Professional Documents

Culture Documents

Nhom 8

Nhom 8

Uploaded by

Luận Nguyễn0 ratings0% found this document useful (0 votes)

39 views22 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views22 pagesNhom 8

Nhom 8

Uploaded by

Luận NguyễnCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 22

Evaporators and

the Refrigeration System

OBJECTIVES

Aer studying this unt you should be able

define high, medium, and low-temperature refrigeration,

+ determine the boling tempecatute in an evaporator.

+ identify diferent types of evaporators

+ descrivea paraliel-low, plate-anc-fn evaporator.

+ describe multple- and single-crcult evaporators

CEE eee

SAFETY CHECKLIST

[14 ear goggles and gloves when attaching arremaving gauges to

transfer eigerant oto check pressures,

a veaesrarm clothing when working ina wallcincooleror freezer

21.1 REFRIGERATION

Refrigeration is the process of removing heat from a place

where itis nor wanted and transferring thar heat roa place

where it makes litle or no difference. Commercial refrigera-

tion is similar to the refrigeration thar occurs in your house-

hold refrigerator. The food that you keep in the refrigerator

is stored ata temperature lower than the room temperature.

Typically, the fresh-food compartment temperature is about

35°K Heat trom the room (typically noves through

the walls of the refrigerator to the cooler temperature in

the refrigerator. Heat travels normally and naturally from a

‘warm t0 a cool medium.

If the heat that is transferred into the refrigerator re-

mains in the refrigeratos, it will warm the food products

and spoilage will occur. This heat may be removed from the

refrigerator by mechanical means using the refrigerator’

refrigeration equipment, which requires energy, or work

Figure 21.1 shows how heat is removed with the com-

pression eyele, Because itis 35°F in the box and 75°F in

the room, the mechanical energy in the compression cycle

MoToR DRIVEN

‘COMPRESSOR

\

at ere

oom a 756) tal Conta

fexrraow

INSIDE THE Box

ier to na

sorin the rel

that forces the

ots ate nosmaly driven by elect

actually pumps the heat to & warmer environment from the

box to the room,

The heat is transferred into a cold refrigerant coil and

pumped by the system compressor to the condenser, where it

Js released into the room. This is much like using. sponge to

move water from one place to another. When a dry sponge

is allowed to absorh water in a puddle and you take the wet

sponge to a container and squeeze t, you exert energy, much

like a compressor in the refrigeration system, Figure 21.2.

Another example of refrigeration is a central air-

conditioning system in a

residence. It absorbs heat from the

v2

Figure 21.2 A sponge absorbs wate. The water can then be carted in

the sponge to another place. When the sponge i squeeze the water

Isrejected to another place. The squeezing ofthe sponge may be con-

Sdeted the energy that it akesto pump the watec

oom supty

AIR (55°F)

OUTSIDE (95°6

COIL TEMPERATURE

Gor)

<== ROOM RETURN

AIR (75°F)

Figure21.3 An aiccondiloning example of etigeaton,

home by passing indoor air at about 75°F over a coil that

1s cooled to about 40°E. Heat will transter from the room

air to the coil cooling the air. This cooled air may be mixed

with the room air, lowering its temperature, Figure 21.3.

‘This process is called air-conditioning, but itis also refrig-

eration at a higher temperacure level than that of the house

hold refrigerator, so itis frequently called high-temperacure

refrigeration.

‘Commercial refrigeration is used in commercial busi-

ness locations. The food store, fast-ood restaurant, drug

store, flower shop, and food processing plant are only a few

of the applications. Some of the commercial systems are

plug-in appliances, such as a small, reach-in ice storage bin

at the local convenience store. The system is entirely located

within the one unit. Some systems consist of individual

boxes with single remore condensing units, and some are

complex systems with several compressors in a rack serving

several reach-in display cases, as in a supermarket. Most

commercial refrigeration is installed and serviced by a spe

cial group of technicians who work only with commercial

refrigeration and the food-service business.

‘aa nthe tigen Str

21.2 TEMPERATURE RANGES,

OF REFRIGERATION

‘The temperature ranges for commercial retrigeration may

refer to the temperature of the refrigerated box or the boil-

ing temperature of the refrigerant in the coil. The following,

temperatures illustrate some of the guidelines used in the

industry when discussing box temperacures.

HIGH-TEMPERATURE APPLICATIONS. High-temperature

refrigeration applications will normally involve box tem-

peratures of 47°F to 60°F. Storing such products as flowers

and candy may require these temperatures.

MEDIUM-TEMPERATURE APPLICATIONS. The household

relrigerator fresh-food compartment is a good example of

‘medium-temperature refrigeration, which typically ranges

from 28°F co 40°F. Many different products are stored at

the medium-temperacure range, For most products, the

‘medium-temperature refrigeration range is above freezings

few products are stored below 32°F. Items such as eggs,

lettuce, and tomatoes lose their appeal if they freeze in a

refrigerator

LOW-TEMPERATURE APPLICATIONS. Low-temperature re-

{rigeration produces temperaturce below the freezing point

of water, 32°F One of the higher low-temperature applica-

tions is the making of ice.

Low-temperature food storage applications generally

start at O°F and go as low as ~20°F. Ar this temperature

ice eream would be frozen hard. Frozen meats, vegetables,

and dairy products are ony a few of the foods preserved by

freezing, Some foods may be kept for long periods of time

and are appetizing when thawed for cooking, provided they

are frozen correctly and kept frozen.

21.3 THE EVAPORATOR

‘The evaporator in a refrigeration system is responsible for

absorbing heat into the system from whatever medium is

to be cooled. This heat-absorbing process is accomplished

bby maintaining the evaporator coil ata lower temperature

than the meditim to be cooled. For example, if a walk-in

cooler is to be maintained at 35°F to preserve food prod-

ucts, the col in the cooler must be maintained at a lower

temperature than the 35°F air that will be passing over it

Irigure 21.4 shows the refrigerant in the evaporator boiling

at 20°F, which is 15°F lower than the entering ar. The evap-

‘orator operating at these low temperatures removes latent

and sensible heat from the cooler. Operating at 20°F, as in

the preceding example, the evaporator will collect moisture

from the air in the cooler, latent heat: The removal of sen-

sible heat reduces the food temperature

am.

8

sects

RETURN AIR (25°F)

HAS PASSED

‘OVER FOOD.

PRODUCTS.

‘TEMPERATURE

DIFFERENCE (15°F)

‘COIL TEMPERATURE

(20°F)

FAN AND MOTOR

THE COMPRESSOR IS RUNNING —

THIS LOWERS COIL TEMPERATURE.

Figure 21.4 The relationship ofthe ails bling temperature tothe ai

passing over the col while it operating inthe design range,

21.4 BOILING AND CONDENSING

‘Two important factors in understanding refrigeration are

the (1) boiling temperature and (2) condensing tempera

ture. The boiling temperatuee and its relationship to the

system involve the evaporator. The condensing tempera-

ture involves the condenser and will be discussed in the

next unit. These temperatures can be followed by using the

temperatirelpressure chat in conjunction with a set of re-

frigeration pressure gauges, Figure 21.5 and Figure 21.6.

21.5 THE EVAPORATOR

AND BOILING TEMPERATURE

‘The boiling temperature of the liquid refrigerant deter-

‘mines the coil operating temperature In an air-conditioning,

system a 40°F evaporator coil with 75°F air passing over

ir produces conditions used for airconditioning or high-

temperature refrigeration. Boiling is normally associated

with high temperatures and water. Unit 3, “Refrigeration

and. Kefrigerants,” discussed. the fact that water boils at

2I2PF at atmospheric pressure. It also discussed the fact

that water boils at other temperatures, depending on the

pressure. When the pressure is reduced, warer will boil at

40°E. This is still boiling—changing a liquid to a vapor. In

a refeigeration system, the refrigerant may boil at 20°F by

absorbing heat from the 35°F food.

‘The service technician must be able to determine what

‘operating pressures and temperatures are correct for the

various systems being serviced under different load con-

ditions. Much of this knowledge comes from experience.

‘When taking readings from thermometers and gauges, the

Commer Retgertn

readings must be evaluated. There can be as many differ

ent readings as there are changing conditions. Guidelines

‘can help the technician know the pressure and temperature

anges at which the equipment should operate. There are

relationships between the entering ai temperature and the

evaporator for each system, These relationships are similar

from installation to installation.

21.6 REMOVING MOISTURE

Dehumidifying the air means to remove the moisture, and

this is frequently desirable in refrigeration systems, Moisture

removal is similar from one refrigeration system to another.

Knowing what the coibto-air relationship is can help the

technician know what conditions to look for. The load on.

the coil would rise or fall accordingly as the return-air tem-

perature rises or falls. Warmer return aie in the box will also

have more moisture content, which imposes further load on

the ail, the cooler is warm die ro food added ta it the col

would have more heat to remove because it has more load

on it Iewould be much like boiling water in an open pan on.

the stove, The warer boils atone rate with the burner on me-

dium and at an inereased rate with the burner on high. The

boiling pressure stays the same in the boiling water in a pan

because the pan is open to the atmosphere. When this same

boiling process occurs in an enclosed coil, the pressures will

rise when the boiling occurs at a faster rate. This causes the

operating pressure of the whole system to rise, Figure 21.7.

When the evaporator removes heat from air and lowers

the temperature of the aig, sensible heat is removed. When

moisture is removed from the air latent heat is removed

“The moisture is piped to a drain, Figure 21.8, Latent heat

is called hidden heat because it does not register on a ther-

rmometer, but it is heat, like sensible heat, and it must be

removed, which takes energy.

‘The refrigeration evaporator is a component that ab-

sorbs heat from the conditioned space into the refrigeration

system. The evaporator ean be thought of as the sponge of

the system. Iris responsible fora heat exchange between the

conditioned space or product and the refrigerant inside the

system. Some evaporators absorb heat more efficiently than |

others. Figure 21.9 illustrates the heat exchange between air

and refrigerant.

21.7 HEAT EXCHANGE

CHARACTERISTICS

OF THE EVAPORATOR

‘The following are conditions that govern the rate of heat

exchange:

1, The evaporator material theough which the heat has

to be exchanged. Evaporators may be manufactured

from copper, steel, brass, stainless steel, of aluminum,

a9,

Unt 21- ana andthe eigen Sse

idsoden pue 774 erase vEare YOU PUE VCS

sunssaua 2919

sects

Figure 21.6 Many pressure gauges have temperatue/pressure rel

‘Nonships printed onthe gauge.

AIR RETURNING.

TOCOIL

50°F DUE TO WARM

FOOD BEING

ADDED TO BOX

© sv4 psi '

eicea i

CORRESPONDS

Soastcon

TewPeRATURE &

Figure 21.7 The colHo-air temperature relationship under increased

oo

Corrosion is one factor that determines what material

is used. For instance, when acidic materials need to be

cooled, copper or aluminum evils would be eaten away.

Stainless steel may be used instead, bur stainless steel

does not conduct heat as well as copper. Some evapo-

rators are even coated with a plastic-hke substance to

protect the metal underneath fom rust or oxidation.

“This application is often seen in restaurants with smaller

commercial, medium-temperature coolers that store

salad preparation materials, which are acidic because

they often have a vinegar base for added flavor and for

‘extended shelf life

Commer Retgertn

MOISTURE

DRIPPING.

a

‘LOR DRAIN 3

Figure 21.8 The cooing collcondenses masture tam the a

FINS

RETURN AIR (95°F) WITH

HEAT FROM FOOD PRODUCTS

REFRIGERANT BOILING.

‘AT 20°F ABSORBS HEAT

THROUGH THE WALL OF

‘THE COPPER TUBING.

TUBING

THE FINS GIVE THE COPPER TUBING MORE

SURFACE AREA FOR GREATER HEAT EXCHANGE,

Figure21.9 The hestcichange lstionchip betwicen stand rekigeant

2. The medium to which the heat is exchanged. Giving

heat up from air to refrigerant is an example. The best

heat exchange oceurs between two liquids, such as wa-

ter to liquid refrigerant. This is because liquids are more

dense than vapors and usually have a higher specific

heat. However, this isnot always practical because heat

frequently has to be exchanged between air and vapor

refrigerant. The vapor‘to-vapor exchange is slower than

the liguid-to-liquid exchange, Figure 21.10.

3. The film factor. This isa relationship between the me-

dium gig up heat and the heat exchange surface.

‘The film factor relates to the velocity of the medium

passing over the exchange surface. When the velocity is

too slows; the film berween the medium and the surface

becomes an insulator and slows the heat exchange,

‘The velocity keeps the film to a minimum, Figure 21.11.

‘The correct velocity is chosen by the manufacturer.

v2

WATER (65°F)

—

VAPOR

REFRIGERANT

100% VAPOR

APPROXIMATELY

25% VAPOR

79% UQUIO

CHILLED WATER

7

LIQUID

REFRIGERANT

WATER (45°F)

METERING’

DEVICE

Figure 21.10 The heat exchange relationship between a liquid in a

Theaverahange axlersingeant fsa te wa

Figure 21.11. One of the deterring factors in anormal heat exchange.

“Tre fm factors the fy of ai oF guid next to the tube inthe heat

‘aa nthe tigen Str

4. The temperature difference between the two mediums

in which the heat exchange is taking place. The greater

the temperature difference between the evaporator coil

and the medium giving up the heat, ehe faster the heat

exchange will occur,

21.8 TYPES OF EVAPORATORS

Numerous types of evaporators are available, and each

hhas its purpose. The first evaporators for cooling air were

of the natural-convection type. They were actually bare

pe evaporators with refrigerant circulating through them,

Figure 21.12. This evaporator was used in carly walk-in cool=

crs and was mounted high in the ceiling. Ie relied on the air

being cooled, falling to the floor, and setting up a natural ir

current. The evaporator had to be quite lage forthe particu-

lar application because the velocity ofthe air passing over the

coil was 30 slow. Natural convection evaporators are stil oc

casionally used today. The use ofa blower co force or induce

air over the coil improved the efficiency of the heat exchange.

‘This meant that smaller evaporators could be used to do the

same job, Design trends in the industry have always been to-

‘ward smaller, more efficient equipment, Figure 21.13.

‘The expansion of the evaporator surface to a surface

larger than the pipe itself produces a more efficient heat

exchange. The stumped etuporstor was one of the Brae de

signs to create a large pipe surface. It consisted of two pieces

‘of metal stamped with the impression of a pipe passage

through it, Figure 21.

‘A pipe with fins attached, called a fnned-tube evapo-

zator,is today used more than any other type of heat ex

changer between air and refrigerant. This hear exchanger is

exchanger efficient because the fins are in good contact with the pi

nay ficient by the fi good h the pipe

ACONVECTION CURRENT INSULATED BARE PIPES WITH

IS SET UP WHEN THE COLDER, CEILING REFRIGERANT

HEAVIER AIN DISPLACE THE CIRCULATING

WARMER AIR NEAR THE FLOOR.

CONDENSATE

CONDENSATE

=—_ ——

wee )F

Figure 21.12 A bare-pipe evaporator

\s AIR

2

Figure 21.13 forced cia evaporator cunmyl

carrying the refrigerant. Figure 21.15 shows an example of

a finned-tube evaporator, Figure 21.15(B) shows a finned-

tube evaporator used in a low-temperature, commercial,

well-type freezer. The leading fins come in contact with the

aur first and must have wider spacing between the fins. Its

these leading fins that are more prone to frost accumula:

tion. The wider fin spacing can accumulate more frost be-

fore becoming plugged and impeding the airflow. The fins

toward the back of the evaporator then encounter drier air

‘with less frost and so are more closely spaced.

Multiple circuits improve evaporator performance and

efficiency by reducing pressure drop inside the evaporator.

Even though the pipes inside the evaporator might be pol

ished smooth, they still offer resistance to the flow of both

liguid and vapor refrigerants. The shorter the evaporator

is, the less resistance there is to this flow. The “U" bends

at the ends of the evaporator also offer a great deal of re-

sistance to the flow of refrigerant. As evaporators hecome

longer, they have more and more pressure drop associated

Commer Regen

®)

Figure 21.15 (AIA

commerell reng

evaporator for a medi

Cate W) rinned tube vapor

with refrigerant flowing through them. The manufacturer

will design the evaporator so thatthe tubing bundles are in

parallel ro one another, Figure 21.16

The evaporator for cooling liquids of making ice oper

ates under the same principles a¢ one for cooling air but

is designed differenely. It may be strapped on the side of

a cylinder with liquid inside, submerged inside the liquid

container, or be a double-pipe system with the refrigeranc

inside one pipe and the liquid to be cooled circulated inside

fn enter pipe, Fig 21.17,

Every central splir-cooling system manufaerured in

the United States today must have a Seasonal Energy

Efficiency Ratio (SEER) of atleast 13. This energy require-

‘ment was mandated by federal law as of January 23, 2006

Also, with the phascoue of R-22 just around the comner,

‘manufacturers of HVACIR equipmcat have been looking

for energy-efficient methods to apply to their equipment

to meet these new energy requirements, The timeline for

R22 is as follows:

© 2010—R-22 use is banned at the original equipment

manufacturer (OEM) level with a 75% reduction of

HEC production.

+ 2015—90% reduction of HCFC production,

© 2020—Total ban of R-22 production

Une2t asain tigen Stem 6

Z suchow

EXPANSION LINE TO

2 VALVE COMPRESSOR

“ : r

| ‘

EVAPORATOR PIPING F

AROUND CYLINDER 2

Oy)

PLATE-TYPE

EVAPORATORS

Liguip LeveL

uaUID

REFRIGERANT

TO EXPANSION

VALVE |

Oy

‘GUCTION

LINE TO «

‘COMPRESSOR ©

e)

©

Figure 21.16 (4) A

duce pressure cr

evaporator. Thes in paral to reduce BeS- Figure 21.17 Liquid heat exchangers. (A) A drum-type evaporator

sure drop Couey Spoon Compu ard) Cues Fer Ste rier (8) A plate type evaporator na tank {C) A ppe-in pine evaporstor

Sy Prtos by hee (Ccouner/ nora Met ates re

©

sects

The equipment covered by this federal mandate includes

*# unitary equipment from 1.5 to 5 tons,

+ splitipackaged air conditioners and heat pumps.

Equipment not covered includes

+ commercial equipment greater than 6 tons,

* spaceeonstrained units smaller than 3 t0ns (room air

conditioners),

SEER is caleulated on the basis of the total amount of

cooling {in Bru} the system will provide over the entire sea-

son, divided by the total number of wart-hours it will con-

swine, Higher SEERS reflow « snore efficient cooling system

TThe federal mandate impacts 95% of che unitary market in

the United States, which is about $ million units manufac

tured at the time of this writing. Because of the new federal

‘mandate of 13 SEER, most airconditioning and heat pump

manufacturers are looking for more efficient evaporator

and condenser designs, more efficient compressors and fan

‘motors, and more sophisticated control systems in order to

reer the new energy efficiency requirement

‘One such evaporator design incorporates an aluminum

parallel-flow, flat-plate-and-fin configuration with small

parallel channels inside the flat plate. The plates are flat-

tened, streamlined tubes each one of which is split into

smalls, parallel ports, Viguse 24.18. % Refigerant willphase

‘change or evaporate from a liquid toa vapor inside the channels

in the plate, while strategically shaped fins (extended surfaces)

will enhance heat transfer fromthe air into the evoporator, The

plates and fins are bonded or soldered to increase heat transfer

‘and to eliminate any contact resistance (air gaps) that will reduce

heat transfer Headers at the inlet and outlet of the heat

texchanger are also bonded to the plates through soldering,

Heat is transferred from the air to the evaporating re-

Irigerane in three steps, as follows:

1. Air side—hetween the fins and the air to be cooled

2. Heat conduetion—berween the fins and the tubes

3. Refrigerant side—hetween the tubes and the evaporat-

ing refrigerant

{The air side of the heat exchange can be enhanced through

fin geometry. Louvres, lances, and ippled edges all increase heat

transfer Figure 21.19, The conduction between the fins andthe

tubes is enhanced through the application of a metalic bond

(soldering) that eliminates any airgaps.%9 The refrigerant side

of the heat transfer deals with how much surface area of the

incide n the bes will eame intr enmact with the phace

changing refrigerant. This intemal surface area is often re-

ferced to as a wetted perimeter. As the internal surface area

of the tubes increases, the heat transfer increases. Internal

surface area can be increased by:

* increasing the number of parallel channels inside the flat

plates,

Commer Regen

©)

Figure 21.18 An aluminum paralle-Tow, fat plate-and fin heat ex

AMEE cure Meine Manacting Ca are

+ increasing the number of fae plates (decreasing the spac

ing between chem)

Te capacity (tonnage) of the heat exchanger ean vary

with its height and length. The plaes can be oriented vert

eally for an evaporator application oF horizontally for con

denser applications. The Vertical orientation of the flar plates

v2

©

Figure 21.19 Fin geometry fer increasing heat wansie.

sy ene Natt Co, aie

allows condensate removal to occur naturally, alleviating any

water drainage issues from the evaporator Figure 21.20. This

technology is being used with condensers as well as evapora-

tors, Figire 21.21. Applications in the HVACR fed inclnde

residential airconditioning, rooftop airconditioning, chillers,

geothermal heat pumps, electronic cooling, packaged termi-

nal air conditioners (PTAC), ice machines, beverage dispens-

cr, refrigerated display cases, and foodservice refrigeration,

Some of the benefits of this parallelflow; plate-and-fin heat

‘exchanger technology are as follows:

‘+ Reduces static pressure through the coil—which means

fewer fan watts and less horsepower

‘+ Reduces coil depth for the evaporator and condenser,

which leads to easier cleaning and less airside static

pressure

‘+ Reduced internal volume reduces refrigerant charge

‘+ Reduced face area of condenser and evaporator

‘+ Smaller foorprin forthe condensing unit

‘aa nthe tigen Str

MOUNTING WITH VERTICAL HEADERS.

HEADER i

MA GAEnen TUBE SIDE += FIN SIDE

‘TuBe sive view

LRAT

“FIN ORIENTATION IS NOT + CONDENSATE

‘CRITICAL ‘WILL MOVE

“AIRFLOWMUST ENTERTUBE ——_-WITHAIRFLOW

SIDE OF EVAPORATOR AND DRAIN

Down Fit SIDE

“

MOUNTING WITH HORIZONTAL HEADERS

FIN ORIENTATION MUST BE FLOW DIRECTION

CONCAVE SHEY FACE). SNOT CRITICAL

=. =,

l

FINORIENTATION

OAS

‘CONDENSATE WILL ORAIN THROUGH FIN LOUVERS

©

Figure 21.20 Condensate removal for vertical and horzontal header

‘configuration, Coun Medre trating Co. Rate Mt

‘+ 4.30% reduction in coil weight and size

‘+ A reduction in packing costs, sizes, and weights

‘+ The allaluminum coil, header, and fins enhance corro-

*+ Lower system costs

‘+ Higher system efficiencies than a round, copper-tube heat

exchanger with aluminum fins, Figure 21.16(C)

‘+ Lower operating costs

+ Quieter operations

Field repair of leaking heat exchangers, Figure 21.22, can

bbe accomplished by

recovering the refrigerant,

cleaning the leaking area with a solution,

‘brushing the area with a wire brush,

using a utility knife blade to remove any fins that may be

in the local area,

6 Sexton Commer Reign

Oy) ®

Figure 21.21 (A) Condenser (8) Evaporator Couns

Figure 21.22 Feld repair of aleaking heat exchan

v2

+ palling wacunm with a vacuses pomp,

+ applying a two-part epoxy that will be sucked into the

fla plate where the leak exists,

‘+ applying heat with an clecri blow dice wntl the epoxy

is cured,

1» evacuating ro 2 500-micron vacuum,

‘charging with the appropriate refrigerant.

Field cleaning heat exchangers can be accomplished using.

the same methods as for a standard round copper-tube heat

exchanger with aluminum fins:

‘+ Elevate the temperature of the mixed cleaner t0 120°

‘© Use a power washer with a broad spray pattern.

‘+ Use nonacidic cleaners (pH < 10.5).

= When che heat exelianger is el

clean water.

ringe ule coil with

21.9 EVAPORATOR EVALUATION

Knowing the design considerations helps in evaporator

evaluation. When the service technician arrives atthe job,

iemay be necessary 3 evaluate whether a parscular evapo

ator is performing properly. This can be considered one

of the starting points in organized teoubleshooting. The

evaporator absorbs heat, the compressor pumps it, and the

condenser rejects it. The following example pertains to a

fumicmperalace walk-in bos, Lloweves the procede

‘would be about the same for any typical application,

SUCTION LINE

TO COMPRESSOR,

170 psig

100% PURE

LiguiD)

35% VAPOR

155% LIQUID

PERE oe rev ersrune arruicanon, yorwas oreninion

tad psig

‘aa nthe tigen Str

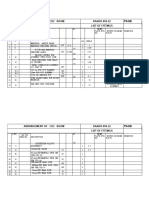

Evaporator Specifications

Copper pipe coil

Aluminum fins attached to the copper-pipe coil

Forced draft with a prop-type fan

One continual refrigerant circuit

Re134a

Evaporator to maintain space temperature at 35°F

Evaporator clean and in good working condition

First we describe how the evaporator functions when itis

working correctly

Entering the evaporator isa partial liquid-partal vapor

mixture at 20°F and 18.4 psig; it is approximately 65%

liquid and 35% vapor. Approximately 35% of the liquid

cenvering the expansion devive at che evaporavor is changed

to a vapor and cools the remaining 65% of the liquid to

the evaporator's boiling temperature (20°F). This is accom

plished by the pressure drop across the expansion device.

‘When the warm liquid passes through the small opening

in the expansion device into the low pressure (184 psig)

of the evaporator side, some of the liquid flashes to a gas,

Figure 21.23.

‘As the parcial liguidepartial vapor mixture moves

through the evaporator, more of the liquid changes to a va-

pot. This is called boiling and is a result of heat absorbed

into the col from whatever medium the evaporator is cool

ing, Finally, near the end of the evaporator the liquid is

all boiled away wo a vapos. At this point the teftigerant is

known as saturated vapor. This means that the refrigerant

184 psi

EVAPORATOR COIL.

i

Flqure 21.23 When the | 1Fliquid passes through the eansion vale rice, some ofthe liquid Rashes toa vanor and cools the remainina ligld

tothe evaparator temperature a 20°

aa

Sexton Commer Reign

vapor is saturated with heat. Ifany more heat is added to

it, it will rise in temperature. If any heat is taken away from

it, it will stare changing back to aliquid. This vapor is satu-

rated with heat, but i is still atthe evaporating temperature

corresponding to the boiling point, 20°F. 9 This isa most

important point in the function of an evoporator becouse all of

the quid must be boiled away as close to the end ofthe col as

possible. This s necessary to (1) keep the coil efficiency up and

(2) ensure that liquid refrigerant doesnot leave the evaporator

{and move into the compressor: For efficient operation, the

evaporator must be as full of liquid as possible without al-

lowing liquid to reach the outlet of the coil, because the bese

heat exchange is between the liquid refrigerant and the air

passing over the col

‘The pressurefemblpy chart in Figure 21.24 shows

sraphically what happens inside the evaporator of the pre-

ceding walk in cooler example. The refrigerant enters the

evaporator at point A (after leaving the expansion valve)

