Professional Documents

Culture Documents

6hym Product Information

6hym Product Information

Uploaded by

Son Dang0 ratings0% found this document useful (0 votes)

33 views80 pagesOriginal Title

6HYM PRODUCT INFORMATION

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

33 views80 pages6hym Product Information

6hym Product Information

Uploaded by

Son DangCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 80

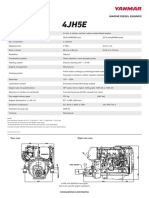

=~ YANMAR

MARINE

PROPULSION

DIESEL ENGINE

PRODUCT

INFORMATION

2nd edition

MODEL 6HYM-ETE

FOREWORD

We release the HYM engine which features the energy-saving performance

and environmental compliance at a higher level

We raised the boosting system capacity and utility factor of the air for superior

combustion. The power was enhanced while keeping the engine

dimensions identical to those of KYM

In addition to the robust structure of the conventional Yanmar marine

engines, the vibration isolation structure was improved in the new HYM

engine.

Further fuel economy was pursued and the engine is not only powerful but

also comfortable and friendly to the people and to our environment

CONTENTS

1, Engine Specifications .. 1

4-1 Engine Principal Particulars 1

1-2. External View. 2

4-3 Cross Sectional View. 3

1-4 6HYM-ETE Performance Curve 4

8

8

9

2. Sales Conditions.

2-1 Marine Propulsion Engine (without Marine Gear).

2-2 Selection of Fuel Oil, Lubricating Oil and Cooling Water.

3. Selling Points of the 6HYM-ETE....

4, Features of the 6HYM-ETE...

4-1 Operational Efficiency.

4-2 Strategies to Obtain Good Fuel Economy and Low Emissions sone 13)

4-3 Ensuring Reliability and Durability 14

5. Comparison Table with Competitors. :

5-1. Light Duty Applications (without Marine Gear) 16

5-2 Heavy Duty Applications (without Marine Gear) 16

6. Front P.T.O. (Front Power Take Off) .

6-1 Method of Front Power Take Off.

6-2. Diagram of Allowable Power from Front PT... a

6-3 Detail of Front P.T.O (Standard), 20

6-4. Detail of Front Drive System (Option), 20

7. Drawings of Engine Outline and Piping Diagram 2

7-1 Engine Outline: GHYM-ETE (without Marine Gear) 2

7-2 Piping Diagram 23

8. Engine Monitoring System .. .

8-1 Monitoring System with Manufacture's Standard Panel... ne 25

8-2 Rule Compliant Monitoring System (Option) 36

9, Remote Control .

9-1 Type of Remote Control Head 40

9-2 Supplementary Functions

9-3. Cautions for Cable Wiring

10. Accessories.

10-1 Specifications & Accessories Menu. 43

10-2 Extra Accessories. 45

10-3 Other Specifications oo — sone AB

10-4 Spare Parts. 65

10-5 Rule Required Spare Parts (For reference only) 65

10-6 Tools (Standard). aa sna snes 66

10-7 Special Tools 67

10-8 Interchangeabilty of Main Accessories 68

11. Maintenance Schedule... :

11-1. Periodical Maintenance 69

14-2 Periodic Maintenance Schedule. 69

11-3 Routine Maintenance Serviceability Parts List m1

12. Important Check Points on Installation and Rigging

[Rating Definitions]

@ Commercial Ratings of EHYM-ETE

Ratings s L M H

Allowable continuous

operation hours atrated | somin, or below | 2hrs orbelow | 10hrs orbelow | 24hrs or below

PB (30% or below) | (40% or below) | (60% or below) | (80% or below)

(Operation hour ratio

per year)

Typical total operation

eee poy 41000 2000 3000 4000

Ferry!

Patrol/ fast going | Light duty fishing?

Planing hull ike Tug!

Typical applications pieasrceran | Hahtduy fshing | High speed Fraghter

boat passenger boat bch

I The atmospheric and operation condition

‘The power of this engine assumes the use under the following atmospheric and operation conditions.

‘Standard Condition

TSosuIerT Service Condition

Ambient temp. e 25 0-45

‘Atmospheric pressure kPa (mm) 100 (750) =

Relative humidity % 30 85 or below

32 or below

Air cooler inlet water temp. c 25 (on condition of sea water)

1. Engine Specifications

1-1 Engine Principal Particulars

Model Unit GHYMAETE

Type = Vertical, water-cooled, 4-cycle diesel engine

Combustion chamber = Direct injection type

No.of ojinders- cylinder bore x stioke| _mm 6-192.8 «165

Total cylinder displacement t 1373

Ratings = 3s v ™ a

Rated power (at fywhee) sw(mHP) | 816(700) | 478 (650) | 441600) | 368(600)

Raled engine speed min 2200 2160 2100 7950

Brake mean effecive pressure | MPakgion®)| 2.04208) | 194188) | 1.890187) | 1.640168)

‘Mean piston speed mis 124 118 15 107

wPavms | 247 22.9 212 177

ceeimen cae (kflem?-mis)| (252) (34) 216) (180)

Specific fuel

at 100% Load,

fwnen HO NOx. | Without omiwn | an | zoe | zoe | zor

standards are met) | Arne gear

Specified lubricating ol consumption | _gikith 0.1 — 0.4(at 100% Load)

Compression ratio = 182

Crankshaft rotation direction 7 Counterclockwise, when viewed from the fiywheel

Operating side = On the le, when viewed from the flywheel

1-4-263-51

omen - (The opposite side of flywheel is No.1 cylinder)

~ Exhaust gas turbocharger (with an air cooler)

Supercharging system RHCT(HI) x 2 (win turbo)

‘Constant high temperature cooling system

ot - (with a fresh water cooler)

Volume of cooling fresh water @ 40 (in coolers & jacket)

Lubricating system = Wet sump system, forced lubrication by gear pump

max:36 _min12 effective: 24

Volume of tubricating oil Engine) | Coenen

Staring system = Elect staring motor DC24V-5KW

Size of flywheel housing & Mywhesl_ | _— SAE #1 & 355(H4)

Overall enath_| _mm 1556

Dimensions [Overall wath mm 7014

Overall Reight_| _mm 7133

Engine dry mass er

(Without marine gear) ee

1-2 External View

1 Operation Side

1-3 Cross Sectional View

Valve mechanism [Supercharging

+ 2 intake, 2 exhaust valves "Twin exhaust gas

+ Specially hardened cylinder] turbo charging system

type tappet

Intake air system

+ Integrated inter cooler|

and intake manifold

Fucl injection system

+ In fine fuel injection pump

[Cylinder block

* Hanging bearing

structure

+ Cast in one piece

for all oylinders

* Horizontal split type

‘connecting rod

+ Balancing weights are

integrated to crankshaft }

ie

\ oh Tubrcating al aystem

Ne + Pump is equipped inside block

ie + Mulitubular type cooler

~ Engine mounting bracket Ni A + Paper iter (arrdge type)

{or vibration isolator rubber + Dipstick can be equipped both

(Option) ct side of operation or non operator

1-4 6HYM-ETE Performance Curve

The following curves show the performance of the engine without marine geer.

