Professional Documents

Culture Documents

Power Window Control System: Section

Uploaded by

Diego496Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Power Window Control System: Section

Uploaded by

Diego496Copyright:

Available Formats

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

POWER WINDOW CONTROL SYSTEM

SECTION PWC B

E

CONTENTS

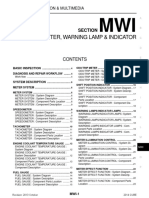

BASIC INSPECTION .................................... 4 COMMON ITEM .........................................................14 F

COMMON ITEM : CONSULT Function (BCM -

DIAGNOSIS AND REPAIR WORK FLOW ......... 4 COMMON ITEM) .....................................................14

WorkFlow .................................................................. 4 G

RETAIND PWR ..........................................................14

INSPECTION AND ADJUSTMENT ..................... 5 RETAIND PWR : CONSULT Function (BCM - RE-

TAINED PWR) .........................................................14

ADDITIONAL SERVICE WHEN REMOVING BAT- H

TERY NEGATIVE TERMINAL ..................................... 5 DTC/CIRCUIT DIAGNOSIS ......................... 16

ADDITIONAL SERVICE WHEN REMOVING

BATTERY NEGATIVE TERMINAL : Description ...... 5 POWER SUPPLY AND GROUND CIRCUIT .... 16

I

ADDITIONAL SERVICE WHEN REMOVING

BATTERY NEGATIVE TERMINAL : Special Re- POWER WINDOW MAIN SWITCH ............................16

pair Requirement ....................................................... 5 POWER WINDOW MAIN SWITCH : Diagnosis

Procedure ................................................................16 J

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT .......................................................... 5 FRONT POWER WINDOW SWITCH (PASSEN-

GER SIDE) .................................................................17

ADDITIONAL SERVICE WHEN REPLACING

FRONT POWER WINDOW SWITCH (PASSEN- PWC

CONTROL UNIT : Description .................................. 5

GER SIDE) : Diagnosis Procedure ..........................17

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement ...... 6 REAR POWER WINDOW SWITCH ...........................17

L

REAR POWER WINDOW SWITCH : Diagnosis

SYSTEM DESCRIPTION .............................. 7 Procedure ................................................................17

POWER WINDOW SYSTEM ............................... 7 FRONT POWER WINDOW SWITCH (PAS- M

System Diagram ....................................................... 7

SENGER SIDE) ................................................. 19

System Description ................................................... 7

Description ...............................................................19

Component Parts Location ...................................... 9

Component Function Check ....................................19 N

Component Description ............................................. 9

Diagnosis Procedure ...............................................19

DIAGNOSIS SYSTEM (BCM) (WITH INTELLI- Component Inspection .............................................20

GENT KEY SYSTEM) .........................................11 REAR POWER WINDOW SWITCH .................. 21 O

COMMON ITEM ......................................................... 11 Description ...............................................................21

COMMON ITEM : CONSULT Function (BCM - Component Function Check ....................................21

COMMON ITEM) ..................................................... 11 Diagnosis Procedure ...............................................21 P

Component Inspection .............................................22

RETAIND PWR .......................................................... 12

RETAIND PWR : CONSULT Function (BCM - RE- POWER WINDOW MOTOR .............................. 23

TAINED PWR) ........................................................ 12

DRIVER SIDE .............................................................23

DIAGNOSIS SYSTEM (BCM) (WITHOUT IN- DRIVER SIDE : Description .....................................23

TELLIGENT KEY SYSTEM) ...............................14 DRIVER SIDE : Component Function Check ..........23

Revision: 2013 October PWC-1 2014 CUBE

DRIVER SIDE : Diagnosis Procedure .................... 23 FRONT PASSENGER SIDE POWER WIN-

DOW DOES NOT OPERATE ........................... 103

PASSENGER SIDE ................................................... 24

PASSENGER SIDE : Description ........................... 24 WITH BOTH POWER WINDOW MAIN SWITCH

PASSENGER SIDE : Component Function Check AND FRONT PASSENGER SIDE POWER WIN-

... 24 DOW SWITCH ......................................................... 103

PASSENGER SIDE : Diagnosis Procedure ........... 24 WITH BOTH POWER WINDOW MAIN SWITCH

AND FRONT PASSENGER SIDE POWER WIN-

REAR LH ................................................................... 25

DOW SWITCH : Diagnosis Procedure .................. 103

REAR LH : Description ........................................... 25

REAR LH : Component Function Check ................ 25 WITH FRONT POWER WINDOW SWITCH ONLY . 103

REAR LH : Diagnosis Procedure ............................ 25 WITH FRONT POWER WINDOW SWITCH

ONLY : Diagnosis Procedure ................................ 103

REAR RH .................................................................. 26

REAR RH : Description .......................................... 26 REAR LH SIDE POWER WINDOW DOES

REAR RH : Component Function Check ................ 26 NOT OPERATE ................................................ 104

REAR RH : Diagnosis Procedure ........................... 26

WITH BOTH POWER WINDOW MAIN SWITCH

ENCODER CIRCUIT .......................................... 28 AND REAR POWER WINDOW SWITCH LH .......... 104

Description .............................................................. 28 WITH BOTH POWER WINDOW MAIN SWITCH

Component Function Check ................................... 28 AND REAR POWER WINDOW SWITCH LH : Di-

Diagnosis Procedure .............................................. 28 agnosis Procedure ................................................ 104

ECU DIAGNOSIS INFORMATION .............. 31 WITH REAR POWER WINDOW SWITCH LH

ONLY ....................................................................... 104

BCM (BODY CONTROL MODULE) .................. 31 WITH REAR POWER WINDOW SWITCH LH

WITH INTELLIGENT KEY ......................................... 31 ONLY : Diagnosis Procedure ................................ 104

WITH INTELLIGENT KEY : Reference Value ........ 31 REAR RH SIDE POWER WINDOW DOES

WITH INTELLIGENT KEY : Wiring Diagram -

NOT OPERATE ................................................ 105

BCM - ..................................................................... 51

WITH INTELLIGENT KEY : Fail-safe ..................... 62 WITH BOTH POWER WINDOW MAIN SWITCH

WITH INTELLIGENT KEY : AND REAR POWER WINDOW SWITCH RH ......... 105

DTC Inspection Priority Chart .............................. 63 WITH BOTH POWER WINDOW MAIN SWITCH

WITH INTELLIGENT KEY : DTC Index ................. 64 AND REAR POWER WINDOW SWITCH RH : Di-

agnosis Procedure ................................................ 105

WITHOUT INTELLIGENT KEY ................................. 66

WITHOUT INTELLIGENT KEY : Reference Value... 66 WITH REAR POWER WINDOW SWITCH RH

WITHOUT INTELLIGENT KEY : Wiring Diagram - ONLY ....................................................................... 105

BCM - ..................................................................... 80 WITH REAR POWER WINDOW SWITCH RH

WITHOUT INTELLIGENT KEY : Fail-safe .............. 88 ONLY : Diagnosis Procedure ................................ 105

WITHOUT INTELLIGENT KEY :

DTC Inspection Priority Chart .............................. 89 ANTI-PINCH SYSTEM DOES NOT OPERATE

WITHOUT INTELLIGENT KEY : DTC Index .......... 89 NORMALLY (DRIVER SIDE) ........................... 106

Diagnosis Procedure ............................................. 106

POWER WINDOW MAIN SWITCH .................... 91

Reference Value ..................................................... 91 POWER WINDOW RETAINED POWER OP-

Wiring Diagram - POWER WINDOW CONTROL ERATION DOES NOT OPERATE PROPERLY

SYSTEM - ............................................................... 93 .. 107

Fail Safe ................................................................. 99 Diagnosis Procedure ............................................. 107

SYMPTOM DIAGNOSIS ............................ 101 AUTO OPERATION DOES NOT OPERATE

BUT MANUAL OPERATE NORMALLY

NONE OF THE POWER WINDOWS CAN BE

(DRIVER SIDE) ................................................. 108

OPERATED USING ANY SWITCH ................. 101 Diagnosis Procedure ............................................. 108

Diagnosis Procedure .............................................101

POWER WINDOW LOCK SWITCH DOES

DRIVER SIDE POWER WINDOW DOES NOT

NOT FUNCTION ............................................... 109

OPERATE ........................................................ 102 Diagnosis Procedure ............................................. 109

Diagnosis Procedure .............................................102

PRECAUTION ........................................... 110

Revision: 2013 October PWC-2 2014 CUBE

PRECAUTIONS ................................................ 110 PREPARATION ............................................... 111

Precaution for Supplemental Restraint System Commercial Service Tools ................................... 111 A

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................... 110 REMOVAL AND INSTALLATION ............. 112

Precautions for Removing of Battery Terminal ..... 110 B

POWER WINDOW MAIN SWITCH ................. 112

PREPARATION ......................................... 111 Removal and Installation ....................................... 112

PWC

Revision: 2013 October PWC-3 2014 CUBE

DIAGNOSIS AND REPAIR WORK FLOW

< BASIC INSPECTION >

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORK FLOW

WorkFlow INFOID:0000000009950844

DETAILED FLOW

1.OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain the malfunction information (conditions and environment when the malfunc-

tion occurred) as much as possible when the customer brings the vehicle in.