‘The liquid pressure is 18.4 psig and contains 48.7 Beu/lb of

heat at this point. Approximately 33% of the liquid flashed

to a vapor when passing through the expansion valve. As

the liquid proceeds through the evaporator, it is changing

to a vapor. All of it has changed to a vapor at point B, but

the vapor temperature is still 20°F and capable of absorbing,

heat; in the form of superheat. The vapor temperature starts

‘orice while iis ll n the evaporator until the temperature

is 30°F (containing 10°F of superheat). The vapor leaves the

evaporator at point C with a heat content of 108.1 Btuflb,

‘The usable refrigeration in the evaporator is from points

A to CG, where the refrigerant absorbed 59.4. Bra/lb

(108.1 Bru/lb ~ 48.7 Bro/Ib) of the circulating refrigerant.

You only need roknow how many Brufh capacity is needed %6

determine the amount of refrigerant that needs to be circu-

lated. For example, ifthe evaporator needs to have a capacity

of 33,000 Buu, it must have 389.2 Ib of refsiges

‘culate through it per hour (35,000 Brwh + 59.4 Bru/lb

5389.2 lbh). This sounds like a lot of refrigerant, bue it is

only 9.82 Ihvmin (589.2 Ibvh + 60 minfh = 9.82 lbvmin).

“The siz of the compressor and the system operating condi-

tions determine how much refrigerant can be pumped.

g

Pressure (psia)

5888

3

EFFECT

Figure 21.24 The refgeration effect inthe evaporator. outer | Dont

NET REFRIGERATION

108.1

=487

504 Blus NET REFRIGERATION EFFECT

°

soa

v2

21,10 LATENT HEAT

IN THE EVAPORATOR

‘The latent heat absorbed during the change of state is much

‘more concentrated than the sensible heat that would be

added to the vapor leaving the coil. Refer to the example

in Unie 1, Section 1.3, that showed how it takes 1 Bru to

change the temperature of 1 Ib of 68°F water to 69°F water.

Section 1.8 also showed that itrakes 9/0 btu to change 1 1D

(of 212°F water to 212°F steam, The change of state is where

the greatest amount of heat is absorbed into the system.

The preceding example showed that 59.4 Bru of heat were

absorbed for every 1 Ib of refrigerant that was circulated

{59.4 Bru/lb). This happened at a boiling temperature of

20°F, without a change in pressure.

21.11 THE FLOODED EVAPORATOR

“To get the maximum effcieney from the evaporator heat

exchange, some evaporators are operated full of liquid, oF

flooded, and are equipped with a device to keep the liquid

refrigerant from passing to the compressor. These flooded

evaporators are specially made and normally use a float me-

tering device to keep the liquid evel as igh as possible inthe

evaporator This text will not go into detail about ths system

Ihecause itis not a device often encountered, The manufactur

ers literature should be consulted for any special application.

RETURN

AIR

es

2F

35°F ——>

37

so}

39°F ——>

39°F

METERING

DEVICES

100% LIQUIDS

184 psig Liou.

REFRIGERANT

UNE

t

f (sucTion une)

Figure 21.25 The evaporator operating under normal load.

|-—VAPOR REFRIGERANT LINE.

‘aa nthe tigen Str

When an evaporator is flooded, it would operate much

like water boiling in a pot with a compressor taking the

vapor off the top of the liquid. There would always be a lig

uid level. Ifthe evaporator is not flooded, that is, when the

refrigerane starts out as a partial liquid and boils away toa

vapor in the heat exchange pipes; it ix known as a dry-type,

‘or direct-expansion, evaporator,

21.12 DRY-TYPE EVAPORATORS,

PERFORMANCE

‘To check the performance of a dry-type evaporator, the ser-

vice technician would first make sure that the refrigerant

col is operating with enough liquid inside the eoil. To de-

termine this, the technician must calculate the evaporator

superheat. This is generally done by comparing the boiling

temperature of the refrigerant inside the coil with the line

temperature leaving the coil. The difference in temperatures

is usually 8°F to 12°F For example, in the coil pictured in

Figure 21.25, the superheat in the coil was arrived at by

converting the coil pressure (suction pressure) to tempera-

ture, In this example, the pressure is 18.4 psig, which eor-

responds to 20°F. The suction pressure reading is important

to the technician because the boiling temperature must be

known to arrive at the superheat reading for the coil. In

the following example, the evaporator supetheat reading is

10°F (30°F = 20°F),

[HIS HEFHIGEHAN CONIAINS

LAST POINT

‘OF LIQUID

REFRIGERATED

— _AR

— Spy

ones

CONDENEATE DRAIN

‘APPROXIMATELY 35% VAPOR,

165% LIQUID

\

8

sects

21,13 EVAPORATOR SUPERHEAT

‘The difference in temperature between the boiling relriger-

ant temperature and the evaporator outlet tempcrature is

known as evaporator superheat. Superheat is the sensible

heat added to the vapor refrigerant ater the change of state

hhas occurred. Supetheat is the best method of checking to

see when a refrigerant coil has a proper level of refrigerant.

When a metering device is not feeding enough refrigerant ta

the coil the col is said to be a starved coil, and the super-

hreat is greater, Figure 21.26. Itcan be seen from the exam-

ple that all of the refrigeration takes place at che beginning

of the col. The suction pressure is very low; below freezing,

but only a portion of the coil is being used effectively. This

coil would freeze solid and no air would pass through

‘The freeze line would creep upward until the whole coil

was a block of ice, and the refrigeration would do no good.

‘The refrigerated box temperature would rise because ice is

21.14 HOT PULLDOWN (EXCESSIVELY

LOADED EVAPORATOR)

‘When the refrigerated space has been allowed ro warm up

considerably, the system must go through a hot pulldown.

On a hot pulldown the evaporator and metering device

are not expected to act exactly as they would in a typical

design condition, For instance, if a walk-in cooler supposed

~.

AB AUF

AIR 40°F

FAN AND MOTOR

Commer Retgertn

to maintain 35°F were allowed to warm up to 60°F and had

some food or beverages inside, it would take an extended

time to pull the air and product temperacure down. The coil

‘may be boiling the refrigerant 3 fast thatthe supetheat may:

not come down to §°F to 12°F until the box has cooled

dlown closer to the design temperature.

