Bulky Pawns 8. I. Service Charge 9. 10Document18 pagesA. Pawnshops 4. B. Pawner 5. C. Pawnee D. Pawn 6. E. Pawn Ticket 7. F. Property G. Stock H. Bulky Pawns 8. I. Service Charge 9. 10Darwin SolanoyNo ratings yet

- MarketNexus Editor: Teri Buhl Character LetterDocument2 pagesMarketNexus Editor: Teri Buhl Character LetterTeri BuhlNo ratings yet