>> GO TO 2.

2.REPRODUCE THE MALFUNCTION INFORMATION

Check the malfunction on the vehicle that the customer describes.

Inspect the relation of the symptoms and the condition when the symptoms occur.

>> GO TO 3.

3.IDENTIFY THE MALFUNCTIONING SYSTEM WITH “SYMPTOM DIAGNOSIS”

Use “Symptom diagnosis” from the symptom inspection result in step 2 and then identify where to start per-

forming the diagnosis based on possible causes and symptoms.

>> GO TO 4.

4.IDENTIFY THE MALFUNCTIONING PARTS WITH “COMPONENT DIAGNOSIS”

Perform the diagnosis with “Component diagnosis” of the applicable system.

>> GO TO 5.

5.REPAIR OR REPLACE THE MALFUNCTIONING PARTS

Repair or replace the specified malfunctioning parts.

>> GO TO 6.

6.FINAL CHECK

Check that malfunctions are not reproduced when obtaining the malfunction information from the customer,

referring to the symptom inspection result in step 2.

Are the malfunctions corrected?

YES >> INSPECTION END

NO >> GO TO 3.

Revision: 2013 October PWC-4 2014 CUBE

INSPECTION AND ADJUSTMENT

< BASIC INSPECTION >

INSPECTION AND ADJUSTMENT

A

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : De-

B

scription INFOID:0000000009950845

If any of the following work has been done Initial setting is necessary.

• Power supply to the power window main switch or power window motor is cut off by the removal C

of battery terminal or the battery fuse is blown.

• Disconnection and connection of power window main switch harness connector.

• Removal and installation of motor from regulator assembly. D

• Operation of regulator assembly as an independent unit.

• Removal and installation of glass.

• Removal and installation of door glass run.

NOTE: E

The following specified operations can not be performed under the non-initialized condition.

• Auto-up operation

• Anti-pinch function F

• Retained power operation

Refer to PWC-5, "ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : Special

Repair Requirement".

G

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : Spe-

cial Repair Requirement INFOID:0000000009950846

H

INITIALIZATION PROCEDURE

1. Disconnect battery minus terminal or power window main switch connector. Reconnect it after a minute or

more. I

2. Turn ignition switch ON.

3. Operate power window switch to fully open the window. (This operation is unnecessary if the window is

already fully open)

4. Continue pulling the power window switch UP (AUTO-UP operation). Even after glass stops at fully closed J

position, keep pulling the switch for 2 seconds or more.

5. Initializing procedure is completely.

6. Inspect anti-pinch function. PWC

CHECK ANTI-PINCH FUNCTION

1. Fully open the door window.

2. Place a piece of wood near fully closed position. L

3. Close door glass completely with AUTO-UP.

• Check that glass lowers for approximately 150 mm (5.9 in) without pinching piece of wood and stops.

• Check that glass does not rise when operating the power window main switch while lowering. M

CAUTION:

• Perform initial setting when auto-up operation or anti-pinch function does not operate normally.

• Check that AUTO-UP operates before inspection when system initialization is performed.

• Do not check with hands and other body parts because they may be pinched. Do not get pinched. N

• It may switch to fail-safe mode if open/close operation is performed continuously without full close.

Perform initial setting in that situation. Refer to PWC-99, "Fail Safe"

• Finish initial setting. Otherwise, next operation cannot be done. O

1. Auto-up operation

2. Anti-pinch function

3. Retained power operation

P

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Description

INFOID:0000000009950847

Refer to PWC-5, "ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : Descrip-

tion".

Revision: 2013 October PWC-5 2014 CUBE

INSPECTION AND ADJUSTMENT

< BASIC INSPECTION >

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Re-

quirement INFOID:0000000009950848

Refer to PWC-5, "ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : Special

Repair Requirement" for initialization procedure and check anti-pinch function.

Revision: 2013 October PWC-6 2014 CUBE

POWER WINDOW SYSTEM

< SYSTEM DESCRIPTION >

SYSTEM DESCRIPTION A

POWER WINDOW SYSTEM

System Diagram INFOID:0000000009950849

B

I

JMKIA3998GB

J

System Description INFOID:0000000009950850

• Power window system is activated by power window switch when ignition switch turns ON, or during the

retained power operation after ignition switch turns OFF. PWC

• Power window main switch opens/closes all door glass.

• Front and rear power window switch opens/closes the corresponding door glass.

• AUTO UP/DOWN operation can be performed when power window main switch turns to AUTO. L

• Power window lock switch can lock all power windows other than driver seat.

• If door glass receives resistance that is the specified value or more while power window of driver seat is in

AUTO-UP operation, power window of driver seat operates in the reverse direction.

M

POWER WINDOW AUTO-OPERATION (FRONT DRIVER SIDE)

• AUTO UP/DOWN operation can be performed when power window main switch turns to AUTO.

• Encoder continues detecting the movement of power window motor and transmits to power window switch

as the encoder pulse signal while power window motor is operating. N

• Power window switch reads the changes of encoder signal and stops AUTO operation when door glass is at

fully opened/closed position.

• Power window motor is operable in case encoder is malfunctioning. O

RETAINED POWER OPERATION

Retained power operation is an additional power supply function that enables power window system to oper-

ate for 45 seconds even when ignition switch is turned OFF. P

Retained Power Cancel Conditions

• Front door CLOSE (door switch OFF) → OPEN (door switch ON).

• When ignition switch is ON again.

• When timer time passes (45 seconds).

POWER WINDOW LOCK

Revision: 2013 October PWC-7 2014 CUBE

POWER WINDOW SYSTEM

< SYSTEM DESCRIPTION >

Ground circuit inside power window main switch shuts off when power window lock switch is ON. This inhibits

each power window switch operation except the power window main switch.

ANTI-PINCH SYSTEM (FRONT DRIVER SIDE)

• Pinch foreign material in the door glass during AUTO-UP operation, and it is the anti-pinch function that low-

ers the door glass 150 mm (5.9 in) when detected.

• Encoder continues detecting the movement of front power window motor (driver side) and transmits to

power window main switch as the encoder pulse signal while front power window motor (driver side) is oper-

ating.

• Resistance is applied to the front power window motor (driver side) rotation that changes the frequency of

encoder pulse signal if foreign material is trapped in the door glass.

• Power window main switch controls to lower the window glass for 150 mm (5.9 in) after it detects encoder

pulse signal frequency change.

Operation Condition

When front door glass (driver side) AUTO-UP operation is performed (anti-pinch function does not operate just

before the door glass closes and is fully closed).

NOTE:

Depending on environment and driving conditions, if a similar impact or load is applied to the door glass, it

may lower.

Revision: 2013 October PWC-8 2014 CUBE

POWER WINDOW SYSTEM

< SYSTEM DESCRIPTION >

Component Parts Location INFOID:0000000009950851

PWC

JMKIA3996ZZ M

1. BCM Refer to BCS-10, "Component 2. Rear power window switch LH 3. Front door switch (driver side)

Parts Location" (With Intelligent Key)

or BCS-95, "Component Parts Loca- N

tion" (Without Intelligent Key)

4. Power window main switch 5. Front power window motor (driver side) 6. Rear power window motor LH

View with front door finisher re- O

A. B. View with rear door finisher removed.

moved.

Component Description INFOID:0000000009950852

P

Component parts Description

• Supplies power supply to power window switch.

BCM

• Controls retained power.

• Directly controls all power window motor of all doors.

Power window main switch

• Controls anti-pinch operation of power window.

Revision: 2013 October PWC-9 2014 CUBE

POWER WINDOW SYSTEM

< SYSTEM DESCRIPTION >

Component parts Description

Front power window switch (passenger side) Controls power window motor of front passenger side door.

Rear power window switch (LH & RH) Controls power window motor of rear door (LH & RH).

• Integrates the encoder and power window motor.

• Operates with signals from power window main switch.

Front power window motor (driver side)

• Transmits front power window motor (driver side) rotation as a pulse signal to

power window main switch.

Operates with signals from power window main switch and front power window

Front power window motor (passenger side)

switch (passenger side).

Operates with signals from power window main switch and rear power window

Rear power window motor (LH & RH)

switch (LH & RH).

Detects condition of the front power window motor (driver side) operation and

Encoder

transmits to power window main switch as pulse signal.

Front door switch Detects door open/close condition and transmits to BCM.