‘A superheat reading on a hot pulldown should be in-

terpreted with caution, Figure 21.27. The reading will be

ETHAN AIR

(65°F)

Figure 21.27 1lot pulldown witha coll Thisis@ medium temperature

evaporator that should be operating at 18a psig 38a, 20°F The e-

turn airs 55 instead of 35° This causes the pressure in the colo a,

The warm box balls the refrigerant a faster Fate. The thermostatic exe

pansion vaive isnat abl to ee the evaporator quickly enough ta keep

the supatheat at 10% The evaporator has 15 of superhoat

THIS

30°F

GAS CONTAINS,

-F SUPENHEAT,

f= OF LIQUID

gy ase

FEFHIGEHATED AIH

104 \, NAPPRONATELY G5 VAPOR, 65% LOUID =

| t \ \wererine ovce 4

100% LIQUID i

HIGH PRESSURE m LOW TEMPERATURE coo, tow §

(WARM LIQUID LOW-PRESSURE LIQUIDNAPOR PRESSUREVAPOR

Figure 21.26 A starved evaporator col showing 38°F (40°F ~ 27) of evanoratarsuperheat,

v2

AIR (95°F) FAN

Figure 21.28 The evanorator is Fading because the thermostatic

fearsion device s nat conteing religeant flow propery

correct only when the coil is at or near design conditions

However, many modern thermostatic expansion valves

(TXVs) have wide temperature control ranges. Some ean

control evaporator superheat from +20*F to ~20°F, and

they are advertised to do this effectively even when un-

der heavy or light heat loadings of the evaporaror. TXVs

should control superheat under most normal conditions

However, when a system is under a hot pulldown, the

technician should let the system get past this heavy load

period and reach a somewhat stabilized condition before

trying to calculate an evaporator superheat reading. Hot

pulldowns are not considered normal conditions, and the

technician must be patient when calculating evaporator

supetheat. Ir eakes time for a TXY to fill aut the evapora

tor with refrigerant even when itis wide open during a

hot pulldown.

When a dey.cype col is fed too much sofigerant, not all

the refrigerant changes to a vapor. This coils thought of asa

flooded coil—flooded with liquid refrigerants, Figure 21.28

Do not confuse this with a coil flooded by design. This is

rmptom that can cause real trouble because unless the

Tiquid fn the snction line hails tr a vaper before it reaches

the compressor, compressor damage may occur. Remember,

the evaporator is supposed to boil al ofthe liquid to a vapor.

‘Therefore, a thermostatic expansion devies that is not oper-

ating correctly can cause compressor failure,

21,15 PRESSURE DROP

IN EVAPORATORS

“Mulkicircuie evaporators are used when the coil would be-

come t00 long for a single circuit, Figure 21.29, The same

evaluating procedures hold true for a multicircut evapora-

tor as fora singlecireuit evaporator.

‘aa nthe tigen Str

cameras

JCONDENSEA VALVE REWOTE BULB

Figure 21.29 A mulcicuit evaporator counry “pink Company

A dry-type evaporator has to be as full as possible

with refrigerant to be efficient. Each circuit should be

feeding che same amount of refrigerant. If this needs to

be checked, the service technician can check the common

pressure tap for the boiling pressure, which can be con-

verted ra temperature. Then the temperature will have

to be checked at the outlet of each circuit to see whether

circuit is overfeeding or starving, Figure 21.30 and

Figure 21.31.

Some reasons for uneven feeding of a mulkicireuit evap-

orator are the following:

Blocked distribution system

Direy coil

Uneven air distribution

Coil circuits of different lengths

In larger commercial and industrial-type evaporators,

an associated pressure drop usualy is caused from friction

as the refrigerant eravels the length of the evaporator and

down a long suction line to the compressor. This causes the

pressure at the compressor to be a bit lower than the pres-

sure at the evaporator outlet. With larger evaporators and

longer suction lines, itis importanc to measure the refriger-

ant’s pressure atthe evaporator outlet—not at the compres-

sor service valves—when measuring evaporator superheat,

Figure 21.29 and Figure 21.30, It is best to measure the

refrigerant pressure at the same location that che evapora-

tor outlet temperature is taken when measuring evaporator

supecheat. This will give the service technician a more ac-

curate evaporator superheat reading and, therefore, better

evaporator efficiencies. Schrader taps are often provided at

the outlet of larger evaporators for this reason. Line taps

also can be used to gain access to evaporator outler pres-

sure. This method also will protect the compressor from

flooding or slugging problems caused by inaccurate evapo-

rator superheat readings.

2 Secon Comme ei

ecHnapen

VALVE AND

GAGE

THERMOSTATIC

EXPANSION VALVE

REFRIGERANT SENSING ELEMEN

DISTRIBUTOR

FIN. EXTERNAL EQUALIZER TUBE —~

SLOPE DOWN — CoMPRESSOR

|-—REFRIGERANT VAPOR

{oF SUBEANEAT

UST PONT OF TOUD NEROTEOIL

Liquip f

tne] A

[

{_EQUAL-LENGTH DISTRIBUTOR TUBES FOR EXACT COIL FEEDING $

THERMOSTATIC EXPANSION VALVE j

Figure 21.30 The 2pcaarcec amultdicut oapactr onthe sie when ted comet reels soxtleapnctr plpedin pal

TO

COMPRESSOR

SUPERHEAT IN THIS

CIRCUIT IS 20°F AND

THE OTHER CIRCUITS:

ARE 10°F THIS IS A

STARVED CIRCUIT.

CRIMP IN LINE CAUSING THIS CIRCUIT TO

SLIGHTLY STARVE FOR REFRIGERANT

LIQUID LINE

THERMOSTATIC

t EXPANSION VALVE

Figure 21.31 The appearance ofa mulicicuit evaporator onthe inside wien itis nt fe

tne21 fa

2

-16 LIQUID COOLING

EVAPORATORS (CHILLERS)

A ditferent type of evaporator is required for liquid cooling.

Ir functions much like the one for cooling air and is nor-

‘mally a dry-type expansion evaporator in smaller systems,

Figure 21,32(A). Evaporators for larger-tonnage chiller are

usually the flooded type. They have sarurated liquidivapor

refrigerant in the shell and the water to be chilled flows in

the tube bundles, Figure 21.32(B). They use a low side float

to meter the refrigerant into the shell of the evaporator to

maintain the proper refrigerant level,

Liquid cooling evaporators have more than one refrigerant

circuit to prevent pressure drop. These evaporators sometimes

have to be checked to see whether they are absorbing heat as

THERMOMETER —

Vv

WATER

our,

er

THERMOSTATIC

EXPANSION VALVE —

LQUID-LINE

REFRIGERANT IN

Figure 21.3218) Adi

OPERATING THERMOSTAT \,

/

‘or cooing liquids

sand the ageraton Sse 2

they should. Using refrigeration gauges and some accurate

method for checking the temperature of the suction line are

very important. These evaporators have anormal superheat

range similar to airtype evaporators (8°F to 12°F). When the

superheat is within this range and all circuits in a mulicircuit

evaporator are performing alike, the evaporator is doing its job

‘on the refrigerant side, However, this does not mean that it will

cool properis. The liquid side of the evaporator must be clean so

that the guid will come in proper contact withthe evaporator,

“The following problems are typical on the liquid side of

the evaporators

Mineral deposits may build up on the liquid side and cause

‘a poor heat exchange. They would act like an insulator

2. Poor circulation of the liguid to be cooled where a cir

culating pump is involved,

THERMOMETER,

PRESSURE

TAPS

;-FREEZE ae

* STAT WATER,

IN

REFRIGERANT OUT =

SUCTION LINE

TO COMPRESSOR

HARDWARE AND CONTROL

BOARD COMPARTMENT

CHILLED WATER

RETURN

100-tn F134) flooded type evaporator Use

chil water for cooling al

CONTROLLER

WATER,

INSULATED EVAPORATOR

(OF CHILLER BARREL

CHILLING WATER

sects

51.3 psig OH 55° 15°F SUPERHEAT. |

‘SUCTION LINE

LIQUID LINE

Commer Retgertn

CHILLED WATER CHILLED WATER OUT

(75°F) INTO THE (esr)

EVAPORATOR CONTAINS

HEAT FROM BUILDING.

