Professional Documents

Culture Documents

Kapoor Manish - IJPQA, Vol12, Issue3, Article4 v1

Uploaded by

Sunita GiriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kapoor Manish - IJPQA, Vol12, Issue3, Article4 v1

Uploaded by

Sunita GiriCopyright:

Available Formats

RESEARCH ARTICLE

An Appraisal of Adoption Status of “Quality By Design” Approach in

Pharmaceutical Industries in Himachal Pradesh, India

Manish Kapoor1*, Chand K. Rojhe2, Manjir S. Kataki3, Neeraj Mahindroo1,4

1

School of Pharmaceutical Sciences, Shoolini University of Biotechnology and Management Sciences, Solan, Himachal

Pradesh, India

2

School of Management Sciences and Liberal Arts, Shoolini University of Biotechnology and Management Sciences, Solan,

Himachal Pradesh, India

3

Department of Pharmaceutical Sciences, Dibrugarh University, Dibrugarh, Assam, India

4

School of Health Sciences, University of Petroleum and Energy Studies (UPES), Dehradun, Uttarakhand, India

Received: 28th July, 2021; Revised: 19th August, 2021; Accepted: 14th September, 2021; Available Online: 25th December, 2021

ABSTRACT

The present study aimed to evaluate the current status and adoption of the Quality by Design (QbD) approach in the

pharmaceutical industries of Himachal Pradesh. The study was conducted by distributing a well-designed questionnaire survey,

and data were collected electronically. In the study, the status of QbD adoption among pharmaceutical industries of Himachal

Pradesh was investigated and also aimed to evaluate the factors influencing the QbD adoption. A total of 112 pharmaceutical

units were enrolled initially for the study, but finally, 100 units participated in this study. A total of 97 responses were received

and analyzed by SPSS to derive the inferences related to QbD adoption status and the factors influencing QbD adoption. The

results revealed a significant degree of QbD adoption among the participant pharmaceutical units. A total of 14 factors had

been identified with 57 indicators. It has been observed that the key area where the adoption of QbD influences the industry

output are ‘Risk Assessment and efficient management of the unit’ with the highest Eigen-value at maximum variance and

highest factor loading. This identified factor (F1) was found to be a crucial element in QbD adoption. The study indicated

the identification of several factors for a successful QbD adoption and implementation in pharmaceutical manufacturing and

the regulatory authority should inspire, be aware and support the companies by organizing consistent workshops, seminars,

and pre-designed training programs.

Keywords: Pharmaceutical manufacturing, Pharmaceutical Quality, QTPP, Quality by Design (QbD), Risk Assessment, Risk

Management.

International Journal of Pharmaceutical Quality Assurance (2021); DOI: 10.25258/ijpqa.12.4.00

How to cite this article: Kapoor M, Rojhe CK, Manjir S. Kataki, Mahindroo N. An Appraisal of Adoption Status of

“Quality By Design” Approach in Pharmaceutical Industries in Himachal Pradesh, India. International Journal of

Pharmaceutical Quality Assurance. 2021;12(4):1-8.

Source of support: Nil.

Conflict of interest: None

INTRODUCTION performance, serviceability, robustness, ease of application,

Quality has become the utmost important norm laid by all and trustworthiness.2 Generally, products are tested for quality

regulatory bodies for pharmaceutical products1 and Indian control and assurance. But, just analysis of final product will

regulators have been constantly revising the guidelines to not ensure the quality of the product; rather the quality should

pave the way for adoption and implementation of a quality be designed into entire process and the product. The emphasis

driven approach. Quality denotes customer satisfaction via must be on precaution rather than on just testing followed by

consistency in terms of service, product, and process. Quality correction of quality problems. The quality by testing has

and related activities have become the trend for success in every become an obsolete concept in present day scenario. The

aspect for excelling in local and global markets.1 Customer various quality related product features must be built into the

satisfaction has evolved to new height demanding superior product and the manufacturing process should be such that the

quality products and services at low cost with consistency and product is free from all kind of deficiencies. This concept of

timely schedule. Various product parameters are involved in building quality into product paved the QbD approach, which

maintaining a satisfied customer pool, including cost, product has become a driving strategy in present day world.3,4

*Author for Correspondence: manishkphd17@gmail.com

Pharmaceutical QbD Adoption Status in Himachal Pradesh

Well-known quality expert, Joseph Moses Juran first described seven districts; Bilsapur, Kangra, Mandi, Shimla, Sirmour,

the concept of QbD approach5 and believed that mostly all Solan and Una. The study population comprised of all the

quality problems arise due to issues from initial product manufacturing units which responded to the survey invitation

planning steps. He believed that quality can be planned and Sample Size

built into the product, provided proper optimized panning is

The study is descriptive and utilized a pre-structured

done first. The principles of QbD have been applied to improve

questionnaire for performing the survey. At the time of review,

the product and process quality in every industry.3

558 pharmaceutical companies were operating in different state

Cost and clinically effective drugs with high safety profiles

locations as per the data available from the office of the Drug

are the need of the hour for the pharmaceutical industry.

Controller of Himachal Pradesh. The companies were divided

They are investing a fortune to achieve the same in the drug

into large, medium and small-scale industries based on their

discovery and development process, endeavoring to design

annual turnovers. Sample size for the present study was 112

quality products with consistency in the manufacturing process

based on stratified proportionate random sampling.

to deliver the product’s intended performance. A plethora of

gathered pharmaceutical knowledge and information related Participants

to manufacturing, provides a basic framework for logical and Respondents for this study were either Quality Assurance

scientific understanding of process variables to prop up a design Heads or Quality Control Heads or a person holding both

space, manufacturing controls, and control of materials. The responsibilities in the participant companies.

knowledge of pharmaceutical development can help to make Procedure

protocols for risk management for quality arena.6 The data

A comprehensive review of the existing literature and

relating to manufacturing alongside the data from lifecycle

regulatory guidelines on quality by design approach was

management forms a basis for the design space.7 This design

performed to construct a relevant and effective measurement

space is planned initially and can be submitted for regulatory

scale. While constructing the questionnaire, due consideration

audit and assessment following approval. The audited design

was given to keep it simple and easy to understand. QbD

space can be explored while manufacturing or processing to

adoption and indicators influencing QbD adoption were

ensure no failure in quality norms.8 However, any operation

selected based upon literature review. The organization

out of this design space is considered a change and needs to be

demographic factors considered in this study included,

audited and addressed as a post approval regulatory change.9

position of the respondent, his/her department, education,

There are various parameters related to drug development and

the experience of the respondent in the company, age of the

manufacturing, such as active pharmaceutical ingredients,

company, number of employees, type of products, quality

excipients, container closure systems, processes involved in

management trainings, approvals, certifications, awards,

manufacturing, and quality control tests,10 which are critical

and awareness. The QbD adoption and its indicators were

to finished product quality. These can be designed and planned

considered for evaluation, followed by extracting significant

for an optimized quality product. The QbD approach can lead

factors using SPSS. The organizational variables were also

to a state of industrial art standard which ultimately equips

studied, and descriptive statistical analysis was performed

the industries to manufacture quality products with superior

to derive insight into the organization’s status in the quality

acceptability and financial gains. Therefore, the present study

context. An attempt was made to understand QbD adoption

aimed to investigate the status of the adoption of QbD and

and its influencing indicators in the context of organizational

indicators influencing the QbD adoption by the pharmaceutical

and other pre-framed factors. The questionnaire comprised of

units in Himachal Pradesh.

general question like the organizational demographic profile

METHODS of the manufacturers along with details about the respondents.

The questionnaire also comprised of questions related to

Study Design quality and QbD approach. The questionnaire was sent to 112

We conducted a survey of Pharmaceutical Industries in state representatives of pharmaceutical companies across Himachal

of Himachal Pradesh for exploring the status of adoption of Pradesh. Out of 112, 12 companies were observed to be closed

QbD approach. and a response to the survey was sought from 100 companies.

Study Area A time frame of one month was allotted to each participant

The area for the present study was the state of Himachal for filling up the survey. The survey was constructed and

Pradesh. Himachal Pradesh is considered a pharmaceutical distributed via Google forms. A rather high response rate of

manufacturing hub in India and all categories of pharmaceutical 97% was received with 97 out of 100 companies approached

manufacturing industries based upon their annual turnover viz; for the survey responding in the given time frame. This can

large scale, medium scale and small-scale pharmaceutical be attributed to the frequent follow-ups and the online mode

units exist in Himachal Pradesh. Himachal Pradesh comprises of the survey. As certain data, especially about ongoing

of twelve districts: Bilaspur, Chamba, Hamirpur, Kangra, development projects, is kept confidential by pharmaceutical

Kinnaur, Kullu, Lahaul and Spiti, Mandi, Shimla, Sirmaur, companies, some of the contacted individuals were reluctant

Solan, and Una. The pharmaceutical industries are present in to participate to avoid handing out any confidential data. This

IJPQA, Volume 12 Issue 4, October 2021 – December 2021 Page 2

Pharmaceutical QbD Adoption Status in Himachal Pradesh

issue was known beforehand and addressed with great care. Table 1: Organizational demographic findings of the surveyed

It was ensured that the survey was completely anonymous, pharmaceutical industries

and the questionnaire was designed in a way to avoid any Organizational Demographic Parameters Frequency Percent

sensitive information and leave the possibility to enter blank The position of the respondent

data through open-ended questions. Yet, some questions were still QC Head 41 42.27

perceived to ask for semi- or full-sensitive data which drove

QA Head 46 47.42

many potential participants to halt participation.

Both 8 8.25

Measurements Not answered 2 2.06

The 5 points Likert’s scale categorized under the interval scale Qualification of the respondent

was utilized to measure the respondents opinions by specifying

PhD 4 4.13

by what range they agree or disagree to the statement in the

questionnaire i.e. range between strongly disagree (1) to Master degree 53 54.64

strongly Agree (5). Another 5point modified Likert’s scale Bachelor degree 40 41.24

was also utilized to measure the respondents knowledge/ Background of the respondent

perception by specifying by what point they agree or disagree Engineering 2 2.06

to the statement i.e. range between never (1) to always (5).11,12 Business 3 3.09

Statistical Analyses Science 68 70.10

The data were analyzed using SPSS version 20.0 (IBM Corp. Pharmacy 22 22.68

Released 2011, IBM SPSS Statistics for Windows, and Version Science and pharmacy 2 2.06

20.0. Armonk, NY: IBM Corp.). Participants with more than

Experience of the respondent

one missing value within a scale were excluded. A p-value

0-5 years 32 32.99

of ≤0.05 was considered statistically significant. Coefficients

between 0 and 0.30 were defined as a weak correlation, from 6-10 years 27 27.84

0.30 to 0.50 as moderate, and 0.50 or higher, as a strong 11-15 years 17 17.53

correlation. Factor analyses were performed to extract the 16 years and above 16 16.50

factors.12 Not answered 5 5.15

RESULTS AND DISCUSSION Quality Improvement Training of the respondent

Yes 40 41.24

Organizational Demography: Findings About the

No 57 58.76

Pharmaceutical Industry

Number of employees Frequency Percent

In total, 97 responses were received representing 97 unique

manufacturing units. Out of the responses received, 43.2% Below 50 25 25.77

were from Quality Control department (QC Head), 48.4% from Between 50-100 20 20.62

Quality Assurance department (QA Head), and 8.4% were from Between 101-250 14 14.43

the person holding both QC Head and QA Head positions. Above 250 9 9.28

Participating units were based in the following zones: BBN Not answered 29 29.90

(Baddi, Brotiwala and Nalagarh) 54.5%, Sirmour20.2%, Solan

Age of the company

(except BBN) 15.1%, Kangra 3%, Una3% and others 2%.WHO

GMP Certified units comprised 32% of participants, whereas Below 5 years 5 5.15

2.1% were MHRA approved and 1% is USFDA approved units. Between 6-10 years 25 25.77

Out of 97 units, 33.3% of participants deal with their brands as Above 10 years 41 42.27

well as third-party manufacturing, 27.3% are only third part Not answered 26 26.80

manufacturers, 18.2% are dealing with all possible kind of Year of Establishment

business dealings, 13.1% manufacturer only their brands, 5.1%

Between 1980 and 1990 2 2.06

are exporting their brands and 1% are exporting as third-party

Between 1991 and 2000 4 4.12

manufacturers. It is noteworthy that all participating units

were engaged in continuous manufacturing activities. The Between 2001 and 2010 56 57.73

respondents’ experience in their current positions ranged from After 2010 10 10.31

less than one to over sixteen years. While 34.3% of respondents Not answered 25 25.77

had 0-5 years of experience, 27.3% had 6-10 years, 17.2% had Dealings (Trade Type)

11-15 years, 16.5% had over 16 years of experience, and 7% of Own brand 13 13.40

respondents did not answer this question. The frequency and

Third party 27 27.84

percent data from the organizational demography are presented

in Table 1. The sample contained all different kinds of units: Own brand and third party 18 18.56

IJPQA, Volume 12 Issue 4, October 2021 – December 2021 Page 3

Pharmaceutical QbD Adoption Status in Himachal Pradesh

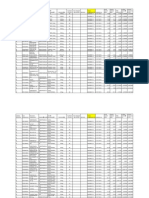

Table 2: Total variance Explained: Factor extraction

Organizational Demographic Parameters Frequency Percent

Own brand and export 33 34.02 Total Variance Explained

Third party and export 5 5.15 Rotation Sums of Squared Loadings

Own brand and third party and export 1 1.03 Component Total % of Variance Cumulative %

Turnover (2016-2017) Frequency Percent 1 6.371 11.176 11.176

Below 10 cr 30 30.93 2 4.817 8.451 19.627

10-50 cr 36 37.11 3 4.656 8.169 27.796

51-100 cr 9 9.28 4 4.177 7.329 35.125

101-200 cr 5 5.15` 5 3.302 5.792 40.918

201-500 cr 8 8.25 6 3.249 5.701 46.618

501-1000 cr 4 4.12` 7 3.070 5.387 52.005

Above 1000 cr 3 3.09 8 2.680 4.702 56.707

Not answered 2 2.06 9 2.301 4.036 60.743

Approvals 10 2.150 3.772 64.514

USFDA approved 1 1.03 11 1.786 3.133 67.647

MHRA approved 2 2.06 12 1.762 3.091 70.738

WHO GMP certified 31 31.96 13 1.575 2.764 73.502

None of these 63 64.95 14 1.426 2.501 76.003

Schedule M Compliance Extraction Method: Principal Component Analysis.

Complied 97 100 the interactions and correlations between parameters based

Not Complied 0 0 on statistical relevance. Principal Component Analysis was

ISO Certification used as an extraction method in the factor analysis followed

IS0 9001 11 11.34 by Varimax rotation with Kaiser Normalization. Based on the

Eigen-values and rotation component matrix, 14 factors were

ISO 9001:2000 5 5.15

extracted from the adoption section.

ISO 9001:2008 43 44.33

Elucidation of the Extracted Factors

No ISO Certification 38 39.18

F1: Risk Assessment and Efficient Management: Out of the 14

Certificate of International Quality Assurance System

factors extracted, it is the first factor. It has the maximum Eigen-

Certified 11 11.34

value of 6.371 and accounted for 11.176% of the total variance.

Not Certified 70 72.16 The indicator of supportive statistical tools has the highest

Cannot Say 16 16.49 factor loading of 0.741. This suggests that Risk Assessment and

efficient management factor explained most of the variance and

from small, medium and rather local up to large scale units

was the most important factor in determining the overall QbD

and from highly specialized to very broadly operating units.

adoption in the study area. There were 10 indicators associated

Also in terms of popular manufacturing brands, most major

with Risk Assessment and Efficient Management. Among

manufacturers (India) were represented. Additionally, there

these, the indicator ‘supportive statistical tools’ were highly

were participants from two departments (e.g. Quality Control

correlated with ‘Risk Assessment and Efficient Management

and Quality Assurance) with different experience levels. Based

followed by Failure Mode’, ‘Effects & Criticality Analysis

on the demographics of the respondents, the sample appears

(FMECA)’, ‘Fault Tree Analysis (FTA)’, ‘Preliminary Hazard

to be a good representation of the pharmaceutical industry in

Analysis (PHA)’, ‘Failure Mode Effect Analysis (FMA) as a

India and can, therefore, be used to derive inferences about

risk management tool’, ‘Hazard Analysis & Critical Control

the current state of the pharmaceutical industry.

Points (HACCP)’, ‘company policy to assess risks, Risk

Factor Extraction: Adoption of QbD in the Ranking & Filtering’, ‘Basic risk management facilitation

Pharmaceutical Industries methods (Flow charts, check sheets etc)’, and ‘Setting up of

Data analysis was performed using SPSS for analysis and appropriate calibration and maintenance schedules’ (Table 2).

evaluation of data from organizational demography and F2: Effective company policy to ensure quality: It became

adoption parameters. The factor analysis was carried out on the second most important factor in the analysis. This factor

SPSS version 20.0 as a dimension reduction test. Since the comprises of 8 indicators. They together exhibit 8.451%

present study variables are multi-dimensional concepts, there variance and have Eigen value of 4.817. The indicator ‘regular

was a need to examine the dimensionality of each main variable internal and external auditing/inspections’ has the highest

and define the number of dimensions that constitute the variable. factor loading of 0.801 followed by ‘Risk minimization steps’,

Factor extraction becomes handy for analyzing and evaluating ‘Hygiene aspects’, ‘The process control strategies’, ‘periodically

IJPQA, Volume 12 Issue 4, October 2021 – December 2021 Page 4

Pharmaceutical QbD Adoption Status in Himachal Pradesh

conduct Internal and External auditing/inspections’, ‘Internal F8: Effective company policy to ensure quality (AMV, PDR

and External auditing/inspections’, ‘periodical review of and vigilance): This came out to be the eighth important factor

Quality policy and timely feedback’ respectively. in the analysis. This factor comprises of 3 indicators. They

F3: Good documentation practice in terms of implementing together exhibit 4.702% of the variance and have Eigen value

company policy and control strategy: This shows 8.169% of 2.680. The indicator ‘documentation (AMV/PDR)’ had the

variance with Eigen value of 4.656. The indicator ‘documentation highest factor loading of 0.698 followed by ‘Responsible Senior

prepared or not before commencing production’ was found to Management for effective Pharmaceutical Quality System’,

be highly correlated with this factor having the highest factor 0.559; and ‘Manufacturing process validation’, 0.473.

loading of 0.873 followed by ‘quality policy’ is communicated F9: QTPP (documentation about primary & secondary

with 0.779 loading; ‘structured approach for implementing packaging, stability studies and quality testing): The factor’

corrective and preventive actions’ with, 0.761; ‘monitoring QTPP’ explained 4.036% of the variance with Eigen value

critical process parameters’, 0.601; ‘Data management and of 2.301. The indicator ‘documentation prepared (respect to

statistical tools’, 0.537; ‘Process flow diagrams prepared’, container closure system)’ was highly correlated with this

0.454; and ‘Rationale for selection of container closure system’, factor having the highest factor loading of 0.843; followed by

0.422. ‘documentation prepared (respect to factors about drug product

F4: QTPP (quality target product profile): Six indicators viz quality criteria)’ with 0.653.

‘documentation prepared (respect to route of administration, F10: Effective company policy to ensure effective risk

dosage for m and deliver y system)’, ‘documentation assessment and to update regulatory authority on time:

prepared (concerning factors affecting pharmacokinetics)’, This factor is comprised of 3 indicators, namely ‘sharing

‘documentation prepared (respect to intended use)’, information related to identified risk with other companies’,

‘documentation prepared (related to factors affecting release ‘sharing information related to identified risk with the

of therapeutic moiety/moieties)’, ‘appropriate Control Strategy regulators’ and ‘company policy for sharing risk assessment

(Chemical properties) and appropriate Control Strategy report within the company’. This extracted factor explained

(Physical properties)’ were found to be associated with the 3.772% of the variance with Eigen value of 2.150 and factor

factor name ‘QTPP (quality target product profile)’. This loadings of 0.726, 0.700 and 0.487, respectively.

factor explained 7.329% variance with Eigen value of 4.177. F11: Effective quality assurance protocol and in-process

The indicator ‘documentation prepared (respect to the route quality control strategy: This is the eleventh factor obtained

of administration, dosage form and delivery system)’ had the from the analysis and exhibits 3.133% of the variance with

highest factor loading of 0.805 as compared to other indicators. Eigen value of 1.786 and factor loading of 0.803 and 0.392,

F5: Continuous improvement: This is the fifth factor obtained respectively.

from the analysis and exhibited 5.792% of the variance with F12: Risk management: Risk management comprises one

Eigen value of 3.302. The indicator having the highest factor indicator, namely ‘Literature reviews including Historical data/

loading of 0.743 was ‘designed/installed aspects such as the literature/theoretical analysis/informed opinions etc for risk

flow of materials & personnel’ followed by ‘contamination identification’. This extracted factor explained 3.091% of the

minimization aspects’, ‘dedicated facilities and dedicate variance with Eigen value of 1.762 and factor loading of 0.613.

equipment’, ‘appropriate resources/training to the employees’ F13: Audit readiness: It comprises one indicator namely

and ‘open vs. close equipment. ‘regular Internal and External auditing/inspections’ to ensure

F6: Effective company policy to ensure quality: This factor 100% compliance to SOPs. This extracted factor explained

is comprised of five indicators namely ‘Material analysis 2.764% of the variance with Eigen value of 1.575 and factor

and equipment monitoring’, ‘sharing information related loading of 0.742.

to identified risk’, ‘identification of Sources of variations F14: Interaction of QA/QC people with production: The factor

affecting process performance and product quality’, ‘ensured ‘Interaction of QA/QC people with production’ comprises one

improvement’, and ‘periodical review of Information and data indicator, namely ‘company policy to ensure the interaction

about product quality and manufacturing experience’. This of QA/QC people with production staff’ periodically. This

extracted factor explained 5.701% of the total variance with an extracted factor explained 2.501% of the variance with Eigen

Eigen value of 3.249 and the highest factor loading of 0.785for value of 1.426 and factor loading of 0.568 (Table 3).

‘Material analysis and equipment monitoring’. The findings of the study relate to QbD adoption by

F7: Calibration of instruments and revision of SOPs at a pre- the pharmaceutical manufacturers in Himachal Pradesh. A

determined schedule: This factor explained 5.387% of the total of 14 factors with 57 variables were considered in the

variance with Eigen value of 3.070. The indicator ‘Regular and questionnaire. On the basis of the Factor Analysis, fourteen

periodical maintenance of the facility, ‘utilities and equipment’ new factors were identified. It is imperative that the new factors

was found to be highly correlated with this factor with the obtained after applying factor analysis can serve as an important

highest factor loading of 0.766 followed by ‘implementation tool to understand QbD adoption by the pharmaceutical

of necessary steps to ensure prevention of mix-ups’,0.613; and units. First factor obtained was ‘risk assessment and efficient

‘Scrutiny of intra-batch as well as inter-batch variation’ 0.590 management’ with indicators like ‘supportive statistical tools’,

respectively. ‘Failure Mode, Effects & Criticality Analysis (FMECA)’, ‘Fault

IJPQA, Volume 12 Issue 4, October 2021 – December 2021 Page 5

Pharmaceutical QbD Adoption Status in Himachal Pradesh

Tree Analysis (FTA)’, ‘Preliminary Hazard Analysis (PHA)’, documentation practice in terms implementing company

‘Failure Mode Effect Analysis (FMA) as a risk management policy and control strategy’, which comprises of the indicators

tool’, ‘Hazard Analysis & Critical Control Points (HACCP)’, like, ‘documentation prepared or not before commencing

‘company policy to assess risks’, ‘Risk Ranking & Filtering’, production’, ‘quality policy is communicated’, ‘structured

‘Basic risk management facilitation methods (Flow charts, approach for implementing corrective and preventive actions’,

check sheets etc)’, and ‘Setting up of appropriate calibration ‘monitoring critical process parameters’, ‘Data management

and maintenance schedules’. These indicators were strongly and statistical tools’, ‘Process flow diagrams prepared’ and

associated with the first factor. Second factor obtained was ‘Rationale for selection of container closure system’. Fourth

‘effective company policy to ensure quality’ and the indicators factor obtained was ‘QTPP (Quality Target Product Profile)’,

involved were ‘regular internal and external auditing/ which involved indicators like, ‘documentation prepared

inspections’, ‘Risk minimization steps’, ‘Hygiene aspects’, (respect to route of administration, dosage form and delivery

‘The process control strategies’, ‘periodically conduct Internal system)’, ‘documentation prepared (concerning factors

and External auditing/inspections’, ‘Internal and External affecting pharmacokinetics)’, ‘documentation prepared (respect

auditing/inspections’, and ‘periodical review of Quality to intended use)’, ‘documentation prepared (related to factors

policy and timely feedback’. Third factor obtained was ‘good affecting release of therapeutic moiety/moieties)’, ‘appropriate

Table 3: Component Transformation Matrix: Factor extraction

Component Transformation Matrix

Component 1 2 3 4 5 6 7

1 .530 .340 .386 .329 .271 .277 .253

2 .621 .075 .288 .076

3 .539 .147 .332

4 .447 .162

5 .168 .650 .114

6 .262 .302 .552

7 .195 .313 .085 .257

8 .068 .256 .155 .270

9 .137 .110 .692

10 .413 .055 .145 .080

11 .120

12 .073 .137 .176 .334

13 .149 .023 .210 .086

14 .141 .101

Component Transformation Matrix (Continued..)

Component 8 9 10 11 12 13 14

1 .232 .147 .176 .089 .043 .072 .105

2 .238 .051

3 .378 .207 .103

4 .336 .274 .144 .065 .127 .041

5 .047 .395 .052 .320 .081

6 .282

7 .209 .048

8 .037 .349 .364 .284

9 .386 .128

10 .480 .214 .092

11 .302 .484 .209 .243 .103 .382

12 .045 .134 .572 .302 .341 .004

13 .155 .448 .297 .018

14 .244 .083 .038 .359

Extraction Method: Principal Component Analysis.

Rotation Method: Varimax with Kaiser Normalization.

IJPQA, Volume 12 Issue 4, October 2021 – December 2021 Page 6

Pharmaceutical QbD Adoption Status in Himachal Pradesh

Control Strategy (Chemical properties)’ and ‘appropriate Pradesh. The status of QbD adoption and factors influencing

Control Strategy (Physical properties)’. The fifth factor QbD adoption in the pharmaceutical manufacturing units were

obtained was a continuous improvement having indicators studied using 57 variables about QbD adoption. The study

like, ‘designed/installed aspects such as the flow of materials & has classified these 57 variables into 14 factors using factor

personnel’ followed by ‘contamination minimization aspects’, analysis. The outcome of this present study demonstrated

‘dedicated facilities and dedicated equipment’, ‘appropriate that the pharmaceutical manufacturing units are approaching

resources/training to the employees’ and ‘Open Vs Close a better-quality orientated protocol by adopting and

Equipment’. Sixth factor obtained was ‘effective company implementing various quality norms about the QbD concept.

policy to ensure quality’ containing indicators like, ‘Material It has been observed that the key area where the adoption of

analysis and equipment monitoring’, ‘sharing information QbD influences the industry output are ‘Risk Assessment

related to identified risk’, ‘identification of sources of variations and efficient management of the unit’ with the highest Eigen

affecting process performance and product quality’, ‘ensured value at maximum variance and highest factor loading which

improvement’, and ‘periodical review of Information and data explains the importance of factor F1. F1 is a crucial element

about product quality and manufacturing experience’. The in QbD adoption. Therefore, pharmaceutical manufacturers

seventh factor obtained was ‘calibration of instruments and aiming at QbD adoption must involve and practice ‘Failure

revision of SOPs at a pre-determined schedule’. It contained Mode, Effects and Criticality Analysis (FMECA)’, ‘Fault

indicators like, ‘Regular and periodical maintenance of the Tree Analysis (FTA)’, ‘Preliminary Hazard Analysis (PHA)’,

facility’, ‘utilities and equipment’ followed by ‘implementation ‘Failure Mode Effect Analysis (FMA) as a risk management

of necessary steps to ensure prevention of mix-ups’ and tool’, ‘Hazard Analysis and Critical Control Points (HACCP)’,

‘Scrutiny of intra-batch as well as inter-batch variation’. ‘company policy to assess risks’, ‘Risk Ranking and Filtering’,

The eighth factor obtained was ‘effective company policy to ‘Basic risk management facilitation methods (Flow charts,

ensure quality (AMV, PDR and vigilance)’ involves indicators, check sheets etc)’, and ‘Setting up of appropriate calibration

‘documentation (AMV/PDR)’ followed by ‘Responsible Senior and maintenance schedules for achievement of quality’. Other

Management for effective Pharmaceutical Quality System and factors like ‘Effective company policy to ensure quality’, ‘Good

Manufacturing process validation’. Ninth factor obtained was Documentation Practice in terms of implementing company

‘QTPP (documentation pertaining to primary & secondary policy and Control strategy’, ‘QTPP (Quality Target Product

packaging’, stability studies and quality testing)’ containing Profile)’, ‘Continuous improvement’, ‘Effective company policy

indicators like, ‘documentation prepared (respect to container to ensure quality’, which were further identified as important

closure system)’ followed by ‘documentation prepared (respect factors based on Eigen value, variance and factor loading

to factors pertaining to drug product quality criteria)’.Tenth which disclose that organizations need a solid company policy

factor obtained was ‘effective company policy to ensure and control strategy towards making their product quality

effective risk assessment and to update regulatory authority consistent. Organizations need to focus on these factors to

in a timely manner’ including indicators, ‘sharing information adopt QbD for achieving maximum benefits in terms of product

related to identified risk with other companies’, ‘sharing quality and company growth.

information related to identified risk with the regulators’ and

REFERENCE

‘company policy for sharing risk assessment report within

the company’. Eleventh factor obtained was ‘effective quality 1. Sangshetti JN, Deshpande M, Zaheer Z, Shinde DB, Arote R,

assurance protocol and in-process quality control strategy Quality by design approach: Regulatory need. Arabian Journal

of Chemistry. 2017;10:S3412-S3425.

including indicators, Pest Control measures, and monitoring

2. Zhang L, Mao S. Applications of quality by design (QbD) and its

the manufacturing process. The factor twelve obtained was tools in drug delivery. Asian Journal of Pharmaceutical Sciences.