[Rating: S] 515kW/2200 min“

{Condon «+

temp. : 25°C, Air Pressure : 0.102 MPa, LHV: 42700 kifkg )

‘Al propeller load exp. 25

025

020 :

0.15 -

0.10

| a

Boost press. (MPa)

0.05 -

[at

0.00

1000 1100 1200 1300 1400 1500

700

1600 1700 1800 1900 2000 2100 2200 2300

00

500

400

Exh, temp, inlet of TC (C)

-—

300)

{by thermo couple)

1000 1100 1200 1300 14001500

169)

1600 1700 1800 1900 2000 2109 2200 2300

140

120

109]

0] .

«| t

ro)

Fuel consumption (2h)

Ll |

°

1000 1100 1200 1300 14001500,

700

1600 1700 1800 1900 2000 2109 2200 2300

00 :

500) :

400 t

200)

Power (ki)

200)

109] .

°

1000 1100 1200 1300 14001500,

Engine speed (min)

1600 1700 1800 1900 2000 2109 2200 2300

[Rating: L] 478kW/2150 min”

{(Consition «+++ temp. : 25 °, Air Pressure : 0.102 MPa, LHV: 42700 kg }

‘Al propeller load exp. 25

025

020

015

0.10 + + +

0.05 t +

0.00

1000 1100 1200 1300 1400 1800 1600 1700 1800 1900 2000 2100 2200 2300

700

tT (0)

e

400 4 { L t

Exh. temp,

(@y thermo couple)

300

1000 1100 1200 1300 1400 1509 1600 1700 1800 1900 2000 2100 2200 2300

160

140 : | | |

120

100

80

60 : ——— {

40

20 + | | |

al

1000 1100 1200 1300 1400 1500 1600 1709 1400 1900 2000 2100 2200 2300

Fuel consumption (1h)

700

600 - - + +

500

400

00

200 — +

Fan] p

5 l L

1000 1100 1200 1809 1400 1800 1600 1700 1800 1900 2000 2100 2200 2300

Power (kW)

Engine speed (min’)

[Rating: M] 441kW/2100

(Condition +--+ temp. : 25°C, Air Prossure 0.102 MPa, LHV : 42700 kikg )

‘At propeller load exp. 3

025

020

015

0.10

0.05 ee

0.00

Boost press. (MPa)

1000 1100 ©1200 1300 1400 1500 1609 1700 1800 1900 2000 2100 2200

600

600

| |

400

300

Exh, temp, inlet of TIC CC)

(by hero ouple)

200

1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200

160

= 140 bees .

= 120

5 100

80 {| __t |

60 —

49 —

20 ————

o

5

5

:

1000 1100 1200 1900 ©1400 «1800 1600 1700 1800 1900 2000 2100 2200

700

#00 | |_| |

500 |

400

200

200

100

°

1000 1100 1200 1900 1400 1600 1600 1700 1800 1900 2000 2100 2200

Engine speed (min) son

[Rating: H] 368kW/1950 min’

(Condition

028,

temp, : 25°C, Aie Pressure : 0,102MPa, LHV: 42700 kukg )

A propeller load exp. 3

020 +

ons, -

010 -

0.05

Boost pross. (MPa)

ee

| eer |

0.09

1000 © 110012001300 1400,

600

1500 1600-1700 1800-1900

500 t

400

300

Exh, temp, inlet of TIC ('e)

200

{by thermo couple)

1200 13001400

160

1500 16001700 «18001900204

140

120 .

100

ao

60

2

Fuel consumption (2h)

10001100 12001300400

700

1600 1700 1800-1900

600 t

500 :

400

300

200

Power (ew)

100

1000

1100

1200 13001400

1500 1600 1700 «180019002000

Engine speed (min) exe

2.

Sales Conditions

2-1 Marine Propulsion Engine (without Marine Gear)

No] ttem Sales conditions Model: 6HYM-ETE

Operating | Ratings 8 L M H

1 | conditions

1) Rated power (kW) [Rated engine speedimin'*) | §15/2200 | 478/2150 | 441/210 | 368/1950

MGO or ADO

Fuel oll (Cetane number 2 45, Sulfur contents<1%)

[Note: Marine diesel oil is not allowed.]

2 |Fuelused | Fuel fer replace- | Sulfur cont. = 0.5% 1000 hr

ent mena ‘Sulfur cont, 0.5-1.0% 500 hr

Water separator Shall be equipped

Grade SAE J183 CD or CF-4

‘SAE40 or SAEISW40

Viscosity (GAE15W-40 is limited to the case of using

3g | tub. oll the fue! less than 0.5% sulfur contents)

haa Lub. oi! Sulfur cont, $ 0.5% 500 hr

exchange interval | Suifur cont. 0.5-1.0% 250 hr

Lub. oil fier replacement interval ‘500 hr

Front drive | Refer to the diagram for

4 |system —_| Allowable power each front driving system

«5 | Torsional [Need to request torsional vibration calculation on ordering after checking the

vibration _| necessity of it

6 | Reverse rotation ‘Available through reduction/reversion unit

Minimum speed (min) / allowable hours 600/4

8 | Necessary fresh air volume (m°/min) (at 100% load) 2105

9 | Ambient temperature (°C ) S45

in case of using sea water S 32

10 4

ari ceraaa ey in case of using fresh water < 38

11 | Exhaust back pressure (max. kPa (mmAq)) 5.9 600)

12 [Battery Battery capacity 24V-150An (200Ah for cold district)

Be sure to equip air heater when outside tem-

13]Air heater | Optional equipment Seam eeu

14|Rake angle Less than 8”

(°1) Typical marine gear mechanical loss 3% must be considered in case of the engine supplied with marine gear.

