Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

26 viewsSurvey Report Class BV

Survey Report Class BV

Uploaded by

jeri adovelinCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Drawing Hydraulic Hatch CoverDocument3 pagesDrawing Hydraulic Hatch Coverjeri adovelinNo ratings yet

- Product Quotation: Weifang Yongneng Power Electromechanical Equipment Co.,LtdDocument3 pagesProduct Quotation: Weifang Yongneng Power Electromechanical Equipment Co.,Ltdjeri adovelinNo ratings yet

- Fuel ConsumptionDocument12 pagesFuel Consumptionjeri adovelinNo ratings yet

- 06766320220222181721Document2 pages06766320220222181721jeri adovelinNo ratings yet

- KUT 4ADORAH005E - PT. Adovelin RaharjaDocument1 pageKUT 4ADORAH005E - PT. Adovelin Raharjajeri adovelinNo ratings yet

- UWILD Survey Requirement MVR Part 7 Appendix 1Document5 pagesUWILD Survey Requirement MVR Part 7 Appendix 1jeri adovelinNo ratings yet

Survey Report Class BV

Survey Report Class BV

Uploaded by

jeri adovelin0 ratings0% found this document useful (0 votes)

26 views31 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views31 pagesSurvey Report Class BV

Survey Report Class BV

Uploaded by

jeri adovelinCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 31

ants

Se

1828

aw

ae

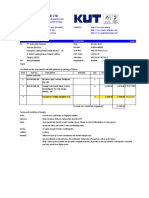

SHIPS IN SERVICE SURVEY REPORT

DKT0/2022/J5593

10811D MICRONESIAN PRIDE 9148805

‘Connecting District BV JAKARTA (MARINE) (DKTO)

Marine Operation ‘Far East.

Center

Flag VANUATU

Ship Manager PT. ADOVELIN RAHARJA

Ship Owner NAURU SHIPPING LINE

DATES OF SURVEY PLACE OF SURVEY

Start 4411112022 Batam Island : PT Marcopolo shipyard

End 24/01/2023 INDONESIA

SURVEYOR ssam

Kresno HERWINDO ‘Agus SURYANTORO.

Report validated Stamp

on 06-09-2023,

by ‘Agus SURYANTORO.

‘Bureau Veritas Marine & Offehore

© re mses tues ete an ome a ancora Pa

om ‘oateabe

Regtgp SS ICRONESIAN pripE __Ref:DiTova022/J5593

SURVEY STATEMENT

eee ata

Certificates / Documents of Compliance

‘Status

Expiry Date

Ballast Water Management

Classification Gertiiat ‘ew dive corificate issued 3010172028

UL Loed Line ‘New deitve coificato issued 30/01/2028

‘SOLAS Safely Constucion Harmonized ‘New defive coriicata issued 3010172028

‘SOLAS Safely Equipment Harmonized ‘New defitve coificata issued 3001/2028

‘SOLAS Safely Radio Harmonizes ‘Now defiitve conficate issued 301002028

SOLAS Dangerous goods ‘New definve coiicao issued 301012028

MARPOL Annes Prevention of Ol Poltion| ‘Naw detintve coiicae issued 01012028

MARPOL AnnexiV Prevention of Pollution by Sewage New derive ceriicate issued 301032028

(MARPOL Annex Vi Prevention ofA Polution New Shen Tarn Corticate issues | 2309/2028

New delve cericate issued 3010712028

TAFS AntiFouing Syeiom

Now definitive cericate issued

Taro keri hele

Code ‘Survey Name

35H Tall Glass Renewal Survey (Compete)

ASHR Hull Annual Survey for Renewal

DOK Periocal Bottom Survey in Dry Dock

os# Hull Occasional Survey (reason : Occasional survey of Hull futher dose recommendation)

ssu Machinery Class Renewal Survey (Compete)

ASR Machinery Annual Survey for Renewal

ups Load Line Periodical Survey

HSCN Harmonized Salety Construction Renewal Survey (Complete)

HSAR Harmonized Safety Const, Annual Survey For Renewal

HSE Harmonizod Safely Equipment Renewal Survey

sor ‘Quinguiennal tet of Launching Applances.

HSRO Harmonized Safety Racio Renewal Survey

bors Dangerous Goods Renewal Survey

POPS: OPP Periccical Survey

SEWS Sewage System Renewal Survey

apr IAPP Renewal Survey

BWMR | Ballast Water Management Renewal Survey

coPs ILO 152 Cargo Gear Periodical Survey

cout LO 182 Cargo Gear Load Test Suey

AFSS ‘Ant-Fouling Systom Fenewal_Surve}

Rech incase ancy

her ay Limit Verit,] Extends /

fees pees Date | T¥P*} scn.'| Upgrades

‘Statutory - MARPOL Annex VI Prevention Air Pollution Certfic.

[DKTO20221J5690-AP1R | Pending approval of EEX! Technical fle zaou20zs| Rec | 1

‘Veriton senome

To" nspectontestepor by authorized person and confimaion of action taken though ip:ww.verstar.com by the indicated

mit date, Documentary evidence o be kept on board. Vericaton/eanfmation by the Socety Surveyar dung nox attendance

onboard

2, Survey by the Society Surveyor by limit date

‘Bureau Veritas Marine & Offshore

©

= ‘naleabe

“The etost published Rules of Bure Varta Marine & feb andthe Gonerl Condos ari ae

Page 2/31

mog:togip MICRON SIAN pri _Rf OKTO2N22U6598

Ped seen sot eas tee eee

Number Deseription

Status

Class - Hull

‘Heavily wasted cargo hold coaming stiffener WO STAD OBWBT2 vert heads tobe

px To/2022155476-H1C | deintively repaired. Cargo held coaming stlener to be further checked by UT and oat wits

repaired as necessary

Pee ene UP Ne kote

No. Description Status

2 Thermal ol healers: (el valves set at 10.0 bar Deleted

[Not por wing WT. side shel fom Fr 105 to 178 Tound indortod. Damage internals wer repaired and found | Deleted

satisfactory.

7 Lifeboat onioad reloase mechariem fal do nol comply with paragraphs 44 7.6.80 44.766 ofthe reve Dated

[LSA cove ae to be replaced or modified not ar than the frst schedule dry docking of th ship after 1 July

ota. but nat later than 1 akty 208, upon verification tis memo isto be deleted.

S| Underwater porion pte hl coated wih igh resistant paint: Manufacture Jotun, Ory fi thickness - 990 Dated

77 | Aa per Vanuatu fag agreement daled 27 August 2007, he installation of Balt Water Treatment system wit | Deleted

be Gefered ta the nent scheduled cry docking but rot iter than 30 January 2023.

2 | Subtantal_corosion aroa TMi O Stake STR, TMS LM Adjacent sliflene: HFO-NO.S ST at 601 space) Endorsed

‘THO LM Adjacent stoner WE-NO.2 ST at fr. 51 in space; TMS LM Adjacent stiffener W-NO.2 ST atf. Sin

‘pave, TMS LM Adjacent stiflener WB-NO.| ST af. 100 in space; TMS LM Adjacent stifener WB-NO.1 ST at

Fe fot in space, TMD LM Adjacent stilnor WB-NO. 1ST af. 103 in space, TMS LM Adjacent stifenor

WBNO.1 ST a fr. 105 in space: TMG FORE CASTLE DECK FORE CASTLE DECK PLATING to be annval

‘examination

72 incinerator was notin used and and to be surveyed before pul in senice Endowed

12] Boller was not in used and and io be surveyed befor putin service Endorsed

@ ‘Bureau Varitas Marine & Offshore

Page x01

“The lest pushed Rus of Buran Vertas Marin & sre andthe Generel Condiors ein ae

== ‘oalcabe.

. Kr

SURVEY REPORT

Table of contents Page

1, Surveyor's statement

2. Documentation.

3. Hull

4. Bottom survey..

S. Structure...

6. Machinery and electricity.

7. Fire protection and fire fighting

8 Safety - Miscellaneous ...

9. Life-saving appliances

10, Radiocommunications ....

11, Sewage.

12, Air pollution.

13, Anti-Fouling....

14, Ballast Water Managoment

1s. Cargo gear.

16, Annex for Tank Testing.

17. Annex for Overall/internal Tank Survey

18, Annex for Internal Examination of compartments other than cargo & ballast...

19, Annex for Documentation on board

20. Annex for Safety and Fire Fighting Equipment.

Veritas Marine & Offehore

a

@ —snemupnes unetsona est en mate aint a

= oa

Page 41

Reg: 108110. MICRONESIAN PRIDE Ref: DKTO/2022155593

1, Surveyor's statement

c FSS-ASHR-ASMR-EM Coot :0.0 ‘See Remark

R-LLPS-POPS-SER

Confirmation that applicable items of Rules and Regulations and International Conventions relevant to the present survey

‘ave been surveyed to the surveyor’s satisfaction without remark, except whven indicated otherwise hereunder

Remark

“The following of oowner request and information as verified on board, memoranda as mentioned below

canceled

Ssh

2. Thermal oil heaters: relief valves set at 10.0 bar.

3. No.1 port wing WT. side shell from Fr. 105 to 118 found indented. Damage intemals were repaired and

found satisfactory.

4, Lifeboat on-load release mechanism that do not comply with paragraphs 4.4.7.6.4 to 4.4.7.6.6 of the revise

LSA code are to be replaced or modified not later than the first schedule dry docking of the ship after 4 July

2014, but not later than ‘July 2019, upon verification, this memo is to be deleted.

5. Underwater portion pf the hull coated with high resistant paint: Manufacture Jotun, Dry flm thickness - 330

microns.

11.As per Vanuatu flag agreement dated 27 August 2021, the installation of Ballast Water Treatment system

wil be deferred til tne next scheduled dry docking but not later than 30 January 2023

for memoranda no, 4 above cancel it refer to flag agreement attached to this report

Refer to Owner Request for decomissioning of incinerator and boiler due to unnecessary for ship's operation

and memoranda issued mentioned below

13 Incinerator was not in used and and to be surveyed before put in service

14 Boiler was not in used and and to be surveyed before put in service

T-cGPS-D0 Cost 0.0

Confirmation that the Master has been asked if he had anything to declare or put to his attention and that no additional

poinis have been raised by the Master with respect to the ship's classification and statutory certification.

OGLT-CGPS.D Cost 0.0 See Remark

ISCNHSEO-HSOT-HSRO-D

Confirmation that in case of class and statutory findings related to ISM code, ike maintenance, operations, emergency

preparedness, a PR17 report is issued.

‘Remark

Class and statory has no finding related to ISM Code, PR17 is not issued during survey.

2. Documentation

Documents

DcEG0A "AR-HSEQ coet00

Is the ship requesting @ document indicating compliance with the special requirements for carrying dangerous goods.

@ Yes ONo

© Bureau Veritas Marine & Offshore

“The lt pubahed Rus of Bureau Verte Marne & Ofshore andthe General Conon herein are Page 51

appieabie

091

0 s Coot 00

Number and SWL of inspected cranes:

‘Grane Geriifeation NoSWL [SWI (ons)

‘No.1 Cargp Crane 1 40

‘No.2 Cargo Grane 1 [40

'SB Provision Crane 1 24

3. Hull

Hull and hull equipment

GACO10B—_ASHR-HSAR Coot :0.0 ‘See Remark

General examination of decks and side shell above waterline. Examination, if applicable, of accessible parts of the

rudder.

Remark

General Examination of deck and side shell carried out and found definitive carried for area below

1. Side Shell

SIDE SHELL STBD 4600MM X 560MM X 10MM Fr. 39 - 42

SIDE SHELL STBD 2350MM X 560MM X 10MM Fr. 43 - 48

SIDE SHELL STBD 4600MM X 560MM X 10MM Fr. 49 - 57

SIDE SHELL STBD 8150MM X 550MM X 10MM Fr. 57 - 70

SIDE SHELL STBD 2450MM X SSOMM X 10MM Fr. 70 - 74

SIDE SHELL STBD 3700MM X 550MM X 10MM Fr. 74 - 80

SIDE SHELL STBD 2500MM X 550MM X 10MM Fr. 80 - 84

SIDE SHELL STBD 3100MM X 550MM X 10MM Fr. 84 - 89

‘SIDE SHELL STBD 620MM X SSOMM X 10MM Fr. 69 - 90

‘SIDE SHELL STBD 500MM X 570MM X 10MM Fr. 90 - 98

‘SIDE SHELL STBD 400MM X 570MM X 10MM Fr. 98 - 105,

‘SIDE SHELL STBD 4200MM X 570MM X 10MM Fr. 105 - 110

‘SIDE SHELL STBD 12000MM X 550MM X 10MM Fr. 111 - 129

‘SIDE SHELL PORT 2950MM X 550MM X 10MM Fr. 29 - 34

‘SIDE SHELL PORT 3000MM X 550MM 10MM Fr. 34 - 39

‘SIDE SHELL PORT 3300MM 550MM X 10MM Fr. 39 ~ 45

‘SIDE SHELL STBD 800MM X 500MM X 10MM Fr. 134 - 135

SIDE SHELL PORT 2350mm x 300mm x 10mm 144 - 147

2. Main Deck

MAIN DECK STBD 4000MM X 1700MM X 10MM Fr.68 - 64

MAIN DECK STBD 2320MM X 1700 X 10MM Fr. 64 - 67

MAIN DECK STBD 3300MM X 1700MM X 10MM Fr. 67 - 72

MAIN DECK STBD 600MM X 450MM X 10MM Fr. 72-73

MAIN DECK STBD 3700MM X 450MM X 10MM Fr. 75 - 81

MAIN DECK STBD 3820MM X 700MM X 10MM Fr. 81 - 85

MAIN DECK STBD 650 MM X 600MM 10MM Fr. 94 - 96

MAIN DECK STBD 3770MM X 600MM X 10MM Fr. 94 - 102

MAIN DECK STBD 520MM X 900MM X 10MM Fr. 101 - 102

MAIN DECK STBD 1360MM X 750MM X 10MM Fr. 108 - 110

MAIN DECK PORT 3900MM X 1500MM X 10MM Fr. 127 - 136

MAIN DECK PORT 3200MM X 1680MM X 10MM Fr. 92 - 99)

MAIN DECK PORT 2000MM X 1700MM X 10MM Fr. 55 - 59

MAIN DECK PORT 2450MM X SSOMM X 10MM Fr. 43 - 46

MAIN DECK PORT 2450MM X 1150MM X 10MM Fr. 43 - 46

MAIN DECK PORT 600MM X 600MM X 10MM Fr. 43 - 44

3, Tunnel Deck and Forecastle Deck

TUNNEL DECK STBD 5700MM X 1630MM X 8MM Fr. 29-37

Veritas Marine & Offshore

a

@ sre st pusnes Rss ot dues Vote ern fo te Gee Coors ee #0 Page 691

= spmcabe

Rogge MIGRONESIAN PRIDE _Ref DicTovz022448503

TUNNEL DECK STBD 4700MM X 160MM X 8MM Fr.

TUNNEL DECK STBD 8150MM X 1700MM X 8MM Fr.

TUNNEL DECK STBD 2450MM X 1700MM X 8MM Fr.

TUNNEL DECK STBD 3700MM X 170MM X 8MM Fr.

TUNNEL DECK STBD 2450MM X 1700MM X 8MM Fr.

‘TUNNEL DECK STBD 3500MM X 1700MM X 8MM Fr.

TUNNEL DECK STBD 3500MM X 1700MM X 8MM Fr.

TUNNEL DECK STBD 3500MM X 1700MM X 8MM Fr.

37-46

87-70

70-74

74-80

80-84

89-95

95 - 100

105-110

TUNNEL DECK STBD 2350MM X 300MM X 8MM Fr. 110 - 114

TUNNEL DECK STBD 600MM X 400MM X 8MM Fr. 118 - 119

TUNNEL DECK STBD 3600MM X 1500MM X 8MM Fr. 120 - 126

‘TUNNEL DECK PORT 2500MM X 1650MM X 8MM Fr. 77 - 82

‘TUNNEL DECK PORT 2400MM X 1650MM X 8MM Fr. 66 - 70

‘TUNNEL DECK PORT 3550MM X 900MM X 10MM Fr. 48 - 54

TUNNEL DECK PORT 3550MM X 785MM X 10MM Fr. 48 - 54

FORECASTLE DECK PORT 2500MM X 950MM X 10MM Fr. 147 - 147

FORECASTLE DECK STBD 2700MM X 1200MM X 10MM Fr. 147 - 148

‘TRANS BHD AFT 700MM X 500MM X 12MM Fr. 29

4, Long bulkhead

LONG BHD STBD 4100MM X 400MM X 10MM Fr. 32 - 39

LONG BHD STBD 13090MM X 400MM X 10MM Fr. 48 - 69

LONG BHD STBD 2100MM X 750MM X 10MM Fr. 65 - 57

LONG BHD STBD 10880MM X 400MM X 10MM Fr. 77 - 102

LONG BHD STBD ACCESS 700 MM X 430 MM X 10 MM Fr. 110-110,

LONG BHD STBD 6500 MM X 400 MM X 10 MM Fr. 108 - 119

LONG BHD STBD 880 MM X 500 MM X 10 MM Fr. 119 - 120

LONG BHD STBD 4500MM X 650MM X 10MM Fr. 87 - 70

LONG BHD STBD 14000MM X 650MM X 10MM Fr. 70 - 90

LONG BHD STBD 12500MM X 660MM X 10MM Fr. 89 - 111

LONG BHD PORT 2500MM X 400 10MM Fr. 34 - 45

LONG BHD PORT 6100MM X 400MM X 10MM Fr. 48 - 60

LONG BHD PORT 1150MM X 1000MM X 10MM Fr. 60 - 61

LONG BHD PORT 1250MM X 900MM X 10MM Fr. 69 - 71

LONG BHD PORT 5400MM X 400MM X 10MM Fr. 55 - 64

LONG BHD PORT 1920MM X 1050MM X 10MM Fr. 67-72

LONG BHD PORT 500MM X 800MM X 10MM Fr. 79 - 80

LONG BHD PORT 3330MM X 400MM X 10MM Fr. 77 - 83

LONG BHD PORT 6170MM X 400MM X 10MM Fr. 83 - 93

LONG BHD PORT 1200MM X 400MM X 10MM Fr. 99 - 102

LONG BHD PORT 1950MM X 400MM X 10MM Fr. 115 - 118

LONG BHD PORT 600MM X 700MM X 10MM Fr. 120 - 121

LONG BHD PORT 2400MM X 700MM X 10MM Fr. 77 - 82

5. Internal structure and trans bulkhead

SUPPORT ON FRAME U - CHANNEL PORT Fr.

‘SUPPORT ON FRAME U - CHANNEL PORT Fr.

SUPPORT ON FRAME U - CHANNEL PORT Fr.

SUPPORT ON FRAME U - CHANNEL PORT Fr.

‘SUPPORT ON FRAME U - CHANNEL PORT Fr.

SUPPORT ON FRAME U - CHANNEL PORT Fr.

SUPPORT ON FRAME U - CHANNEL PORT Fr.

SUPPORT ON FRAME U - CHANNEL PORT Fr.

SUPPORT ON FRAME LU - CHANNEL PORT Fr.

SUPPORT ON FRAME U - CHANNEL PORT Fr. 1520MM X 190MM X 65MM X 10 57.

SUPPORT ON FRAME U - CHANNEL PORT Fr. 1520MM X 190MM X 65MM X 10 58

WEB FRAME STBD Fr. 190MM X 500MM X 10MM 110

WEB FRAME STBD Fr. 1200MM X 600MM X 10MM 80.

WEB FRAME STBD Fr. 1300MM X 350MM X 10MM 59

WEB FRAME PORT Fr. 1670MM X 2150MM X 10MM 59

©

120MM X 190MM X 65MM X 10 74

120MM X 190MM X 65MM X 1076

120MM X 190MM X 65MM X 10 81

1520MM X 190MM X 65MM X 10 51

1520MM X 190MM X 65MM X 10 52

1520MM X 190MM X 65MM X 10 53

1520MM X 190MM X 65MM X 10 54

1520MM X 190MM X 65MM X 10 55

41520MM X 190MM X 65MM X 10 56

‘Bureau Veritas Marine & Offshore

“Tuts putianed Rules of Bureau Veras Maina 8 Otshor andthe General Condon herin ara

‘epabie

Page 7191

‘Rog: 108110 MICRONESIAN PRIDE. Ref: DKT0/2022158503

WEB FRAME PORT Fr. 200MM X 1660MM X 10MM 60

WEB FRAME PORT Fr. 1670MM X 2250MM X 10MM 62

WEB FRAME PORT Fr. 250MM X 170MM X 40MM 68

WEB FRAME PORT Fr. 1870MM X 840MM X 10MM 79

WEB FRAME PORT Fr. 1600MM X 400MM X 10MM 80

‘TRANS BHD FWD PORT Fr. 1250MM X 300MM X 10MM 130

DRY TANK FWD STBD Fr. 2400MM X 300MM X 10MM 120

WEB FRAME PORT Fr. 60mm x 400mm x 10mm 62

WEB FRAME PORT Fr. 600mm x 400mm x 10mm 68

‘TRANS BHD FWD STBD Fr. 900MM X 300MM X 12MM

Definitive repair carried out by PT Marcopolo Shipyard Batam Indonesia, Material Certificate, WPS, Welder

certificate are verified, Visual examination, NDT Test, Leakage test by Vacuum carried out, verified,

‘examination carried out and found satisfactory.

c HRSA Coot :0.0

Verification of proper operation of the loading instrument, if any, with standard test

Test results|

‘© Satisfactory © Not satisfactory - See Remarks

18001 Cost 00

Verification of means of embarkation and disembarkation from ships for use in port and in port~elated operations, such

88 gangways and accommodation ladders, are in satisfactory condition

Date of the ast 5-yearly test 24 January 2023,

160028 F Coet 0.0

Was the five-yesrly operational test of moans of embarkation and disembarkation from ships for use in port and in

por-related operations, such as gangways and accommodation ladders, Including associate winch and fitings performed

during this survey?

‘e Yes ONo

MB0038 = Cost 0.0

Five-yearly operational test of accommodation ladders including associated winch and ftings andior gangways

‘Equipment descripion TestToad Tost satstatory (YN)

4 {one) PS 0.75 ¥

(one) $8 0.75. ¥

Ssiti70 7 Coef 0.0. Done in eurent ob ‘Soo Remark

Internal examination of steering gear and mooring equipment. Description of surveys, dismantlings and tests

rk

Extemal examination carried out and found sartisfactory.

Hatch covers, hatchways and coamings

020 RL Coot 0.0 ‘See Remark

[All types of hatch covers] Verification ofthe satisfactory condition of hatch coamings and stitfeners,

Vk

Verification of Hatch cover and coaming carried out and found definitive repair carried out for area below

HATCH COAMING STBD 500MM X 480MM X 12MM Fr. 131

HATCH COAMING STBD 500MM X 300MM X 12MM Fr. 129,

HATCH COAMING STBD 550MM X 320MM X 12MM Fr. 121

HATCH COAMING STBD 500MM X 300MM X 12MM Fr. 120

HATCH COAMING STBD 550MM X 500MM X 12MM Fr. 110

HATCH COAMING STBD 360MM X 330MM X 12MM Fr. 108

HATCH GOAMING STBD 1300MM X 750MM X 12MM Fr. 110 - 112

© ‘Bureau Veritas Marine & Ofishore

“The ost pblshod Rules of Bara Vea Maro & Offshore andthe Gonarl Condtns tein a Page ast

on ‘ealeble

Beg: 108110 MIGRONESIAN PRIDE Rot: 0707202215803

HATCH COAMING STBD 350MM X 380MM X 12MM Fr. 108

HATCH COAMING STBD 320MM X 380MM X 12MM Fr. 100

HATCH COAMING STBD 370MM X 370MM X 12MM Fr. 98

HATCH COAMING STBD 1600MM X 1000MM X 12MM Fr. 89 - 93

HATCH COAMING STBD 400MM X 350MM X 12MM Fr. 88

HATCH COAMING STBD 720MM X 520MM X 12MM Fr. 86

HATCH COAMING STBD 360MM X 360MM X 12MM Fr. 80

HATCH COAMING STBD 400MM X 350MM X 12MM FR. 78

HATCH COAMING STBD 850MM X 600MM X 12MM Fr. 76

HATCH COAMING STBD 1500MM X 1000MM X 12MM Fr. 66 - 68

HATCH COAMING STBD 1675MM X 850MM X 12MM Fr. 60 - 63.