Revision: 2013 October PWC-10 2014 CUBE

DIAGNOSIS SYSTEM (BCM) (WITH INTELLIGENT KEY SYSTEM)

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM) (WITH INTELLIGENT KEY SYSTEM)

A

COMMON ITEM

COMMON ITEM : CONSULT Function (BCM - COMMON ITEM) INFOID:0000000010229661

B

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BCM.

C

Diagnosis mode Function Description

Work Support Changes the setting for each system function.

D

Self Diagnostic Result Displays the diagnosis results judged by BCM.

CAN Diag Support Monitor Monitors the reception status of CAN communication viewed from BCM.

Data Monitor The BCM input/output signals are displayed. E

Active Test The signals used to activate each device are forcibly supplied from BCM.

Ecu Identification The BCM part number is displayed.

• Read and save the vehicle specification. F

Configuration

• Write the vehicle specification when replacing BCM.

SYSTEM APPLICATION

G

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

×: Applicable item H

Diagnosis mode

System Sub system selection item

Work Support Data Monitor Active Test

I

Door lock DOOR LOCK × × ×

Rear window defogger REAR DEFOGGER × ×

Warning chime BUZZER × × J

Interior room lamp timer INT LAMP × × ×

Exterior lamp HEAD LAMP × × ×

Wiper and washer WIPER × × ×

PWC

Turn signal and hazard warning lamps FLASHER × × ×

Automatic air conditioner AIR CONDITONER × L

• Intelligent Key system

INTELLIGENT KEY × × ×

• Engine start system

Combination switch COMB SW × M

Body control system BCM ×

NVIS - NATS IMMU × × ×

Interior room lamp battery saver BATTERY SAVER × × × N

Back door TRUNK ×

Vehicle security system THEFT ALM × × ×

O

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER × ×

TPMS TPMS (AIR PRESSURE MONITOR) × × × P

FREEZE FRAME DATA (FFD)

The BCM records the following vehicle condition at the time a particular DTC is detected, and displays on

CONSULT.

Revision: 2013 October PWC-11 2014 CUBE

DIAGNOSIS SYSTEM (BCM) (WITH INTELLIGENT KEY SYSTEM)

< SYSTEM DESCRIPTION >

CONSULT screen item Indication/Unit Description

Vehicle Speed km/h Vehicle speed of the moment a particular DTC is detected

Odo/Trip Meter km Total mileage (Odometer value) of the moment a particular DTC is detected

While turning BCM status from low power consumption mode to

SLEEP>LOCK

normal mode (Power supply position is “LOCK”*)

While turning BCM status from low power consumption mode to

SLEEP>OFF

normal mode (Power supply position is “OFF”.)

LOCK>ACC While turning power supply position from “LOCK”* to “ACC”

ACC>ON While turning power supply position from “ACC” to “IGN”

While turning power supply position from “RUN” to “ACC” (Vehicle

RUN>ACC

is stopping and selector lever is except P position.)

While turning power supply position from “CRANKING” to “RUN”

CRANK>RUN

(From cranking up the engine to run it)

While turning power supply position from “RUN“ to “ACC” (Emer-

RUN>URGENT

gency stop operation)

ACC>OFF While turning power supply position from “ACC” to “OFF”

OFF>LOCK Power position status of While turning power supply position from “OFF” to “LOCK”*

Vehicle Condition the moment a particular

OFF>ACC DTC is detected While turning power supply position from “OFF” to “ACC”

ON>CRANK While turning power supply position from “IGN” to “CRANKING”

While turning BCM status from normal mode (Power supply posi-

OFF>SLEEP

tion is “OFF”.) to low power consumption mode

While turning BCM status from normal mode (Power supply posi-

LOCK>SLEEP

tion is “LOCK”*.) to low power consumption mode

LOCK Power supply position is “LOCK”*

OFF Power supply position is “OFF” (Ignition switch OFF)

ACC Power supply position is “ACC” (Ignition switch ACC)

Power supply position is “IGN” (Ignition switch ON with engine

ON

stopped)

Power supply position is “RUN” (Ignition switch ON with engine

ENGINE RUN

running)

CRANKING Power supply position is “CRANKING” (At engine cranking)

The number of times that ignition switch is turned ON after DTC is detected

• The number is 0 when a malfunction is detected now.

IGN Counter 0 - 39 • The number increases like 1 → 2 → 3...38 → 39 after returning to the normal condition

whenever ignition switch OFF → ON.

• The number is fixed to 39 until the self-diagnosis results are erased if it is over 39.

NOTE:

*: Power position shifts to “LOCK” from “OFF”, when ignition switch is in the OFF position, selector lever is in

the P position (CVT models), and any of the following conditions are met.

• Closing door

• Opening door

• Door is locked using door request switch

• Door is locked using Intelligent Key

The power position shifts to “ACC” when the push-button ignition switch (push switch) is pushed at “LOCK”.

RETAIND PWR

RETAIND PWR : CONSULT Function (BCM - RETAINED PWR) INFOID:0000000010229662

DATA MONITOR

NOTE:

The following table includes information (items) inapplicable to this vehicle. For information (items) applicable

to this vehicle, refer to CONSULT display items.

Revision: 2013 October PWC-12 2014 CUBE

DIAGNOSIS SYSTEM (BCM) (WITH INTELLIGENT KEY SYSTEM)

< SYSTEM DESCRIPTION >

Monitor Item Description A

DOOR SW-DR Indicates [ON/OFF] condition of driver side door switch.

DOOR SW-AS Indicates [ON/OFF] condition of passenger side door switch.

B

PWC

Revision: 2013 October PWC-13 2014 CUBE

DIAGNOSIS SYSTEM (BCM) (WITHOUT INTELLIGENT KEY SYSTEM)

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM) (WITHOUT INTELLIGENT KEY SYSTEM)

COMMON ITEM

COMMON ITEM : CONSULT Function (BCM - COMMON ITEM) INFOID:0000000010229663

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BCM.

Diagnosis mode Function Description

Work Support Changes the setting for each system function.

Self Diagnostic Result Displays the diagnosis results judged by BCM.

CAN Diag Support Monitor Monitors the reception status of CAN communication viewed from BCM.

Data Monitor The BCM input/output signals are displayed.

Active Test The signals used to activate each device are forcibly supplied from BCM.

Ecu Identification The BCM part number is displayed.

• Read and save the vehicle specification.

Configuration

• Write the vehicle specification when replacing BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

×: Applicable item

Diagnosis mode

System Sub system selection item

Work Support Data Monitor Active Test

Door lock DOOR LOCK × × ×

Rear window defogger REAR DEFOGGER × ×

Warning chime BUZZER × ×

Interior room lamp control INT LAMP × × ×

Remote keyless entry system MULTI REMOTE ENT × × ×

Exterior lamp HEAD LAMP × × ×

Wiper and washer WIPER × × ×

Turn signal and hazard warning lamps FLASHER × ×

Manual air conditioner AIR CONDITONER × ×

Combination switch COMB SW ×

Body control system BCM ×

NVIS - NATS IMMU × × ×

Interior room lamp battery saver BATTERY SAVER × × ×

Back door TRUNK ×

Vehicle security system THEFT ALM × × ×

RAP system RETAINED PWR × ×

Signal buffer system SIGNAL BUFFER × ×

TPMS TPMS (AIR PRESSURE MONITOR) × × ×

Panic alarm system PANIC ALARM ×

RETAIND PWR

RETAIND PWR : CONSULT Function (BCM - RETAINED PWR) INFOID:0000000010229664

DATA MONITOR

NOTE:

Revision: 2013 October PWC-14 2014 CUBE

DIAGNOSIS SYSTEM (BCM) (WITHOUT INTELLIGENT KEY SYSTEM)

< SYSTEM DESCRIPTION >

The following table includes information (items) inapplicable to this vehicle. For information (items) applicable

to this vehicle, refer to CONSULT display items. A

Monitor Item Description

DOOR SW-DR Indicates [ON/OFF] condition of driver side door switch. B

DOOR SW-AS Indicates [ON/OFF] condition of passenger side door switch.

PWC

Revision: 2013 October PWC-15 2014 CUBE

POWER SUPPLY AND GROUND CIRCUIT

< DTC/CIRCUIT DIAGNOSIS >

DTC/CIRCUIT DIAGNOSIS

POWER SUPPLY AND GROUND CIRCUIT

POWER WINDOW MAIN SWITCH

POWER WINDOW MAIN SWITCH : Diagnosis Procedure INFOID:0000000009950857

1.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition OFF.

2. Disconnect power window main switch connector.

3. Turn ignition switch ON.

4. Check voltage between power window main switch harness connector and ground.

(+)

Voltage (V)

Power window main switch (–)

(Approx.)

Connector Terminal

D5 10

Ground Battery voltage

D6 19

Is the inspection result normal?

YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between power window main switch harness connector and ground.

Power window main switch

Continuity

Connector Terminal Ground

D6 17 Existed

Is the inspection result normal?

YES >> INSPECTION END

NO >> Repair or replace harness.

