Professional Documents

Culture Documents

Antioxidant Change During Processing Cocoa

Uploaded by

Thuc TrinhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Antioxidant Change During Processing Cocoa

Uploaded by

Thuc TrinhCopyright:

Available Formats

Changes during processing

Fermentation

Figure 1. Phenol level of dried cocoa beans after fermentation

Figure 1 shows the total phenol content of unfermented cocoa beans is 5,00% and

decreased by 50% in 3 days of fermentation (2.33%) and 5 days to 2.13%

Phenol level decreased by approximately 50% after fermentation.

The content of polyphenol and antioxidant activity in the fermented cocoa beans is lower

than in the unfermented cocoa beans because oxidation, polymerization, and protein

binding process could reduce the polyphenol level in cocoa beans during fermentation. In

general, the fermentation process of cocoa beans may take between 5 to 7 days, and there

are two processes, namely external and internal fermentation. External fermentation is the

process of sugar catabolism by microorganisms, whereas internal fermentation includes

biochemical processes into the seed cotyledons. During the fermentation process,

polyphenol compounds disperse out of their storage cells and then undergo oxidation that

forms high molecular compounds. The decrease in phenol levels during fermentation was

suspected caused by the hydrolysis and oxidation of phenolic compounds during the

fermentation process. The decline is due to the oxidation of polyphenols by the activity of

the oxidase polyphenol enzyme (PPO). The oxidase polyphenol enzyme is an enzyme

that is essential in the process of oxidation of polyphenol compounds in cocoa. The

enzyme started working during the fermentation process and continued until the early

stages of the drying process

Drying

Flavor development from cocoa beans precursors continues during drying with the

development of characteristic brown color. After fermentation, the beans are removed

from the heaps or boxes and dried in the sun on raised platforms covered with mats or on

the ground until fully dried within 7-8 sunny days. During the process, major polyphenol

oxidizing reactions are catalyzed by polyphenol oxidases. The content of polyphenols

decreases significantly as an effect of high temperature, diffusion of components from

beans with evaporating water, and enzymatic browning processes.

Roasting

Roasting is the principal technological operation affecting the quality of both roasted

cocoa beans and their derived products. The cocoa beans were roasted at four different

temperatures (110–150°C) and three different air humidities (0.3–5.0%). The temperature

and duration of thermal processing strongly affected the character of physical and

chemical changes occurring in cocoa beans during roasting. Changes the antioxidant

activity of cocoa beans caused by their roasting. Although natural antioxidant compounds

are lost during heating, the overall antioxidant properties of roasted cocoa beans can be

maintained or enhanced by the formation of new antioxidants, such as the Maillard

reaction products.

The air humidity used in roasting did not affect the total phenolic content and antioxidant

activity for the lowest roasting temperature (110oC). Roasting at 110°C caused negligible

changes in total phenolic content and antioxidant activity of cocoa beans, while almost all

samples tended to have lower antioxidant potential when roasting temperature increased.

The total phenolic content in roasted cocoa beans remained unchanged or only slightly

decreased after roasting at a temperature of 110°C as compared to raw cocoa beans.

There was no effect of air humidity on phenolic content when the roasting temperature

was 110°C.

The thermal treatment conducted at higher temperatures (120 and 150°C) caused a

gradual decrease in the total phenolic level in almost all analyzed cocoa cultivars (except

cv. Forastero from Brazil). At high temperatures (120–150°C) these losses depended on

the roasting air humidity and were slightly less advanced when the air humidity was

increased from 0.3 to 5.0%. A significant rise in phenolic compounds (2.4–4.8% of the

initial content) was observed in the case of cv. Forastero from Brazil after roasting at 120

and 135°C. The increase in the phenolic content observed in this study could be

explained by the cellular structure degradation during heat treatment and in consequence

release of the bound phenolic compounds. An increase in the phenolic content after

roasting could be also explained by the polymerization or condensation of the monomeric

flavan-3-ols and anthocyanins with other phenols, and the formation of the high

molecular weight proanthocyanidins.

