Professional Documents

Culture Documents

Ficha Tecnica de Montacargas

Uploaded by

Prueba Video llamadas manttoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ficha Tecnica de Montacargas

Uploaded by

Prueba Video llamadas manttoCopyright:

Available Formats

Electric Counterbalance Trucks

MOVING YOU FURTHER

HYUNDAI HEAVY INDUSTRIES

Your satisfaction is Compact forklift with proven AC technology

Maximum performance

our priority! Spacious operator’s cab

Fingertip controlled mini levers available (optional)

Weight indicator (optional)

Hyundai introduces a new line of 9-series battery forklift trucks. Safety system that prevents over loading (optional)

The newly designed 4 wheel counterbalance trucks provide every operator

Battery side loading system available

comfortable driving, increased productivity and easy maintenance.

Curve control system

02 HYUNDAI FORKLIFT HYUNDAI FORKLIFT 03

High Efficiency & Efficient, smooth running and powerful performance

Optimal Performance make your work more productive.

Curve control

Curve Control limits travel speed based on

turning radius, reducing speed for a smooth,

precise turning operation for the driver.

Limit

Driving Speed the speed

More efficient operating control levers

Electronic directional control and secondary horn are

mounted to the hydraulic lift lever for quick and precise

maneuvering.

Dual drive system

Using a dual drive system will minimise aisle

width and energy consumption. Plus, the drive

units and AC motors intergrated in the front axle

provide the operator with extremely improved

gradient capacity.

Finger tip control levers (Optional)

Fingertip control levers allow more precise control and fatigue-free working.

The ergonomically designed armrest can be adjusted up, down, forward and backward

for various operator’s body type.

Max. Gradeability (loaded) Max. Travel Speed (unloaded)

Model % Model Km / h

22B-9 34 22B-9 18

25B-9 31 25B-9 18

30B-9 27 30B-9 18

32B-9 26 32B-9 18

35B-9 23 35B-9 18

Advanced drive and lift performance with proven durability Auto fork leveling system (Optional)

Anti roll back system, travel speed and gradeability

and low maintenance In order to improve productivity the auto fork

leveling system will automatically stop the tilt Anti Roll-back system offers protection against the machine rolling back

The enclosed drive and pump motor with AC technology combine power, high

movement when the mast is in a straight on a ramp in combination with exceptional ramp start capabilities.

maintenance intervals and excellent durability.

The brushless AC motors offer improved efficiency and reduce maintenance cost. position.

04 HYUNDAI FORKLIFT HYUNDAI FORKLIFT 05

Advanced Safety

The safely designed driver's space makes

your operating more comfortable.

Lift Lock

Fork safety features

When the forks are being lowered, a down-control valve maintains the

controlled speed. The down-safety valve prevents forks from dropping

down in case of sudden damage of hydraulic line.

Tilt Lock

OPSS (Operator Presence Sensing System)

When the operator is not in the seat all mast and drive movements are

impossible.

Excellent visibility for safe operation

Optimized lift cylinder arrangement provides operator with wider visibility.

The panoramic mirror expands the driver’s view when backing up.

Drive Lock

Strong overhead guard Safety lamps & rear reflectors

Exceeding CEE and ANSI regulations, the overhead guard offers Halogen headlights and rear LED combination lights offer the driver visibility in all circumstances.

great protection combined with excellent all-round visibility. Rear reflectors mounted on the counterweight enhance safety for the driver and the application.

06 HYUNDAI FORKLIFT HYUNDAI FORKLIFT 07

Optimised Ergonomics & An ideal arrangement of components

ensures easy access and convenience for

Fast and Easy Maintenance maintenance.

Spacious operator cabin Easy battery replacement

The newly designed cabin was conceived for more space, a wider The battery compartment is equipped with a side battery removal

field of view and operator comfort. assembly for easy removal and replacement.

Optimized pedal position Advanced LCD Monitor

and floor mat

This tool is available in 12 different languages. The LCD monitor with 3.5 inch

The position of accelerator and graphic smart display allows the operator to easily and efficiently control the

throttle have been optimized machine.

through human engineering. The monitor provides information about speed & accelerator level, steer angle &

travel direction, battery discharge indicator, hour meter & working mode. The

optional load indicator displays the load weight in the monitor. The operator

can select various performance modes to meet all working conditions.

H (High) mode

N (Normal) mode

E (Economic) mode

Turtle mode (maintain 7 km/h travel speed when lifting)

Low entrance height Adjustable steering wheel Grammer seat (Option) Brake oil reservoir with level sensor

In order to get in and out of the To achieve a comfortable drive An easily adjustable suspension The enhanced brake oil reservoir, located in the upper left dash, is

cabine in an easy and safe way position, the angle of the steering seat, based on a human equipped with an electronic level sensor and easily visible through

the height of the entrance step is column can easily be adjusted engineering design, provides the monitor.

only 400mm high. through a lever on the right-hand greater comfort reducing

side of the steering column. operator fatigue.

08 HYUNDAI FORKLIFT HYUNDAI FORKLIFT 09

New 9 Series

Mast Specification (22/25/30B-9) Load Capacity

Free Lift Height (mm)

Maximum Overall Height

Tilt Angle

Forward /

Load Capacity

without side shift

Load Capacity

with side shift

Truck Weight 22B-9 25B-9 30B-9 32B-9 35B-9

Fork Height (Lowered) (Unloaded)

Mast Type With Load Without Backward at (500mm LC) at (500mm LC)

(mm) (mm) (kg)

Backrest Load Backrest (deg) (kg) (kg) V / VF MAST V / VF MAST V / VF MAST V / VF MAST V / VF MAST

22/25/30B-9 22/25/30B-9 22/25/30B-9 22/25B-9 30B-9 22/25/30B-9 22B-9 25B-9 30B-9 22B-9 25B-9 30B-9 22B-9 25B-9 30B-9

V300 3005 2012 115 115 115 6 / 10 2200 2500 3000 2200 2500 3000 4028 4293 4557

Load (kg)

Load (kg)

Load (kg)

Load (kg)

Load (kg)

* V330 3305 2162 115 115 115 6 / 10 2200 2500 3000 2200 2500 3000 4047 4312 4578

V350 3505 2262 115 115 115 6 / 10 2200 2500 3000 2200 2500 3000 4064 4329 4596

2- Stage V370 3705 2412 115 115 115 6 / 10 2200 2500 3000 2200 2475 3000 4086 4351 4620

Limited V400 4005 2562 115 115 115 6 / 10 2200 2500 3000 2200 2425 3000 4108 4373 4644

free lift V430 4305 2712 115 115 115 6/6 2200 2450 3000 2200 2375 3000 4157 4422 4694

115 6/6 3000 2950 4186 Load Center (mm) Load Center (mm) Load Center (mm) Load Center (mm) Load Center (mm)

V450 4505 2862 115 115 2200 2400 2175 2325 4451 4725

V470 4705 2962 115 115 115 6/6 2200 2360 3000 2125 2285 2875 4201 4466 4741 TF / TS MAST TF / TS MAST TF / TS MAST TF / TS MAST TF / TS MAST

V500 5005 3112 115 115 115 6/6 2150 2350 2900 2075 2275 2775 4223 4488 4765

VF295 2976 2012 832 1379 1317 6/6 2200 2500 3000 2200 2500 3000 4088 4353 4592

2- Stage 1467 6/6 3000 2950 4121

VF325 3276 2162 982 1529 2200 2500 2200 2500 4386 4625

Load (kg)

Load (kg)

Load (kg)

Load (kg)

Load (kg)

full free lift

VF345 3476 2262 1082 1629 1567 6/6 2200 2500 3000 2175 2475 2875 4143 4408 4650

TF370/TS370 3705 1812 632 1122 1117 6/6 2200 2500 3000 2200 2475 3000 4174 4439 4721

TF400/TS400 4005 1912 732 1222 1217 6/6 2200 2500 3000 2200 2425 3000 4194 4459 4742

TF430/TS430 4305 2012 832 1322 1317 6/6 2200 2450 3000 2200 2375 2950 4215 4480 4786

TF450/TS450 4505 2112 932 1422 1417 6/6 2200 2400 3000 2175 2325 2875 4236 4501 4791 Load Center (mm) Load Center (mm) Load Center (mm) Load Center (mm) Load Center (mm)

3 - Stage TF470/TS470 4705 2162 982 1472 1467 6/6 2200 2350 2950 2125 2275 2825 4247 4512 4803 QF MAST QF MAST QF MAST QF MAST QF MAST

full free lift TF500/TS500 5005 2262 1082 1572 1567 6/6 2150 2300 2900 2075 2225 2775 4272 4537 4828

TF550/TS550 5505 2462 1282 1772 1767 6/6 2100 2200 2800 2025 2125 2675 4311 4576 4871

TF600/TS600 6005 2662 1482 1972 1967 6/6 2000 2150 2700 1925 2075 2575 4348 4613 4913

Load (kg)

Load (kg)

Load (kg)

Load (kg)

Load (kg)

TF650/TS650 6505 2862 1682 2172 2167 3/3 1650 1800 2250 1575 1725 2125 4399 4664 4964

TF700/TS700 7005 3062 1882 2372 2367 3/3 1200 1400 1850 1125 1325 1725 4432 4697 4997

QF610 6115 2147 967 1514 1452 3/3 1550 1650 1800 1475 1575 1675 4613 4878 5111

QF660 6615 2347 1167 1714 1652 3/3 1450 1550 1700 1375 1475 1575 4673 4938 5171

4- Stage 1814 1752 3/3 1275 4703

QF700 7015 2447 1267 1250 1300 1400 1175 1225 4968 5201 Load Center (mm) Load Center (mm) Load Center (mm) Load Center (mm) Load Center (mm)

full free lift

QF745 7465 2597 1417 1964 1902 3/3 1150 1200 1250 1075 1125 1125 4749 5041 5247

QF790 7915 2747 1567 2114 2052 3/3 700 750 750 625 675 625 4850 5115 5348

Mast Specification (32/35B-9) Optional Items

Free Lift Height (mm) Tilt Angle Load Capacity Load Capacity • Fork (mm)

Maximum Overall Height Truck Weight

Forward / without side shift with side shift 22/ 25B-9 : 900, 1000, 1050 (Standard), 1200, 1350, 1500, 1650, 1800

Mast Type

Fork Height (Lowered)

Without Backward at (500mm LC) at (500mm LC)

(Unloaded) • Finger Tip Control

(mm) (mm) With (kg) 30/32/35B-9 : 900, 1050 (Standard), 1150, 1200, 1650, 1800, 1970, 2120, 2300, 2400

Load Backrest Load Backrest (deg) (kg) (kg) • Basic cold storage

• Overshoe (mm) • M.C.V : 2-Spool, 3-Spool, 4-Spool (Standard)

32/35B9 32B-9 35B-9 32B-9 35B-9 32B-9 35B-9 32/35B-9 32B-9 35B-9 32B-9 35B-9 32B-9 35B-9 22/ 25B-9 : 1300, 1500, 1700, 1800 • Auto Fork Leveling (Standard)

V300 3005 2082 2093 115 115 115 115 6 / 10 3200 3500 3200 3500 4761 5003 30/32/35B-9 : 1500, 1700, 1800 • Beacon Lamp

* V330 3305 2232 2243 115 115 115 115 6 / 10 3200 3500 3200 3500 4782 5024 • Integral side shift • Load Indicator

V350 3505 2332 2343 115 115 115 115 6 / 10 3200 3500 3075 3500 4801 5043 • Tire : Solid (Standard) / Pneumatic / Non-marking • Work Lamp

2- Stage V370 3705 2482 2493 115 115 115 115 6 / 10 3190 3500 3065 3500 4825 5067 Wide tire [22/25/30/32B-9 : Front tire (23x10-12)]

115 6 / 10 4848

• Cabin

Limited V400 4005 2632 2643 115 115 115 3120 3500 2995 3430 5090 • Seat : Grammer

free lift V430 4305 2782 2793 115 115 115 115 6/6 3050 3500 2925 3350 4899 5141

V450 4505 2932 2943 115 115 115 115 6/6 3000 3450 2875 3300 4931 5173

V470 4705 3032 3043 115 115 115 115 6/6 2960 3400 2835 3250 4947 5189

V500 5005 3182 3193 115 115 115 115 6/6 2900 3300 2775 3150 4970 5212

VF295 2976 2082 2093 913 913 1377 1377 6/6 3200 3500 3200 3500 4815 5057

2- Stage 1527 1527 6/6 4838

VF325 3276 2232 2243 1063 1063 3200 3500 3200 3430 5080

full free lift

VF345 3476 2332 2343 1163 1163 1627 1627 6/6 3200 3500 3075 3350 4864 5106

TF370/TS370 3705 1882 1893 702 713 1112 1177 6/6 3190 3500 3065 3430 4962 5204

TF400/TS400 4005 1982 1993 802 813 1212 1277 6/6 3120 3500 2995 3350 4984 5226

TF430/TS430 4305 2082 2093 902 913 1312 1377 6/6 3060 3450 2935 3300 5009 5251

TF450/TS450 4505 2182 2193 1002 1013 1412 1477 6/6 3010 3400 2885 3250 5033 5275

3 - Stage TF470/TS470 4705 2232 2243 1052 1063 1462 1527 6/6 2980 3350 2855 3200 5124 5366

full free lift TF500/TS500 5005 2332 2343 1152 1163 1562 1627 6/6 2920 3300 2795 3150 5072 5314

TF550/TS550 5505 2532 2543 1352 1363 1762 1827 6/6 2820 3150 2695 3000 5117 5359

TF600/TS600 6005 2732 2743 1552 1563 1962 2027 6/6 2730 3100 2605 2950 5160 5402

TF650/TS650 6505 2932 2943 1752 1763 2162 2227 3/3 2300 2600 2175 2450 5211 5453

TF700/TS700 7005 3132 3143 1952 1963 2362 2427 3/3 1900 2200 1775 2050 5245 5486

QF610 6115 2147 2158 1017 1017 1459 1459 3/3 1810 2500 1685 2350 5337 5579

QF660 6615 2347 2358 1217 1217 1659 1659 3/3 1710 2400 1585 2250 5397 5639

4- Stage 1317 1317 1759 1759 3/3 1295 5427 5669

QF700 7015 2447 2458 1420 2100 1950

full free lift

QF745 7465 2597 2608 1467 1467 1909 1909 3/3 890 1950 765 1800 5470 5712

QF790 7915 2747 2758 1617 1617 2059 2059 3/3 500 1450 375 1300 5574 5816

ø TS-Mast : Wide Visible 3-Stage Full Free Lift Mast with 2 Free Lift Cylinders. * Standard

10 HYUNDAI FORKLIFT HYUNDAI FORKLIFT 11

Dimensions Specifications

Identification

1. 1 Manufacturer HYUNDAI

1. 2 Type 22B-9 25B-9 30B-9 32B-9 35B-9

1. 3 Drive: Electric, Diesel, LPG Gas electric electric electric electric electric

1. 4 Type of operation: hand, pedestrian, standing, seated, order-picker seated seated seated seated seated

1. 5 Load capacity (standard) Q (kg) 2,200 2,500 3,000 3,200 3,500

1. 6 Load center distance c (mm) 500 500 500 500 500

1. 8 Load distance, center of drive axle to forks x (mm) 458 458 458 458 470

1. 9 Wheelbase y (mm) 1,400 1,400 1,600 1,600 1,600

Weights

2. 1 Service weight kg 4,045 4,310 4,750 4,935 5,190

2. 2 Axle loading, loaded front / rear kg 5,400 / 845 5,930 / 88 6,740 / 1,010 7,080 / 1,055 7,590 / 1,100

2. 3 Axle loading, unloaded front / rear kg 1,695 / 2,350 1,720 / 2,590 1,940 / 2,810 1,965 / 2,970 1,970 / 3,220

Wheels, chassis

3. 1 Tires : solid rubber (V), superelastic (SE), pneumatic (P), polyurethane (PE) SE, P SE, P SE, P SE, P SE, P

3. 2 Tires size, front (Ø x width) 23X9-10 23X9-10 23X9-10 23X9-10 23X10-12

3. 3 Tires size, rear (Ø x width ) 18X7-8 18X7-8 18X7-8 18X7-8 18X7-8

3. 5 Wheels, number front rear (x = driven wheels) 2x/2 2x/2 2x/2 2x/2 2x/2

3. 6 Track width, front b10 (mm) 993 993 993 993 1,005

3. 7 Track width, rear b11 (mm) 980 980 980 980 980

Basic dimensions

4. 1 Mast / fork carriage tilt forward / backward degrees 6/10 6/10 6/10 6/10 6/10

4. 2 Lowered mast height (standard) h1 (mm) 2,162 2,162 2,162 2,232 2,243

4. 3 Free lift h2 (mm) 115 115 115 115 115

4. 4 Lift height (standard) h3 (mm) 3,300 3,300 3,300 3,300 3,300

4. 5 Extended mast height (standard) h4 (mm) 4,485 4,485 4,485 4,485 4,485

4. 7 Overhead load guard (cab) height h5 (mm) 2,230 2,230 2,230 2,230 2,230

4. 8 Seat height / standing height h7 (mm) 1,180 1,180 1,180 1,180 1,180

4. 12 Coupling height h10 (mm) 325 325 325 325 325

4. 19 Overall length l1 (mm) 3,345 3,345 3,538 3,553 3,640

4. 20 Length to face of forks l2 (mm) 2,295 2,295 2,488 2,503 2,590

4. 21 Overall width b1 (mm) 1,200 1,200 1,200 1,200 1,250

4. 22 Fork dimensions (hook type) LxWxT s / e / l (mm) 1,050 x 100 x 45 1,050 x 100 x 45 1,050 x 122 x 45 1,050 x 122 x 45 1,050 x 122 x 45

4. 23 Fork carriage ISO 2328, class / type A,B II/A II/A III/A III/A III/A

4. 24 Fork carriage width b3 (mm) 1,102 1,102 1,102 1,102 1,102

4. 31 Ground clearance, loaded, under mast m1 (mm) 117 117 117 117 128

4. 32 Ground clearance, centre of wheelbase m2 (mm) 130 130 130 130 130

4. 33 Aisle width for pallets 1000 x 1200 crossways (L x W) Ast (mm) 3,637 3,637 3,829 3,843 3,896

4. 34 Aisle width for pallets 800 x 1200 lengthways (W x L) Ast (mm) 3,803 3,803 4,009 4,023 4,076

4. 35 Turning radius Wa (mm) 1,939 1,939 2,150 2,164 2,205

4. 36 Internal turning radius b13 (mm) 257 257 257 257 257

Performance data

5. 1 Travel speed, loaded/ unloaded (48V) km/h 17 / 18 17 / 18 17 / 18 17 / 18 17 / 18

5. 2 Lift speed, loaded / unloaded (48V) mm/s 420 / 610 410 / 610 340 / 500 330 / 500 300 / 460

5. 3 Lowering speed, loaded / unloaded mm/s 500 / 450 500 / 450 500 / 450 500 / 450 500 / 450

5. 6 Drawbar pull, loaded N 20,310 / 19,910 20,370 / 19,840 20,230 / 19,820 20,170 / 19,790 19,210 / 19,010

5. 8 Gradient performance, loaded / unloaded % 34 / 20 31 / 18 27 / 18 26 / 17 23 / 17

5. 10 Service brake Hydraulic Hydraulic Hydraulic Hydraulic Hydraulic

E - Motor

6. 1 Drive motor rating S2 60 min (48V) kW 7.0 x 2 7.0 x 2 7.0 x 2 7.0 x 2 7.0 x 2

6. 2 Pump motor rating at S3 - 15 % (48V) kW 17 17 17 17 17

6. 4 Battery voltage, nominal capacity K5 (48V) V/Ah 660 715 740 740 740

6. 5 Battery weight kg 1,090 1,150 1,320 1,320 1,320

Battery compartment dimensions L / W /H mm 1,035 / 806 / 540 1,035 / 806 / 540 1,035 / 1,000 / 540 1,035 / 1,000 / 540 1,035 / 1,000 / 540

Other details

8. 1 Type of drive control AC AC AC AC AC

* Standard and optional equipment may vary per country. Contact your Hyundai dealer for more information.

* The photos may include attachments and optional equipment that are not available in your area.

* Materials and specifications are subject to change without advance notice.

* All imperial measurements rounded off to the nearest pound or inch.

PLEASE CONTACT

www.hyundai.eu EN - 2013.11 Rev 0

You might also like

- Hyundai Heavy Industries: Electric Counterbalance TrucksDocument12 pagesHyundai Heavy Industries: Electric Counterbalance TrucksDragan PilipovićNo ratings yet

- Compact Design High On Performance: BRAVO Electric ForkliftDocument7 pagesCompact Design High On Performance: BRAVO Electric ForkliftNagi Reddy ChintakuntaNo ratings yet

- Hyundai 14 - 16 - 20 - 25BRJ-9Document8 pagesHyundai 14 - 16 - 20 - 25BRJ-9NayanajithNo ratings yet

- Te D375a-5Document16 pagesTe D375a-5Copemaq CopemaqNo ratings yet

- Montacarga HYUNDAI 50D-9SA PDFDocument8 pagesMontacarga HYUNDAI 50D-9SA PDFdanielaNo ratings yet

- Pasillo AngostoDocument9 pagesPasillo AngostoRafael GuerraNo ratings yet

- FRENIC-Mini (C2) Catalog PDFDocument24 pagesFRENIC-Mini (C2) Catalog PDFLong NguyễnNo ratings yet

- Series 1216 Data SheetDocument2 pagesSeries 1216 Data SheetSenthilKumarNo ratings yet

- Montacargas Electrico 10131518202530br-9 (Updated)Document14 pagesMontacargas Electrico 10131518202530br-9 (Updated)luismdmjNo ratings yet

- With Tier 2 Engine Installed: Please ContactDocument10 pagesWith Tier 2 Engine Installed: Please Contacthamdi galipNo ratings yet

- Liebherr RTG Cranes BrochureDocument7 pagesLiebherr RTG Cranes Brochurered patriotNo ratings yet

- 16 18 20b 9fDocument9 pages16 18 20b 9fVũ Anh TuấnNo ratings yet

- Ficha Tecnica Erp025-030vcDocument8 pagesFicha Tecnica Erp025-030vcRAUL HERRERANo ratings yet

- ps300b PDFDocument12 pagesps300b PDFRached DouahchuaNo ratings yet

- 305C CR Specalog (AEHQ5683)Document12 pages305C CR Specalog (AEHQ5683)Fulkan HadiyanNo ratings yet

- Reach Truck 1 4 2tonDocument2 pagesReach Truck 1 4 2tonanupthattaNo ratings yet

- Series 1220 Data SheetDocument2 pagesSeries 1220 Data SheetramoNo ratings yet

- Linde 1219 PDFDocument2 pagesLinde 1219 PDFanupthattaNo ratings yet

- PM 200Document16 pagesPM 200dioneslealNo ratings yet

- Yale Reach Truck TVRS-569Document6 pagesYale Reach Truck TVRS-569Aaron PerezNo ratings yet

- Cruise PDFDocument2 pagesCruise PDFAlderNo ratings yet

- Hyundai LPG Forklift Trucks: - Applied Tier 4 EngineDocument12 pagesHyundai LPG Forklift Trucks: - Applied Tier 4 Engineedwinvartuan-1No ratings yet

- DX210WDocument13 pagesDX210WScanner Camiones CáceresNo ratings yet

- We Build A Better Future: Equipped With Tier 3 EngineDocument20 pagesWe Build A Better Future: Equipped With Tier 3 EngineNacer NacerNo ratings yet

- D475a-5 Eess017008 1701Document16 pagesD475a-5 Eess017008 1701berahma abd allahNo ratings yet

- Moving You Further: With Tier 2 Engine InstalledDocument10 pagesMoving You Further: With Tier 2 Engine InstalledMichaelNo ratings yet

- Linde EN Typ en Series1158 T20ap04Document2 pagesLinde EN Typ en Series1158 T20ap04Nadeem AhmedNo ratings yet

- DX300LC PDFDocument20 pagesDX300LC PDFAugusto OliveiraNo ratings yet

- Doosan BR15-18J-5 BrochureDocument4 pagesDoosan BR15-18J-5 BrochureMuhammad SohailNo ratings yet

- Moving You Further: With Tier 3 Engine InstalledDocument10 pagesMoving You Further: With Tier 3 Engine InstalledSabahNo ratings yet

- Wheel Loader Specifications: Service Weight 13.7 T - 14,5 T Engine Output 130 KW Loading Buckets 2.3 - 6.0 MDocument10 pagesWheel Loader Specifications: Service Weight 13.7 T - 14,5 T Engine Output 130 KW Loading Buckets 2.3 - 6.0 MIbrahim AwadNo ratings yet

- CatalogDocument16 pagesCatalogMaryamNo ratings yet

- R210W 9S NamibiaDocument10 pagesR210W 9S NamibiaTran Trong PhuNo ratings yet

- DL300 enDocument11 pagesDL300 enVusal AbdullayevNo ratings yet

- Linde e 16 02 - 335Document2 pagesLinde e 16 02 - 335Eryx0% (1)

- ETV 114n 116n 118n 120nDocument6 pagesETV 114n 116n 118n 120nganteng deweNo ratings yet

- SD300SD200 enDocument10 pagesSD300SD200 enBhagoo Hathey100% (1)

- SD300-200 EN 130521 LowDocument9 pagesSD300-200 EN 130521 LowMoises Garcia DuranNo ratings yet

- Reconditioned R305 Small Assembly With Lift: Features Benefits AGV OptionsDocument2 pagesReconditioned R305 Small Assembly With Lift: Features Benefits AGV OptionsCoreconNo ratings yet

- Features Standard and Optional EquipmentDocument2 pagesFeatures Standard and Optional Equipmentjackson.santosgreentechNo ratings yet

- Hydraulic Crawler CraneDocument8 pagesHydraulic Crawler CraneJoshuaNo ratings yet

- Chariot Elevateur Hyundai PDFDocument9 pagesChariot Elevateur Hyundai PDFhocine gherbiNo ratings yet

- Kawasaki Wheel Loader 90zv 2 Spec SheetDocument12 pagesKawasaki Wheel Loader 90zv 2 Spec Sheetjoaquinfern100% (2)

- Construction EquipmentDocument11 pagesConstruction EquipmentSÓLIDA ESTRUTURAS PREMOLDADAS LTDANo ratings yet

- Yale Reach Truck NR-NDR-DB Specification SheetDocument6 pagesYale Reach Truck NR-NDR-DB Specification SheetNoelia Brand100% (1)

- PC88MR-10 Wenss07608 1911Document16 pagesPC88MR-10 Wenss07608 1911vitaliyNo ratings yet

- CAT 302.5C Mini Hydraulic Excavator PDFDocument12 pagesCAT 302.5C Mini Hydraulic Excavator PDFricardo gajardo bascuñan100% (1)

- Doosan DX62r 3 - DX63r 3Document8 pagesDoosan DX62r 3 - DX63r 3Wagner Damian100% (1)

- Agrotron M: Evolving AgricultureDocument13 pagesAgrotron M: Evolving Agriculturejohn deereNo ratings yet

- FBR85 Nichiyu BrochureDocument6 pagesFBR85 Nichiyu BrochureLui DavidNo ratings yet

- R305PDocument2 pagesR305PCoreconNo ratings yet

- Dx260lca enDocument11 pagesDx260lca enميلاد النعيريNo ratings yet

- D275a 5R Eensb15000 2203Document16 pagesD275a 5R Eensb15000 2203korchirachid39No ratings yet

- Hitachi zw310Document9 pagesHitachi zw310BABA GlobalNo ratings yet

- Godrej Reach Truck CatalogueDocument8 pagesGodrej Reach Truck Catalogueasif.ayyub7624No ratings yet

- Please Contact: Hyundai Material HandlingDocument8 pagesPlease Contact: Hyundai Material HandlingLeonardo VilarinhoNo ratings yet

- Wa380 1 1994 (D1e)Document8 pagesWa380 1 1994 (D1e)Plstina RamsNo ratings yet

- Moving You: FurtherDocument16 pagesMoving You: FurtherJonathan KaleNo ratings yet

- Introduction to Fly-by-Wire Flight Control Systems: The professional pilot’s guide to understanding modern aircraft controlsFrom EverandIntroduction to Fly-by-Wire Flight Control Systems: The professional pilot’s guide to understanding modern aircraft controlsNo ratings yet

- Robot Mechanisms and Mechanical Devices IllustratedFrom EverandRobot Mechanisms and Mechanical Devices IllustratedRating: 4 out of 5 stars4/5 (1)

- Mix Design As Per Is 10262Document5 pagesMix Design As Per Is 10262Sonia MohapatraNo ratings yet

- Chapter 9 Towing and TaxiingDocument3 pagesChapter 9 Towing and TaxiingHrishikesh NarasimhanNo ratings yet

- Fiesta Xr2 Mk2: Buyer'S GuideDocument4 pagesFiesta Xr2 Mk2: Buyer'S GuidetimingtoolNo ratings yet

- Driver Assistance System: SectionDocument175 pagesDriver Assistance System: Sectionwilder0l0pezNo ratings yet

- ULI Austin Case Study: Community First! VillageDocument11 pagesULI Austin Case Study: Community First! VillageThe GeorgNo ratings yet

- PC 695SR 10 EUDocument292 pagesPC 695SR 10 EUДима ТукачNo ratings yet

- Top-Mech TX Serie Eot Cranes Pricelist-25tdg-Fem2mDocument1 pageTop-Mech TX Serie Eot Cranes Pricelist-25tdg-Fem2mfaisal3arainNo ratings yet

- Historical Perspective of Grand Challenge - Invention of The WheelDocument2 pagesHistorical Perspective of Grand Challenge - Invention of The WheelMeer IbadullaNo ratings yet

- 2000 Duratec Base EngineDocument20 pages2000 Duratec Base EngineJUAN LUIS GARCIANo ratings yet

- Better Solutions For Trade and ExportDocument3 pagesBetter Solutions For Trade and ExportAjdeLSNo ratings yet

- Manuale Stazione Di Servizio: APE TM BenzinaDocument144 pagesManuale Stazione Di Servizio: APE TM BenzinaAhmed KasamNo ratings yet

- Odd K-Line Problem On Citroen C2 - Ideas - MHH AUTO - Page 1Document1 pageOdd K-Line Problem On Citroen C2 - Ideas - MHH AUTO - Page 1Martinito MacraméNo ratings yet

- Lookup Chevy Transmission by Model, YearDocument13 pagesLookup Chevy Transmission by Model, YearMarco MeloncelliNo ratings yet

- Capítulo. Mobility Accesibility and Social Equity. A Comparative and Interdisciplinary Empirical Study in The Metropolitan AreasDocument20 pagesCapítulo. Mobility Accesibility and Social Equity. A Comparative and Interdisciplinary Empirical Study in The Metropolitan AreasDani FríasNo ratings yet

- Labour Department SchemesDocument16 pagesLabour Department SchemesBasavaraj S PNo ratings yet

- Total 24,000,000.00: Summary of Price For 2Km Road Construction DescriptionDocument86 pagesTotal 24,000,000.00: Summary of Price For 2Km Road Construction DescriptionIbrahim Dawud100% (1)

- JT7020 M1 JT8020 M1 Parts Manual 053-074 (1) ExportDocument3 pagesJT7020 M1 JT8020 M1 Parts Manual 053-074 (1) ExportMohamedNo ratings yet

- