Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

318 viewsUWILD Survey Requirement MVR Part 7 Appendix 1

UWILD Survey Requirement MVR Part 7 Appendix 1

Uploaded by

jeri adovelinCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Drawing Hydraulic Hatch CoverDocument3 pagesDrawing Hydraulic Hatch Coverjeri adovelinNo ratings yet

- Product Quotation: Weifang Yongneng Power Electromechanical Equipment Co.,LtdDocument3 pagesProduct Quotation: Weifang Yongneng Power Electromechanical Equipment Co.,Ltdjeri adovelinNo ratings yet

- Survey Report Class BVDocument31 pagesSurvey Report Class BVjeri adovelinNo ratings yet

- Fuel ConsumptionDocument12 pagesFuel Consumptionjeri adovelinNo ratings yet

- 06766320220222181721Document2 pages06766320220222181721jeri adovelinNo ratings yet

- KUT 4ADORAH005E - PT. Adovelin RaharjaDocument1 pageKUT 4ADORAH005E - PT. Adovelin Raharjajeri adovelinNo ratings yet

UWILD Survey Requirement MVR Part 7 Appendix 1

UWILD Survey Requirement MVR Part 7 Appendix 1

Uploaded by

jeri adovelin0 ratings0% found this document useful (0 votes)

318 views5 pagesOriginal Title

UWILD survey requirement MVR Part 7 Appendix 1

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

318 views5 pagesUWILD Survey Requirement MVR Part 7 Appendix 1

UWILD Survey Requirement MVR Part 7 Appendix 1

Uploaded by

jeri adovelinCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

14

13

15

| ABS

PART 7

APPENDIX 4

SECTION 4

9 Surveys (2013)

Underwater Inspections in Lieu of Drydoc!

Introduction

‘Scope and Application

‘A request for Underwater Inspection may be accepted as an altemative to Drydocking Inspection provided

‘that all arrangements and equipment meet the requirements specified in this Appendix.

For vessels 15 years of age or over and subject to the Enhanced Survey Program (ESP), Underwater

Inspections in Liew of Drydocking are not permitted as an alternate Drydocking Surveys.

‘This Appendix contains the minimum requirements for an Underwater Inspection in Liew of Drydocking.

Additional specific requirements for the UWILD Class Notation are noted accordingly.

Approval Procedure for UWILD Class Notation (2019)

An ABS optional notation, UWILD, for Underwater Inspection in Liew of Drydocking, may be assigned to

1 vessel in full compliance with the requirements as specified in this Appendix. The entire procedure for

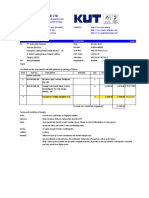

assignment of the UWILD notation is shown in 7-A-1/1.5 FIGURE 1.

Specific additional elements required for UWILD notation include the following:

i) Preparation and submission of plans to ABS Engineering as noted in 7-AI-1/3.3.5 “Plans and

Data” and 7-A1-1/3.5 “Physical Features”

4) Outof water survey to verify hull markings,

iii) Bolted access plates are required to be provided to determine the condition and clearance of the

rudder bearings, and the physical condition and securing arrangements of the pintle as noted in 7-

AL-BS2,

iv) Hinged sea suction grids for access to sea chest and sea suction openings as noted in 7-A1-1/3.5.3.

¥) Hull markings or other means of orientation as noted in 7-A1-1/3.3.5.

Governmental Regulations (2019)

‘The requirements specified in this Appendix are for classification only. Flag Administrations may have

specific regulations for Underwater Inspection in Liew of Drydocking, including requirements for

enrollment, hull markings, extent of visibility and procedures for older vessels.

[ABS RULES FOR SURVEY AFTER CONSTRUCTION - 2022 394

Part

7 Survey After Construction

‘Appendix 4

Section

1_Underwater Inspections in Lieu of Drydocking Surveys (2013) TA

34

FIGURE 1

Approval Procedures for UWILD Class Notation (2010)

Ss

Request for UWILD Notation

(by Owner/Operator)

Preparation and submission of plans to

an ABS Engineering office as required

byT-A-173.35, A135

Initial survey of underwater hull markings

and ather means of orienting the diver

during new construction

OR

An out-of-water drydocking (Existing Vessel) |

————e

Issue certification of compliance

with UWILD requirements

Conditions and Procedures

General (2019)

At the request of the Owner, ABS may consider Underwater Inspection in Liew of Drydocking Survey

provided all arrangements and conditions meet the requirements of this Appendix.

All requests for Underwater Inspection in Liew of Drydocking Survey are to be submitted to ABS for

review and authorization,

Underwater inspection is to be carried out under the surveillance of the attending Surveyor by an in-water

survey company recognized by ABS.

The Surveyor is to be satisfied with the method of pictorial representation, and a good two-way

communication between the Surveyor and divers or remotely operated vehicle (ROV) operators is to be

provided,

Ifthe Underwater Inspection reveals damage or deterioration that requires further attention, the Surveyor

‘may require thatthe vessel be drydocked in order to undertake a detailed survey and necessary repairs

The extent of the underwater inspection is to be sufficient to include all items which would normally be

examined if the vessel was on drydock, some of which are listed in 7-A1-1/3.7.2

[ABS RULES FOR SURVEY AFTER CONSTRUCTION - 2022 395

Part 7

‘Appendix 4

Section 1

Survey After Construction

Underwater Inspections in Lieu of Drydocking Surveys (2013) TA

The following Paragraphs describe the conditions and procedures under which a properly conducted

underwater inspection may be credited as an alternative of Drydocking Survey.

3.3 Conditions

3.34

3.3.2

3.3.3

3.34

3.38

Limitations

i) NonsESP vessels 15 years of age or over applying for Underwater Inspection in Liew of

Drydocking are subject to special consideration based on the following review and

examination before being permitted to have underwater inspection:

‘© Review of vessel's records to verify that no unapproved repairs have been made

‘¢ Internal examination of representative tanks and cargo holds

ii) Underwater Inspection In Lieu of Drydocking Survey may be restricted or limited where

there is record or indication of abnormal deterioration, existing condition of class, or

‘damage to underwater body, rudder, or propeller.

Existing Conditions of Class

Underwater Inspection in Lieu of Dry docking may not be applicable if there are conditions of

class for repairs to propeller, rudder, stern frame, underwater structure, or sea valves. It may also

be inapplicable if damage affecting the fitness of the vessel is found during the course of the

survey.

Thickness Measurements and Nondestructive Testing

Undervwater or internal thickness measurements of suspect areas may be required in conjunction

with the underwater inspection, Means for underwater nondestructive testing may also be required

for fracture detection,

Note: Thiokness measuremens ofthe hull underater body, a required for Special Periodical Survey, ste tobe

taken at drydock in conjunction with visual inspection ofthe bottom plating by the Surveyor.

Tailshaft Surveys

Tailshaft Surveys are not covered by this Appendix and are to be dealt with in accordance with

Chapter 5 of the ABS Rules for Survey Afler Construction (Part 7) and other applicable Rules,

Plans and Data (1 July 2019)

Plans showing the following items are to be submitted to the attending Surveyor, together with the

proposed inspection procedures for review well in advance of the inspection,

Y Location of bottom shell seams and butts (Shell Expansion), including any doublers,

siraps, bottom plugs, and all underwater openings.

i) Hull markings or other means to orient the in-water survey and identifying photographs,

which entail specific areas of plating, (e.g., locations of bulkheads or tanks) sea suction

‘and discharge openings, propeller blades and rudder surfaces, Such preparations may

include a weld bead or center puch grid system on the hull, a contrasting color coating,

system, a movable grid, or an acoustic locating system. Other suitable arrangements may

be submitted for consideration. The hull markings or other means of orientation are

required for the UWILD Class Notation.

Reference data and instructions to the diver or ROV operator for any necessary

underwater operations such as means of access to sea chests to inspect the external sie o

hhull connections and sea valves, to rudder bearings to determine clearances of rudder

bearings, to propeller shaft strut and stern bearings, or to the athwartship thrusters, if

fitted,

ix) Most recent gaugings and gauging report from last Special Periodical Survey and the as-

built scantlings for the underwater body.

[ABS RULES FOR SURVEY AFTER CONSTRUCTION - 2022 396

Part 7 Survey After Construction

‘Appendix 4

Section _1_Underwater Inspections in Lieu of Drydocking Surveys (2013) TA

3.3.6 Underwater Conditions (2013)

The in-water visibility and the cleanliness of the hull below the waterline is to be clear

enough to permit a meaningful examination which allows the Surveyor and in-water

survey to determine the condition of the plating, appendages and the welding. Additional

cleaning may be necessary. Overall or spot cleaning may be required at the discretion of

the attending Surveyor.

i) Whete possible, the underwater examination should be carried out in protected waters,

preferably with weak tidal streams and currents

3.5 Physical Features

The following physical features are to be incorporated into the vessel's design in order to facilitate the

underwater inspection. Access and provisions must be made to determine stern bearing and rudder bearing

clearances. When verified they are (o be noted in the vessel’s records for reference at subsequent surveys.

3.8.4

3.8.2

3.8.3

3.84

Stern Bearing

Means are to be provided to ascertain that the seal assembly remains intact on oil

lubricated bearings and to verify that the clearance or weardown is within limits on the

ster bearing,

i) For oilelubricated bearings, this may only require the review of operating history and

‘onboard testing, including accurate oilloss records and a check of the oil for

‘contamination by sea water or white metal and/or oil sample reports (considerations are to

bbe included in the proposals for Underwater Inspection In Lieu of Drydocking). For wood

‘or rubber bearings, an opening in the top of the rope guard and a suitable gauge or wedge

is sufficient for checking the clearance.

Any doubt on wear-down of oil-lubricated metal stem bearings from above examinations

and review is to be further checked by external measurements or by the vessel's weat-

‘down gauge, where the gauge wells are located outboard of the seals or the vessel can be

tipped. For use of the wearsdown gauges, up-to-date records of the base depths are to be

‘maintained onboard the vessel. Whenever the seal sleeve is renewed or machined, the

base readings for the wear-down gauge are to be re-established and noted in the vessel's

records and in the survey report.

Rudder Bearings (2011)

Means and access are to be provided to determine the condition and clearance of the rudder

bearings, and verify that all parts ofthe pintle and gudgeon assemblies are intact and secure. This

may require bolted access plates, threaded plugs, and a measuring arrangement. Bolted access

plates or threaded plugs are required for the UWILD Class Notation

Where the capability does not exist for the measurement ofthe rudder bearing clearance when the

Underwater Inspection In Liew of Drydocking is carried out, the rudder pintle clearance portion of

the survey may be specially considered by the attending Surveyor after assessment of the physical

condition and securing arrangements of the pintle and review of the operating history and the

onboard testing. These considerations are to be included in the proposals for Underwater

Inspection In Liew of Drydocking

‘Sea Suctions (2019)

‘Means are to be provided to enable the in-water survey company to confirm that the sea suction

‘openings are clear. Hinged sea suction grids may be used to facilitate this operation and are

roquired for the UWILD Class Notation.

‘Soa Valves

‘Sea valves and their attachment to sea chests are to be examined externally, including expansion

pieces in sea water cooling and circulating systems.

[ABS RULES FOR SURVEY AFTER CONSTRUCTION - 2022 397

Part 7 Survey After Construction

Appendix 4

Section Underwater inspections in Lieu of Drydocking Surveys (2013) Tats

37 Procedures

3.7.1 Exposed Areas

‘An examination of the outside of the shell plating above the waterline and exposed portions of

appendages, such as propeller, rudder and rudder bearings, is to be carried out by the attending

Surveyor. Means are to be provided to enable the Surveyor to accomplish his visual inspection.

3.7.2 Underwater Areas (2019)

‘An examination ofthe entre vessel below the watertne is to be carried out by an ABS-approved

in-water survey company using closed-circuit television with two-way communication. The

progress of the in-water survey isto be monitored by the attending onboard Surveyor as required,

and can be supplemented with photographic or video documentation. Items that must be recorded

con the tapeiphotograph include but are not limited t

D—Vesse's draft

i) Time at which in-water survey commences

Point of commencement

iy) Time viewed

¥) Conditions of hull markings

i) Random areas of plating

vil) All sea chests

vill) All inlets and discharges

jx) Rudder

2) Pintles

xi) Propeller

xii) Time and point of completion ofthe in-water survey:

‘The above examination is to be supplemented by the in-water survey company’s report describing

and attesting to the conditions found. A copy of this report and pertinent photographs are to be

submited tthe attending Surveyor. Copies are also to be retained onboard

3.7.3 Damage Arcas

Damage and corrosion areas are to be tapediphotographed. Intemal examination oF thickness

gauging of such locations may be necessary, as determined by the attending Surveyor. Means are

to be provided for orienting and identifying underwater surfaces in photographs, a8 noted in 7-

ALB...

3.7.4 Planning (2019)

The equipment and procedure for observing and reporting the survey are to be discussed with the

parties involved prior to the Underwater Inspection In Lieu of Drydocking, and suitable time is to

be allowed to permit the in-water survey company to test all equipment beforehand.

3.9 Alternatives

3.1

ABS is prepared to consider alternatives to the above guidelines.

Maintenance of UWILD Class Notation

For maintenance of the UWILD notation, a vessel’s markings and equipment installed for UWILD are to

be satisfactorily verified by the attending Surveyor at each Drydocking.

[ABS RULES FOR SURVEY AFTER CONSTRUCTION - 2022 398

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Drawing Hydraulic Hatch CoverDocument3 pagesDrawing Hydraulic Hatch Coverjeri adovelinNo ratings yet

- Product Quotation: Weifang Yongneng Power Electromechanical Equipment Co.,LtdDocument3 pagesProduct Quotation: Weifang Yongneng Power Electromechanical Equipment Co.,Ltdjeri adovelinNo ratings yet

- Survey Report Class BVDocument31 pagesSurvey Report Class BVjeri adovelinNo ratings yet

- Fuel ConsumptionDocument12 pagesFuel Consumptionjeri adovelinNo ratings yet

- 06766320220222181721Document2 pages06766320220222181721jeri adovelinNo ratings yet

- KUT 4ADORAH005E - PT. Adovelin RaharjaDocument1 pageKUT 4ADORAH005E - PT. Adovelin Raharjajeri adovelinNo ratings yet