The roasting of the cocoa beans at 150°C led to a considerable decrease in the total

phenolic content. The application of humid air for the roasting of cocoa beans effectively

reduced the losses of phenolic compounds. This phenomenon can be explained by the

formation of the protective layer of water (present in humid air) on the surface of samples

that reduced the access of oxygen into the seeds. The greatest decrease in total phenolic

content was observed when cocoa beans were roasted at 150°C and the lowest RH

(RH=0.3%). This finding is in accordance with the fact that phenolic compounds are

easily degraded and/or become bound to polymer structures at high temperatures in the

presence of oxygen. Roasting under mentioned above conditions resulted in total

phenolics losses ranging from 2.4 to 15.2%

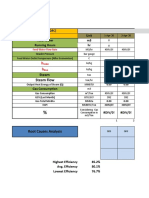

Superheated steam roasting and convectional roasting

The total phenol content of cocoa beans during convection roasting and superheated

steam roasting at different temperatures (150℃, 200℃ and 250℃) for 10 − 50 min

The highest loss may occur due to high oxidation during the convectional method

because of the presence of oxygen during the roasting process. Whereas the lowest loss

may due to the absence of oxygen when roasted by the superheated steam method. Effect

of oxidative enzymes might be another factor to reduce antioxidant properties in

convection method roasting with superheated steam caused the lower loss of total

phenolics than conventional roasting of cocoa beans

The highest antioxidants were observed in roasted during superheated steam at 150℃ for

10 min and lowest at 250℃ for 50 during convectional roasting

Superheated steam roasting could be more appropriate and flexible than the convectional

method because the higher total phenol and antioxidant properties are preserved using the

same temperature and time. This method takes short time to achieve the optimum

roasting characteristics whereas the conventional method takes too long that may

contribute the loss of antioxidant properties of the products.

Figure 2. Changes in the total phenol content (TPC) of cocoa beans during convection and

superheated steam roasting at different temperatures (150oC, 200oC, and 250oC) for 10-50

min

Vacuum roasting

During vacuum roasting of cocoa powder (45.6 and 60.8 cmHg) at temperatures

ranging from 100 to 120°C the limited content of oxygen in the roasting space

slowed down the oxidative degradation of catechins.

The low oxygen in the roasting space caused low oxidation of catechin which made

degradation of catechin slow. However, there was also a possibility of the degradation of

procyanidin or proanthocyanidin (precursors), as both were the constructors of catechin

compound which made the synthesis rate always higher than the degradation rate. As the

roasting space was vacuum, the roasting process and many of its components occurred

faster. On the other hand, in non-vacuum roasting, high concentration of oxygen could

possibly make catechin oxidation fast.

Vacuum roasting of 60.8 cmHg at 100° C for 25 minutes produced the highest percentage

of catechin concentration of cocoa powder. The increased temperature to beyond 100° C f

or the length of more than 25 minutes would reduce the

catechin concentration of cocoa powder. The increased catechin in cocoa powder during

vacuum roasting occurred due to the degradation of procyanidin (either in form of dimer,

trimer or tetramer).

The effect of roasting on the antioxidant properties of cocoa beans depends on the balance

between the thermal degradation of naturally occurring phenolic compounds and the formation

of new antioxidants, such as polymeric pigments and Maillard reaction products. The phenolic

content and antioxidant activity of roasted cocoa beans can be increased by thermal processing

at lower temperatures with humid air.

Alkalization

The pH change caused by the addition of alkaline agents influenced the total polyphenols

content in the produced cocoa powder. It has turned out that natural cocoa powders (pH

5.39–5.76) showed higher levels of antioxidative capability and total content of

polyphenols. Alkalization causes high losses of polyphenols (over 60% loss of total

polyphenols content) and changes their composition. The greatest losses are observed for

epicatechin and catechin (up to ca. 98% and 80%, respectively). Further degrees of

alkalization lead to a noticeable decrease in polyphenol content. These changes may be

ascribed to the oxidation and polymerization of polyphenols under alkaline conditions.

Alimuddin, S. (2018). Changes in phenol level and antioxidant activity of cocoa beans during

fermentation and roasting. Journal of Food Research, 7(4), 23-29.

Oracz, J., & Nebesny, E. (2016). Antioxidant properties of cocoa beans (Theobroma cacao L.):

influence of cultivar and roasting conditions. International Journal of Food Properties,

19(6), 1242-1258.