Figure 21.33 Ahot pulldown on aliquid evaporator aving up its heat to refrigerant This evaporator notmaly has 55°F water in and 45°F weer out

Tre hot plldowin th 75 ner inated of $5 ater bo the efigeront ata fate rae The expansion valve ry not beable to feed the evapo

ter quichlyenaugh to maintan 10"

‘When the supetheat is correct and the coil is feeding cor

rectly in a multicireuit system, the echnician should con-

sider the temperature ofthe hquid. the superheat may not

be within the prescribed limits ifthe liquid to be cooled is

not close to the design temperature. On a hot pulldown of a

liquid product, the heat exchange can be such that the coil

appears t0 be starved for refrigerant because itis so loaded

up that itis boiling the refrigerant faster than normal. The

technician must be patient because a pulldown cannot be

rushed, Figure 21.33. Airto-refrigerant evaporators do not

have quite the pronounced difference in pulldown that lig-

uid heat exchange evaporators do because of the excellent

heat exchange properties ofthe liquid to the refrigerant.

21,17 EVAPORATORS FOR

LOW-TEMPERATURE

APPLICATIONS

Low-temperature evaporators used for cooling space or

product to below freezing are designed differently because

they require the coil to operate below freezing.

In an airflow application, the water that accumulates on

the coil will freeze and will have to be removed, The design

of the fn spacing must be carefully chosen, because a very

small amount of ice accumulated on the fins will restriet

the airflow. Low-temperature coils have fin spacings that

are wider than medium-temperature coils, Figure 21.34.

Other than the airflow blockage due to ice buildup, these

low-temperature evaporators perform much the same as

:medium-temperature evaporators. They are normally dry-

type evaporators and have one or more fans to circulate the

air across the coil. The defrosting of the coil has to be done:

by raising the coil temperature above freezing to melt the ice.

Superheat. No conclusions should be made untl the system aparoaches design cantons,

@

Figure 21.4 Fin scacng, (8) Law-tempertue evaccat (8) Mediu:

temperature evaporate Peasy Berean

v2

“Then the condensate water has to be drained aff and kept

from freezing. Defrost is sometimes accomplished with heat

from outside the system. Electric heat can be added to the

evaporator to melt the ie but this heat adds to che load of

the system and needs to be pumped out after defrost.

21.18 DEFROST OF

ACCUMULATED MOISTURE

Defrost can be accomplished with heat from inside the sys-

tem using the hot gas from the discharge lin of the compres

sor by routing a hot gas lin from the compressor discharge

line to the outlet of the expansion valve and insalling a

solenoid valve to control the flow. When defrost is needed,

hot gas is released inside the evaporator, which will quickly

smelt any ice, Figure 21.35

‘When the hor gas enters the evaporator, tis likely chat

liquid refrigerane will be pushed out of the suction line to-

ward the compeessoe. In fact, when hor gas enters an evapo-

rator and starts to cool. as it melts ice or frst, it wll soon lose

all of its supesheat and turn to liquid or condense. This ig-

uid will goto the aecumolator and fall to ts hortom. Dense

saturated vapors will be drawn into the compressor’ suction

stroke. The compressor will see an increased load from these

dense vapors and may draw a highce amp than during the

normal running cycle. Ifthe system does not have an accu

‘mulator, this condensed liquid may flood the compressors

crankcase and foaming of the oil in the crankcase may occu,

Figure 21.36. This can lower the oil level in the crankease

SOLENOID VALVE ~

TO CONTROL

‘SUCTION-LINE HOT GAS,

ACCUMULATOR

RECEIVER, 7

DRIER SIGHT

GLASS

Figure 21.35 Using hot gas to defrost an evaporator

‘aa nthe tigen Str

and cause scoring of bearing surfaces in the compresion. This

condition is often referred to as bearing washout

Flooding the compressor’ crankcase with liquid refi

«rant ean also cause the foaming refrigerant and oil mixtare

to pressurize the crankcase, which causes the mixture of lig

vid and vapor refrigerant and ol foam to be forced through

any crevice available, including the compressor’s piston

rings. The mixture is often pumped into the high side of the

system by the compressor. The compressor’ discharge tem

perature will decrease from the wet compression of the rich

mixture of refrigerant and oil foam, As soon as this mixture

is compressed, it will vaporize and absorb heat away from

the cylinder walls. This is what causes a lower-than-normal

discharge temperature on the compressor's discharge line.

Some manufaciurers of systems incorporating hoc yas de

frost place a thermistor on the discharge line of the compres-

sof f0 sense this cooler than normal discharge temperacure

) e

Figure 21.36 (A) A compressors clear cl sight glass. (6 A sight lass

from loading crankcase foams with Iquidreigeant.

EVAPORATOR

REFRIGERATED

‘SPACE

+ CONDENSATE

DAAIN LINE

eS

sects

while in the defrost mode. The thermistor relays a mescage

t0 a control circuit ro deenergize the hot gas solenoid; clos-

ing the hor gas solenoid temporarily prevents any more hot

1 from entering the evaporator and dus turning to liquid

[As the compressor’ discharge temperature rises again, the

thermistor rensct the dae in temperature and relays a mes:

sage to the control circuit to continue with hot gas defrost

by energizing the hot gas solenoid again.

This sequence of events may continue until defrost is com

plete. The sequence simply protects the compressor from bear-

ing washout and wet compression while in defrost I may also

protect the compressor during the refrigeration eycle by shut

ting down the compressor if the discharge temperature gets

100 low indicating wer compression. To prevent this liquid

from eter the Compressor, ofcn a sui line wecunulstor

will be added to the suction piping, Figure 21.35.

‘The hot gos defost system is economical because power

does not have to be purchased for defost using external

heat, such as electric heaters that will heat the evaporator.