3.CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between BCM harness connector and power window main switch harness connector.

BCM Power window main switch

Continuity

Connector Terminal Connector Terminal

M67: Without Intelligent Key 68 D5 10

Existed

M70: With Intelligent Key 69 D6 19

4. Check continuity between BCM harness connector and ground.

BCM

Continuity

Connector Terminal

Ground

M67: Without Intelligent Key 68

Not existed

M70: With Intelligent Key 69

Is the inspection result normal?

YES >> Replace BCM. Refer to BCS-88, "Removal and Installation" (With Intelligent Key). Refer BCS-

155, "Removal and Installation" (Without Intelligent Key).

NO >> Repair or replace harness.

Revision: 2013 October PWC-16 2014 CUBE

POWER SUPPLY AND GROUND CIRCUIT

< DTC/CIRCUIT DIAGNOSIS >

FRONT POWER WINDOW SWITCH (PASSENGER SIDE)

A

FRONT POWER WINDOW SWITCH (PASSENGER SIDE) : Diagnosis Procedure

INFOID:0000000009950858

B

1.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect front power window switch (passenger side) connector. C

3. Turn ignition switch ON.

4. Check voltage between front power window switch (passenger side) harness connector and ground.

(+)

D

Voltage (V)

Front power window switch (passenger side) (–)

(Approx.)

Connector Terminal E

D25 8 Ground Battery voltage

Is the inspection result normal?

YES >> INSPECTION END F

NO >> GO TO 2.

2.CHECK HARNESS CONTINUITY G

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between BCM harness connector and front power window switch (passenger side) har-

ness connector. H

BCM Front power window switch (passenger side)

Continuity I

Connector Terminal Connector Terminal

M67: Without Intelligent Key

68 D25 8 Existed

M70: With Intelligent Key

J

4. Check continuity between BCM harness connector and ground.

BCM

Continuity PWC

Connector Terminal

Ground

M67: Without Intelligent Key

68 Not existed

M70: With Intelligent Key

L

Is the inspection result normal?

YES >> Replace BCM. Refer to BCS-88, "Removal and Installation" (With Intelligent Key). Refer to BCS-

155, "Removal and Installation" (Without Intelligent Key). M

NO >> Repair or replace harness.

REAR POWER WINDOW SWITCH

REAR POWER WINDOW SWITCH : Diagnosis Procedure INFOID:0000000009950859

N

1.CHECK POWER SUPPLY CIRCUIT

O

1. Turn ignition switch OFF.

2. Disconnect rear power window switch connector.

3. Turn ignition switch ON.

4. Check voltage between rear power window switch harness connector and ground. P

Revision: 2013 October PWC-17 2014 CUBE

POWER SUPPLY AND GROUND CIRCUIT

< DTC/CIRCUIT DIAGNOSIS >

(+)

Voltage (V)

Rear power window switch (–)

(Approx.)

Connector Terminal

LH D63

1 Ground Battery voltage

RH D43

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between BCM harness connector and rear power window switch harness connector.

BCM Rear power window switch

Continuity

Connector Terminal Connector Terminal

M67: Without Intelligent Key LH D63

68 1 Existed

M70: With Intelligent Key RH D43

4. Check continuity between BCM harness connector and ground.

BCM

Continuity

Connector Terminal

Ground

M67: Without Intelligent Key

68 Not existed

M70: With Intelligent Key

Is the inspection result normal?

YES >> Replace BCM. Refer to BCS-88, "Removal and Installation" (With Intelligent Key). Refer to BCS-

155, "Removal and Installation" (Without Intelligent Key).

NO >> Repair or replace harness.

Revision: 2013 October PWC-18 2014 CUBE

FRONT POWER WINDOW SWITCH (PASSENGER SIDE)

< DTC/CIRCUIT DIAGNOSIS >

FRONT POWER WINDOW SWITCH (PASSENGER SIDE)

A

Description INFOID:0000000009950860

Front power window motor (passenger side) will be operated if front power window switch (passenger side) is B

operated.

Component Function Check INFOID:0000000009950861

C

1. CHECK FRONT POWER WINDOW SWITCH (PASSENGER SIDE) FUNCTION

Check front power window motor (passenger side) operation with front power window switch (passenger side).

Is the inspection result normal? D

YES >> Front power window switch (passenger side) is OK.

NO >> Refer to PWC-19, "Diagnosis Procedure".

E

Diagnosis Procedure INFOID:0000000009950862

1.CHECK FRONT POWER WINDOW SWITCH (PASSENGER SIDE) INPUT SIGNAL F

1. Turn ignition switch OFF.

2. Disconnect front power window switch (passenger side) connector.

3. Turn ignition switch ON. G

4. Check voltage between front power window switch (passenger side) harness connector and ground.

(+)

Voltage (V) H

Front power window switch (passenger side) (–) Condition

(Approx.)

Connector Terminal

UP Battery voltage I

12

Power window DOWN 0

D25 Ground main switch

(passenger side) UP 0

11 J

DOWN Battery voltage

Is the inspection result normal?

YES >> GO TO 2. PWC

NO >> GO TO 3.

2.CHECK FRONT POWER WINDOW SWITCH (PASSENGER SIDE)

Check front power window switch (passenger side). L

Refer to PWC-20, "Component Inspection".

Is the inspection result normal?

YES >> GO TO 4. M

NO >> Replace front power window switch (passenger side). Refer to PWC-112, "Removal and Installa-

tion".

3.CHECK FRONT WINDOW SWITCH (PASSENGER SIDE) CIRCUIT N

1. Turn ignition switch OFF.

2. Disconnect power window main switch connector.

O

3. Check continuity between power window main switch harness connector and front power window switch

(passenger side) harness connector.

Power window main switch Front power window switch (passenger side) P

Continuity

Connector Terminal Connector Terminal

16 12

D5 D25 Existed

12 11

4. Check continuity between power window main switch harness connector and ground.

Revision: 2013 October PWC-19 2014 CUBE

FRONT POWER WINDOW SWITCH (PASSENGER SIDE)

< DTC/CIRCUIT DIAGNOSIS >

Power window main switch

Continuity

Connector Terminal

Ground

16

D5 Not existed

12

Is the inspection result normal?

YES >> Replace power window main switch. Refer to PWC-112, "Removal and Installation".

NO >> Repair or replace harness.

4.CHECK INTERMITTENT INCIDENT

Refer to GI-40, "Intermittent Incident".

>> INSPECTION END

Component Inspection INFOID:0000000009950863

1.CHECK FRONT POWER WINDOW SWITCH (PASSENGER SIDE)

1. Turn ignition OFF.

2. Disconnect front power window switch (passenger side) connector.

3. Check front power window switch (passenger side).

Front power window switch

(passenger side) Front power window switch condition Continuity

Terminal

8 7

UP

11 6

11 6

NEUTRAL Existed

12 7

8 6

DOWN

12 7

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace front power window switch (passenger side). Refer to PWC-112, "Removal and Installa-

tion".

Revision: 2013 October PWC-20 2014 CUBE

REAR POWER WINDOW SWITCH

< DTC/CIRCUIT DIAGNOSIS >

REAR POWER WINDOW SWITCH

A

Description INFOID:0000000009950864

Rear power window motor will be operated if rear power window switch is operated. B

Component Function Check INFOID:0000000009950865

1. CHECK REAR POWER WINDOW SWITCH FUNCTION C

Check rear power window motor operation with rear power window switch.

Is the inspection result normal?

D

YES >> Rear power window switch is OK.

NO >> Refer to PWC-21, "Diagnosis Procedure".

Diagnosis Procedure INFOID:0000000009950866 E

1.CHECK REAR POWER WINDOW SWITCH INPUT SIGNAL

1. Turn ignition switch OFF. F

2. Disconnect rear power window switch connector.

3. Turn ignition switch ON.

4. Check voltage between rear power window switch harness connector and ground. G

(+)

Voltage (V)

Rear power window switch (–) Condition H

(Approx.)

Connector Terminal

UP Battery voltage

2

DOWN 0 I

Power window

LH: D63

main switch: LH UP 0

3

DOWN Battery voltage

Ground J

UP Battery voltage

2

Power window DOWN 0

RH: D43 main switch: RH UP 0 PWC

3

DOWN Battery voltage

Is the inspection result normal?

L

YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK REAR POWER WINDOW SWITCH M

Check rear power window switch.

Refer to PWC-22, "Component Inspection".

Is the inspection result normal? N

YES >> GO TO 4.

NO >> Replace rear power window switch. Refer to PWC-112, "Removal and Installation".

3.CHECK REAR POWER WINDOW SWITCH CIRCUIT O

1. Turn ignition switch OFF.

2. Disconnect power window main switch connector.

3. Check continuity between power window main switch harness connector and rear power window switch P

harness connector.

Revision: 2013 October PWC-21 2014 CUBE

REAR POWER WINDOW SWITCH

< DTC/CIRCUIT DIAGNOSIS >

Power window main switch Rear power window switch

Continuity

Connector Terminal Connector Terminal

1 2

LH D63

3 3

D5 Existed

5 3

RH D43

7 2

4. Check continuity between power window main switch harness connector and ground.

Power window main switch

Continuity

Connector Terminal

1

Ground

3

D5 Not existed

5

7

Is the inspection result normal?

YES >> Replace power window main switch. Refer to PWC-112, "Removal and Installation".

NO >> Repair or replace harness.

4.CHECK INTERMITTENT INCIDENT

Refer to GI-40, "Intermittent Incident".

>> INSPECTION END

Component Inspection INFOID:0000000009950867

1.CHECK REAR POWER WINDOW SWITCH

1. Turn ignition switch OFF.

2. Disconnect rear power window switch connector.

3. Check rear power window switch.

Rear power window switch

Rear power window switch condition Continuity

Terminal

1 5

UP

3 4

3 4

NEUTRAL Existed

2 5

1 4

DOWN

2 5

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace rear power window switch. Refer to PWC-112, "Removal and Installation".

Revision: 2013 October PWC-22 2014 CUBE

POWER WINDOW MOTOR

< DTC/CIRCUIT DIAGNOSIS >

POWER WINDOW MOTOR

A

DRIVER SIDE

DRIVER SIDE : Description INFOID:0000000009950868

B

Door glass moves UP/DOWN by receiving the signal from power window main switch.

DRIVER SIDE : Component Function Check INFOID:0000000009950869

C

1. CHECK FRONT POWER WINDOW MOTOR (DRIVER SIDE) OPERATION

Check front power window motor (driver side) operation with power window main switch. D

Is the inspection result normal?

YES >> Front power window motor (driver side) is OK.

NO >> Refer to PWC-23, "DRIVER SIDE : Diagnosis Procedure". E

DRIVER SIDE : Diagnosis Procedure INFOID:0000000009950870

1.CHECK POWER WINDOW MOTOR (DRIVER SIDE) INPUT SIGNAL F

1. Turn ignition switch OFF.

2. Disconnect front power window motor (driver side) connector.

3. Turn ignition switch ON. G

4. Check voltage between power window motor (driver side) harness connector and ground.

(+) H

Voltage (V)

Power window motor (driver side) (–) Condition

(Approx.)

Connector Terminal

UP Battery voltage

I

1

Power window DOWN 0

D7 Ground

main switch UP 0

3 J

DOWN Battery voltage

Is the inspection result normal?

YES >> Replace power window motor (driver side). Refer to GW-21, "Removal and Installation". PWC

NO >> GO TO 2.

2.CHECK POWER WINDOW MOTOR CIRCUIT L

1. Turn ignition switch OFF.

2. Disconnect power window main switch connector.

3. Check continuity between power window main switch harness connector and front power window motor

(driver side) harness connector. M

Power window main switch Front power window motor (driver side)

Continuity N

Connector Terminal Connector Terminal

8 1

D5 D7 Existed

11 3

O

4. Check continuity between power window main switch harness connector and ground.

Power window main switch P

Continuity

Connector Terminal

Ground

8

D5 Not existed

11

Is the inspection result normal?

YES >> Replace power window main switch. Refer to PWC-112, "Removal and Installation".

NO >> Repair or replace harness.

Revision: 2013 October PWC-23 2014 CUBE

POWER WINDOW MOTOR

< DTC/CIRCUIT DIAGNOSIS >

PASSENGER SIDE

PASSENGER SIDE : Description INFOID:0000000009950871

Door glass moves UP/DOWN by receiving the signal from power window main switch or front power window

switch (passenger side).

PASSENGER SIDE : Component Function Check INFOID:0000000009950872

1. CHECK FRONT POWER WINDOW MOTOR (PASSENGER SIDE) OPERATION

Check front power window motor (passenger side) operation with power window main switch or front power

window switch (passenger side).

Is the inspection result normal?

YES >> Power window motor (passenger side) is OK.

NO >> Refer to PWC-24, "PASSENGER SIDE : Diagnosis Procedure".

PASSENGER SIDE : Diagnosis Procedure INFOID:0000000009950873

1.CHECK FRONT POWER WINDOW MOTOR (PASSENGER SIDE) INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect front power window motor (passenger side) connector.

3. Turn ignition switch ON.

4. Check voltage between front power window motor (passenger side) harness connector and ground.

(+)

Voltage (V)

Front power window motor (passenger side) (–) Condition

(Approx.)

Connector Terminal

UP Battery voltage

2

Front power win- DOWN 0

D27 Ground dow switch

(passenger side) UP 0

1

DOWN Battery voltage

Is the inspection result normal?

YES >> Replace front power window motor (passenger side). Refer to GW-21, "Removal and Installation".

NO >> GO TO 2.

2.CHECK FRONT POWER WINDOW MOTOR (PASSENGER SIDE) CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect front power window switch (passenger side) connector.

3. Check continuity between front power window switch (passenger side) harness connector and front power

window motor (passenger side) harness connector.

Front power window switch (passenger side) Front power window motor (passenger side)

Continuity

Connector Terminal Connector Terminal

6 1

D25 D27 Existed

7 2

4. Check continuity between front power window switch (passenger side) harness connector and ground.

Front power window switch (passenger side)

Continuity

Connector Terminal

Ground

6

D25 Not existed

7

Is the inspection result normal?

YES >> Replace front power window switch (passenger side).PWC-112, "Removal and Installation".

Revision: 2013 October PWC-24 2014 CUBE

POWER WINDOW MOTOR

< DTC/CIRCUIT DIAGNOSIS >

NO >> Repair or replace harness.

REAR LH A

REAR LH : Description INFOID:0000000009950874

B

Door glass moves UP/DOWN by receiving the signal from power window main switch or rear power window

switch LH.

REAR LH : Component Function Check INFOID:0000000009950875 C

1.CHECK REAR POWER WINDOW MOTOR LH OPERATION

Check rear power window motor LH operation with power window main switch or rear power window switch D

LH.

Is the inspection result normal?

YES >> Rear power window motor LH is OK. E

NO >> Refer to PWC-25, "REAR LH : Diagnosis Procedure"

REAR LH : Diagnosis Procedure INFOID:0000000009950876

F

1.CHECK REAR POWER WINDOW MOTOR LH INPUT SIGNAL

1. Turn ignition switch OFF. G

2. Disconnect rear power window motor LH connector.

3. Turn ignition switch ON.

4. Check voltage between rear power window motor LH harness connector and ground.

H

(+)

Voltage (V)

Rear power window motor LH (–) Condition

(Approx.)

I

Connector Terminal

UP Battery voltage

1

Rear power win- DOWN 0 J

D67 Ground

dow switch LH UP 0

2

DOWN Battery voltage

PWC

Is the inspection result normal?

YES >> Replace rear power window motor LH. Refer to GW-25, "Removal and Installation".

NO >> GO TO 2.

L

2.CHECK REAR POWER WINDOW MOTOR LH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear power window switch LH connector. M

3. Check continuity between rear power window switch LH harness connector and rear power window motor

LH harness connector.

N

Rear power window switch LH Rear power window motor LH

Continuity

Connector Terminal Connector Terminal

4 2 O

D63 D67 Existed

5 1

4. Check continuity between rear power window switch LH connector and ground.

P

Rear power window switch LH

Continuity

Connector Terminal

Ground

4

D63 Not existed

5

Is the inspection result normal?

Revision: 2013 October PWC-25 2014 CUBE

POWER WINDOW MOTOR

< DTC/CIRCUIT DIAGNOSIS >

YES >> Replace rear power window switch LH. Refer to PWC-112, "Removal and Installation".

NO >> Repair or replace harness.

REAR RH

REAR RH : Description INFOID:0000000009950877

Door glass moves UP/DOWN by receiving the signal from power window main switch or rear power window

switch RH.

REAR RH : Component Function Check INFOID:0000000009950878

1. CHECK REAR POWER WINDOW MOTOR RH OPERATION

Check rear power window motor RH operation with power window main switch or rear power window switch

RH.

Is the inspection result normal?

YES >> Rear power window motor RH is OK.

NO >> Refer to PWC-26, "REAR RH : Diagnosis Procedure".

REAR RH : Diagnosis Procedure INFOID:0000000009950879

1.CHECK REAR POWER WINDOW MOTOR RH INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect rear power window motor RH connector.

3. Turn ignition switch ON.

4. Check voltage between rear power window motor RH harness connector and ground.

(+)

Voltage (V)

Rear power window motor RH (–) Condition

(Approx.)

Connector Terminal

UP Battery voltage

1

Rear power win- DOWN 0

D47 Ground

dow switch RH UP 0

2

DOWN Battery voltage

Is the inspection result normal?

YES >> Replace rear power window motor RH. Refer to GW-25, "Removal and Installation".

NO >> GO TO 2.

2.CHECK REAR POWER WINDOW MOTOR RH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear power window switch RH connector.

3. Check continuity between rear power window switch RH harness connector and rear power window motor

RH harness connector.

Rear power window switch RH Rear power window motor RH

Continuity

Connector Terminal Connector Terminal

4 2

D43 D47 Existed

5 1

4. Check continuity between rear power window switch RH harness connector and ground.

Rear power window switch RH

Continuity

Connector Terminal

Ground

4

D43 Not existed

5

Is the inspection result normal?

Revision: 2013 October PWC-26 2014 CUBE

POWER WINDOW MOTOR

< DTC/CIRCUIT DIAGNOSIS >

YES >> Replace rear power window switch RH. Refer to PWC-112, "Removal and Installation".

NO >> Repair or replace harness. A

PWC

Revision: 2013 October PWC-27 2014 CUBE

ENCODER CIRCUIT

< DTC/CIRCUIT DIAGNOSIS >

ENCODER CIRCUIT

Description INFOID:0000000009950880

Detects condition of the front power window motor (driver side) operation and transmits to power window main

switch as pulse signal.

Component Function Check INFOID:0000000009950881

1.CHECK ENCODER OPERATION

Check front driver side door glass perform AUTO open/close operation normally when power window main

switch.

Is the inspection result normal?

YES >> Encoder operation is OK.

NO >> Refer to PWC-28, "Diagnosis Procedure"

Diagnosis Procedure INFOID:0000000009950882

Encoder Circuit Check

1.CHECK ENCODER OPERATION

1. Turn ignition switch ON.

2. Check signal between power window main switch harness connector and ground with oscilloscope.

(+)

Signal

Power window main switch (–)

(Reference value)

Connector Terminal

9

D5 Ground Refer to following signal

13

JMKIA5210GB

Is the inspection result normal?

YES >> GO TO 7.

NO >> GO TO 2.

2.CHECK ENCORDER SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect power window main switch connector and front power window motor (driver side) connector.

3. Check continuity between power window main switch harness connector and front power window motor

(driver side) harness connector.

Power window main switch Front power window motor (driver side)

Continuity

Connector Terminal Connector Terminal

9 6

D5 D7 Existed

13 5

4. Check continuity between power window main switch harness connector and ground.

Revision: 2013 October PWC-28 2014 CUBE

ENCODER CIRCUIT

< DTC/CIRCUIT DIAGNOSIS >

Power window main switch A

Continuity

Connector Terminal

Ground

9

D5 Not existed B

13

Is the inspection result normal?

YES >> GO TO 3. C

NO >> Repair or replace harness.

3.CHECK ENCORDER POWER SUPPLY CIRCUIT

1. Connect power window main switch connector. D

2. Turn ignition switch ON.

3. Check voltage between front power window motor (driver side) harness connector and ground.

E

(+)

Voltage (V)

Front power window motor (driver side) (–)

(Approx.)

Connector Terminal F

D7 2 Ground Battery voltage

Is the inspection result normal?

G

YES >> GO TO 4.

NO >> GO TO 5.

4.CHECK GROUND CIRCUIT H

1. Turn ignition switch OFF.

2. Check continuity between front power window motor (driver side) harness connector and ground.

I

Front power window motor (driver side)

Continuity

Connector Terminal Ground

D7 4 Existed J

Is the inspection result normal?

YES >> GO TO 7.

PWC

NO >> GO TO 6.

5.CHECK HARNESS CONTINUITY 1

1. Turn ignition switch OFF. L

2. Check continuity between power window main switch harness connector and front power window motor

(driver side) harness connector.

M

Power window main switch Front power window motor (driver side)

Continuity

Connector Terminal Connector Terminal

D5 15 D7 2 Existed N

3. Check continuity between power window main switch harness connector and ground.

Power window main switch O

Continuity

Connector Terminal Ground

D5 15 Not existed

P

Is the inspection result normal?

YES >> Replace power window main switch. Refer to PWC-112, "Removal and Installation".

NO >> Repair or replace harness.

6.CHECK HARNESS CONTINUITY 2

1. Disconnect power window main switch connector.

Revision: 2013 October PWC-29 2014 CUBE

ENCODER CIRCUIT

< DTC/CIRCUIT DIAGNOSIS >

2. Check continuity between power window main switch harness connector and front power window motor

(driver side) harness connector.

Power window main switch Front power window motor (driver side)

Continuity

Connector Terminal Connector Terminal

D5 2 D7 4 Existed

Is the inspection result normal?

YES >> Replace power window main switch. Refer to PWC-112, "Removal and Installation".

NO >> Repair or replace harness.

7.CHECK INTERMITTENT INCIDENT

Refer to GI-40, "Intermittent Incident".

>> INSPECTION END

Revision: 2013 October PWC-30 2014 CUBE

BCM (BODY CONTROL MODULE)

< ECU DIAGNOSIS INFORMATION >

ECU DIAGNOSIS INFORMATION A

BCM (BODY CONTROL MODULE)

WITH INTELLIGENT KEY

B

WITH INTELLIGENT KEY : Reference Value INFOID:0000000010230391

VALUES ON THE DIAGNOSIS TOOL C

NOTE:

The following table includes information (items) inapplicable to this vehicle. For information (items) applicable

to this vehicle, refer to CONSULT display items. D

CONSULT MONITOR ITEM

Monitor Item Condition Value/Status

Other than front wiper switch HI Off E

FR WIPER HI

Front wiper switch HI On

Other than front wiper switch LO Off

FR WIPER LOW F

Front wiper switch LO On

Front washer switch OFF Off

FR WASHER SW

Front washer switch ON On G

Other than front wiper switch INT Off

FR WIPER INT

Front wiper switch INT On

H

Front wiper is not in STOP position Off

FR WIPER STOP

Front wiper is in STOP position On

Wiper intermittent dial I

INT VOLUME Wiper intermittent dial is in a dial position 1 - 7

position

Other than rear wiper switch ON Off

RR WIPER ON

Rear wiper switch ON On J

Other than rear wiper switch INT Off

RR WIPER INT

Rear wiper switch INT On

PWC

Rear washer switch OFF Off

RR WASHER SW

Rear washer switch ON On

Rear wiper is in STOP position Off L

RR WIPER STOP

Rear wiper is not in STOP position On

Other than turn signal switch RH Off

TURN SIGNAL R

Turn signal switch RH On M

Other than turn signal switch LH Off

TURN SIGNAL L

Turn signal switch LH On

N

Other than lighting switch 1ST and 2ND Off

TAIL LAMP SW

Lighting switch 1ST or 2ND On

Other than lighting switch HI Off O

HI BEAM SW

Lighting switch HI On

Other than lighting switch 2ND Off

HEAD LAMP SW 1 P

Lighting switch 2ND On

Other than lighting switch 2ND Off

HEAD LAMP SW 2

Lighting switch 2ND On

Other than lighting switch PASS Off

PASSING SW

Lighting switch PASS On

Revision: 2013 October PWC-31 2014 CUBE

BCM (BODY CONTROL MODULE)

< ECU DIAGNOSIS INFORMATION >

Monitor Item Condition Value/Status

Other than lighting switch AUTO Off

AUTO LIGHT SW

Lighting switch AUTO On

Front fog lamp switch OFF Off

FR FOG SW

Front fog lamp switch ON On

Driver door closed Off

DOOR SW-DR

Driver door opened On

Passenger door closed Off

DOOR SW-AS

Passenger door opened On

Rear RH door closed Off

DOOR SW-RR

Rear RH door opened On

Rear LH door closed Off

DOOR SW-RL

Rear LH door opened On

Back door closed Off

DOOR SW-BK

Back door opened On

Other than power door lock switch LOCK Off

CDL LOCK SW

Power door lock switch LOCK On

Other than power door lock switch UNLOCK Off

CDL UNLOCK SW

Power door lock switch UNLOCK On

Other than driver door key cylinder LOCK position Off

KEY CYL LK-SW

Driver door key cylinder LOCK position On

Other than driver door key cylinder UNLOCK position Off

KEY CYL UN-SW

Driver door key cylinder UNLOCK position On

Hazard switch is OFF Off

HAZARD SW

Hazard switch is ON On

Rear window defogger switch OFF Off

REAR DEF SW

Rear window defogger switch ON On

NOTE:

TR/BD OPEN SW Off

The item is indicated, but not monitored.

NOTE:

TRNK/HAT MNTR Off

The item is indicated, but not monitored.

Blower fan OFF Off

FAN ON SIG

Blower fan ON On

Air conditioner OFF (A/C switch indicator OFF) Off

AIR COND SW

Air conditioner ON (A/C switch indicator ON) On

LOCK button of the key is not pressed Off

RKE-LOCK

LOCK button of the key is pressed On

UNLOCK button of the key is not pressed Off

RKE-UNLOCK

UNLOCK button of the key is pressed On

BACK DOOR OPEN button of the key is not pressed Off

RKE-TR/BD

BACK DOOR OPEN button of the key is pressed On

PANIC button of the key is not pressed Off

RKE-PANIC

PANIC button of the key is pressed On

LOCK/UNLOCK button of the key is not pressed and held simultaneously Off

RKE-MODE CHG

LOCK/UNLOCK button of the key is pressed and held simultaneously On

Revision: 2013 October PWC-32 2014 CUBE

BCM (BODY CONTROL MODULE)

< ECU DIAGNOSIS INFORMATION >

Monitor Item Condition Value/Status

A

Bright outside of the vehicle Close to 5 V

OPTI SEN (DTCT)

Dark outside of the vehicle Close to 0 V

Bright outside of the vehicle (Lighting switch AUTO) Close to 5 V B

OPTI SEN (FILT)

Dark outside of the vehicle (Lighting switch AUTO) Close to 1.50 V

NOTE:

OPTICAL SENSOR Off

The item is indicated, but not monitored. C

NOTE:

RAIN SENSOR Off

The item is indicated, but not monitored.

Driver door request switch is not pressed Off D

REQ SW -DR

Driver door request switch is pressed On

Passenger door request switch is not pressed Off

REQ SW -AS E

Passenger door request switch is pressed On

NOTE:

REQ SW -RR Off

The item is indicated, but not monitored.

F

NOTE:

REQ SW -RL Off

The item is indicated, but not monitored.

Back door request switch is not pressed Off

REQ SW -BD/TR G

Back door request switch is pressed On

Push-button ignition switch (push switch) is not pressed Off

PUSH SW

Push-button ignition switch (push switch) is pressed On H

The clutch pedal is not depressed. Off

CLUCH SW

The clutch pedal is depressed On

I

The brake pedal is not depressed Off

BRAKE SW 1

The brake pedal is depressed On

The brake pedal is depressed when No. 9 fuse is blown Off J

BRAKE SW 2 The brake pedal is not depressed when No. 9 fuse is blown, or No. 9 fuse

On

is normal

Selector lever in P position Off PWC

DETE/CANCL SW

Selector lever in any position other than P On

Selector lever in any position other than P and N Off

SFT PN/N SW L

Selector lever in P or N position On

NOTE:

S/L -LOCK Off

The item is indicated, but not monitored.

M

NOTE:

S/L -UNLOCK Off

The item is indicated, but not monitored.

NOTE: N

S/L RELAY-F/B Off

The item is indicated, but not monitored.

Driver door is locked Off

UNLK SEN -DR

Driver door is unlocked On O

Push-button ignition switch (push-switch) is not pressed Off

PUSH SW -IPDM

Push-button ignition switch (push-switch) is pressed On

Ignition switch in OFF or ACC position Off

P

IGN RLY1 -F/B

Ignition switch in ON position On

Selector lever in any position other than P Off

DETE SW -IPDM

Selector lever in P position On

Selector lever in any position other than P and N Off

SFT PN -IPDM

Selector lever in P or N position On

Revision: 2013 October PWC-33 2014 CUBE

BCM (BODY CONTROL MODULE)

< ECU DIAGNOSIS INFORMATION >

Monitor Item Condition Value/Status

Selector lever in any position other than P Off

SFT P -MET

Selector lever in P position On

Selector lever in any position other than N Off

SFT N -MET

Selector lever in N position On

Engine stopped Stop

While the engine stalls Stall

ENGINE STATE

At engine cranking Crank

Engine running Run

NOTE:

S/L LOCK-IPDM Off

The item is indicated, but not monitored.

NOTE:

S/L UNLK-IPDM Off

The item is indicated, but not monitored.

NOTE:

S/L RELAY-REQ Off

The item is indicated, but not monitored.

Equivalent to speed-

VEH SPEED 1 While driving

ometer reading

Equivalent to speed-

VEH SPEED 2 While driving

ometer reading

Driver door is locked LOCK

DOOR STAT-DR Wait with selective UNLOCK operation (5 seconds) READY

Driver door is unlocked UNLOCK

Passenger door is locked LOCK

DOOR STAT-AS Wait with selective UNLOCK operation (5 seconds) READY

Passenger door is unlocked UNLOCK

Driver side door is open after ignition switch is turned OFF

Reset

ID OK FLAG (Selector lever is in the P position except for M/T models)

Ignition switch ON Set

The engine start is prohibited Reset

PRMT ENG STRT

The engine start is permitted Set

NOTE:

PRMT RKE STRT Reset

The item is indicated, but not monitored.

Operation frequency

RKE OPE COUN1 During the operation of the key

of the key

NOTE:

RKE OPE COUN2 —

The item is indicated, but not monitored.

The key ID that the key slot receives is not recognized by any key ID reg-

Yet

istered to BCM.

CONFRM ID ALL

The key ID that the key slot receives is recognized by any key ID regis-

Done

tered to BCM.

The key ID that the key slot receives is not recognized by the fourth key ID

Yet

registered to BCM.

CONFIRM ID4

The key ID that the key slot receives is recognized by the fourth key ID reg-

Done

istered to BCM.

The key ID that the key slot receives is not recognized by the third key ID

Yet

registered to BCM.

CONFIRM ID3

The key ID that the key slot receives is recognized by the third key ID reg-

Done

istered to BCM.

Revision: 2013 October PWC-34 2014 CUBE

BCM (BODY CONTROL MODULE)

< ECU DIAGNOSIS INFORMATION >

Monitor Item Condition Value/Status

A

The key ID that the key slot receives is not recognized by the second key

Yet

ID registered to BCM.

CONFIRM ID2

The key ID that the key slot receives is recognized by the second key ID

Done B

registered to BCM.

The key ID that the key slot receives is not recognized by the first key ID

Yet

registered to BCM.

CONFIRM ID1 C

The key ID that the key slot receives is recognized by the first key ID reg-

Done

istered to BCM.

BCM detects registered key ID, or BCM does not detect key ID. ID OK

NOT REGISTERED D

BCM detects non-registration key ID. ID NG

The ID of fourth key is not registered to BCM Yet

TP 4

The ID of fourth key is registered to BCM Done E

The ID of third key is not registered to BCM Yet

TP 3

The ID of third key is registered to BCM Done

The ID of second key is not registered to BCM Yet F

TP 2

The ID of second key is registered to BCM Done

The ID of first key is not registered to BCM Yet

TP 1 G

The ID of first key is registered to BCM Done

Air pressure of front

AIR PRESS FL Ignition switch ON (Only when the signal from the transmitter is received)

LH tire H

Air pressure of front

AIR PRESS FR Ignition switch ON (Only when the signal from the transmitter is received)

RH tire

Air pressure of rear I

AIR PRESS RR Ignition switch ON (Only when the signal from the transmitter is received)

RH tire

Air pressure of rear

AIR PRESS RL Ignition switch ON (Only when the signal from the transmitter is received)

LH tire

J

ID of front LH tire transmitter is registered Done

ID REGST FL1

ID of front LH tire transmitter is not registered Yet

ID of front RH tire transmitter is registered Done PWC

ID REGST FR1

ID of front RH tire transmitter is not registered Yet

ID of rear RH tire transmitter is registered Done

ID REGST RR1 L

ID of rear RH tire transmitter is not registered Yet

ID of rear LH tire transmitter is registered Done

ID REGST RL1

ID of rear LH tire transmitter is not registered Yet M

Tire pressure indicator OFF Off

WARNING LAMP

Tire pressure indicator ON On

N

Tire pressure warning alarm is not sounding Off

BUZZER

Tire pressure warning alarm is sounding On

Revision: 2013 October PWC-35 2014 CUBE

BCM (BODY CONTROL MODULE)

< ECU DIAGNOSIS INFORMATION >

TERMINAL LAYOUT

JPMIA1438ZZ

NOTE:

Connector color

• M68, M70: Black

• M69, M71: White

PHYSICAL VALUES

Revision: 2013 October PWC-36 2014 CUBE

BCM (BODY CONTROL MODULE)

< ECU DIAGNOSIS INFORMATION >

Terminal No. Description A

(Wire color) Value

Input/ Condition

Signal name (Approx.)

+ − Output

All switch OFF 0V B

Turn signal switch RH

Lighting switch HI

C

Lighting switch 1ST D

Combination

PKIB4958J

2 Combination switch switch

Ground Input 1.0 V

(BR/W) INPUT 5 (Wiper intermit-

tent dial 4) E

F

Lighting switch 2ND

JPMIA0342JP G

2.0 V

All switch OFF 0V

Turn signal switch LH H

Lighting switch PASS

Lighting switch 2ND

Combination J

PKIB4958J

3 Combination switch switch

Ground Input 1.0 V

(GR) INPUT 4 (Wiper intermit-

tent dial 4)

PWC

Front fog lamp switch ON

L

PKIB4956J

0.8 V M

All switch OFF 0V

Front wiper switch LO

N

Front wiper switch MIST

Combination

4 Combination switch switch Front wiper switch INT

Ground Input

(L/Y) INPUT 3 (Wiper intermit-

tent dial 4) O

Lighting switch AUTO

PKIB4958J

1.0 V P

Revision: 2013 October PWC-37 2014 CUBE

BCM (BODY CONTROL MODULE)

< ECU DIAGNOSIS INFORMATION >

Terminal No. Description

(Wire color) Value

Input/ Condition

Signal name (Approx.)

+ − Output

All switch OFF

0V

(Wiper intermittent dial 4)

Front washer switch

(Wiper intermittent dial 4)

Rear washer ON

(Wiper intermittent dial 4)

Any of the condition below

with all switch OFF

• Wiper intermittent dial 1

5 Combination switch Combination • Wiper intermittent dial 5 PKIB4958J

Ground Input

(G) INPUT 2 switch • Wiper intermittent dial 6 1.0 V

Rear wiper switch ON

(Wiper intermittent dial 4)

PKIB4956J

0.8 V

All switch OFF

0V

(Wiper intermittent dial 4)

Front wiper switch HI

(Wiper intermittent dial 4)

Rear wiper switch INT

(Wiper intermittent dial 4)

Wiper intermittent dial 3

(All switch OFF) PKIB4958J

1.0 V

6 Combination switch Combination Any of the condition below

Ground Input

(L/R) INPUT 1 switch with all switch OFF

• Wiper intermittent dial 1

• Wiper intermittent dial 2

PKIB4952J

1.9 V

Any of the condition below

with all switch OFF

• Wiper intermittent dial 6

• Wiper intermittent dial 7

PKIB4956J

0.8 V

Revision: 2013 October PWC-38 2014 CUBE

BCM (BODY CONTROL MODULE)

< ECU DIAGNOSIS INFORMATION >

Terminal No. Description

(Wire color) Value A

Input/ Condition

Signal name (Approx.)

+ − Output

7 Door key cylinder Door key cylin- NEUTRAL position C

Ground Input

(W/R) switch UNLOCK der switch

JPMIA0587GB

8.0 - 8.5 V D

UNLOCK position 0V

8 Door key cylinder Door key cylin- NEUTRAL position 12 V

Ground Input E

(W/B) switch LOCK der switch LOCK position 0V

OFF (Brake pedal is not

0V

9 Stop lamp depressed)

Ground Stop lamp switch 1 Input F

(R) switch ON (Brake pedal is de-

Battery voltage

pressed)

NEUTRAL position H

12 Door lock and unlock Door lock and

Ground Input

(GR) switch LOCK unlock switch

JPMIA0012GB

I

1.0 - 1.5 V

LOCK position 0V

J

NEUTRAL position PWC

13 Door lock and unlock Door lock and

Ground Input

(BR) switch UNLOCK unlock switch

JPMIA0012GB L

1.0 - 1.5 V

UNLOCK position 0V

When bright outside of the M

Close to 5 V

14 Ignition switch vehicle

Ground Optical sensor Input

(L/G) ON When dark outside of the

Close to 0 V

vehicle N

15 Rear window defog- Rear window Not pressed

Ground Input

(W/L) ger switch defogger switch

P

JPMIA0012GB

1.0 - 1.5 V

Pressed 0V

17 Optical sensor pow- OFF, ACC 0V

Ground Output Ignition switch

(R/G) er supply ON 5V

Revision: 2013 October PWC-39 2014 CUBE

BCM (BODY CONTROL MODULE)

< ECU DIAGNOSIS INFORMATION >

Terminal No. Description

(Wire color) Value

Input/ Condition

Signal name (Approx.)

+ − Output

18

Ground Sensor ground Input Ignition switch ON 0V

(V)

Brake pedal: Depressed

NOTE:

Intelligent Key: Waveform varies each

21 Input/ Intelligent Key time when brake pedal is

Ground NATS antenna amp.

(P/L) Output battery is re- depressed

moved

JMKIA6232JP

Brake pedal: Not de-

12 V

pressed

ON 0V

23 Security indicator Security indica- Blinking (Ignition switch

Ground Output

(R/Y) lamp tor OFF)

JPMIA0590GB

12.0 V

OFF Battery voltage

Brake pedal: Depressed

NOTE:

Waveform varies each

25 Input/ time when brake pedal is

Ground NATS antenna amp. During waiting

(LG) Output depressed

JMKIA6233JP

Brake pedal: Not de-

12 V

pressed

OFF (A/C switch indicator:

27 OFF)

Ground A/C ON Input A/C

(O)

JPMIA0012GB

1.0 - 1.5 V

ON (A/C switch indicator:

0V

ON)

Blower fan switch OFF 0V

28

Ground Blower fan switch Input Fan switch

(G/W) Blower fan switch ON

PKIB4960J

7.0 - 8.0 V

Revision: 2013 October PWC-40 2014 CUBE

BCM (BODY CONTROL MODULE)

< ECU DIAGNOSIS INFORMATION >

Terminal No. Description

(Wire color) Value A

Input/ Condition

Signal name (Approx.)

+ − Output

29 OFF 12 V

(L/W)

Ground Hazard switch Input Hazard switch B

ON 0V

LOCK status (Unlock sen-

Front door lock as- sor switch OFF)

31 D

Ground sembly driver side Input Driver door

(G/B)

(Unlock sensor)

PKIB4960J

7.0 - 8.0 V

E

UNLOCK status (Unlock

0V

sensor switch ON)

All switch OFF

G

(Wiper intermittent dial 4)

PKIB4960J

H

7.0 - 8.0 V

32 Combination switch Combination

Ground Output Front fog lamp switch ON

(LG) OUTPUT 5 switch

(Wiper intermittent dial 4)

I

Rear wiper switch ON

(Wiper intermittent dial 4)

Any of the condition below

with all switch OFF

J

• Wiper intermittent dial 1

• Wiper intermittent dial 2 PKIB4956J

• Wiper intermittent dial 6 1.0 V PWC

• Wiper intermittent dial 7

All switch OFF

(Wiper intermittent dial 4)

M

PKIB4960J

7.0 - 8.0 V

N

33 Combination switch Combination Lighting switch 1ST

Ground Output (Wiper intermittent dial 4)

(Y/L) OUTPUT 4 switch

Lighting switch AUTO

(Wiper intermittent dial 4)

O

Rear wiper switch INT

(Wiper intermittent dial 4)

P

Any of the condition below

with all switch OFF

PKIB4958J

• Wiper intermittent dial 1

1.2 V

• Wiper intermittent dial 5

• Wiper intermittent dial 6

Revision: 2013 October PWC-41 2014 CUBE

BCM (BODY CONTROL MODULE)

< ECU DIAGNOSIS INFORMATION >

Terminal No. Description

(Wire color) Value

Input/ Condition

Signal name (Approx.)

+ − Output

All switch OFF

(Wiper intermittent dial 4)

PKIB4960J

7.0 - 8.0 V

34 Combination switch Combination Lighting switch 2ND

Ground Output (Wiper intermittent dial 4)

(W) OUTPUT 3 switch

Lighting switch HI

(Wiper intermittent dial 4)

Rear washer switch ON

(Wiper intermittent dial 4)

Any of the condition below

with all switch OFF

PKIB4958J

• Wiper intermittent dial 1

1.2 V

• Wiper intermittent dial 2

• Wiper intermittent dial 3

All switch OFF

Combination PKIB4960J

35 Combination switch switch 7.0 - 8.0 V

Ground Output

(R/L) OUTPUT 2 (Wiper intermit- Lighting switch 2ND

tent dial 4)

Lighting switch PASS

Front wiper switch INT

Front wiper switch HI

PKIB4958J

1.2 V

All switch OFF

Combination PKIB4960J

36 Combination switch switch 7.0 - 8.0 V

Ground Output

(L/O) OUTPUT 1 (Wiper intermit- Turn signal switch RH

tent dial 4)

Turn signal switch LH

Front wiper switch LO

(Front wiper switch MIST)

Front washer switch ON

PKIB4958J

1.2 V

Revision: 2013 October PWC-42 2014 CUBE

BCM (BODY CONTROL MODULE)

< ECU DIAGNOSIS INFORMATION >

Terminal No. Description

(Wire color) Value A

Input/ Condition

Signal name (Approx.)

+ − Output

37 Selector lever P po- P position 0V

(G/O)

Ground

sition switch

Input Selector lever B

Any position other than P 12 V

Waiting 12 V

C

Ignition switch

OFF (Remote

keyless entry When operating either

button on Intelligent Key D

communication)

JMMIA0572GB E

38 Receiver communi- Input/ F

Ground

(G/Y) cation Output Waiting

G

Ignition switch JMMIA0573GB

ON (TPMS

communication)

H

When receiving signal