Professional Documents

Culture Documents

Desemsamble de Freno

Uploaded by

Rogelio GonzalezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Desemsamble de Freno

Uploaded by

Rogelio GonzalezCopyright:

Available Formats

SERIES 50 SERVICE MANUAL

1.29.3 Disassembly of Jake Brake

Remove the control valve as follows:

To avoid personal injury, remove control valve covers

carefully. Control valve covers are under load from the

control valve springs.

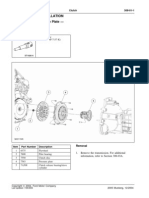

1. Press down on control valve washer using an appropriate diameter rod to relieve spring

pressure. See Figure 1-382a.

1. Jake Brake Assembly 3. Snap Ring Retainer

2. Spring 4. Snap Ring Pliers

Figure 1-382a Relieving Spring Pressure

2. Using retaining ring pliers, remove retaining ring.

All information subject to change without notice.

6SE50 9607 © 1998 DETROIT DIESEL CORPORATION From Bulletin 4-50-99 1-456a

1.29 JAKE BRAKE

3. Slowly remove cover until spring pressure ceases, then remove the two control valve springs

and collar. See Figure 1-382b.

1. Jake Brake Assembly 5. Washer

2. Control Valve 6. Collar Spring

3. Collar 7. Control Valve Spring

4. Snap Ring Retainer

Figure 1-382b Removing Control Valve Springs and Collar

4. Using needle-nose pliers, reach into the bore and grasp the stem of the control valve.

Remove control valve.

All information subject to change without notice.

1-456b From Bulletin 4-50-99 6SE50 9607 © 1998 DETROIT DIESEL CORPORATION

SERIES 50 SERVICE MANUAL

Remove the slave piston adjusting screw as follows:

1. Loosen slave piston adjusting screw locknut.

2. Remove adjusting screw from housing. See Figure 1-382c.

1. Jake Brake Assembly 2. Slave Piston Adjusting Screw

Figure 1-382c Removing Slave Piston Adjusting Screw

Remove the solenoid valve as follows:

NOTICE:

To avoid possible engine damage, do not disassemble or tamper

with the solenoid valve.

1. Disconnect solenoid valve harness.

2. Using a 7/8 in. socket and extension for former solenoids or a 3/4 in., 6 point socket and

extention for current solenoids, unscrew solenoid valve.

All information subject to change without notice.

6SE50 9607 © 1998 DETROIT DIESEL CORPORATION From Bulletin 4-50-99 1-456c

1.29 JAKE BRAKE

3. Remove and discard the three rubber seal rings. See Figure 1-382d.

1. Seal Rings (3) 2. Solenoid

Figure 1-382d Removing Rubber Seal Rings

4. If the lower ring stays in the bottom of the housing bore, remove with a piece of wire.

All information subject to change without notice.

1-456d From Bulletin 4-50-99 6SE50 9607 © 1998 DETROIT DIESEL CORPORATION

SERIES 50 SERVICE MANUAL

Remove the accumulator as follows:

The accumulator spring is under strong compression. To

avoid possible personal injury if the accumulator spring is

discharged, wear safety glasses and use caution when

removing the retaining ring and cover.

1. Push down on the accumulator cover using the appropriate diameter rod, and remove the

retaining ring. See Figure 1-382e.

1. Jake Brake Assembly 3. Retaining Ring Pliers

2. Retaining Ring

Figure 1-382e Removing Retaining Ring

2. Relieve pressure on the accumulator cover.

3. Remove the cover and spring.

All information subject to change without notice.

6SE50 9607 © 1998 DETROIT DIESEL CORPORATION From Bulletin 4-50-99 1-456e

1.29 JAKE BRAKE

4. Use a magnet to remove the piston from the accumulator bore. See Figure 1-382f.

1. Jake Brake Assembly 4. Retaining Ring

2. Piston 5. Washer

3. Spring

Figure 1-382f Removing Piston from Accumulator Bore with Magnet

All information subject to change without notice.

1-456f From Bulletin 4-50-99 6SE50 9607 © 1998 DETROIT DIESEL CORPORATION

SERIES 50 SERVICE MANUAL

Remove the master piston as follows:

1. Remove the screw, washer, and master piston spring from the housing.

2. Remove the master piston. See Figure 1-382g.

NOTE:

Use needle-nose pliers, if necessary.

1. Washer and Screw Assembly 3. Master Piston

2. Jake Brake Assembly 4. Master Piston Spring

Figure 1-382g Removing the Master Piston

All information subject to change without notice.