HATCH COAMING STBD 3350MM X 850MM X 12MM Fr. 57 - 60

HATCH GOAMING STBD 400MM X 300MM X 12MM Fr. 60

HATCH COAMING STBD 450MM X 350MM X 12MM Fr. 59

HATCH COAMING STBD 400MM X 350MM X 12MM Fr. 51

HATCH COAMING STBD 300MM X 300MM X 12MM Fr. 49

HATCH COAMING STBD 360MM X 360MM X 12MM Fr. 40

HATCH COAMING STBD 300MM X 300MM X 12MM Fr. 39

HATCH COAMING STBD 300MM X 300MM X 12MM Fr. 30

HATCH COAMING PORT 300MM X 300MM X 12MM Fr. 30

HATCH COAMING PORT 300MM X 300MM X 12MM Fr. 39,

HATCH COAMING PORT 300MM X 300MM X 12MM Fr. 40,

HATCH COAMING PORT 300MM X 300MM X 12MM Fr. 59

HATCH COAMING PORT 300MM X 300MM X 12MM Fr. 61

HATCH COAMING PORT 350MM X 350MM X 12MM Fr. 69

HATCH COAMING PORT 300MM X 400MM X 12MM Fr. 70

HATCH COAMING PORT 1220MM X 500MM X 12MM Fr. 79 - 82

HATCH COAMING PORT 1400MM X 620MM X 12MM Fr. 82 - 84

HATCH COAMING PORT 350MM X 350MM X 12MM Fr. 89

HATCH COAMING PORT 450MM X 350MM X 12MM Fr. 92

HATCH COAMING PORT 6700MM X 2000MM X 16MM Fr. 96 - 108

HATCH COAMING PORT 400MM X 320MM X 12MM Fr. 118

HATCH COAMING PORT 400MM X 300MM X 12MM Fr. 110

HATCH COAMING PORT 350MM X 300MM X 12MM Fr. 130

Definitive repair carried out by PT Marcopolo Shipyard Batam Indonesia, Material Certificate, WPS, Welder

Certificate are provided, Visual examination, NDT Test carried out, witnessed, verified and found

satisfactory.

Ventilation systems

Nose coot:00 See Remark

“Test ofthe means of closing the main nits and outets of al vetistion systems,

Romark

‘Test carried out and found satisfactory.

veNo¢ SuR-HSAR cost:00 See Remark

“Test of the means of stopping power ventilation systems from outside the spaces served

Remark

‘Test carried out and found satisfactory.

“0 : oot 00 ‘See Remark

Examination and test ofthe fre dampers of ventilation ducts

‘Remark

‘Test carried out and found satisfactory

4. Bottom survey

Bottom (periodical survey)

© Bureau Veritas Marine & Offshore

“Th ates pushed Rus of Bren Vrs Mla & Ose andthe Gantt Consors Pere er Page 991

= ‘ooicabe

Rog: 108110 MICRONESIAN PRIDE Ref: DKTo/20221N6505

10K0 DOK HSCNS: Coet 0.0 Done in curentjob

Propeller-shaft clearances

‘Clearance postions mam

[top - bottom [0.70

ps stbd [0.60

3K KHSCNS' (Goet :0.0 Done incurentjob

Examination of rudder, clearances measured

‘Clearance postion: mm

fwd - aft 32,

ps -stbd 30)

Bottom (every 5 years)

r ss Coaf:0.0. Done in curent job

Recording of permanent chain characteristics

Register of ships diameter aa

Minimum allowed diameter 352

Grade of cable as.

50Ks D0K-SSt ‘Goof :0.0. Done in curent job ‘See Remark

Links measurement: fill out the table hereunder or use its fourth column to specify the references of the complete result

document attached to the present report

Position DamPS (mm) _[Diam.S6 (mm) [Comment (Fanyy

shackleT a4 43.05

ry 43.85

7 4 44.65 [sb more_of original

shacklez a 44.65 [sb more_of original

a 44.00

ss a 44.25. (sb more_of original

shackles 40.50, 44.00

40.70 43.10

40.75 43.20

Rem:

‘See Detail others shacile on report anchor chain calibration as attached.

Bottom (others)

D0K-SSH Goef:0.0. Done in curentjoo

‘Thickness measurements of the outer shell plating,

Ref. io TM report (Page Nbr) 41

608 OOK-SSH Goel :0.0 Done in curent ob ‘See Remark

Confirmation thatthe bottom was cleaned and coated

Remark

‘See OTHOBOA

0808, ssi Coef:0.0 Done in eurent od ‘See Remark

Maintenance and repair works.

Description and remark

Bottom cleaned, Sea chest valve cleaning, serviced, examined and found satisfactory.

5. Structure

Bureau orns Warne &OFchows

© Pogo 18

“The latest pubes Rue of Buren Vera Mavi &Oshre and the General Conatons men a

‘paleabe,

Ros: 108110 MICRONESIAN PRIDE Ret: DIT07202215509

08 «88 Cost :0.0

Date and place of survey planning mesting, name of the master of the ship in attendance or an appropriately qualified

representative appointed by the master or Company, name of the owner's representative(s) and name(s) of the thickness

measurement fms representative(s) so as to ensure the safe and efficient execution ofthe surveys and thickness

measurements to be carried out onboard.

‘Survey planning ‘Survey planning meeting NZ

‘moeting N°t (any)

Date of survey planning meeting 14/41/2022

Placa of survey planning meeting PT Marcopote Shipyard

ata

Waster of the ship oF approprially qualified Mr. ert

representative

‘Owner's representatvels) Mr. Jen

Thickness measurements fim representalive(s) [PT BST

S000 —~—«OSF Coot :0.0 ‘See Remark

‘Scope and description of the Hull occasional survey:

eseriotion and remark

‘At the request of ship'smanager to attend on board from 11 November 2022 until 24 January 2023 for

‘Occasional Survey of Hull further to delete recommendation as mention below

“Heavily wasted cargo hold coaming stiffener WO STBD DBWBT? vent heads to be definitively repaired.

Cargo hold coaming stiffener to be further checked by UT and repaired as necessary.

Limit date : 09 November 2022

Deifiniive repair has been carried out by PT Marcopolo Shipyard Batam Indonesia, Mateial Certificate, WPS,

Welder Certificate are provide it, Visual examination, NDT test are carried out, witnessed and found

satisfactory.

Recommendation Deleted.

Internal surveys

c 5 eet 0.0 Done in curent ob

Internal survey of all ballast tanks.

See Annex

wih s Coet 0.0 Done in curent ob

Internal survey of all cargo holds.

Seo Annex

IN Coot 0.0 Done in current job

Internal examination of al peak tanks (al use)

‘See Annex

wn Coet 0.0 Done in eurent ob Soe Remark

Internal survey ofall machinery spaces other than tanks.

‘See Annex

Remark

Definitive repair has been carried out for ara below

E/R SETLING TANK 1200MM X 2300MM X 8MM Fr. 19-21

E/R SETLING TANK 1200MM X 2100MM X 8MM Fr. 20 - 23,

E/R SETLING TANK 1200MM X 1900MM X 8MM Fr. 22 - 24

E/R SETLING TANK AKSES 620MM X 520MM X 8MIM Fr. 21 - 22

"TANK TOP 1500MM X 1200MM X 12MM Fr. 33 - 35

Defintive repair carried out by PT Marcopolo shipyard, Visual examination, NDT test carried out and found

satisfactory.

Bureau Veritas Marine & Offshore

Page 11131

“The lates pubished Fes of Bureau Veras Mane & Otshore and he General Condon her are

sppeable

Reg 1091p MIGRONESIAN PRIDE _Refs D¥Tov2072109503

ss! Coef:0.0 Done in curent job

Internal survey ofall fresh-water incorporated tanks.

See Annex

020 SH Cost 0.0. Done in curentob

Internal survey of one (1) fuel ol bunkertank in engine room.

‘See Annex

036 5 Cost 0.0 Done ia curent jb

Internal survey of haf, minimum two (2), fue! oil Bunkertanks in the cargo area (one deep tank for FO in the cargo area is

to be included, i fited),

See Annex.

Noa 3 Coet:0.0 Done in curent job

Internal survey of two (2) fuel-oll bunkertanks outside of engine room (if fitted), when no tanks in cargo length area.

‘See Annex

4 5 Cet :0.0 Done in curent job

Internal survey of one (1) lubricating incorporated tank.

See Annex

N HSCN (bet :0.0 one in curent job

Internal examination of selected cargo spaces

See Annex

Tank testing

020 Coef: 0.0 Done ineurentjob

Test of all ballast tanks.

See Annex

. 5 Coet:0.0 one ineurent ob

‘Test ofall tanks other than ballast tanks, |¢ all integral and independant tanks, including holds adapted for the carriage

Cf salt water ballast, fuel oll tanks, lube oll tanks and fresh water tanks.

See Annex

‘Systematic and other thickness measurements

c SSH Coef 0.0 Done ineurentjob

Confirmation that thickness measurements required in the context of hull structural classification surveys are witnessed

by a Surveyor.

‘This requires the Surveyor to be on board while gaugings are taken to the extent necessary to control the process,

‘This includes a survey meeting to be held prior to commencement of the survey, the monitoring of the thickness

measurement process on-board and the review and veriication of preliminary and final reports.

Concurrent crediting to both Intermediate Survey and Class Renewal Survey for surveys and thickness measurements of

spaces are not acceptable.

Date of fist measurement TTR

Date of fast measurement — Barvir2022,

Mest 5 Coet:0.0. Done in exrentob ‘S00 Remark

‘Thickness measurements of suspect areas.

Description and remark

There is no suspect area identified at previous survey.

Es06 38 Done in eurent ob

‘Thickness measurements of thee (3) transverse sections in way of cargo spaces within the amidships 0.6L.

Section Frame Number Reference to TH reper (page number) Goat. Done

4 30-0 [6a 00) x

z erates [oss 00) x

z Tir fe102 [65 00) x

Mest ose Coef:0.0 one in erent

‘Thickness measurements of representative exposed superstructure deck plating (poop, bridge and forecast decks)

iran Verne Ware & OF

© aoe 12

“Te aot plished Ruler of ure Vaan aos & shore and tho General Conan tein a

= ‘sppcable

108 pe 509

Ref, to TM report (Page Nbr) 684

r SH Coat 0.0. Done in curentjob

Thickness measurements ofall cargo-hold-hatch covers and coamings (plates and stiffeners).

Ref, to TM report (Page Nor) 733

mesos Coef :0.0 Done in current jo

‘Thickness measurements of shell plating in way of overboard discharges as considered necessary by the Surveyor.

Ref. to TM report (Page Nor) 814,

Mesou SH Coet :0.0 Done in curent job

‘Thickness measurements of internals in forepeak and atipeak ballast tanks,

Ref to TM report (Page Nor) 776

Messo08 Coot 0.0 ‘See Remark

Examination of suspect areas identiied at previous surveys. Thickness measurements of the areas of substantial

corrosion.

Description and remark

‘There is no suspect are identified at previous survey.

EX0006 SHR-DOK-SS (pet 0.0. Done ineurent job

‘Aaiitonal thickness measurements as deemed necessary.

‘OYes @No

x &HSCNSS Coef 0.0 Done in eurento

Haye substantial corrosion areas been identified during survey or before present survey ?

‘Yes @No

6. Machinery and electricity

Machinery special survey

ssioc q (Geet :0.0 Done in curent job Soe Remark

During the deck trial confirmation that main and auxiliary machinery are working satisfactory

Description and remark

Internal examination, verification test carried out and found satisfactory.

0 = Coet:0.0 Cone incurent job

Have siginficant repairs been carried out to main or auxilirary machinery or steering gear (consideration should be given

toa sea tril) ?

OYes @No

5 1 eet :0.0 Done in eurent job Soe Remark

Main machinery (diesel or turbine): Description of installation, surveys and dlismantings

‘columns and entablature, cylinders, pistons, driven air compressors... crankshafts, reverse gear, reduction gear and

clutches, if ited

Deseription and remark

Internal examination, verification test carried out and found satisfactory.

i , oot: 0.0. Done in eurentjob See Remark

Main diesel engines : Verification of crankshaft deflection, results:

‘Description and remark

Verification of Crankshaft deflectioncarried out and found satisfactory.

5 sh CCoet:0.0 Done in eurent job ‘Soe Remark

Reduction gears, thrust bearings, couplings, intermediate shafts: Description of surveys and dismantings

Description and remark

External examination, verification test carried out and found satisfactory.

ovens Vein Warne & Ochre

® Page 1381

“The tats publened Rules of Bureau Verse Maine & Ofshore and he General Conon hrin ae

sppcable

Reg: 199110 MIGRONESIAN PRIDE. Ret DiT0/20221N5599

o Coef: 0.0 Done in curent job ‘See Remark

‘Ausilary engines: Description of the installation, surveys and dismantings

Inepecton of he columns, entablures, cylinders, pistons, crankshafts, reverse gear, reduction gear and clutches, if ited.

Deseription and remark

intemal examination, verification test carried out and found satisfactory,

1050 Coef :0.0. Done in current job ‘Soe Remark

Electtical installation (generators, switchboard, electrical circuits): Description of surveys and dismantings.

Examination at random of electrical cables and cables runs (especially where there is more risk of deterioration) and

‘examination at random of terminal boxes

Des ni

Internal examination, verification test carried out and found satisfactory.

ssshioe Coef 0.0 Done ineurent job ‘See Remark

Verification of results of insulation tests, results

Description and remark

Verification of insulation test carried out and found satisfactory.

5 Coet 0.0. Done in eurent job Soe Remark

(C02 and halon containers : Description of surveys and tests:

Deseription and remark

External examination, verification test carried out and found satisfactory.

ssh Coef 0.0. Done in eurent ob ‘See Remark

Compressed air installation (compressors, receivers, pipings, safety devices) : Description of surveys and tests

Description and remark

Internal examination, verification test carried out and found satisfactory.

1 Coef:0.0. Done in curent job ‘See Remark

Fue! oll system (pumps, fuel tanks, heaters, puriers,pipings, accessories) : Description of surveys, dismantings and

tests

escription and remark

External examination, verification test carried out and found satisfactory.

ssw ss Coef|0.0. Done in curent job ‘See Remark

Lubricating oil system (pumps, oll tanks, coolers, purifiers, pipings, accessories) : Description of surveys, dismantiings

and tests

‘Deserlotion and comark

Exteral examination, verification test carried out and found satisfactory.

seat q Coot :0.0. Done in curent ob ‘Soe Remark

Forcod draught fens and air ducts of boilers : Description of surveys and dismantling

Description and remark

Extemal examination, verification test carried out and found satisfactory.

wm a Coef:0.0. Done in curent job ‘Soe Remark

‘Steam piping and accessories : Description of surveys, dismantings and tests

Description and remark

Extemal examination, verification test carried out and found satisfactory.

" "i oeF:0.0 Done in curent oo ‘Soe Remark

Water feed pumps, pipings, accessories, evaporators : Description of surveys, dismantlings and tests

Description and remark

Extemal examination, verification test carried out and found satisfactory.

@ ‘Bureau Veritas Marine & Offshore

“The latest pubaned Rus of Burau Verse Min & Ofshore andthe General Conon thera ara Page 14/31

=m ‘spneable

Regitggp SS CMIGRONESIAN PRIDE _Ref To/a0221J5599

sit Coe :0.0. Done in eure job See Remark

Condensers, water circulating pumps, pings, accessories: Description of surveys, dismantiings and tests

Description and remark

External examination, verification test carried out and found satisfactory.

i 5s Coet 0.0. Done in curent job ‘Soe Remark

Engine cooling pumps, coolers, pipings, accessories: Description of surveys, dismantlings and tests :

Description and remark

Extemal examination, verification test carried out and found satisfactory.

ssi st Coet:0.0 Done in curent job ‘S00 Remark

Bilge, ballast end general service pumps, pipings, accessories: Descrition of surveys, dismantings and tests

tion rh

Extemal examination, verification test carried out and found satisfactory.

7. Fire protection and fire fighting

‘Automatic sprinklers and automatic water mist nozzles

151 E Coet 0.0

Has the Automatic Sprinkler / Automatic Water Mist nozzles bean installed on the ship for § years or more ?

‘Yes @No

154 seo Coet 00

Confirmation that functional test of 2 randomly selected sprinkler headsinozzles of each type installed on board have

passed the Basic Testing as contain in MSC. 1(Circ.1516.

Special arrangements in machinery spaces

020 ASURHSE Coot 0.0

“Type of gas used in the fixed fire-Nghting system for the machinery spaces ?

‘O Halon

ecoz

0 Other

Cargo spaces

eM MR-HSEQ Cost :0.0

“Type of ges used in the fixed fire-fighting system for the cargo spaces ?

‘O Halon

ecoz

2 Other

Carriage of dangerous goods

FreWr 2S HS Cost 0.0

Examination and test of additional safety measures in cargo spaces intended for the carriage of dangerous goods.

8. Safety - Miscellaneous

Safety of navigation

: Cost :00

‘Checking that records are maintained identiying any plot ladders placed into service and any repair effected

‘Applicable fo equipment and arrangomients for plot Wansfer which are installed on orafier tat [NA

July 2012.

‘Applicable, 60 far as is reasonable and pracicable, fo equipment and arrangements for pilot | YES

transfer which are installed on or after 1st July 2012 and which are a replacement of equipment

‘and arrangements provided on ship before 1st July 2012.

© ‘Bureau Veritas Marine & Offshore

att pubened Rules of Bureau Verte Mine &Ofstor and ha General Conon han aro Pago 16°31

spaicable

peginp = MIGRONESIAN PRIDE _Rof. DKTO‘RN22L8588

9. Life-saving appliances

Lifeboats

1 Coot 00

Servicing ofthe lifeboat.

Period. serviced : Confirmation thatthe lifeboat has been periodically serviced in accordance with instruction for

Gn-board maintenance and in accordance with the Requirements for maintenance, thorough examination, operational

testing, overhaul and repair - MSC.402(96)

‘Confirmation that the ifeboat has been thoroughly examined and checked for satisfactory condition and operation

faboat No [Period serviced Thoroughly exam, Dee

Taft $B YES. YES YES.

Lsazeo WsEQ Cost 0.0

Test of lowering of one lifeboat to the water, if practicable.

Number and side of the lowered lifoboat(s): 1 AFT SB.

Coot 0.0

Determination of the lifeboat maximum working load.

‘Weightifeboat : Weight ofthe lifeboat, tings and equipment

‘Weight/persons : Weight of the persons carried by the lifeboat (75/82.5kq as applicable X carrying capacity)

Total Weight : Total weight of the lifeboat

‘Weighttest: Weight ofthe lifeboat (or spreader) to be used for the test (Total weight X 1.1)

Tieboat N*__ | Weightiifeboat Waightipersons [Total Weight | Weighttest

‘TAFT SB [YES YES YES. YES.

roo SOT Coot 0.0

‘Servicing ofthe lifeboat launching appliance and test ofthe winch brake.

Period, serviced : Confirmation thatthe launching appliance has been periodically serviced in acoordance with instruction

for on-board maintenance and in accordance with the Requirements for maintenance, thorough examination, operational

testing, overhaul and repair - MSC.402(96)

“Thoroughly exam. : Confirmation thatthe launching appliance has been thoroughly examined,

Doo. : Examination of the documentation and certificates (Davits, winches, falls, biocks, shackles, release gear hook).

Brake tested : Confirmation thatthe brake has been tested, at the maximum lowering speed, at 1.1 time the lifeboat

‘maximum working load.

Tieboai N” [Period serviced Thoroughly exam Dox. Brake tested

TAFT SB [YES YES YES YES

: Hse Coet 0.0

Inspection ofthe lifeboat launching appliance after the test

Examination of foundations, davits, falls, blocks, shackles, hooks.

‘Opening and internal examination of the winch,

Lifeboat N" [Examination [Opening winch,

TAFT SB [YES YES.

aoros «SOT Cost 0.0

Inspection ofthe lifeboat launching appliance - Opening and internal examination ofthe winch drum.

Tfeboat No [Opening winch drum

TAFT SB [YES

Bureau Veritas Marine & Offshore

Page 16131

“The latest pubished Rubs of Burau Vers Mane & Osnore andthe Gower Conon tern are

sppicable

MICRONESIAN PRIDE

cose coxt-00

Text ofthe release gear (inciting free fl ifeboat release systems)

Fee na et (roan tat he rlease gear hoe vee pericaly sercadin aocoréance with the insrctons for

Pe sand accordance wth fe Reguements for maintenance, thorough examination, operesonal

{oxumg,overoul and repr MSC 40219)

‘eed exon, -Contmation that te etease gear has boon thoroughly examined

Fee een tat he eboat Nas ben lowered ister of te water andthe ono release gear test

Lifeboat N° [Period serviced “Thoroughly exam. Test

‘TAFT SB |YES Yes YES

Rescue boat

10 Hs¢ Cost 0.0

‘Servicing of the rescue boat including fast rescue boat

Potiod. serviced - Confirmation thatthe the rescue boat including fast rescue boat has been periodically serviced in

‘becordance with instruction for on-board maintenance and in accordance with the Requirements for maintenance,

rational testing, overhaul and repair - MSC.402(96)

thorough examination, op

hhave been thoroughly examined and checked for

Confirmation that the rescue boat including fast rescue boat

salisfactory condition and operation

Rescue boat No | Perodserviced Thoroughly am Boe

“AFT PS YES YES YES.

Coot 00

Determination ofthe rescuo-boat maximum working load

Weightrescue-boat: Weight of the rescue: boat tings and equipment.

‘Weightipersons - Weight of the persons carried by the rescue-boat (75I82.5kq as applicable X carrying capacity).

Total weight : Total weight of the rescue-boat

Weighttest : Weight of the rescue-boat (or spreader) to be used forthe test (Total weight X 1,1).

Rescue-boat N° | Weightirescue-boat Weightparsons [Total weight Weighttest

TAFT PS, YES. YES. Yes YES

sc Cost 0.0

‘Servicing ofthe rescue-boat including fast rescue boat launching appliance and test ofthe winch brake.

Period. serviced : Confirmation thatthe launching appliance has been periodically serviced in accordance with instruction

for on-board maintenance and in accordance with the Requirements for maintenance, thorough examination, operational

testing, overhaul and repair - MSC.402(98)

‘Thoroughly exam. : Confirmation thatthe launching appliance has been thoroughly examined

oc. : Examination of the documentation and certificates (Davits, winches, fais, Docks, shakles, release gear hook).

Brake tested - Confirmation that the brake has beon tested at the maximum lowering speed at 1.1 time the rescue-bost

maximum working load as indicated in item QQTO11A above

Resove-boat N° [Period serviced ‘Thoroughly exam, Doe Brake tested

TAFT PS, YES YES YES! [YES

g oot:00

Inspection ofthe rasoue-boat launching appliance aftr the test

Examination: Examination of foundations, davis, falls, locks, shackles, links, hooks.

Opening of winoh: Opening and intanal examination ofthe winch.

Resaue-boal W" [Examination [Opening ofwinch

TAFT PS YES YES

Liferafts (inflatable)

Bureau Veritas Marine & Offshore

cmt panes nuns etter Vora inn een nt errant ri Page 17131

‘rslcabe

sat Coo 0.0

Determination ofthe erat maximum working load.

Weightliferaft : Weight of the lifraf itings and equipment.

Welghtipersons , Weight ofthe persons carried by the Iferaft (75182.5kg as applicable X carrying capacity).

‘Total weight: Total weight of the lferaft.

\Weightftest: Weight ofthe liferaft (or spreader) to be used forthe test (Total weight X 1,1)

Tien’ [Weghulferat Waightpersons [Total weight | Weighttest

TAFT PS |150 KG 100 KG YES. YES

caro2e 3 Cost 0.0

Servicing ofthe lferet launching appliance and test ofthe winch brake,

Period. serviced : Confirmation thatthe launching appliance has been periodically serviced in accordance with instruction

for on-board maintenance nd In accordance with the Requirements for maintenance, thorough examination, operational

testing, overhaul and repair -MSC.402(96).

‘Thoroughly exam. : Confirmation that the launching appliance has been thoroughly examined.

oe. Examination of the documentation and certificates (Davts, winches, falls, blocks, shakles, release gear hook)

Brake testad : Confirmation thatthe brake has been tested at the maximum lowering speed at 1,1 time the liferat

‘maximum working load as indicated in item QQTO21A above

Liferaht NW" [Periodicaly sonviced Thowoughly examined [Documentation [Brake tested

TAFT PS [YES YES. ‘YES YES.

0 Cost 0.0

Inspection ofthe lferaft launching appliance after the test.

Examination : Examination of foundations, davis, falls, locks, shackles, hooks.

‘Opening of winch : Opening and internal examination ofthe winch.

Tiferaft NW" [Examination [Opening of winch

TAFT PS [YES YES.

Cost 0.0

‘Servicing of the Davit-Jaunched lferaft automatic release hooks.

Period. serviced : Confirmation that the Davit-launched lferaft automatic release hooks have been periodically serviced

in accordance with instruction for on-board maintenance and in accordance with the Requirements for maintenance,

thorough examination, operational testing, overhaul and repair - MSC.402(96)

Confirmation that the Davi-launched liferaft automatic release hook has been operationally tested under at 1.1 time the:

liferaft when loaded wit its full complement of persons and equpment whenever the aulomatic release hook is

‘overhauled

Liferaft N° [Perodically serviced | Thoroughly examined | Documentation [release gear tested

TAFT PS [YES YES. YES NA.

10, Radiocommunications

Reference of Radio Surveyor s report

sTR009 Coot 0.0 See Remark

Reference of Radio Surveyor's report

Description and remark

Radio Survey carried out by Radio Surveyor company approved by BV "PT Sulendra Putra suksess" with

Radio Surveyor Mr.Satria Hermawan on 11 January 2023, Verified, witnessed, verified and found

satisfactory.

See detail report attached.

11. Sewage

1 Voritas Marine & Offshore

Bi

] settsissses isisocnrens ates mo cure en one Cc orn

sopeable

Page 18°31

‘Rea: 108110 MICRONESIAN PRIDE. Ref, DKTO/202295503

EWS Coet:0.0

“The ship ie equipped with a sewage treatment plant of a type approved by the Administration.

Maker Aquamar GmbH

Type MSP

Ref. of approval MEPC.20V))

W Coet 0.0 ‘See Remark

Description ofthe facilities for temporary storage of sewage supplementing the sewage comminuting and disinfecting

system

tion ark

Extemal examination carried out and found satisfactory.

s ws Goer 0.0 ‘See Remark

References of the drawings showing the piping of drainage from toilets, urinals, medical premises, oto.

Description and remark

Refer to Sanitary Drawing

12. Air pollution

Incinerators

Inco} i Coot 00 ‘See Remark

Confirmation that shipboard incineration of sewage sludge or sludge olin boilers or marine power plants is not

Lundertaken while the ship is inside ports, harbours or estuaries

Remark

Refer to Memoranda no. 13 issued

13. ncinerator was not in used and and to be surveyed before put in service

13. Anti-Fouling

Cost 0.0

“Type of anti-fouling system

‘TBT FREE SELF POLISHING ANTIFOILING

A a Cost :0.0

Name of ant-fouling system manufacturer.

‘AKZO NOBEL COATINGS VIETNAM LIMITED

Ars Cost 0.0

Name and color of antfouling system.

Intersmooth 7476S! SPC BEA644 Brown BEAG47 Red

Coot :0.0 ‘Soe Remark

‘Active ingredient(s) and their Chemical Abstract Service Registry Number (CAS number (s).

Description and remark

CAS No. 1317-39-1 Cuprous Oxide

CAS No, 12122-67-7 Zinc ethylenebis(75 % of wear limit) - adé sketches as deemed necessary)

‘TM3 LM Adjacent stiffener WB-NO.1 ST at fr. 100 in space;

‘TM3 LM Adjacent stiffener WB-NO.1 ST at fr. 101 in spai

M3 LM Adjacent stiffener WB-NO.1 ST at fr. 103 in space;

‘TMS LM Adjacent stiffener WB-NO.1 ST at fr. 105 in space

Other Comments/Conclusion

Satisfactory.

© ‘Bureau Veritas Marine & Offshore

“To lates pushed Rls of Suaau Verne Marna & Ofshor and he Geral Conon hren are

am ‘soacane

Page 25191

Regitopip __wicrowesiwpring Re icTovz0z2id5999

‘Tank characteristics : Side WB Tk. 1S

Init. Frame : 83 Final Frame: 132 Use ‘Ballast Tank Postion : Starboare

Close Up Survey

EXTENT (locate frame n°. type of structure examined as per Rules) : Transverse web frame, Transverse bulkhead

Corresponding thickness measurements (reference of report page, N°) : Transverse web frame page 197

‘Transverse bullkhead page 588

Findings

‘Suspect areas - Substantial Corrosion(>75 % of weer limit) - add sketches as deemed necessary)

‘TMS LM Adjacent stiffener WB-NO.1 ST at fr. 100 in space;

‘TM3 LM Adjacent stiffener WB-NO.1 ST at fr. 101 in space;

‘TM3 LM Adjacent stiffener WB-NO.1 ST at fr. 103 in space; T

(M3 LM Adjacent stiffener WB-NO.1 ST at fr. 105 in space

Other Comments/Conclusion

Satisfactory.

Tank characteristics : Side WB Tk. 2P

Init. Frame: 80° Final Frame: 83 Use :Ballast Tank Position Portside

Close Up Survey

EXTENT (locate frame n*. type of structure examined as per Rules) : Transverse web frame, Transverse bulkhead

Corresponding thickness measurements (reference of report, page, N”): Transverse web frame page 146

‘Transverse bullkhead page 583

Findings

‘Suspect areas - Substantial Corrosion(>75 % of wear limit) - add sketches as deemed necessary)

‘TM3 LM Adjacent stiffener WB-NO.2 ST at fr. 51 In space;

‘TM3 LM Adjacent stiffener WB-NO.2 ST at fr. 54in space

Other Comments/Conclusion

Satisfactory.

Tank characteris ‘Side WB Tk. 2S.

Init. Frame : 50. Final Frame :83 Use :Ballast Tank Position : Starboard

Close Up Survey

EXTENT (locate frame n°. type of structure examined as per Rules) : Transverse web frame, Transverse bulkhead

Corresponding thickness measurements (reference of report, page, N") : Transverse web frame page 146

Transverse bullkhead page 583

Findings

‘Suspect areas - Substantial Corrosion(>75 % of wear mit) - ade sketches as deemed necessary)

TMS LM Adjacent stiffener WB-NO.2 ST at fr. 51 in space;

‘TM LM Adjacent stiffener WB-NO.2 ST at fr. 64 in spa

Other Comments/Conclusion :

Satisfactory.

——aeaarieeees

® a

=

‘The leos pushed Rules of Busou Veras Manne & Ofstore andthe Geral Conon tern ae

spueable

Reg: 108110 MICRONESIAN PRIDE. Ret: DKT0/2022495599

18. Annex for Internal Examination of compartments other than cargo & ballast

Identification Use! | Frames Internal examination Remark |Done| item

Engine Room ws [0-0 Coane x |x [vero

Fresh Water TG Fw [10 Eanted |x [vneze

king water 5 ew fone Seamed xx [woes

ME Cool TP ew [esa Beanie x [x | vnoze

FO sotirg Th 7S fo [ainzs Cried [x [wane

FO Seting Te 2S Fo [19-21 Erained x [x | ome30

FO Sere TP 0 [22-25 a x [x | vwen0

DO Settling Tk. S FD | 21-25 Examined x x [vinoao

00 SenicaTk § [a1 Banned |x| vmez0

FO Lanag0 TS #0 [5-28 ened x [x [weno

arom. 1p v0 |ss-7 Examined x | x [ee

oa FOTK 1S ro |ss-7 Examined x | x fee

aaoFOTK a ro [ae Canned |x [vse

eerOTK 38 fo [za-20 tanned xx [eae

TO Serge Tk to [18-21 Erained ed

lore Ke to [17-25 Banned |x [one

(use

MS "Machina Space LO = Lub O1Tark

FW Fresh Water Tank

FO: FuevDwse 1 Tank

‘Remarks:

DB FO Tk. 1 P-vINOG

Satisfactory.

DB FO Tk. 1 §- VINO

Satisfactory.

D0 Service Tk. §- ViNO30

Satisfactory.

0 Setting Tk. §-viNOSO

Satisfactory.

inking water Tk. §-VINO2S

Satisfactory.

Engine Room -ViNO10

Satisfactory.

FO Leakage Tk $ -VINO3O.

‘Satisfactory.

FO Service Tk. P-VINO30

Satisfactory.

FO Setting Tk. 1 $ -VINO3O

Satisfactory.

FO Setting Tk. 28 -VINO30

Satisfactory.

Frosh Water Tk. -VING2A

Satisfactory.

LO Cire. Tk. C= VINOAS

‘Satisfactory

LO Storage Tk. P-VINO4

‘Bureau Veritas Marine & Offshore

@setentpannesninst sone eset Or nate Ginter Page2r

= ‘aoateabe

og: 108110 MICRONESIAN PRIDE. Ref: 702022155503

Satisfactory

ME CoolTk P-viNis

‘Satisfactory

Side FO Tk. 3 P-VINOD

Satisfactory

Side FO Tk. 38-VIN0D6

Satisfactory.

19. Annex for Documentation on board

Reference Documents

awn wn coef 0.0

Verification thatthe Ballast Water Management Pian is on board

‘Approved on [30/42/2022

‘Approved by [BV

Language [ ENGLISH.

A086 Seo Coet 0.0

Verification that the ECDIS Type Approval Cerificate is available on boars

@ENC ORCDS

Cerificate No. 02445

Navito ‘SEO Coot 0.0

Confirmation that the Automatic Identification System has been subject to an annual testing and that a AIS Test Report

issued by the testing facility is kept on board the ship

Test report issued by: ptsulendra putra sukses,

Dale of issuance: 1970172029

11 Coot 0.0

Confirmation that the voyage data recorder (VDR) or Simplified Voyage Data Recorder (S-VDR) has been subjected to

‘an annual performance test and that a certificate of compliance issued by the testing facility is kept on board the ship.

‘Cerificate issued by: KELVIN HUGHES,

Date of issuance: (05/06/2022

avias Cost 0.0

Confirmation that a valid conformance test report for the LRIT is available on board

ASP name. Pole star space App.

Data of issuance [09 September 2021

20, Annex for Safety and Fire Fighting Equipment

Fire protection and fire fighting

Fighter's outfits

Str cost 0.0

Date of recharge of the air cylinders

Date : 04/01/2023

Fire extinguishers

eran Vros Wane 8 OFC

© ag 284

“helt putanad Rls of Burau Verne Marino & Osher andthe Gane Contons hero are

= sppeable

‘Reg: 108110 MICRONESIAN PRIDE. fet: DKT0/2022155503,

A RHE Cost 0.0

Date of recharge or date of inspection of the portable fie extinguishers :

Date : 04/01/2023

SMR-HSEQ Cost 0.9

Date of recharge or date of inspection of the non-portable fre extinguishers

Date : 04/01/2023

‘Special arrangements in machinery spaces

FREOT2A MR HS coef 0.0

Date when the CO2 cylinders were weighed or date when their level was checked

© Checked © Weighted

date 04/01/2023

Cargo spaces

F Coet 10.0

Date when the C02 cylinders were weighed or date when their level was checked

Date "04 January 2023

Life-saving appliances

DCE0RB Se Cost 0.0

Verification through documentary evidence that survival crafts and rescue boat launching appliances were subjected to a

pperioccal thorough examination and a dynamic test of the winch brake at the maximum lowering speed by a competent,

pperson. (record dates of last annal and 6-yearly examination and test)

‘Surv. craft type & identification [Annual year

FreeFall Lifebaot [oar0t/2023 [03/12/2020

Rescue Boat & Liferatt fosro1/2023 | 03/12/2020

Coot: 0.0

‘Verification through documentary evidence that the survival craft and rescue boat on-load release systems were

‘subjected to a thorough examination and operational test by a competent person. (record dates of last annual and

B-yearly examination and test)

(Sur craft type and identification Tanaal year

Freefall Lifebaot ‘09/01/2023 [03/12/2020

Rescue Boat & Lferaft (09/07/2022 [03/12/2020

Communications

7 coef :00

Date of vaicty ofthe rockets ofthe linethrowing appliance :

‘SEPTEMBER 2025

5 “ Coet 0.0

Date of validity of the parachute distress signals

‘SEPTEMBER 2025

Lifeboats

HSE Cost 0.0

Checking that the hand flares are not out of date

Validity date: JANUARY 2025

SAt6 F Coot 0.0

Checking thatthe rockets parachute fares are not out of date

Validity date: JANUARY 2025

SEO cost 0.0

Confirmation that the buoyant smokes signals provided in ifeboats are not out of date

Validity date: JANUARY 2025

Bursa Vrs Mabe 8 Oars

© ets winsner suas te rays ohare Cotter eo a eee 081

a oe

Liferafts (inflatable)

a Cont :00

Date when each inflatable Iferaft was serviced by an approved servicing station

Tera nor Date ‘Serviced by

2015 1610672022 LIFERAFT SALES & SERVICES.

0572 716/06/2022 LIFERAFT SALES & SERVICES

Personal

oct: 0.0

Confirmation that the smoke signals provided for personnal fe saving appliances are not out of date

Validity date: JUNE 2025

iran Vas Wane & OFS

© — aoe 08

eta pts en voter trays Stowe Sea

wan

Rea: 106110 MICRONESIAN PRIDE. Ref: DKT0/2022145503

LIST OF DOCUMENTS ATTACHED TO

JOB NUMBER DKT0/2022/J5593

RFS SIGNED

FINAL UTM REPORT

LAPSED CERTIFICATE

TAILSHAFT CLEARENCE REPORT

RUDDER CLEARENCE REPORT

RADIO SURVEY REPORT

ENDORSMENT OF CARGO GEAR BOOK

VDR REPORT

End of List

‘Bureau Veritas Marine & Offehore

Dice ptineisndinommninneg panna icc Page 101

sppleabe

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Drawing Hydraulic Hatch CoverDocument3 pagesDrawing Hydraulic Hatch Coverjeri adovelinNo ratings yet

- Product Quotation: Weifang Yongneng Power Electromechanical Equipment Co.,LtdDocument3 pagesProduct Quotation: Weifang Yongneng Power Electromechanical Equipment Co.,Ltdjeri adovelinNo ratings yet

- Fuel ConsumptionDocument12 pagesFuel Consumptionjeri adovelinNo ratings yet

- 06766320220222181721Document2 pages06766320220222181721jeri adovelinNo ratings yet

- KUT 4ADORAH005E - PT. Adovelin RaharjaDocument1 pageKUT 4ADORAH005E - PT. Adovelin Raharjajeri adovelinNo ratings yet

- UWILD Survey Requirement MVR Part 7 Appendix 1Document5 pagesUWILD Survey Requirement MVR Part 7 Appendix 1jeri adovelinNo ratings yet