‘risk management including indicator, ‘Literature reviews 2016;11(1):144-145.

including Historical data/literature/theoretical analysis/ 3. Djuris J, Ibric S, Djuric Z. 1 - Quality-by-design in pharmaceutical

informed opinions etc for risk identification’. Thirteenth factor development. In Computer-Aided Applications in Pharmaceutical

obtained was ‘audit readiness including indicator, ‘regular Technology, Djuris, J., Ed. Woodhead Publishing: 2013; pp

Internal and External auditing/inspections to ensure 100% 1-16.

compliance to SOPs’. Lastly, factor 14 was obtained as the 4. Nadpara NP, Thumar RV, Kalola VN, Patel PB. Quality by

‘interaction of QA/QC people with production’ having only design (QbD): A complete review. Int. J. pharm. sci. Rev. Res

2012;17(2):04-20.

indicator, ‘company policy to ensure the interaction of QA/

5. Bindhu MR. Quality by Design: A Brief Introduction. J

QC people with production staff periodically’. Each of the Pharmacovigilance. 2015;3(4):e142.

indicators mentioned in the above paragraph showed a strong 6. Pallagi E, Ambrus R, Szabo-Revesz P, Csoka I. Adaptation of the

correlation for the factors they were mapped to. quality by design concept in early pharmaceutical development

of an intranasal nanosized formulation. International journal of

CONCLUSION

pharmaceutics. 2015;491(1-2):384-92.

The present study focused on understanding the status of 7. Patil AS, Pethe AM. Quality by Design (QbD): A new concept

adoption of QbD and the factors which influence QbD adoption for development of quality pharmaceuticals. Int J Qual Assur

among pharmaceutical manufacturing units of Himachal 2013;4(2):13-19.

IJPQA, Volume 12 Issue 4, October 2021 – December 2021 Page 7

Pharmaceutical QbD Adoption Status in Himachal Pradesh

8. Zhang L, Mao S. Application of quality by design in the current (QbD) for biotechnology products. Trends in biotechnology.

drug development. Asian Journal of Pharmaceutical Sciences. 2009;27(9):546-553.

2017;12(1):1-8. 11. Dawes J. Do data characteristics change according to the number of

9. Van Buskirk GA, Asotra S, Balducci C, Basu P, DiDonato G, scale points used? An experiment using 5-point, 7-point and 10-point

Dorantes A, Eickhoff WM, Ghosh T, González MA, Henry T. scales. International journal of market research. 2008; 50(1):61-104.

Best practices for the development, scale-up, and post-approval 12. Cummins RA, Gullone E. In Why we should not use 5-point

change control of IR and MR dosage forms in the current quality- Likert scales: The case for subjective quality of life measurement,

by-design paradigm. AAPS Pharm Sci Tech. 2014;15(3):665-693. Proceedings, second international conference on quality of life

10. Rathore AS. Roadmap for implementation of quality by design in cities, 2000; pp 74-93.

IJPQA, Volume 12 Issue 4, October 2021 – December 2021 Page 8

You might also like

- Drug Study - SalbutamolDocument2 pagesDrug Study - SalbutamolryanNo ratings yet

- Quality Assurance and Quality Management in Pharmaceutical IndustryFrom EverandQuality Assurance and Quality Management in Pharmaceutical IndustryRating: 4 out of 5 stars4/5 (4)

- GMP Audit in Pharmaceutical Companies-Review ArticleDocument6 pagesGMP Audit in Pharmaceutical Companies-Review Articleraju1559405No ratings yet

- Resume Book: Columbia Healthcare and Pharmaceutical Management ProgramDocument44 pagesResume Book: Columbia Healthcare and Pharmaceutical Management ProgramJohn Mathias100% (2)

- Solvent List For PolycaprolactoneDocument8 pagesSolvent List For Polycaprolactonedibyodibakar100% (2)

- Quality by Design (QBD) - Complete ReviewDocument9 pagesQuality by Design (QBD) - Complete ReviewDrSajithChandranNo ratings yet

- Quality by Design JournalDocument6 pagesQuality by Design JournalMiftahul ChairadNo ratings yet

- Pharmaceutical Product Development A Quality by deDocument10 pagesPharmaceutical Product Development A Quality by deNishitha Chowdary AluruNo ratings yet

- A Quantitative Approach For PharmaceuticDocument8 pagesA Quantitative Approach For PharmaceuticHalil İbrahim ÖzdemirNo ratings yet

- Quality by Design For Biopharmaceuticalsa Historical Review and Guide ForimplementationDocument18 pagesQuality by Design For Biopharmaceuticalsa Historical Review and Guide ForimplementationMariela Elizabeth Carmen ZenónNo ratings yet

- QBD MaterialDocument5 pagesQBD MaterialRodrigo BressanNo ratings yet

- Quality by DesignDocument15 pagesQuality by Designdalbertodiaz90No ratings yet

- Inprocessqualitycontrol PDFDocument13 pagesInprocessqualitycontrol PDFMarvela CrNo ratings yet

- White PaperDocument32 pagesWhite PaperAndroid modded gamesNo ratings yet

- Research Article: Jack Cook, Maria T. Cruañes, Manish Gupta, Steve Riley, and John CrisonDocument9 pagesResearch Article: Jack Cook, Maria T. Cruañes, Manish Gupta, Steve Riley, and John CrisonnarendragcpNo ratings yet

- Quality by Design Approach :regulatory Guidelines and Currrnt StatusDocument1 pageQuality by Design Approach :regulatory Guidelines and Currrnt Statusjayesh rajputNo ratings yet

- Clinical Quality by Design: FDA Point of ViewDocument20 pagesClinical Quality by Design: FDA Point of ViewMohammed HammedNo ratings yet

- Understanding Pharmaceutical QBD PDFDocument13 pagesUnderstanding Pharmaceutical QBD PDFcabeto124211No ratings yet

- PharmaceuticalQualityAssurance CleanedDocument5 pagesPharmaceuticalQualityAssurance CleanedTomás Zamorano FernándezNo ratings yet

- Cha Roo 2012Document15 pagesCha Roo 2012José RojasNo ratings yet

- Process Validation of Solid Dosage FormDocument24 pagesProcess Validation of Solid Dosage Formsiddpandit89No ratings yet

- 5 Vol. 4 Issue 4 IJPSR April 2013 RE 850 Paper 5Document7 pages5 Vol. 4 Issue 4 IJPSR April 2013 RE 850 Paper 5imaneabdelli1997No ratings yet

- Journal of Drug Discovery and Therapeutics 1 (6) 2013, 47-55Document9 pagesJournal of Drug Discovery and Therapeutics 1 (6) 2013, 47-55k.p.No ratings yet

- QBD ... Plackett Burman...Document12 pagesQBD ... Plackett Burman...cabeto124211No ratings yet

- The Concept of Process Validation in Tablet ManufacturingDocument4 pagesThe Concept of Process Validation in Tablet ManufacturingCarlos CruzNo ratings yet

- AssignmentDocument14 pagesAssignmentsandyrocks1194No ratings yet

- 1.sharmada S. Sinai Kakodkar Dr. Shilpa Bhilegaonkar Dr. Ajeet M. Godbole Pankaj Gajare PDFDocument19 pages1.sharmada S. Sinai Kakodkar Dr. Shilpa Bhilegaonkar Dr. Ajeet M. Godbole Pankaj Gajare PDFOlavRueslattenNo ratings yet

- 4 Vol. 7 Issue 3 March 2016 IJPSR RE 17831Document16 pages4 Vol. 7 Issue 3 March 2016 IJPSR RE 17831John Jairo Trochez AmpudiaNo ratings yet

- Emulsion IpcDocument12 pagesEmulsion IpcCitra DewiNo ratings yet

- Pharmaceutics 13 00919 v2Document45 pagesPharmaceutics 13 00919 v24n4n4sNo ratings yet

- Quality by Design Approaches For Topical Dermatological Dosage FormsDocument19 pagesQuality by Design Approaches For Topical Dermatological Dosage FormsDoinița UrsuNo ratings yet

- QD FabDocument3 pagesQD Fabfabianosir321No ratings yet

- Quality by DesignDocument2 pagesQuality by DesignOwaisNo ratings yet

- Process-Validation - General-Principles-and-Practices-10Document1 pageProcess-Validation - General-Principles-and-Practices-10Kendry JoseNo ratings yet

- OPQ 2022 Annual Report 230206Document7 pagesOPQ 2022 Annual Report 230206rodcam1No ratings yet

- Quality by Design (QBD) Approach in Pharmaceuticals: Status, Challenges and Next StepsDocument8 pagesQuality by Design (QBD) Approach in Pharmaceuticals: Status, Challenges and Next StepsnabilahNo ratings yet

- Clinical Trials & Partnering India 2010: Towards Global Standards and Excellence in Clinical DevelopmentDocument5 pagesClinical Trials & Partnering India 2010: Towards Global Standards and Excellence in Clinical Developmentmuffinz87No ratings yet

- Comparison of Various International Guidelines For Analytical Method ValidationDocument12 pagesComparison of Various International Guidelines For Analytical Method Validationeduardo3000No ratings yet

- Prospective Validation A Review PDFDocument7 pagesProspective Validation A Review PDFedgar palominoNo ratings yet

- Validation Technology in The Pharmaceutical Industry - A ReviewDocument5 pagesValidation Technology in The Pharmaceutical Industry - A ReviewAdvanced Research PublicationsNo ratings yet

- "Current Approach of Quality by Design" An OverviewDocument11 pages"Current Approach of Quality by Design" An OverviewResearch ParkNo ratings yet

- Es - Assets - 2019ebook - Optimizing - Pharmaceutical - Formulations (002) - tcm61-65306 PDFDocument33 pagesEs - Assets - 2019ebook - Optimizing - Pharmaceutical - Formulations (002) - tcm61-65306 PDFCarlos Alberto Salazar DuqueNo ratings yet

- Process ValidationDocument5 pagesProcess ValidationNarongchai PongpanNo ratings yet

- CPGM 7345.848 - Inspection of Biological Drug ProductsDocument20 pagesCPGM 7345.848 - Inspection of Biological Drug ProductsKisho RamNo ratings yet

- Norms and Standards: Good Review Practices: Guidelines For National and Regional Regulatory AuthoritiesDocument6 pagesNorms and Standards: Good Review Practices: Guidelines For National and Regional Regulatory AuthoritiesadhanazharyNo ratings yet

- The Central Role of Analytic Method Development and Validation in Pharmaceutical DevelopmentDocument3 pagesThe Central Role of Analytic Method Development and Validation in Pharmaceutical DevelopmentPrashansa ShresthaNo ratings yet

- Development of Integrated Industrial Process Layout Design For The Production and Quality Control Facility of Various Pharmaceutical FormulationsDocument15 pagesDevelopment of Integrated Industrial Process Layout Design For The Production and Quality Control Facility of Various Pharmaceutical FormulationsAntony Joel Meza LoardoNo ratings yet

- Quality by Design (QBD) : A Comprehensive Understanding of Implementation and Challenges in Pharmaceuticals DevelopmentDocument8 pagesQuality by Design (QBD) : A Comprehensive Understanding of Implementation and Challenges in Pharmaceuticals DevelopmentmcamilaarredondovelezNo ratings yet

- 01 Complete ThesisDocument98 pages01 Complete ThesisAkhilesh KajarekarNo ratings yet

- Prospective Process Validation of Gliclazide TabletDocument11 pagesProspective Process Validation of Gliclazide Tabletanandhra2010No ratings yet

- In Process Quality ControlDocument13 pagesIn Process Quality ControlnamhupNo ratings yet

- Quality KPIDocument4 pagesQuality KPIAdriana ANo ratings yet

- Process Validation of Polyherbal Cough Syrup FormulationDocument7 pagesProcess Validation of Polyherbal Cough Syrup FormulationBhavesh NayakNo ratings yet

- Quality Metrics and KpiDocument5 pagesQuality Metrics and Kpidilip das100% (2)

- Quality by Design (QBD) : A New Concept For Development of Quality PharmaceuticalsDocument7 pagesQuality by Design (QBD) : A New Concept For Development of Quality PharmaceuticalsVitalis MbuyaNo ratings yet

- KB002839-MRK1609-01 Pharma Manufac Set Effective SpecsDocument14 pagesKB002839-MRK1609-01 Pharma Manufac Set Effective SpecsMiguel Zuniga MarconiNo ratings yet

- Total Quality Management in Pharmaceuticals PDFDocument11 pagesTotal Quality Management in Pharmaceuticals PDFNarongchai PongpanNo ratings yet

- Implementation of QBD AQbD Approach in Pharmaceutical Formulation and Analytical Method Development A Comprehensive Research Review Ijariie18342 PDFDocument32 pagesImplementation of QBD AQbD Approach in Pharmaceutical Formulation and Analytical Method Development A Comprehensive Research Review Ijariie18342 PDFrbmoureNo ratings yet

- QBD in API ManufacturingDocument78 pagesQBD in API ManufacturingManivannan KathirvelNo ratings yet

- QBT To QBDDocument7 pagesQBT To QBDshelfinararaNo ratings yet

- Anoop 1Document23 pagesAnoop 1Akash YadavNo ratings yet

- Basic Concept of Process Validation in Solid Dosage Form (Tablet) : A ReviewDocument10 pagesBasic Concept of Process Validation in Solid Dosage Form (Tablet) : A Reviewqc jawaNo ratings yet

- Drug Designing, Discovery and Development Techniques: Elvis A. Martis and Rakesh R. SomaniDocument19 pagesDrug Designing, Discovery and Development Techniques: Elvis A. Martis and Rakesh R. SomanitahafeNo ratings yet

- Oxygen AdministrationDocument33 pagesOxygen AdministrationDiah Sukmawati Hidayah100% (1)

- Methylcobalamin and Diabetic NeuropathyDocument49 pagesMethylcobalamin and Diabetic NeuropathyNiko DiamesisNo ratings yet

- 5 Years High and Low PointsDocument7 pages5 Years High and Low PointsNaresh Kumar VishwakarmaNo ratings yet

- Pharmacology MnemonicsDocument26 pagesPharmacology MnemonicsArthur JamesNo ratings yet

- Madanaphala (Randia Dumetorum Lam.) : A Phyto-Pharmacological ReviewDocument9 pagesMadanaphala (Randia Dumetorum Lam.) : A Phyto-Pharmacological ReviewprasdNo ratings yet

- Gujarat Technological University: B.Pharm Semester: IiiDocument2 pagesGujarat Technological University: B.Pharm Semester: IiiSachin Narkhede100% (2)

- BHUIAMLAKIDocument28 pagesBHUIAMLAKIkuntaljuNo ratings yet

- Term Paper On Investment Management: Presented byDocument42 pagesTerm Paper On Investment Management: Presented byChinmoy Prasun GhoshNo ratings yet

- 1 PHA6120 IntroductionDocument86 pages1 PHA6120 Introductionchristian redotaNo ratings yet

- 01.07.2010 Lista MedicamenteDocument407 pages01.07.2010 Lista MedicamenteCATALINMARCUNo ratings yet

- Follow-Up Lto & CPRDocument1 pageFollow-Up Lto & CPRCharissa MillarNo ratings yet

- Pharmaceutical Calculation - Pacop BlueDocument31 pagesPharmaceutical Calculation - Pacop BlueSophia AndresNo ratings yet

- Pharmaceutical Solutions For Oral Administration-2 PDFDocument31 pagesPharmaceutical Solutions For Oral Administration-2 PDFHanaa Abo Sweirh100% (1)

- History TakingDocument67 pagesHistory TakingOluremi KehindeNo ratings yet

- Cor PulmonaleDocument62 pagesCor PulmonaleAlbert NixonNo ratings yet

- FHJP010R30 Pharmaceutical CCC Code of TaiwanDocument27 pagesFHJP010R30 Pharmaceutical CCC Code of TaiwanKhaw Seek ChuanNo ratings yet

- MFDocument380 pagesMFjayram 8080100% (1)

- History of EDTA Chelation Therapy-Michael Schachter 9-14-13 With Notes PDFDocument56 pagesHistory of EDTA Chelation Therapy-Michael Schachter 9-14-13 With Notes PDFMiro KasoNo ratings yet

- EmaDocument11 pagesEmans_ranaNo ratings yet

- 8-Drugs Used in Anxiety and Panic Disprder (Edited)Document8 pages8-Drugs Used in Anxiety and Panic Disprder (Edited)himanshukumar839496No ratings yet

- UNIT3 Communication in Drug Safety Crisis ManagementDocument4 pagesUNIT3 Communication in Drug Safety Crisis Managementworkvasudha18No ratings yet

- Clinical Pathway: Perhimpunan Dokter Spesialis Anestesiologi Dan Terapi Intensif Indonesia 2013Document43 pagesClinical Pathway: Perhimpunan Dokter Spesialis Anestesiologi Dan Terapi Intensif Indonesia 2013tar1195No ratings yet

- Medication Worksheets: Condition Medication Type Use Nutrition Interactions/Guidelines ExamplesDocument8 pagesMedication Worksheets: Condition Medication Type Use Nutrition Interactions/Guidelines ExamplesLupuleac ClaudiaNo ratings yet

- Compliance Program Guidance Manual Chapter - 45 Biological Drug Products Inspection of Biological Drug Products (CBER) 7345.848Document57 pagesCompliance Program Guidance Manual Chapter - 45 Biological Drug Products Inspection of Biological Drug Products (CBER) 7345.848ana_mondekarNo ratings yet

- India As The Heritage of Medicinal Plant and Their Use: Gangola S, Khati P, Bhatt P, Parul and Anita SharmaDocument2 pagesIndia As The Heritage of Medicinal Plant and Their Use: Gangola S, Khati P, Bhatt P, Parul and Anita SharmaSanjiv KubalNo ratings yet

- dm2016 0258Document2 pagesdm2016 0258Vincent John RigorNo ratings yet