6SE50 9607 © 1998 DETROIT DIESEL CORPORATION From Bulletin 4-50-99 1-456g

1.29 JAKE BRAKE

Remove the slave piston as follows:

1. Remove the screw and washer that retains the slave piston return spring.

2. Remove the bridge and the slave piston. See Figure 1-382h.

1. Slave Piston Bridge 4. Return Spring

2. Jake Brake Housing 5. Washer

3. Slave Piston 6. Screw

Figure 1-382h Removing Bridge and Slave Piston

All information subject to change without notice.

1-456h From Bulletin 4-50-99 6SE50 9607 © 1998 DETROIT DIESEL CORPORATION

SERIES 50 SERVICE MANUAL

3. Loosen the leveling screw locknut and remove the leveling screw from the bridge.

See Figure 1-382i.

1. Slave Piston Bridge 2. Slave Piston Leveling Screw

Figure 1-382i Removing the Leveling Screw from the Bridge

1.29.3.1 Cleaning of Jake Brake

Clean the Jake Brake as follows:

NOTE:

Use an OSHA-approved cleaning solvent when washing parts. Be sure to coat parts

with clean engine oil when reinstalling them.

1. Wash the control valves with approved cleaning solvent.

2. Push a wire through the hole in the base of the valve to the distance required to ensure

that the ball check is free.

NOTE:

The ball should lift with light pressure on the wire.

All information subject to change without notice.

6SE50 9607 © 1998 DETROIT DIESEL CORPORATION From Bulletin 4-50-99 1-456i

1.29 JAKE BRAKE

To prevent possible personal injury when using compressed

air, wear adequate eye protection (face plate or safety

glasses) and do not exceed 40 psi (276 kPa) air pressure.

3. Dry the valve with compressed air, and wipe clean with a paper towel.

4. Thoroughly clean the control valve bore in the housing using clean paper towels.

5. Clean slave piston adjusting screw in an approved cleaning solvent.

NOTICE:

Use clean paper towels to clean the solenoid valve bore. Never

use rags, as they may leave lint and residue which can plug the

oil passageways, causing Jake Brake malfunction.

6. Clean out the solenoid valve bore in the housing.

7. Use a brush to clean the oil screen.

8. Rinse the solenoid valve in cleaning solvent.

9. Clean the master piston in approved cleaning solvent.

1.29.3.2 Inspection of Jake Brake

The Jacobs engine brake is typically a trouble-free device. However, inspections are necessary

and some maintenance is required. Use the following procedures to keep the engine brake in

top condition.

Inspect the Jake Brake as follows:

1. Inspect slave piston adjusting screw for protrusion, spring pressure and freedom

of movement.

NOTE:

The plunger should protrude from the bottom of the screw, have light spring pressure

apparent when depressed, and move freely.

[a] If the plunger does not protrude, the spring does not have light pressure or does not

move freely, replace the entire screw assembly. Refer to Section 1.29.4.

[b] If the slave piston adjusting screw meets specifications, continue with inspection.

All information subject to change without notice.

1-456j From Bulletin 4-50-99 6SE50 9607 © 1998 DETROIT DIESEL CORPORATION

SERIES 50 SERVICE MANUAL

2. Inspect the accumulator for wear or damage.

[a] If worn or damaged, replace the accumulator. Refer to Section 1.29.4.

[b] If accumulator is not worn or damaged, continue with inspection.

3. Inspect the master piston bore for wear or damage.

NOTE:

Some wear marks are permissible.

[a] If worn or damaged, replace the master piston. Refer to Section 1.29.4.

[b] If not worn or damaged, continue with inspection.

4. Apply clean lube oil to the piston, and insert into bore.

NOTE:

Master piston should move in and out freely with no binding.

[a] If binding occurs, replace master piston and/or housing. Refer to Section 1.29.4.

[b] If no binding occurs, continue with inspection.

5. Inspect master piston spring for relaxation.

NOTE:

The spring should hold the master piston completely in the housing.

[a] If relaxed, replace the spring. Refer to Section 1.29.4.

[b] If spring holds tightly, continue with inspection.

6. Inspect slave piston components for excessive wear or damage.

[a] If worn or damaged, replace slave piston component.

[b] If not worn or damaged, proceed with inspection.

1.29.3.3 Inspection of Control Valve

Inspect the control valve as follows:

1. Dip the control valves in clean lube oil.

2. Holding the control valve by the stem, let it drop into the bore.

[a] If binding occurs or if the ball sticks in the valve, replace the control valve.

Refer to Section 1.29.4.

[b] If no binding occurs and the ball does not stick in the control valve, assemble the

Jake Brake. Refer to Section 1.29.4.

All information subject to change without notice.