The heat is aready in thesystem

Electric defrost is accomplished using electric heat-

ing elements located at the evaporator. The compressor is

stopped and the heaters are energized on a call for defrost

and allowed to operate until the frost is melted from the

coil Figure 21.37. These heaters are often embeded in the

actual evaporator fins and cannot be removed if they burn

‘out. Peequently, in uhe event that the heaters do bun out,

hhot gas defrost can be added to the system and the electric

heat defrost procedures discontinued.

‘When either system is used for defrost, the evaporator

fan is often turned off during defrost; if iti not, wwo things

will happens

1. ‘The heat from defrost will be transferred directly to the

‘conditioned space.

2. The cold, conditioned air will slaw down the defrost

process,

Commer Retgertn

:

3

Figure 21.37 A heater used for electric defiost of low-temperature

evaporators

However, some manufacturers design their open frozen-

food cases so that the evaporator fans are left on during

defrost. Ths allows the supply-air and return-air ducts t0

be defrosted along, with the coil. The warm defrost airs dis

‘charged from the supply duct and rises out ofthe case, hav-

ing litte effect on the product temperature. Fans are always

shut off on closed, glass-door cases because of the problem

of fogging on glass or mirrored surfaces.

Evaporators in some ice-making processes have similar

defrost methods. They must have some method of applying,

heat to the evaporator to free the ice. Sometimes the heat

is electric or hot gas. When the evaporator is being used t0

make ice, the makeup water for the ive maker is sometimes

used for defrost. Evaporator defrosting is covered in more

detail in Section 22, (Defrost Cycle) oF Unit 25, “Special

Refrigeration System Components.”

In summary, when checking an evaporator remember

that its job isto absorb heat into the refrigeration system.

SUMMARY

‘+ Heat travels normally from a warm substance to a cool

‘+ For heat to travel from a cool substance to a warm sub-

stance, work must be performed. The motor that drives

the compressor in the refrigetation eyele does this work.

‘+ The evaporator is the component that absorbs the heat

into che refrigeration system.

‘+ The evaporator must be cooler than the medium to be

cooled to have a heat exchange.

++ The refrigerant boils to a vapor in the evaporator and

absorbs heat because it is boiling at a low pressure and

low temperature.

+ The boiling temperature of the refrigerant in the evapo-

savor determines the evaporator (low side) pressure

‘+ Medium-temperature systems can use offcycle defrost.

‘The product is above freezing, and the heat from it can

be used to initiate the defrost.

‘+ Low-temperature refrigeration must have heat added to

the evaporator to mele the ice.

‘+ For the same types of installations, evaporators have the

same characteristies regardless of location,

‘+ Most refrigeration coils ace copper with aluminum fins,

‘© The starting point in organized troubleshooting is to

decermine whether the evaporator is operating el

v2

Checking the superheat is the hese mthod the service

technician has for evaluating evaporator performance.

‘+ Some evaporators are called dry-type because they use a

sninimam of refrigecant.

‘* Dry-type evaporators ae also called direct expansion

evaporators.

‘+ Some evaporators are flooded and use a float to meter

the refrigerant. Supetheat checks on these evaporators

should be interpreted with caution,

‘aa nthe tigen Str

Some evaporators have a single cireuit, and some have

multiple circuits.

Mulicircuit evaporators keep excessive pressure drop

from occurring in the evaporator

‘There is a relationship between the boiling temperature

of the refrigerant in the evaporator and the temperature

of the medium being cooled.

‘The coil normally operates at temperatures from 10°F to

20°F eolder than the temperature of the air pasting over it

REVIEW QUESTIONS

1. What is the function of the evaporator in the refrigera-

sion system?

2. Refrigerant in the evaporator

A. changes from vapor to liquid

B, changes from liquid to vapor.

C.stays in the vapor state,

D. stays in che liquid state.

3. The sensible heat that is added to a saturated vapor af-

ter all of the liguid has boiled away is referred to as

4, What determines the pressure on the low-pressure side

of the system?

5. A refrigerant systems evaporator typically runs about

‘degrees of superheat

6. What docs a high evaporator superheat indicate?

7. A low evaporator supetheat indicates

‘A. undercharge,

B, system restriction

C. overcharge.

D. dirt buildup.

8. Why is a molticircuit evaporator used?

10.

"

13,

4,

9. Flooded evaporators use a

device.

An evaporator that is wo« flooded is thought of xs what

type of evaporator?

‘When an evaporator experiences a heat-load increase,

the suction pressure

A. remains constant.

B. decreases.

C. varies up and down,

D. increases,

. What is commonly used to defrost the ice from a low-

temperature evaporator?

A medium-temperature refrigeration box operates

‘within whae remperature range?

A. 28°F t0 40°F

B. 40°F to 60°F

C.0°F to 20°F

D. O°F to 50°F

List seven advantages that an aluminum paralle-flow,

platen evaporator has over a standard round, copper

tube platefin evaporator.

type of expansion

a

You might also like

- 4.1.OMM Marine Auxiliary EnginesDocument265 pages4.1.OMM Marine Auxiliary EnginesLuận NguyễnNo ratings yet

- T1016 Fire Alarm System Final Drawing: Client: Kouan ShipyardDocument8 pagesT1016 Fire Alarm System Final Drawing: Client: Kouan ShipyardLuận NguyễnNo ratings yet

- Manual KA403Document90 pagesManual KA403Luận NguyễnNo ratings yet

- KA4401-054-08 Emergency Generator Room VentilationDocument2 pagesKA4401-054-08 Emergency Generator Room VentilationLuận NguyễnNo ratings yet

- KA4401-054-25list of General Tools and Fittings For MachinerDocument18 pagesKA4401-054-25list of General Tools and Fittings For MachinerLuận NguyễnNo ratings yet

- 1100TEU (KA403) Final Drawings List Machinery Part : Quantity (Folds) Remarks White Transparent Plastified Framed ItemDocument3 pages1100TEU (KA403) Final Drawings List Machinery Part : Quantity (Folds) Remarks White Transparent Plastified Framed ItemLuận NguyễnNo ratings yet

- Oxygen & Acetylene Piping Diagram KA4401-054-19 List of PipingDocument2 pagesOxygen & Acetylene Piping Diagram KA4401-054-19 List of PipingLuận NguyễnNo ratings yet

- Arrangement of Co2 Room KA4401-054-22 List of Fittings: DN PN QT Y WTDocument2 pagesArrangement of Co2 Room KA4401-054-22 List of Fittings: DN PN QT Y WTLuận NguyễnNo ratings yet

- 126 30010103Document6 pages126 30010103Luận NguyễnNo ratings yet

- 176 Index Operating InstructionDocument3 pages176 Index Operating InstructionLuận NguyễnNo ratings yet

- Binder 1Document9 pagesBinder 1Luận NguyễnNo ratings yet

- Unit 1 Ets 2019Document11 pagesUnit 1 Ets 2019Luận NguyễnNo ratings yet

- .s165l.mt Gas Pn6Document209 pages.s165l.mt Gas Pn6Luận Nguyễn100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)