Professional Documents

Culture Documents

CMP Fuso 2008

Uploaded by

Alex Hernandez0 ratings0% found this document useful (0 votes)

10 views6 pagesOriginal Title

Cmp Fuso 2008

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views6 pagesCMP Fuso 2008

Uploaded by

Alex HernandezCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

13EA\

[Fault code]

Diagnosis code: PO340/Flash code: 12

[Monitor]

Failure of cylinder recognition sensor

[Fault (outline)]

No pulse check

Diagnosis check]

+ Output pulses from engine speed sensor are counted to check pulse output from cylinder recognition sensor dur-

ing engine operation

[Code generation condition]

*+ No pulse is output from cylinder recognition sensor despite more than 132 pulses from engine speed sensor at

engine start. (Waring lamp is lit and diagnosis code is displayed on frst establishment of code generation condi-

tion.)

[Diagnosis check timing]

+ Fault diagnosis is performed only once during the driving cycle.

[Diagnostic requirement]

+ Starter switch: ON

+ Engine speed: more than 20 rpm

[Control effected by electronic control unit during fault]

+ Control is effected with engine speed sensor only

+ Misfire detection is stopped

+ Auto cruise control stopped

+ Related fault check is stopped.

[Probable cause of trouble]

+ Open-circuit or short-circuit of harness between electronic control unit and engine speed sensor

+ Malfunction of each connector

‘+ Malfunction of sensor

+ Malfunction of electronic control unit

[Recoverability]

+ Recovered if signal becomes normal with starter switch in ON position.

(Warning lamp is extinguished and diagnosis code is cleared at fourth display of diagnosis code after recovery.)

13EA-339

TROUBLESHOOTING

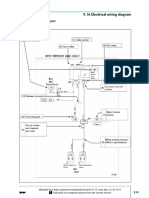

[Electronic Control Unit Connection Diagram]

GE96A When measured from connection side of conngetor

When measured from back side

of connector

‘When measured from connection side

Pros491€

13EA-340

13EA\

Parts Identification and Location]

Engine electronic control unit,

Sxaro)

Tt

Cylinder recogrition sensor

1036196

13EA-341

TROUBLESHOOTING

[Fault diagnosis]

+ Perform checks in the sequence of the following steps.

Inspection items

Inspection by control data

Maintenance tem

‘

+ “Measure item *Ne"

+ Measure item No. 01 "Engine Revolution’ of Service Data.

Step 1

P " Tinspection condition

Requirements

‘Same indication as tachometer is given

inspection resuk (the judg” | YES. [Go to transient fault (See Gr00),

ing standard satisfied?) NO [Goto step?

Inspection tems Inspection by electron contol unl connector eignal)

tenance item ‘Measure value of voltage between connector (GE96A) terminal No. 69 ()

Maintenance ite era

> Measure from back side of connector ofhamess with each device con-

‘step 2 [Inspection condition nected to hamess

+ Starter switch ON

Requirements TVormere

Inspection result (Is the judg- | _YES | Goto step 6.

ing standard satisfied?) NO_[Goto steps,

Inspection fem Inspection by electronic contol unl connector (power suppl)

Maintenance te ‘Measure value of voltage between connector (GE96A) terminal No. 78 ()

aitenance item Measure v

* Measure from back side of connector of harness wih each device oon

Step 3 |!nspection coneltion nected to hamess

+ Sharer switch: ON

Requirements 7

Inspection result isthe judge |_YES [Goto step 4

ing standard satisfied?) NO |Get step 6

inspection tems inspection by electronic contol uni connector (ground)

Maintenance tem “Measure value of volage between connector (GEQBA) terminal No. 83 (#)

and 53 (-).

> Measure from back side of connector of harness with each device con-

Step 4 | Inspection condition nected to hamess

+ Starter switch: ON

Requirements ov

Inspection result (Is the judg |_YES | Go to step 6.

ing standard satisfied?) NO [Goto stop 5:

Inspection tems Inspection of elecronie contol unit connector

Maintenance tem Inspection of connector

inspection condition =

5 > Gonnedor is properly connected

St60 5 | cuirements + No trace of water entry is found

a + No corrosion is found in terminal.

+ Connection to terminal appropriate.

Inspection result isthe judg- | YES [Goto step 12

ing standard satisfied?) NO [Mosily connector.

13EA-342

13EA\

Inspection items

Inspection of sensor connector

Maintenance fem

Tnspection of connector

Inspection condition

Connector is properly connected

step 6 + No trace of water entry is found

Requirements * No corrosion is found in terminal.

+ Connection to terminal's appropriate

Inspection result (ls the judg- |_YES | Go to step 7.

ing standard saisted?) NO _ | Modify connector.

inspection ems inspedion of sensor anit

Maintenance tem Measure value of resistance between connector terminal No. F and

Ingpection condtion =

step 7

Requirements 20010 1800.8

Inspection result (Is the judg- | YES [Goto step 6.

ing standard satisfied?) NO | Replacement of sensor

“Slap 7 inspection dagran>

1

oesv aio ata

seas

Tapeclon tome Trapecton of hamess between electronic contol nil and sensor (power sup-

Inspection i bsp

‘vanionance hem ear vaso vege Powe seen cones eialNa 7) a2

step 8 [panocion oonaon + Remove connector and measure fom hamess sie.

? 8 | Inspection condita + Starter switch: ON

Requirements av

Inspection resi (ste jdg- | YES_[Goto step 10,

ing standard satisfied?) NO TGotoseps

vnapocion tome Trepecton of hamess between electronic contol uni and sensor (power sup-

aly)

‘Check arcu between sensor connetortarinal No. Sand eledronie contol

Maintenance item unit connector (GE96A) terminal No. 78.

step © | napecton conation Disconnect each device fom hamess and measure Yom conneclon side af

hamess connector,

Requirements There is continu

Inspection result (Is the judg |_YES | Go to step 12.

ing standard satisfied?) NO _ [Modify names

13EA-343

TROUBLESHOOTING

Step 19}

Inspection items

Tnspection of hamess between electronic control unit and sensor (ground)

Maintenance tem

‘Check aroult belween sensor connector terminal No. 2 and electronic control

Unit connector (GEQ6A) terminal No. 83

Inspection condition

Disconnect each device from harness and measure from connedion side of

hamess connector.

Requirements

There is continuity,

Inspection result (ls the judg |_YES

Goto step 11

ing standard satisfied?) NO

Modify hamess

step 11

Tnepection items

Thspection of hamess between electronic control unit and sensor (signal)

Maintenance tem

(Check crcult between sensor connector terminal No. 1 and electronic control

Unit connector (GE86A) terminal No. 59

Inspection condition

Disconnect each device from harness and measure from connection side of

hamess connector.

Requirements

There is continuity,

Inspection result (ls the judg- [|_YES

Goto step 12

ing standard satisfied?) NO

Modify hamess

Step 12]

Inspection terns

Inspection by control data

Maintenance item

~

+ "Measure item "Ne"

+ Measure item No, 01 “Engine Revolution’ of Service Data.

Inspection condition

Requirements

‘Same indication as tachometer is given

Inspection result (ls the judg- |_YES

Goto transient fault (See Gr00),

ing standard satisfied?) NO)

Replacement of elecironis control unit

13EA-344

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- YD25 Engine MechDocument35 pagesYD25 Engine MechAlex Hernandez100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Starter System FUSODocument5 pagesStarter System FUSOAlex Hernandez100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Nissan Rogue 2014 Service Repair ManualDocument4,971 pagesNissan Rogue 2014 Service Repair ManualAlex Hernandez100% (1)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- 4HK1 - 6HK1Document174 pages4HK1 - 6HK1Alex HernandezNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- DIAGNOSIS YD25ddtiDocument14 pagesDIAGNOSIS YD25ddtiAlex Hernandez100% (1)

- Códigos de Falla PDFDocument611 pagesCódigos de Falla PDFAlex HernandezNo ratings yet

- ISUZU N-Series 4HK1-manual-de-confianza-2Document34 pagesISUZU N-Series 4HK1-manual-de-confianza-2Alex Hernandez100% (6)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)