6SE50 9607 © 1998 DETROIT DIESEL CORPORATION From Bulletin 4-50-99 1-456k

1.29 JAKE BRAKE

1.29.4 Assembly of Jake Brake

Install the control valve as follows:

1. Slip the control valve into the bore. See Figure 1-382j.

1. Jake Brake Assembly 5. Washer

2. Control Valve 6. Collar Spring

3. Collar 7. Control Valve Spring

4. Snap Ring Retainer

Figure 1-382j Installing the Control Valve

2. Install the control valve collar and two springs.

NOTE:

Ensure the collar is installed with the longer sleeve area facing up. If the collar is

installed upside down, the engine brake cylinder will not operate.

3. Press the cover (washer) into place.

4. While holding the cover tightly in place, install the retaining ring.

5. Rotate retaining ring ears 90° to assure ring is seated in groove.

All information subject to change without notice.

1-456l From Bulletin 4-50-99 6SE50 9607 © 1998 DETROIT DIESEL CORPORATION

SERIES 50 SERVICE MANUAL

Install the slave piston adjusting screw as follows:

1. Place the screw in the housing. See Figure 1-382k.

1. Jake Brake Assembly 2. Slave Piston Adjusting Screw

Figure 1-382k Installing the Slave Piston Adjusting Screw

2. Do not torque the slave piston adjusting screw locknut at this time.

Install the solenoid valve as follows:

NOTE:

As of October 19, 1997, former solenoids have been replaced with the current improved

solenoids. The current solenoids have an increased installation torque and improved

durability. The current solenoid is interchangeable with the former.

1. Coat new solenoid valve seal rings with clean lube oil.

NOTE:

Use current upper seals when installing current solenoids. New seals are identified with

yellow stripes.

All information subject to change without notice.

6SE50 9607 © 1998 DETROIT DIESEL CORPORATION From Bulletin 4-50-99 1-456m

1.29 JAKE BRAKE

2. Install the upper and center seal rings on the solenoid valve body and the lower seal ring into

the bottom of the bore in the housing. See Figure 1 382l.

1. Seal Rings (3) 2. Solenoid

Figure 1-382l Installation of Solenoid Valve Seal Rings

3. Make sure the seals are seated properly.

4. Using a 7/8 in. socket and extension for former solenoids or a 3/4 in., 6 point socket and

extension for current solenoids, carefully screw the solenoid valve into the housing

without unseating the seals.

5. Torque the former solenoid to 12.4 N·m (9 lb·ft). Torque the current solenoid to

20 N·m (15 lb·ft.)

NOTE:

Be careful not to twist the seals while installing.

Install the accumulator as follows:

1. Place the piston into the accumulator bore.

2. Insert the spring, and install the cover.

3. Push down the accumulator cover, and insert retaining ring.

All information subject to change without notice.

1-456n From Bulletin 4-50-99 6SE50 9607 © 1998 DETROIT DIESEL CORPORATION

SERIES 50 SERVICE MANUAL

Install the master piston as follows:

1. Apply clean lube oil to the piston.

2. Insert master piston into bore.See Figure 1-382m.

1. Washer and Screw Assembly 3. Master Piston

2. Jake Brake Assembly 4. Master Piston Spring

Figure 1-382m Inserting Master Piston into Bore

3. Install spring, washer, and screw.

NOTE:

Make sure spring legs are centered around master piston boss.

4. Torque screw to 10 N·m (7.4 lb·ft).

All information subject to change without notice.

6SE50 9607 © 1998 DETROIT DIESEL CORPORATION From Bulletin 4-50-99 1-456o

1.29 JAKE BRAKE

Install the slave piston as follows:

1. Install the screw from the slave piston side of the bridge.

2. Install the leveling screw locknut.

3. Install the bridge with the leveling screw toward the center of the housing.

See Figure 1-382n.

1. Washer 4. Bridge Assembly

2. Screw 5. Jake Brake Housing

3. Torsion Spring

Figure 1-382n Installing Bridge with Leveling Screw Toward Center of Housing

All information subject to change without notice.

1-456p From Bulletin 4-50-99 6SE50 9607 © 1998 DETROIT DIESEL CORPORATION

SERIES 50 SERVICE MANUAL

4. Install the slave piston assembly torsion spring with the ends over the bridge.

See Figure 1-382o.

Figure 1-382o Installing the Slave Piston Assembly Torsion Spring

5. Install the screw over the center part of the spring.

NOTICE:

While tightening the screw on the torsion spring, push the spring

toward the slave piston assembly. Failure to do so may result in

contact between the intake valve adjusting screw and torsion

spring. Serious engine damage may result.

6. Torque the screw to 20 N·m (15 lb·ft.).

All information subject to change without notice.

6SE50 9607 © 1998 DETROIT DIESEL CORPORATION From Bulletin 4-50-99 1-456q

1.29 JAKE BRAKE

1.29.5 Installation of Jake Brake

Install the Jake Brake as follows:

1. Adjust the intake and exhaust valve clearances and set the injector heights.

Refer to section 12.2.