Urbańska, B., Derewiaka, D., Lenart, A., & Kowalska, J. (2019). Changes in the composition

and content of polyphenols in chocolate resulting from pre-treatment method of cocoa

beans and technological process. European Food Research and Technology, 245(10),

2101-2112.

Yuwono, S., Estiasih, T., & Santoso, U. (2012). The Change of Catechin Antioxidant during

Vacuum Roasting of Cocoa Powder. Nutrition & Food Sciences.

Zzaman, W., Bhat, R., Abedin, M. Z., & Yang, T. A. (2013). Comparison between superheated

steam and convectional roasting on changes in the phenolic compound and antioxidant

activity of cocoa beans. Food Science and Technology Research, 19(6), 949-956.

You might also like

- Changes in Total Polyphenols, O-Diphenols and Anthocyanin Concentrations During Fermentation of Pulp Pre-Conditioned Cocoa (Theobroma Cacao) BeansDocument7 pagesChanges in Total Polyphenols, O-Diphenols and Anthocyanin Concentrations During Fermentation of Pulp Pre-Conditioned Cocoa (Theobroma Cacao) BeansNgan NguyenNo ratings yet

- Antioxidants 09 00458 v2Document13 pagesAntioxidants 09 00458 v2febriyanti ariska amaliyahNo ratings yet

- Foods: Biogenic Amines, Phenolic, and Aroma-Related Compounds of Unroasted and Roasted Cocoa Beans With DiDocument19 pagesFoods: Biogenic Amines, Phenolic, and Aroma-Related Compounds of Unroasted and Roasted Cocoa Beans With DiNhật Nguyễn SĩNo ratings yet

- Review of Related LiteratureDocument4 pagesReview of Related LiteratureHannah Crystal Agravante-Tampus Capacio-jurolanNo ratings yet

- Resposibility: Compilation + References: Group: 3 Student Names: Kulsoom YounasDocument20 pagesResposibility: Compilation + References: Group: 3 Student Names: Kulsoom YounasAria FinNo ratings yet

- Optimization of The Pretreatment of Wheat Straw For Production of BioethanolDocument5 pagesOptimization of The Pretreatment of Wheat Straw For Production of BioethanolNiranjan Narayan GoriwaleNo ratings yet

- Browning Reactions in FoodsDocument19 pagesBrowning Reactions in FoodsImg UsmleNo ratings yet

- Bio Chemical AssgnDocument4 pagesBio Chemical AssgnAsif IqbalNo ratings yet

- Food Chemistry: Sujung Hu, Byung-Yong Kim, Moo-Yeol BaikDocument6 pagesFood Chemistry: Sujung Hu, Byung-Yong Kim, Moo-Yeol Baikaledrop1No ratings yet

- Antioxidants: Domestic Sautéing With EVOO: Change in The Phenolic ProfileDocument12 pagesAntioxidants: Domestic Sautéing With EVOO: Change in The Phenolic ProfileTirtha Mukerjee ChemistryNo ratings yet

- Changes in Food Caused by Deep Fat FryingDocument8 pagesChanges in Food Caused by Deep Fat FryingjoseNo ratings yet

- Efecto de La Temperatura de Secado Con Aire Caliente Sobre El Contenido de Polifenoles y Las Propiedades Sensoriales de Granos de CacaoDocument6 pagesEfecto de La Temperatura de Secado Con Aire Caliente Sobre El Contenido de Polifenoles y Las Propiedades Sensoriales de Granos de CacaoDianaAfricanoNo ratings yet

- Molasses Types and Its Utilization1Document16 pagesMolasses Types and Its Utilization1Nur AprilianiNo ratings yet

- Arlorio 05 Phenolic Antioxidantsin Cacao Hulls PhysiologyDocument6 pagesArlorio 05 Phenolic Antioxidantsin Cacao Hulls Physiologydjguevara1No ratings yet

- Variations of Peroxidase Activity in Cocoa (Theobroma Cacao L.) PDFDocument4 pagesVariations of Peroxidase Activity in Cocoa (Theobroma Cacao L.) PDFFadli Ryan ArikundoNo ratings yet

- Processes 08 00533 v2Document10 pagesProcesses 08 00533 v2Deborah AlmadaNo ratings yet

- Bioethanol ProductionDocument9 pagesBioethanol ProductionMehran Rasheed Goraya100% (1)

- Exam FinalDocument11 pagesExam FinalsimurabiyeNo ratings yet

- 4.0 Mardawati 2019Document9 pages4.0 Mardawati 2019Bandita DashNo ratings yet

- Differences Between The Content of Phenolic Compounds in Criollo, Forastero and Trinitario Cocoa Seed (Theobroma Cacao L.)Document12 pagesDifferences Between The Content of Phenolic Compounds in Criollo, Forastero and Trinitario Cocoa Seed (Theobroma Cacao L.)Laura NogueraNo ratings yet

- CBE697.TOPIC2.feedstock and Pretreatment2Document34 pagesCBE697.TOPIC2.feedstock and Pretreatment2SyahmiNo ratings yet

- Review Paper Hidrolisis EtanolDocument5 pagesReview Paper Hidrolisis EtanolyanchotaNo ratings yet

- Various Temperature of Vacuum and Conventional Roasting On Color Alteration and Polyphenols Content of Cocoa PowderDocument10 pagesVarious Temperature of Vacuum and Conventional Roasting On Color Alteration and Polyphenols Content of Cocoa PowderYasiqyhaidarNo ratings yet

- Chapter 2 - FruitwastesDocument23 pagesChapter 2 - FruitwastesJusztinAquinoNo ratings yet

- The Fate of Mycotoxins... 2009Document6 pagesThe Fate of Mycotoxins... 2009Fabiola DavilaNo ratings yet

- Conversion of Corn Stover To EnergyDocument14 pagesConversion of Corn Stover To EnergySalamiel Blyte BalladNo ratings yet

- Conversion of Corn Stover To EnergyDocument14 pagesConversion of Corn Stover To EnergySalamiel Blyte BalladNo ratings yet

- Heteroferm Homoferm EthanolDocument9 pagesHeteroferm Homoferm EthanolMaria Ileana LeónNo ratings yet

- Banana Ripening ProcessDocument16 pagesBanana Ripening ProcessFajar SungkarNo ratings yet

- Homo-And Heterofermentative Lactobacilli Differently Affect Sugarcane-Based Fuel Ethanol FermentationDocument9 pagesHomo-And Heterofermentative Lactobacilli Differently Affect Sugarcane-Based Fuel Ethanol FermentationGustavo Theodoro PeixotoNo ratings yet

- Food Chemistry: F. Ioannone, C.D. Di Mattia, M. de Gregorio, M. Sergi, M. Serafini, G. SacchettiDocument7 pagesFood Chemistry: F. Ioannone, C.D. Di Mattia, M. de Gregorio, M. Sergi, M. Serafini, G. SacchettisebastianNo ratings yet

- Sensory Testing For Powder - Ref 2Document8 pagesSensory Testing For Powder - Ref 2a.guptaNo ratings yet

- Effect of Bean Maturity and Roasting Temperature o PDFDocument7 pagesEffect of Bean Maturity and Roasting Temperature o PDFAistya Salsabila AuliaNo ratings yet

- 20Document2 pages20Ara Christine Ancheta89% (9)

- Effect of Preparation Method and Roasting Temperature On Total Polyphenol Content in Coffee BeveragesDocument5 pagesEffect of Preparation Method and Roasting Temperature On Total Polyphenol Content in Coffee Beveragesseptian wiraputraNo ratings yet

- Factors Affecting Ethanol Fermentation Using SaccharomycesDocument7 pagesFactors Affecting Ethanol Fermentation Using SaccharomycesLl FfNo ratings yet

- Ethanol PR: Oduction From Steam-Explosion Pretreated Wheat StrawDocument13 pagesEthanol PR: Oduction From Steam-Explosion Pretreated Wheat StrawJavier Ulises Hernández BeltránNo ratings yet

- AFEXon EPFBFDocument11 pagesAFEXon EPFBFWilly perdanaNo ratings yet

- Klasson 2021Document7 pagesKlasson 2021R AgungNo ratings yet

- Production of PhenolDocument65 pagesProduction of Phenolchaitanyavura67% (3)

- Effects of Hydrothermal Processes On Antioxidants in Brown, Purple and Red Bran Whole Grain Rice (Oryza Sativa L.)Document4 pagesEffects of Hydrothermal Processes On Antioxidants in Brown, Purple and Red Bran Whole Grain Rice (Oryza Sativa L.)Cantika PradinaNo ratings yet

- Endraiyani Et Al-2017-Journal of Food Processing and PreservationDocument6 pagesEndraiyani Et Al-2017-Journal of Food Processing and PreservationAndres Felipe CaballeroNo ratings yet

- Biohydrogen Production From Palm Oil Mill Effluent Pretreated by Chemical Methods Using Thermoanaerobacterium-Rich SludgeDocument8 pagesBiohydrogen Production From Palm Oil Mill Effluent Pretreated by Chemical Methods Using Thermoanaerobacterium-Rich SludgefransiscaNo ratings yet

- Fermentation: Metabolic BiodiversityDocument10 pagesFermentation: Metabolic BiodiversityEduar Moreno LondoñoNo ratings yet

- 12-6-11 Tofu CarrageenanDocument7 pages12-6-11 Tofu Carrageenanmigil66256No ratings yet

- Mepe14-Bio Fuels: Unit - IiiDocument22 pagesMepe14-Bio Fuels: Unit - IiiKrishna GummadiNo ratings yet

- Shelf Life of Apples 2Document45 pagesShelf Life of Apples 2Raj KishanNo ratings yet

- Fermentation 04 00045Document12 pagesFermentation 04 00045hmossNo ratings yet

- Oonkhanond 2017Document37 pagesOonkhanond 2017Gebby FebriliaNo ratings yet

- Wort Boiling Today: January 2001Document16 pagesWort Boiling Today: January 2001Kevin CepedaNo ratings yet

- Production of Bioethanol From Empty Fruit Bunch (Efb) of Oil PalmDocument26 pagesProduction of Bioethanol From Empty Fruit Bunch (Efb) of Oil PalmcelestavionaNo ratings yet

- Delignification, Bioconversion of Substrates and It's Affecting FactorsDocument32 pagesDelignification, Bioconversion of Substrates and It's Affecting FactorsHarshvardhan ZalaNo ratings yet

- Efecto Del Secado en La Acidez y El Contenido de Acidos Grasos Jinap 1994Document5 pagesEfecto Del Secado en La Acidez y El Contenido de Acidos Grasos Jinap 1994Jonathan Torres PezoNo ratings yet

- Food Chemistry: Catherine M.G.C. Renard, J.-M. Le Quéré, R. Bauduin, R. Symoneaux, C. Le Bourvellec, A. BaronDocument9 pagesFood Chemistry: Catherine M.G.C. Renard, J.-M. Le Quéré, R. Bauduin, R. Symoneaux, C. Le Bourvellec, A. Baronкатя калайда100% (1)

- 10 1016@j Procbio 2014 10 012Document9 pages10 1016@j Procbio 2014 10 012LiriamNo ratings yet

- Jsfa.274055021020161117 32447 1hvsqq With Cover Page v2Document11 pagesJsfa.274055021020161117 32447 1hvsqq With Cover Page v2Afandynibandera AfandynibanderaNo ratings yet

- Bioethanol Production From Sugarcane Bagasse Using Fermentation ProcessDocument7 pagesBioethanol Production From Sugarcane Bagasse Using Fermentation ProcessM Syafiq SamadNo ratings yet

- On The Thermal Behavior of Protein Isolated From Different Legumes Investigated by DSC and TGA AnalysesDocument37 pagesOn The Thermal Behavior of Protein Isolated From Different Legumes Investigated by DSC and TGA AnalysesImer Ruben Gonzales SobradosNo ratings yet

- Assignment 2 Food MicrobiologyDocument7 pagesAssignment 2 Food MicrobiologyThuc TrinhNo ratings yet

- Science Environment ReportDocument17 pagesScience Environment ReportThuc TrinhNo ratings yet

- Science Environment ReportDocument17 pagesScience Environment ReportThuc TrinhNo ratings yet

- Assignment 3 Food Microbiology Online LaboratoryDocument4 pagesAssignment 3 Food Microbiology Online LaboratoryThuc TrinhNo ratings yet

- Bunting Powered Bronze Bushings PDFDocument56 pagesBunting Powered Bronze Bushings PDFFitunopNo ratings yet

- Practice Calculations 2012Document58 pagesPractice Calculations 2012Lia Romain67% (6)

- Thermodynamic Process Tutorial 4 1Document2 pagesThermodynamic Process Tutorial 4 1Boon Khai ChienNo ratings yet

- DDFC Boiler Effeciency AnalysisDocument21 pagesDDFC Boiler Effeciency AnalysisPublic DemandNo ratings yet

- Stoichiometry - Determination of Percent by Mass of NaHCO3 in Alka Seltzer TabletsDocument6 pagesStoichiometry - Determination of Percent by Mass of NaHCO3 in Alka Seltzer Tabletsgabbal009No ratings yet

- Carboxylic Acid Questions-1Document6 pagesCarboxylic Acid Questions-1Jape GarridoNo ratings yet

- Theory Lm2500 Principios Basicos de Operacion PDFDocument25 pagesTheory Lm2500 Principios Basicos de Operacion PDFamir8100No ratings yet

- Material GroupsDocument36 pagesMaterial Groupsatish chandra GautamNo ratings yet

- Analysis Synthesis and Design of Chemical Processes 3rd Edition Turton Solutions ManualDocument21 pagesAnalysis Synthesis and Design of Chemical Processes 3rd Edition Turton Solutions ManualdarrenrichncogbpizjkNo ratings yet

- 206 ManualDocument16 pages206 ManualNikshit RafaliyaNo ratings yet

- Chemical EquilibriumDocument162 pagesChemical EquilibriumAshok PradhanNo ratings yet

- Example Chemical and Biological CompositionDocument8 pagesExample Chemical and Biological CompositioniskandarNo ratings yet

- Polyaluminium Chloride: Product SpecificationsDocument2 pagesPolyaluminium Chloride: Product SpecificationsMonica Choi SeungjunhyungNo ratings yet

- Chemical Engineering CommunicationsDocument16 pagesChemical Engineering CommunicationsMichelle Quilaqueo NovoaNo ratings yet

- Chemical Engineering Department Journals Level 4: Holding InformationDocument6 pagesChemical Engineering Department Journals Level 4: Holding Informationmubi_loveNo ratings yet

- Bamboo+Alumina CompositeDocument5 pagesBamboo+Alumina CompositeAmmineni Syam PrasadNo ratings yet

- LIB (Lithium Ion Battery)Document27 pagesLIB (Lithium Ion Battery)Ericke Nandita MaharaniNo ratings yet

- Stable Glow Plasma at Atmospheric PressureDocument4 pagesStable Glow Plasma at Atmospheric PressureproluvieslacusNo ratings yet

- 1.7 Evaporative Air Cooling EquipmentDocument8 pages1.7 Evaporative Air Cooling EquipmentRio BananNo ratings yet

- Particulate Nature of MatterDocument4 pagesParticulate Nature of MatterSandy ItabNo ratings yet

- Salama YoussefDocument1 pageSalama YoussefYoussef SalamaNo ratings yet

- Astm f2129Document9 pagesAstm f2129edgmundarayNo ratings yet

- GDL 10 Series Gas Diffusion Layer: SigracetDocument2 pagesGDL 10 Series Gas Diffusion Layer: SigracetAhmed Emad AhmedNo ratings yet

- Official Draft - 2022-23 Bellevistat-CompressedDocument72 pagesOfficial Draft - 2022-23 Bellevistat-Compressedtemp accNo ratings yet

- Plate Girders - I: ©teaching Resource in Design of Steel Structures IIT Madras, SERC Madras, Anna Univ., INSDAGDocument38 pagesPlate Girders - I: ©teaching Resource in Design of Steel Structures IIT Madras, SERC Madras, Anna Univ., INSDAGArnoldo OlivaNo ratings yet

- Introduction To Turbulence1Document28 pagesIntroduction To Turbulence1Mustafa YılmazNo ratings yet

- European Cat 08 2009-10Document92 pagesEuropean Cat 08 2009-10sitiodossitesNo ratings yet

- 2022 - Hyd 443 - 1Document201 pages2022 - Hyd 443 - 1api-620585842No ratings yet

- Compressor AM2Document3 pagesCompressor AM2Hendra KurniawanNo ratings yet

- 41 Assigment 4 Chapter 6-9Document1 page41 Assigment 4 Chapter 6-9Rishi KumarNo ratings yet