2-2 Selection of Fuel Oil, Lubricating Oil and Cooling Water

(1) Fuel oi

+ Quantity Criteria of Fuel Oil

Viscosity at 90°C mms 3-8

Specific gravity at 15/4 °C <086

Flash point c >60

Residual carbon mass.% <07

Sulfur content mass.% <1.0

Property citical [ASM content mass e008

value Moisture content vol.% 45)

| Several worldwide specifications ere Oe, 2D

for diesel fuels 180 6217 DMX

(2) Lubricating oi!

1) Engine oil

+ API (American Petroleum Institute) service grade: CD or CF-4 equivalent

+ TBN (Total Base Number): 9 - 15 mgKOH/g

+ Viscosity: SAE40 or SAE1SW-40

Recommended oil brands (for reference)

Supplier

porcestcaton Jescne shen Boon Mob

Grade CD 40 GADINIA OIL 40 | MOBIL GARD 412

BPENERGOL

DS3-154

Gradeor-4 | r5mao | piMuLaxtawuao | DELBAGK SUPER

2) Marine gear oil

+ Refer to the operation manual for each marine gear.

(3) Cooling Water

1) Criteria for cooling fresh water

Use distilled or tap water with following quality.

Recommended water quality,

pH 63-85

Total hardness (CaCO;) S 100 ppm

Chlorine ion (Cé") concentration S 100 ppm

M alkalinity, 30 - 100 ppm

[Ammonia ions (NH,*) S$ 0.05 ppm

Sulfate ions (O;") S 100 ppm

Evaporation residue = 400 ppm

Brands of corrosion inhibitor

Since the fresh water cooler and the other parts in the 6HYM engine are made of aluminum alloy, use

the corrosion inhibitor shown below, or its equivalent,

2

Brands of commercial items (marine propulsion engine)

Brand ‘Supplier

Kurilex L-222 Kurita Water Industries Ltd.

Olgard C-601 Organo Co., Ltd

Nalfieet 9-111 NALCO JAPAN Co., Lid

Royal Freeze Yanmar Sangyo Co., Lid.

Note: Refer to the corrosion inhibitor manufacturer's instruction manual and follow the directions.

10

3. Selling Points of the 6HYM-ETE

(1) Fuel economy & Emissions —--- Meets IMO regulations.

‘Combination of fuel economy and low NOx emissions

Fuel consumption at rated power: 201g/kWh (H-rating, without marine gear)

Wide-ranging engine speed with low FOC (fuel oil consumption).

<>

IH The combustion of staggered fuel injection nozzle holes and the most suitable combustion chamber.

I Improvement of the air utility factor and YANMAR original combustion system.

(2) Operational Efficiency

Good acceleration and stable performance for a wider operating range

Shorter down time

Comfort on board

Improvement of the air utility factor and YANMAR original FIE system

Il Large inspection windows on the block allow in-site replacement of pistons.

1 Engine flexible rubber mounts (Optional) reduces the vibration in the engine room.

(3) Excellent Durability and Reliability

Low, stable LOC (Lub. Oil Consumption) and long overhaul interval

<>

1 Forced cooling piston, "Silicard’-treated liner and nitrided stainless steel rings and optimized clear-

ance between piston and liner

W Special treatment nozzle, 3D-CAD design

(4) Safety

Easy maintenance

Type approved by major classification societies

1 Easy-to-replace cartridge type Lub. oil fter

I Full mechanical engine management

u

4, Features of the 6HYM-ETE

4-1. Operational Efficiency

(1) Stable performance for a wider range

onMETE

+ Min. fuel consumption range is wide. | Best FOC Zone

(Line A of right figure)

+ The engine torque-rise characteristics having

much in reserve. (Line B of below figure.) © |pontroc zone /

+ Wide max. power range (Line C of below figure) : SPT

= A wide range propeller matching é J

+ Wide medium load range (Line D of below figure)

Produces stable engine performance even doing

other job duties.

Engine speed (min’)

(9)

120

10

109

40

Power (ki)

209

+09]

800 1000 120014901600 1800 20002200 2400

Engine spoed (min)

Remark: Typical marine gear mechanical loss 3% must be considered in case of engine supplied with marine gear.

12

(2) Astonishing Acceleration

‘The high performance twin turbos have smaller rotating inertia mass than single turbo.

‘Therefore the engine will deliver smooth acceleration starting way down low and extending all the way

up to the rev. range.

Acceleration: Twin Turbo VS Single Turbo Twin Turbo System

Twin Turbo

a Single Turbo

bocca

Time (sec)

4-2 Strategies to Obtain Good Fuel Economy and Low Emissions

Combustion technology patented by YANMAR,

Application of the New technology

oxym eHYM

Number of a | Main (uppen x8

nozzle holes Sacondary (lower) x4

Nozzle hole area | Small Large

Diameter of

each nozziehole | _2*ae con

O SO Deep combustion chamber

‘Staggered nozale holes

Mais IMO NOx standard

Improved air uilzation factor

Reduced fuel injection period

oKyw HYM

The combination of staggered nozzle holes and deep combustion chambers improves the air utilization

factor. This produces fuel economy (therefore low CO,), low NOx emissions, and low smoke power,

along with highly atomized fuel particles.

4-3 Ensuring Reliability and Durability

(1) Countermeasures to reduce lubricating oil consumption (LOC) and wear in the rings and liners

oxy oxy

sy dail ALAlloy Cylinder liners:

ae Slr rated

a £ Piston ngs

a :

OS} () “a

S| Fevenenines pene ego

a sine

Combination of “Silicard”- treated liners (a YANMAR original) and nitrided SUS (stainless steel) rings

‘The combination of "Silicard” liners and the nitrided SUS rings has the following effects, providing

excellent stability in the consumption of lubricating oil, even in heavy load applications.

1) The effects of using silicon carbide (SiC) and nitrided SUS produce good wear resistance in both the

cylinder liners and the rings.