To prevent possible personal injury when using compressed

air, wear adequate eye protection (face plate or safety

glasses) and do not exceed 40 psi (276 kPa) air pressure.

2. Attach the length of tubing to a blow gun nozzle, and blow out the oil from the bolt holes.

3. Cover the holes with hand towels to minimize oil spray.

NOTE:

Removing the oil from the bolt holes prevents the cylinder head from cracking when

tightening the bolts.

All information subject to change without notice.

1-456r From Bulletin 4-50-99 6SE50 9607 © 1998 DETROIT DIESEL CORPORATION

SERIES 50 SERVICE MANUAL

4. Place the spacer bar on the exhaust manifold side of the cylinder head with the center notch

facing the exhaust manifold. See Figure 1-382p.

Figure 1-382p Location of Spacer Bar

5. Place the two engine brake housings over the rocker shafts with the solenoid valves

toward the camshaft side of the engine.

NOTE:

Be sure housings do not interfere with wiring harness.

All information subject to change without notice.

6SE50 9607 © 1998 DETROIT DIESEL CORPORATION From Bulletin 4-50-99 1-456s

1.29 JAKE BRAKE

NOTICE:

Do not mix the rocker arm shaft bolts and the Jake Brake

mounting bolts. If the rocker arm shaft bolt is mistakenly used to

mount the Jake Brake housing, the longer shoulder on the bolt will

block the oil supply to the Jake Brake on the camshaft side of the

housing. The brake will not retard the engine as designed. This

condition could cause loss of vehicle braking control on

downgrades, which may create a risk of personal injury to the

vehicle operator or other persons and damage to the vehicle or

property of others.

NOTE:

The rocker arm shaft mounting bolt and Jake Brake mounting bolt, part of the Jake

Brake assembly, are similar in appearance. Both are M12 x 110 mm (4.33 in.) long and

have 12 point heads.

NOTE:

In the event of a housing hold down bolt failure on a Jacobs engine brake housing,

replace all bolts on that particular housing.

NOTICE:

Use bolts that have the Jacobs logo, circled "J". Installation of

bolts that do not have the circled "J" may result in damage to the

engine, engine brake or both.

[a] The Jake Brake bolt has the Jacobs logo (circled "J") and the letters "EF" marked on

the head. The bolt length is no longer marked atop the bolt head.

[b] The DDC rocker arm shaft bolt has the DDC logo (spinning arrows) and the vendor

I.D. (F-C) on its head.

NOTE:

Be sure that only Jake Brake bolts, see Figure 1-382q, are installed in the

Jake Brake housing.

All information subject to change without notice.

1-456t From Bulletin 4-50-99 6SE50 9607 © 1998 DETROIT DIESEL CORPORATION

SERIES 50 SERVICE MANUAL

[c] The DDC bolt shoulder is much longer, 17.0 mm (.669 in.) versus 4 mm (.157 in.) than

the Jake Brake bolt. See Figure 1-382q.

Figure 1-382q Jake Brake and DDC Bolt Identification

NOTE:

All the housing mounting bolts for models 750, 750A and 750B are the same length.

6. Install a washer on each bolt, and install into housings (three bolts per housing).

All information subject to change without notice.

6SE50 9607 © 1998 DETROIT DIESEL CORPORATION From Bulletin 4-50-99 1-456u

1.29 JAKE BRAKE

7. Move the housing from side to side. For models 750 and 750B locate the housing in the center

position of the movement. For model 750A locate the housing as far towards the camshaft

side of the engine as possible. See Figure 1-382r.

Figure 1-382r Locating Center Position of Housing

8. Torque the engine brake mounting bolts using the following sequence:

[a] Torque the two bolts on the camshaft side of the engine to 55 N·m (40 lb·ft).

[b] Torque the four bolts on the exhaust manifold side of the engine to 55 N·m (40 lb·ft).

[c] Repeat the tightening sequence and re-torque all bolts to 136 N·m (100 lb·ft).

[d] Check the torque to 136 N·m (100 lb·ft).

9. Secure wire harness to spacer bars with plastic ties.

10. Connect wiring harness solenoid connectors to solenoids.

All information subject to change without notice.

1-456v From Bulletin 4-50-99 6SE50 9607 © 1998 DETROIT DIESEL CORPORATION

SERIES 50 SERVICE MANUAL

1.29.5.1 Adjustment of Slave Piston

Make the following adjustment with the engine stopped and cold, and the oil temperature at

60°C (140°F) or below. The exhaust valves on the cylinder must be in the closed position (rocker

arm roller on the base circle of the camshaft). When setting the engine brake lash, the exhaust

valves must be in the closed position.

Adjust the slave piston on all models as follows:

NOTICE:

This application and adjustment information must be strictly

followed. Failure to follow these instructions may result in serious

engine or engine brake damage.

NOTE:

Model 750B Jacobs engine brake requires a special procedure for adjusting the slave

piston. The procedure is clearly indicated in the following adjustment steps.

NOTICE:

Improper slave piston adjustment can result in engine or brake

housing damage.

NOTICE:

Strictly follow the slave piston adjustment procedure. Failure to

use the proper adjustment procedure will result in poor engine

brake performance and/or serious engine damage.

1. Refer to section 1.29 for proper slave piston clearance setting.

All information subject to change without notice.

6SE50 9607 © 1998 DETROIT DIESEL CORPORATION From Bulletin 4-50-99 1-456w

1.29 JAKE BRAKE

2. Back out the leveling screw in the slave piston assembly until the end of the screw is beneath

the surface of the bridge in the slave piston assembly. See Figure 1-382s.

NOTE:

The leveling screw is located in the bridge member of the slave piston assembly.

1. Locknut 2. Leveling Screw

Figure 1-382s Location of Leveling Screw

3. Place the correct size feeler gage between the solid side of the slave piston

(the side without the leveling screw) and the exhaust rocker arm adjusting screw.

Refer to section 1.29 for proper feeler gage sizes.

All information subject to change without notice.

1-456x From Bulletin 4-50-99 6SE50 9607 © 1998 DETROIT DIESEL CORPORATION

SERIES 50 SERVICE MANUAL

4. Turn the slave piston adjusting screw clockwise until a slight drag is felt on the feeler gage.

See Figure 1-382t.

1. Slave Piston Bridge 3. Feeler Gage

2. Slave Piston Adjusting Screw

Figure 1-382t Turn Slave Piston Adjusting Screw Clockwise

5. Perform the following additional steps on model 750B:

[a] Turn in the J-Lash® adjusting screw until the solid side of the slave piston bridge

assembly contacts the exhaust valve and the valve springs begin to compress. Turn

in one additional turn.

NOTICE:

Oil must be purged from the J-Lash adjusting screw. Oil

remaining in the J-Lash screw will cause inaccurate clearance

adjustment, resulting in possible engine or engine brake damage.

If oil is below room temperature (below 60° F), wait at least two

minutes for oil to be purged from the J-Lash adjusting screw.

NOTE:

Wait at least 30 seconds for oil to be purged from the J-Lash adjusting screw.

[b] Back out the adjusting screw only until the correct size feeler gage can be inserted

between the solid side of the slave piston bridge assembly and the exhaust valve.

All information subject to change without notice.

6SE50 9607 © 1998 DETROIT DIESEL CORPORATION From Bulletin 4-50-99 1-456y

1.29 JAKE BRAKE

[c] Adjust the J-Lash so that a light drag is felt on the feeler gage.

NOTE:

Do not back out the J-Lash more than required to obtain a light drag on the feeler gage.

[d] Use a screwdriver to hold the J-Lash in place, and torque the lock nut to

34 N·m (25 lb·ft).

NOTE:

If the J-Lash screw is backed out until it no longer compresses the slave piston spring,

oil will enter the screw and the adjustment will be incorrect. If this occurs, repeat the

J-Lash adjustment procedure.

[e] Recheck the lash settings. If clearance setting is incorrect, repeat the J-Lash

adjustment procedure.

NOTE:

Once the engine brake has been run, oil enters the J-Lash screw making the engine

brake adjustment unreadable. If unsure of the adjustment, repeat the J-Lash adjustment

procedure.

6. Hold the screw in position, and torque the locknut to 35 N·m (26 lb·ft).

7. Check the adjustment, and repeat if necessary.

NOTE:

Do not disassemble the slave piston adjusting screws.

8. Place the correct feeler gage between the leveling screw and the rocker arm

adjusting screw.

All information subject to change without notice.

1-456z From Bulletin 4-50-99 6SE50 9607 © 1998 DETROIT DIESEL CORPORATION

SERIES 50 SERVICE MANUAL

9. Turn the leveling screw clockwise until a slight drag is felt on the feeler gage.

See Figure 1-382u.

1. Feeler Gage 3. Rocker Arm Adjusting Screw

2. Slave Piston Leveling Screw

Figure 1-382u Setting Clearance on Leveling Screw and Rocker Arm

Adjusting Screw

10. Hold the leveling screw in position, and torque the locknut to 47 N·m (35 lb·ft).

11. Check adjustment, and repeat if necessary.

All information subject to change without notice.

6SE50 9607 © 1998 DETROIT DIESEL CORPORATION From Bulletin 4-50-99 1-456aa

1.29 JAKE BRAKE

12.Repeat the adjustment procedures for the remaining cylinders. Refer to step 2.

It is possible that the engine could start when barring over

the engine or "bumping" the starter. To avoid personal

injury, keep hands and clothing away from the engine when

barring over the engine or "bumping" the starter.

NOTE:

Bar over the engine when necessary to place the exhaust valves in the closed position

for slave piston adjustment.

13. Install the engine rocker cover. Refer to section 1.6.2.

14. Install all remaining components that were removed for this procedure.

15. Connect starting power for the engine.

16. Verify proper Jake Brake installation by driving the vehicle, then checking engine

brake performance.

All information subject to change without notice.

1-456bb From Bulletin 4-50-99 6SE50 9607 © 1998 DETROIT DIESEL CORPORATION

You might also like

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Steering System: DescriptionDocument18 pagesSteering System: DescriptionNoe CuandonNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Service Manual SM1-2-24.0: Front Axle, R & IDocument4 pagesService Manual SM1-2-24.0: Front Axle, R & IMohamed RashedNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Clutch ManualDocument16 pagesClutch ManualCO BDNo ratings yet

- Clutch 4Document2 pagesClutch 4api-3710514No ratings yet

- Section 10 - Power Take-OffDocument19 pagesSection 10 - Power Take-OffMiller Andres ArocaNo ratings yet

- Remove Injection Pump c4. 4 SN s1mDocument2 pagesRemove Injection Pump c4. 4 SN s1mBadrus AqmarNo ratings yet

- Manual Terex # 55 (Iguana) - 2Document26 pagesManual Terex # 55 (Iguana) - 2Victor Manuel riveraNo ratings yet

- 1gr Fe - Cadena de DistribucionDocument5 pages1gr Fe - Cadena de DistribucionMartin KoopmannNo ratings yet

- Series 60 Crank Seal11-60-04aDocument22 pagesSeries 60 Crank Seal11-60-04aKeyser SözeNo ratings yet

- Hyundai Kia D4EB Timing Belt ServiceDocument6 pagesHyundai Kia D4EB Timing Belt Servicekaliman78alfa100% (2)

- Tilt Cylinders PDFDocument12 pagesTilt Cylinders PDFamineNo ratings yet

- Exhaust Valve Actuator: S35MC DataDocument6 pagesExhaust Valve Actuator: S35MC DatalijinNo ratings yet

- 1SV34Document20 pages1SV34yasith madhukaNo ratings yet

- Cylinder Head Gasket - Installation (01 - 2010 - ) (Cylinder Head Assembly) - ALLDATA Repair Toyota Camry 2.5LtsDocument17 pagesCylinder Head Gasket - Installation (01 - 2010 - ) (Cylinder Head Assembly) - ALLDATA Repair Toyota Camry 2.5LtsFran SanchezNo ratings yet

- Detroit Series 60 Service Manual - Vibratoare Seismice - 19-60-00aDocument20 pagesDetroit Series 60 Service Manual - Vibratoare Seismice - 19-60-00anguynthanhlongNo ratings yet

- Tier 4 I E E A I Manual C4.4 To C 7.1 Industrial Products TPD1726E1Document29 pagesTier 4 I E E A I Manual C4.4 To C 7.1 Industrial Products TPD1726E1EduardoCastilloNo ratings yet

- C6.6 Cam Shaft InstallDocument5 pagesC6.6 Cam Shaft InstallsenNo ratings yet

- (TM) Ford Manual de Taller Ford Super Duty 2007 2008 en InglesDocument747 pages(TM) Ford Manual de Taller Ford Super Duty 2007 2008 en Inglesjuan carlos delgadoNo ratings yet

- 904 RebuidDocument7 pages904 RebuidDaniel WildNo ratings yet

- Service BulletinDocument12 pagesService BulletinEdward Adrian Moreno FernandezNo ratings yet

- Cummins Ism QSM PDFDocument11 pagesCummins Ism QSM PDFEng-AhmedRashadNo ratings yet

- Cummins Ism, QSMDocument11 pagesCummins Ism, QSMibnu67% (6)

- Fuel Injection Pump Remove DelphiDocument4 pagesFuel Injection Pump Remove DelphiKhalid El SabroutyNo ratings yet

- Culata Motor 3406Document3 pagesCulata Motor 3406Julio GuillenNo ratings yet

- 330C L Excavator - 9 Engine PDFDocument26 pages330C L Excavator - 9 Engine PDFRICHARDNo ratings yet

- Crankshaft Oil 2 PDFDocument2 pagesCrankshaft Oil 2 PDFvictoverNo ratings yet

- Toyota Starlet 4K 1983Document20 pagesToyota Starlet 4K 1983David Emmanuel Turcios CarrilloNo ratings yet

- 2100103-Tilt CylindersDocument17 pages2100103-Tilt CylindersFrancisco DiazNo ratings yet

- SKL Main Bearing ProcedureDocument11 pagesSKL Main Bearing ProcedureVaibhav SinghalNo ratings yet

- 07 2984BDocument22 pages07 2984BCHARLES HUMBERTO0% (1)

- Fuel SistemDocument55 pagesFuel SistemRodolfo AlbertoNo ratings yet

- Bypass Check ValveDocument2 pagesBypass Check Valvealsief1951No ratings yet

- Ati Manual Reverse Valve BodyDocument4 pagesAti Manual Reverse Valve BodyPaul OfsthunNo ratings yet

- Poner A Tiempo ContourDocument4 pagesPoner A Tiempo ContourJuan Carlos Nuñez CastilloNo ratings yet

- Camry Solara SEV6Document13 pagesCamry Solara SEV6arturmikieNo ratings yet

- Steel Piston PDFDocument14 pagesSteel Piston PDFvictoverNo ratings yet

- 700R4 Manual Reverse Valve Body: Installation InstructionsDocument4 pages700R4 Manual Reverse Valve Body: Installation InstructionsAbbode HoraniNo ratings yet

- Description: Steering SystemDocument18 pagesDescription: Steering Systemdiego diazNo ratings yet

- DD15 Detroit DieselDocument10 pagesDD15 Detroit Dieselstarsky100% (4)

- YD25 Engine MechDocument35 pagesYD25 Engine MechAlex Hernandez100% (2)

- 001-016 Crankshaft: Preparatory StepsDocument28 pages001-016 Crankshaft: Preparatory StepsWaad HarbNo ratings yet

- Unidad de Giro (Orbitrol)Document15 pagesUnidad de Giro (Orbitrol)Francisco CortezNo ratings yet

- Caterpillar Cat 236D SKID STEER LOADER (Prefix MPW) Service Repair Manual (MPW00001 and Up)Document21 pagesCaterpillar Cat 236D SKID STEER LOADER (Prefix MPW) Service Repair Manual (MPW00001 and Up)rpoy9396615No ratings yet

- Rocker Shaft and Push Rods - InstallDocument5 pagesRocker Shaft and Push Rods - InstallRajan MullappillyNo ratings yet

- Manitou Tower ServiceDocument35 pagesManitou Tower ServiceKélio Wolfrane Santos MachadoNo ratings yet

- Mazda Fe y f2Document27 pagesMazda Fe y f2Nicolás CastroNo ratings yet

- Caterpillar Cat 330B L EXCAVATOR (Prefix 1JS) Service Repair Manual (1JS00001 and Up)Document26 pagesCaterpillar Cat 330B L EXCAVATOR (Prefix 1JS) Service Repair Manual (1JS00001 and Up)kfm8seuuduNo ratings yet

- Sincronizacion de Motores Ssangyong d20dt d27dt PDFDocument4 pagesSincronizacion de Motores Ssangyong d20dt d27dt PDFMynor WittNo ratings yet

- Sincronizacion de Motores Ssangyong d20dt d27dtDocument4 pagesSincronizacion de Motores Ssangyong d20dt d27dtMynor Witt100% (4)

- 8005Document14 pages8005Renato Assis da SilvaNo ratings yet

- Section 8005: Removal and Installation of The Attachement CylindersDocument14 pagesSection 8005: Removal and Installation of The Attachement CylindersJefferson PaixãoNo ratings yet

- Epa07 Mbe 900 Workshop Manual (Ddc-Svc-Man-0034)Document155 pagesEpa07 Mbe 900 Workshop Manual (Ddc-Svc-Man-0034)Jose Amador Guardado100% (3)

- Camry Solara SLEV6Document13 pagesCamry Solara SLEV6arturmikieNo ratings yet

- Cylinder Head Assembly: Service and Repair Removal and InstallationDocument2 pagesCylinder Head Assembly: Service and Repair Removal and InstallationJose Pichinte100% (1)

- 008 - Automatic Transmission - 6T40 (MH8 MHH) - Repair Instructions - Off VehicleDocument82 pages008 - Automatic Transmission - 6T40 (MH8 MHH) - Repair Instructions - Off VehicleGedas GvildysNo ratings yet

- 1.29 Jake Brake: Figure 1-378 Nameplate Location On HousingDocument8 pages1.29 Jake Brake: Figure 1-378 Nameplate Location On HousingRogelio GonzalezNo ratings yet

- Harley-Davidson Custom Hand Lever KitDocument3 pagesHarley-Davidson Custom Hand Lever KitelvisandmickNo ratings yet

- Event MCQDocument9 pagesEvent MCQpralay ganguly50% (2)

- Research On Surface Roughness by Laser CDocument5 pagesResearch On Surface Roughness by Laser CfatmirhusejniNo ratings yet

- La Naval Drug Co Vs CA G R No 103200Document2 pagesLa Naval Drug Co Vs CA G R No 103200UE LawNo ratings yet

- Analisis Dan Perbandingan Jaringan Wifi Dengan Frekuensi 2.4 GHZ Dan 5 GHZ Dengan Metode QosDocument19 pagesAnalisis Dan Perbandingan Jaringan Wifi Dengan Frekuensi 2.4 GHZ Dan 5 GHZ Dengan Metode QosNoltujuh Nollapan (Congyang)No ratings yet

- Detroit ManualDocument435 pagesDetroit Manualvictorhernandezrega50% (2)

- SecureCore Datasheet V2Document2 pagesSecureCore Datasheet V2chepogaviriaf83No ratings yet

- Invidis Yearbook 2019Document51 pagesInvidis Yearbook 2019Luis SanchezNo ratings yet

- How To Configure VFD - General - Guides & How-Tos - CoreELEC ForumsDocument13 pagesHow To Configure VFD - General - Guides & How-Tos - CoreELEC ForumsJemerald MagtanongNo ratings yet

- Branding HS TalksDocument17 pagesBranding HS TalksumairNo ratings yet

- Guest AccountingDocument8 pagesGuest Accountingjhen01gongonNo ratings yet

- Schema Elctrica Placa Baza Toshiba A500-13wDocument49 pagesSchema Elctrica Placa Baza Toshiba A500-13wnicmaxxusNo ratings yet

- Sowk-625 Iq Tool 4Document22 pagesSowk-625 Iq Tool 4api-405320544No ratings yet

- (The Nineteenth Century Series) Grace Moore - Dickens and Empire - Discourses of Class, Race and Colonialism in The Works of Charles Dickens-Routledge (2004) PDFDocument223 pages(The Nineteenth Century Series) Grace Moore - Dickens and Empire - Discourses of Class, Race and Colonialism in The Works of Charles Dickens-Routledge (2004) PDFJesica LengaNo ratings yet

- Functions and Uses of CCTV CameraDocument42 pagesFunctions and Uses of CCTV CameraMojere GuardiarioNo ratings yet

- Virtual Machine Functionalism (VMF)Document52 pagesVirtual Machine Functionalism (VMF)Cássia SiqueiraNo ratings yet

- Morales v. Lockheed Martin, 10th Cir. (2000)Document2 pagesMorales v. Lockheed Martin, 10th Cir. (2000)Scribd Government DocsNo ratings yet

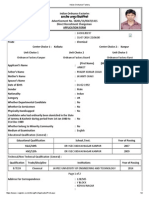

- Indian Ordnance FactoryDocument2 pagesIndian Ordnance FactoryAniket ChakiNo ratings yet

- Tamil Nadu Industrial Establishments (Conferment of Permanent Status To Workman Act, 1981Document12 pagesTamil Nadu Industrial Establishments (Conferment of Permanent Status To Workman Act, 1981Latest Laws TeamNo ratings yet

- JKR SPJ 1988 Standard Specification of Road Works - Section 1 - GeneralDocument270 pagesJKR SPJ 1988 Standard Specification of Road Works - Section 1 - GeneralYamie Rozman100% (1)

- Point of View Task CardsDocument7 pagesPoint of View Task Cardsapi-660227300No ratings yet

- Introduction To Content AnalysisDocument10 pagesIntroduction To Content AnalysisfelixNo ratings yet

- HANA Heroes 1 - EWM Lessons Learned (V2)Document40 pagesHANA Heroes 1 - EWM Lessons Learned (V2)Larissa MaiaNo ratings yet

- D.E.I Technical College, Dayalbagh Agra 5 III Semester Electrical Engg. Electrical Circuits and Measurements Question Bank Unit 1Document5 pagesD.E.I Technical College, Dayalbagh Agra 5 III Semester Electrical Engg. Electrical Circuits and Measurements Question Bank Unit 1Pritam Kumar Singh100% (1)

- Memorandum of AgreementDocument6 pagesMemorandum of AgreementJomar JaymeNo ratings yet

- CH7Document34 pagesCH7Abdul AzizNo ratings yet

- List of Newly and Migrated Programs For September 2022 - WebsiteDocument21 pagesList of Newly and Migrated Programs For September 2022 - WebsiteRMG REPAIRNo ratings yet

- Review of Financial Statements and Its Analysis: Rheena B. Delos Santos BSBA-1A (FM2)Document12 pagesReview of Financial Statements and Its Analysis: Rheena B. Delos Santos BSBA-1A (FM2)RHIAN B.No ratings yet

- SecuritizationDocument46 pagesSecuritizationHitesh MoreNo ratings yet

- Teacher Planner 2023 PDFDocument52 pagesTeacher Planner 2023 PDFitaNo ratings yet