2) Micro-grooves formed in the process of embedding the SIC have the effect of holding lubricating oll

on the walls of the liner. This effect prevents the liner from developing a mirror surface due to carbon

buildup.

YANMAR developed this technology and produced these parts for heavy-load, marine propulsion

engines such as trawlers. We have already sold more than 30,000 of these units,

‘SIC embedded in the surface

‘SiC embedded in the surface

‘The "Silicard’ treatment embeds silicon carbide powder (SIC is an artificial ceramic that is close to dia-

monds in hardness) in the surface of metal using a special surface treatment to form a partial compos-

ite material.

4

(2) Improved fuel injector durability

YANMAR's precision equipment technology is used to improve durability as follows,

1) The comers of the inner nozzle holes are rounded.

2) The surface of the main nozzle body is given a special treatment (to improve heat resistance).

Rounded inner nozzle comers

(3) Technical subject about engine vibration isolating installation with marine gear

(Vibration isolating installation is option)

Technical subject about engine vibration isolating installation with marine gear (Direct couping)

Fixed installation

Benne AB]

soar

Marine gear under load. = Engine is not affectod ‘Slanderd configuration

1: The engine coupled withthe marine gear must be

Intallated on the bed with four muting bracket.

2: The marine gear mouting bracket andthe engine

routing Bracket most boon bo inn plate.

Flywhoo! housing

\Vibeation isolating

installation

reat poi

Engine ae

Thrustload + add the support

‘add the rib in ol pan

Under propulsion load, large stress occurs in the fywhee! housing portion

15

5. Comparison Table with Competitors

5-1 Light Duty Applications (without Marine Gear)

YANMAR cat] volvo | __ WAN

Engine mode!

onymete | exymeTe | 12 bia 6-730

No.of ey Borex Stroke| _mm [6x 132.9 x 165|6 x 192.9 x 16516 x 190 x 15016 x 191 x 150) 6x 128% 166,

Displacement @|_ta73 7378 7195 72.18 12.82

Rated power kw | __ 816 a8 526 478 597

(at fiywhee!) mHP | _700 650 715 650 730

Rated speed min 2200 2200 2300 2300 2300

Dry mass kg 1385 1388 1175, 1400 1305

‘Weight/power kg/kW. 2.69 2.90 2.23 2.93 243

7

515

ey

gs

400

200)

230

220)

Foc

(at rated)

‘oxWh

210)

200

5-2 Heavy Duty Applications (without Marine Gear)

Engine model YANMAR MAN ‘Cummins CAT

GHYM-ETE | 6LAAM-UTE | 02876 | _KTA19-M3 cis

No, of cylxBorexStroke | _mm |6x132.9%165] 6 x 148x165 | 6 x 128x166 | 6x159x159| 6x 145x183,

Displacement a 13.73 17.03 72.82 718.94 18.12

Raled power kW 368 405 360 373 357

(at flywheel) mHP 500, 550, 490 507, 486,

Rated speed min? | 1950 1850 1800 4800 1800

Dry mass kg 1385 1890 1160 2073 1539

Inspection windows = ° ° x x x

450

400

Power

(attw)

KW

350

300

220,

20

Foc

(at rated)

‘awh

210

200

100)

16

6. Front P.T.O. (Front Power Take Off)

Ifyou are planning a front drive system, please contact us.

6-1 Method of Front Power Take Off

System Power take-off procedure

Pulley

a Belt-driven without an outer

bearing (Small load take-off)

Pulleys Floxble coupling

o Driven with flexible coupling

(CGM5507, CGMS508)

Outer bearing

7

6-2 Diagram of Allowable Power from Front P.T.O.

(1) When propeller is not engaged

00

Saami

7072150

M441 2100

s00 2

00 2 it

‘System "0" CGMSS8 rr

MAK allowable PTO power i

t an “ h

= Lied power ee | /

g ‘of Engine i 7 W/L

5 300 < ;

System "D" CGMS507

352) 1950

1M 96072700

5378/2200

200

a La

17011950,

100 M1741 2100.

v

Sone

[seme] a sel

600 g00==«1000-«=«t200~=«400~«=«ne00~=«=«t00 «0002200

Engine Speed (min')

18

(2) When propeller is engaged

es

oe ora

ser

=

400, < < <

Ve : io

i 7

= ([ sysem-o- conse] 1 t

z je

Dey a

i ( i

\ A

L{syiem-o"cowssor }{_1

‘

| =)

H

i

200 of Engine | Ff

| eran Saal)

y a)

as

7 oma)

[trating

Lo t

7 Cy (Csr 2t00min” )

on LL Cease

°

‘00 —«e00~=«t000~=«200~=~=«A.S=SC«OSC«CROS«SCOSSC(O

Engine Speed (min')

19

6-3 Detail of Front P.T.O (Standard)

/ 133

cSWPump c.s.WPump,

3:20 Bats 2

12.M10 Screws Depth 19 Tighton Torque: 275+20N-m

(28 2kgf-m}

265

Damper

Eo

| Eng. Mounting Bracket

6-4 Detail of Front Drive System (Option)

CAUTION: These part numbers will change without notice.

(1) System "A" (B type X 2, PC $250)

12M10 Sores Depth 19/26 (1) V-Pully Type: JIS"B x2

(1) Spec. No, TOOOH-5511A0

(2) Spec. No. T2s6H-5525A0

(9) Paris No. 45423-570580

Total mass: 9.4kg

Crankshaft Center

Damper

Eng, Mounting Bracket

20

12.10 Serows Dopth 18726

(1) Spec, No. TOOOH-5511B0

(2) Spoc. No. T266H-5525A0

(3) Parts No. 45423-570580

Total mass: 11.39

2685

No.t Cyl. Center

Damper

Eng, Mounting Brackot

(8) System "D", Coupling type: CGMS507, 5508

Insert from opposite side of the engine

Coupling Dimension

Twe [oa] B [pcoc|ec/e [oa[F]H[L

[CGM5507 | 281/78 210 | 148/111 28 | 97 | 206 286

(OGM-5508 | 373 100, 280 190 /145| 90 | 102| 253) 347

* Local procurement

L ss

Rotation fee aan af eee

sate 202-5) Mn Lng

ap fa] N01 ot cone

LB ‘|

aL =

(a Pe ats in |

3/8 i

t Hy ir \

u cemeteries

seen Dameer

Eng. Mounting

Bracket

2

Crankshaft Center

eankshaft Center

ee

16287,

Section A

Section B

No] Name

(| Fresh Water Tank

(@)| Air Fiter tor Turbo.

(@) | Staring Motor

(| Fost Fiter

(6) Lub. 01 Fiter

1014

52a 290

‘4:10 Screws Dapth 19

Detail of

Flywhosl Housing & Flyuhoo!

(SAE #1 & FW. 355(444),

{ser10)

a 170, 252 f40

ea

oSCYL. No.tGh

For Removing Piston

Rotation of Crankshaft

Front P.7.0. (SAE #4)

(Dela af rant P10. "See another drawing)

Dwe. No. | 83-26677-0260

‘aulANO auiBuz 4-2

a

ed

x

=

™m

q

m

=

5

3

5

=

>

wesBeiq Buidig pue euljjno eulbuy jo shuimeig “2

7-2 Piping Diagram

(1) Cooling Water System

% 10.635

CEW.sub-Tank Rubber Hose

Lub.01 Cooter

(For Engine)

31.0981

Rubber Hose

Px 00.40

Exh.Gas Manifold

i

ovinder

*OD50

C-SWOutet Pipe

Remark: Pipes marked 3 inthis drawing are not supplied

TS Winet Pipe O

EW Temesta

Soap

Filer Cop s|8

set-otimpa Ff

z|é

e\s

x 1p508

Rubber tose by ~

i

CSW. Line

CRW. Line

3 Lub Oi Cooter

(For Marine Gear)

JRooe

51.0981

Rubber Hose

tnnoe Dia,

0D. : Outer Dia

(2) Lubricating Oil System.

Lub. 04 Cooler

oe

0. Thermostat

‘Set 69-00

GilGailery

“Turbocharger

Lub oll Pump

‘Turbocharger

‘Set’ 0.400 50MPa

Press, Regulating Vah

Rocker Arm

Gamshatt

Piston

Set: 1 1aMPa

Suction

(3) Fuel oil, Exhaust gas & Air System

Fue System Exh Gas & it System

Fuel injection Valve : i :

& 3 a

s|] Ul Li

Toa

xaos i i

: Aer Hose 4

Tanager [Teed

: Mist Pie al

ion 42 .

‘Rubber Hose] 3 Crank Case & ar Ar ov)

+

€ é te

é 5 ay

é H A 7

é 5 3

Remark: Pipes markod 3 are not suppliod by our manufactory

24

8. Engine Monitoring System

8-1 Monitoring System with Manufacture's Standard Panel

(1) Wiring Diagram

1) Earth float & One panel without Air Heater

‘alr coding Procured By Cust

rocurod By Customer

R_ [Red Tg [Light green Starter Switch

B [Bleck [Le [ahi Bue — (0c24v-150 at)

Wo | White Br [Brown 30 [AC] 17 | Gt] G2] Pt] P2 [AR]

Y [Yellow P [Pink ‘Glow | oO oO ot+—to pe ey Battery

1 [Bue | “er [ray aw oes e 28

[Green| Pu [Pure oF Jo 2 i

‘0 lorenge ons 2 anory swan)

8 ~ 8

NA

Eng. Oil C.W, Temp —Tacho with SS

Boost meter pmeler meter Hour meter Ok

io (Reserved Terminal »5 ‘Starter Motor

es a) forma) 28S

al N99 \eeo/| SE R

cell | it Tele eensteem A /

Lg tn Hf Ht a SRS 5) eacered Torna!

; rorartels)

fa” ' we iYw Reser Torna ge 2188

¥ ‘ De ita | eas

a

HL Wd

= 4 d

& Gt ©. Wi Tey

fe we 12 Swi?

2a t YE

base | : 8

Ri

amp. cucu) Arp. Cre

(Boost (Go Presses) :

wet ie

+ y

7 .W-Temp Chch OF Pressure

one ‘Sender ‘Switch (Not supply)

ng. ip, ;

On (Lyw)

c.w.teme. ©wt|||/ Lv i

Gotten. (YS | ‘arm

Cw.tewt Owa_||| lye) Great 4

S XS One

tea otters, QY | | a

il Filter @s so 4

UU Boost Sender Eng. Oi Pressre

mont Pam it Filter Bypass a

Instrument Panel OW Fit Br

= ru lL Remarks

ae ») racine 3] elon] v J 1 Bator & cables shown by broken tne tobe provided by ship yard

ao SSE] eal cn 2. Sectional rea ot battery cables shoud be 65mm when hata engh

Na) ty oy] i toos hon 5 motors ana 120mm when talons move thon 5 mater.

(pay PF) com “otal cao long ar lss than 10 melts. (stoy~ Stator Motor)

2. Keop the etry sich "ON? during operation.

Deal ot Connector Detal ot Connector 4 Cutoff baler ech when qu corging te bates by a charge DWwa No. | £3-26677-0110

(Gorow Aion) (arow 88 View) 6. tr engine stopped, cut ote bat th or

25

2) Earth float & One panel with Air Heater

Color codin i | ae

i 4 | Procured By Customer

R [Red Ta [Light green Starter Switch in 7 |

B Black Lb Light biue cee io | | (0c24v-200An)

Ww |Wito Br | Brown 0 [AC] 47 | G1] G2] Pt | P2TAR| |

oe a om low | [ee

[Bue | Gr Gay Site | ale 9

G_| Green| Pu Purple L

‘0 Orenge

Eng, Ott. Temp Tacto wih euczer

meter meter” Hourmeler — uzzar Stop ium

Gy) (| @e) Jo) B

x i) 8.0, i

oe The wwf ®

Re —¥

& I | cvotuse)

RB

Fuse Step svtch 7

3a PB || wy w_ Wer

j ©.W.Temp. Eng. Oi Pressure

lac cone KA ey on Altemator

Ie 8

cB 2 a B

RW 3k 8 Ys

<| ow + WR

g e

1 Gd ayo U tt

Cluch Of Pressure

_ C.W. Temp, Eng. OlTemp. C.W. Level _—_Tacho Sensor

cme Rs Sender Sach Sensor Switch (Nt sup)

ng, Ol p i

C.W. Temp. wk jay (3

me Ge — ea |

cote Ore rol TFA We

C.W. Level YG, Wire Hamess B &

En. o8 Temp. LY ||| LAR we Tl

orm Oe || 8 8 i

Boost Sender Eng. Oi Prossure

UJ Sender

Ot iter Bypass

Instrument Pane Valve Swit

a es Remarks

1. Battery & cables shown by broken tn to Be povided by shipyard

RGD) |frwfunlalw | | vey 2 Sectional area of battery cables should be 96mm? when their total length

i) \ralal oe [e108 lon is ess than Smeters an 120mm? when thee length s mor tan 5 meters

Total eabe length are less than 10 meters. Battery~ Starter Motor~Batery)

(Pan) rr ema 2. Koop the balloy sich ON" dung operation

Detail of Connector Detail of Connector 4. Cut off hte battery switch when quickly charging the batteries by @ charger. DWG. NO. | E3-26677-0120

(Brrow AA View) (Usrow 8-6 View) 5. Alter engine sopped, eu of te batey sch F

3) Earth float & Two panel without Air Heater

Eng.Oi CW Temoyacne win Ryzzer

Prister “Msiee™ Hour Meter Buzzer ‘Stop Mui

ww PB

sero ee

he

Stop Sieh f="

tater Sven |

Eng.Oip.

cw. Temp:

G.0ip.

CW Lovell

Eng Oil Temp.

Oil Fite

Instrument panel (Sub)

alone ee _

sooner EBS SLE? oun SE" ma

be

Stop wth

C.W. Temp. Switch “| Eng. Oil Prossure Switch

ayo

Eng. 0 CW. Level Sensor

“Temp. Switch

charge

Eng Olp.

eW.Temp.

GOip.

cWLevel

Eng Ot Temp.

OW Fiter

TT © Bas aq eos

— Eee

il sonnector (Arrow Connector (Arrow | Remarks

= ea a. re ‘Starter Switch Dota of Cc (Arrow AA) Detail of Ce tor ( Bs) 1. Battery & cables shown by broken line to be provided by ship builder.

EERE | sutasean TBs aan ne ceretegy a ew

thee — [eee ee sor eaiees ene er ars ee

eee le ee pieohabainy ont (OU dare et ay eye chon

= coe. E EEHePRSy Sit i

(0c24v.150Ah)

Alternator

Procured By Customer

Boost Sender

‘acho Sensor | Clutch Oi Pressure

‘Switch

«Not supp)

Eng Oil Pressure Sender

DWG NO.

E3-26677-0090

a7

4) Earth float & Two panel with Air Heater

Engg Git Tomo Tacs euzzor BE" wa:

Procured By Customer

be

(Not Use)

ke

Stop Switen [~~

tare Switch |

Relay (eczav-200n)

Wire Hames.

Eng Oi p

cw.Temp

Goi,

cwLevel

Eng.01 Temp,

Oi iter

Air Heater

Instrument panel(Sub) be

Eng Oi C.W-Temp Tacho With Buzzer E1 wot use) |

Boost Meter preter ‘Moier”™” HourMeter Buzzer Slop tli sere)

be |

Stop Switch

Eng.0il Pressure Switch

C.W-Temp Switeh™|

ayo

JEng 04 Temp. CW. “Tactio Sensor

‘Switch Level Sensor

Clutch Oi Pressure Switch

(Not supply)

C.W-Tomp. Sender

Eng.Oilp,

cw.Tomp,

GOlp.

CWLevel

Eng. Ci Temp,

Oil Fitter

Boost Sendor Eng Oil Pressure

eam ae ‘Valve Switch

eeu ee omen

aa Dow fcamecer (Aron) Dante Comat ow) SESS in nou oy ening ne poms by ap bale

Spee [] unto | stator suit oh Sie ty ees i ae a

ote — fel oe ‘Texan Store Sed Seen fer ohn mars tors

| eee} — faa See ae ee a eee Sn a erate

retool aoe inne bay ih, CONT dua aparatn ac DWG NO. | £9-26677-0100

ee (al a ey we et Sars batary by charger

S| Seta. 2 kore spb ct i nba omeny ne Dataryby# care co

28

(2) Instrument Panel

41) Detype panel (Standard)

Boost Pressure Gauge LO, Prossure Gauge

CW. Thermometer Tachometer Buzz

70

+

+

(2 1

2

Sch mi Switch

bite.

.. Bs

en

©

ft

"OK" Monitor/ Hour Meter,

Parts No. 12668491201

Mass 2.99

Glock

D)

O.

[8

Buzzer] Starter Switch

Engine Stop Button

6-96 5 Holes [Push the bution

Pr

eile

Sompldoty

2) C-type panel (Sub panel, Option)

L.O.Pressure Gauge CM Themomeler Tachometer Buzzer Sith Mum, Switch

400 abt231

my 7 125. SE

Cow)

ot

©

_&

‘OK* Monitor/ Hour Mater/ Clock Buzz0r

Parts No. 12668491211 (C-ype panel)

Mase : abt2kg

Refiting parts for adding C-panel (2 pole)

Kit No. T206A-558080 (Local procurement)

[Detail parts of Kit]

4. Bend (FWC IN)

2 Sub panel Assy

3. CW. Sender Unit,

4 Hamess

126613-49210

12660-91570

46150-571270

Starior Switch

6-96.5 Holos

1728684-91 160 (include C-ype pane! relay)

29

~ Engine Stop Button

Push the button

untl the engine

‘wil stop

‘complataly

30

(3) Extra Fitting for Engine Trip (Option)

NOTE: Shall be fitted locally.

41) Wiring Diagram

NOTE: The following are available combination of Tachometer indications.

+ For D-panel and C-panel

+ For D-panel and Speed relay

Color coding Procured By Customer

es Starter Switch, 1 “(oczav-isoan)

{ack —fuaf Le bue fo [ac] Jor eae ea a | Poo) [om

nie —]Br[ Brown Rosey o try

Y¥ | Yetlow [P| Pink. oLce os '

Lee er] “Gra jorr_[o. ibeexesrea| =

S| Green [Pu Purge on 0g. Stop Motor patey aon)

oT orange IstaRT a eae 4

s 2 |

Engo CW.Temp Tacho With Buzzer m0 H

Boost Meter p. Meter Mer” Hour Melor Buzzer Slop mi cir |

DS !

I

perce

eo

B

et ee a ow

Step Switch

ag 9

FA C.W.Temp. Switch 4

' ‘tomato

fe 2

i q f

ae CW.Temp Sondor Eng. Oi Temp. CWLovel Sensor Taco Sonsor | Clutch Oi Prssre

' ' Smieh Swit (Not supe)

09 0ip.

coon. =—

Goll SSS

° A 7 a

weve _- a

Eng Oi! Temp.

oi Fitor

wW

eee cee eee

Instrument pane! 1. Battery & cables shown by broken line to be provided by ship builder.

eee ca canta eee ee ace

5 ae Seana ciawes awesseares esiegcreee oes

Ge) =a Tota cablelongh ae 10 moter. Batery~ Starter Moloe~ Battery)

aan (es [ - agcoetem me Stan ete

|| o [re] eas 4. Cutoff the battery switch when quickly charging the battery by a charger.

S eS SS tS smtcamamees sues tacn en

Detail of Connector (Arrow A-A)

Detail of Connector (Arrow 8-B)

E3-26677-0110

4

32

2) Layout of Sensor

Flys!

| z

)

Front Side

CFW. Temp. Sitch

for Alarmi(Standard)

CEW. Temp. Switch

foe Trip(Option)

Eng, Stop Molor(Standard)

efit ~

5 C.FW. Temp.

Sender(Standard)

z

g

#

LO. Press. Switch

{or Tep(Option)

LO. Press, Switch

for AlarmyStandard)

‘Soting Point of Switch: Please refer Page 34

33

3) Switches

NOTE: Non class rule approved.

LO. Press Switch for Trip

Marking Green Terminal Screw

Parts No, 12630-91591

Speciation

4. Sorting Press. :0.028:=0.01MPa0.26:+0 halen)

2. Max, Using Press: 7.4MPa(10.Skgten)

3.Comtact Capacty :€V OC-15Amp, 12V.DC-BAMP,24V DC-AMP

‘20V DC-1AMP, 240 DC-0 5AMP

4. Using Tom. agro ~ “120°C

5. Contact Formation: G—O— (0.028MPaz : ON)

1 C.FW. Temp. Switch for Trip

6

21

Rad

Parts No, 46150-504710,

Marking : Black

Specifications

1 Setting Temp. ON--100:3°C,0FF-oores 2c

2. Contact Capacity. : DC12/24V-7/3.5A

3. Max. Using Temp, : 130"

4. Contact Formation : eo (100"°0< ON)

Tarminal Serow(M)

i Tacho Sensor

maxag|

Parts No.124411-91160,

Ea

248

05 Spacifications

1. Type: Magnetic Pickup

2, Supply Power: Seif Generator

3, Output 2 1V(At800Hz Gapt.mm,20°C)

4, Output Frequency: 142Pulstey

(at model sHYMETE)

ce _5.Col Resistance: 1.6k@at 20°C)

S|] 6. Ambient Temp. -25~140°C

SY] 7 insulation Resistance: OCS0OV =3MQ(atMegger)

8, Tightening Torque: 49N-m(Skg-m)

9, Mass: Ab. 0:2kg

Miax45 Pulse Signal

Output

Test push baton

sensor taut

‘eo

Operation

ED)

REV, SolVR

405 oles

Specifications

Tanarstn Allolthe pats ae on the printed cet boar inthe steel cave

‘Tepid creut boar is constutod win secre pars ETC.

{ne hashigh relarce

2.Conact Out __Contaet tam (14a REV. detactn, 1S constant REY. tection

‘2rover speed delecton,SCelectr open)

{arlet capacity (ACTOOVDCZaV OA)

2, Source Deas, 2:2 (Operaton ime DCT8~32V)

4 Measuring Wlernce: -£1.0% aS.

S.Gheumstance temp. 258~349K (15-700)

8 Gave eae Bc Pate

noe

Operation manual,

1.Geneal

‘One spood ay detects 3 postion af revalutan and detector pen,

[An Lalowe connecting reveuten Pda.

2.Oparton

{a} Sseee dtecten: inp signals rumbororequency suse tom the

"etna aersor magnate revauton detector) ston an angine

(b) Sgra eorvort to BC voage when ein proporton to reauency by

‘rqusey-velage covert To amply tsDC valtage

[erate oft ane oulout a volage sgh

() Cenparson with base vltago: The aut ray works ard LED lights

rat iput signal becomes niger tan base vtage

9.Acjstment

(a) Tetunthe adustrent votage vlumeto cow, Operating point down

Totun the adustront voume ew, operating ost a.

(0) Keep an engina ravluton at operating pant. Tum the soktmentvlume

oni ro righ positon ow pation and stp a LED igh on an

seuse pacing —— tes —_

BEEN years, BESIOVA oxy SOSA)

ea)

4

2 er tok of pie less than 2V/P).

a rina before do nai teat. Dor put over OCSODV.

4 Dontda deter strength et

5

z

Dott test by lst push buton a constart engine reoluton.

(Openthe temirais wien a nt used

‘Adedad wie cable a" snp L-DPYCS-128) recommend fr connactng tom

trevemtterto fs ceree

8, Denstrowe the ZERO and SPAN acustment vue, They are Pr-agusient

ejay peads (y

8-2 Rule Compliant Monitoring System (Option)

(1) Junction Box Wiring (Factory Option)

Junction Box

ot ‘Hu Fting)

Engine Mounting Bracket || _—— Yanmar Supply

om

Engine puct—f

Cable Length :L= 1.5m

(2) Connection Diagram (Factory Option)

Engine Fitings

Batory| | Bauery

“ay Battery

{Oc24v-150An) Switch =

Junction Box ; i

Maite Tar |S [sear

Tuwero2t0 Remark: of wie size indicates "nm

ex) 125425

ooo

Heh isos

telain Eng Panel] PET

em eg Peel | [Loe i =

/ = Fetay

Gland "A 19°

| Ej [atemator

BL pcan ssa

Engine Fitings

Te Ll reat acho sensor [M2

TTEH | Lywveasol po lEng 0, Pres. ow 105 OOPS

ep { _|Smite tor Tip [oczav ano 2argiem) | Gland Sie

TT} Luweyc24.0 [70 | Eng. CFW.Temp.[High :On 973K "a" | Bee

cra {,_|Swich tor top” [pc2av 35a (100%)

ALPS FL enevc2.0 Lo | Eng. 0, ross. [Low : On 0.05HPa | 1. Aer engine stoped, cut oF the terse

eet T © _|Swichfer alm [ocasvanosigiemy | fama pate san ON caw pe

TTS pL iwpve210 19 | ng. cw, Temp|High: On 368K | 4 The rt crate of ermine! nabs are change

apap Tlo_| Sich for tam [oczav 3.5 (95%) |" atcoring we engine numba

Junetion Box (HulFiting) :

(3) Example of Engine Tripping Circuit (Local procurement)

(Reference)

|

20800.

LO. Press

Switch (Low : On)

GW. Temp,

Switch (High - On)

se] eset

wh

=

=]

=

yi | F over Speed Tip

1 8

! Lo bow Pree

wei

crw

Z| Fim. th

= “a

z 8 | eusrb.ton

E | eee see

sous 0020

37

(4) Wide Electric Tachometer

MS Scrow

6 20. 18 Input Terminal rom

=| Speod Relay

15

(Scale range Incase of ~'800 min") MS Sorow

Terminal forlamp DC2¢V Adjusting knob for speed

Incase of amp belonged

Tethelamp | Scalerange 7

Part No, fea tm) Fitted range (rir)

"46150555960 No (0~1800 Rated spaed : Not more than 1200%in"

wen | tet50-586970 No (0~2500 Rated spoed : Notless than 1500min"

46150-556360 Yes (07800 Rated speed Not more than 1200%in"

wes | ae150.556500 Yes (02500 Rated speed : Not less than 1600min"

Notes

4 Type : CO-14 (In case of lamp belonged)

2. Adjusting knob for speed is belonged

3. This dovice should be connacted fram SRT-2 type speod relay specitiod by us.

4. Seale adjusting range 10%

5. Sensitivity Full scale DC10v, ma,

6. Scale Minimum soale : 20min" Division line : Each 100m

Figure: Each 200m"

The cals white,

‘The scales, laters and needles are black

7. Paint color Black (Munsell N1.5/0)

‘Supply voltage of lamp: DC24V (Incase of lamp belonged)

‘9, Marine shielded electric cable (MPYCS-2-1.0)is recommended to connected between

the speed relay and this devico. Note thal such cables should be used inthe

Tollowing cases: where the cables are laid very near (within tm) and in parallet

loan AC Ine or frequently on of-convalled DC line, or where they are lid

beste # kansformer, welding machine, or thyristor

paNeL cur RING DAGRAN

Sy 4.06

: 2 acnometor 9+) lft | Sspootraay

F ol Pe

i +

© Sepa) Sones

38

(6) Alarm and Local Indication Table (Reference)

1) Alarm and Trip Switeh

O: Standard @ : for NK Rule A : Option

Tor Alarm for Tip

Press. | Temp. | Others Press, Temp. Others

Lub. Oil ° ° °

C.F. Water a ° eal A 7

Exh, Gas TIC

inlet 7 = - - . 7

Fuel Oil - 5 Leakage . z

°

Engine Speed = - : - : °

39

9. Remote Control

9-1 Type of Remote Control Head

Ml 2 Handle Type (1 Engine and 1 shaft)

M1 Handle Type (1 Engine and 1 shaft)

MIG Handle (Black)

Governor Handle (Red)

‘Stroke Adjusting Botts

Roomate control Gable (TSK)

Stroke : 100mm

Ext tiroad of Cable ond | M5x0.8

Parts No, 41730-01200

Mase :3.3k9,

20

x

258

Remote control Cable

‘Stoke | {00mm (dinen)

Bit thread of Cable end M5 x0.8

Parts No, 41730-50097

Mass: 2b1-4.9k9/Ip

IW Series type Dual Station Control

2 Engine and 2 shaft

Engine

258

MG Cable

40

9-2 Supplementary Functions

(1) Operation Force for Governor Lever (for reference)

Ball Joint

AS GON GHD

(2) Locking Mechanism

Lock the governor handle when necessary for not

pulled back by the cable.

(3) Neutral Knob for M/G Handle

‘The MIG neutral knob is provided to the one-han-

dle type for idling the engine.

Neutral Knob for M/G handle

120

40]

a“

9-3 Cautions for Cable Wiring

(1) Use the remote control cable with 100mm stroke and MS x 0.8 screws.

35, 206

x0

5.35

(2) We recommend that the length of the remote control cable will be kept within 10m.

(3) When bending the cable at the M/G side is necessary, do not bend it to one direction only. In that case,

the cable loss discrepancy will be caused between push and pull due to backlash, which further causes

the specified forward or reverse stroke to be insufficient.

x °

(4) In cable wiring, make the wiring straight as far as possible with least bending,

(8) The minimum bending radius shall be over 200mm,

ee

(©) Provide thermal insulation plates, etc. for the cable running near the hot engine parts so that heat will

ot be radiated directly to the cable. (The ambient temperature should be bellow 100 °C.)

(7) Clamp the cable at appropriate positions (for preventing vibrations.)

(®) Do not cause extemal force to work on the cable.

(®) Use the cable of the suitable length. Do not use the cable which is too long

x

(10) Do not cause paint to be adhered to the end fixture or cable. Install the cable fast so that it will not be

loosened.

(11) Concerning the service stroke, divide the whole stroke by the center and ensure sufficient allowances

both for forward and reverse.

42

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 12aym Product InformationDocument226 pages12aym Product InformationSon Dang100% (1)

- Brochure Đ NG Cơ Yanmar Model L100NDocument8 pagesBrochure Đ NG Cơ Yanmar Model L100NSon DangNo ratings yet

- Connection Wiring SampleDocument1 pageConnection Wiring SampleSon DangNo ratings yet

- Non-Regulated: Specification SheetDocument3 pagesNon-Regulated: Specification SheetSon DangNo ratings yet

- Marine Diesel Engines: Right Side View Rear ViewDocument2 pagesMarine Diesel Engines: Right Side View Rear ViewSon DangNo ratings yet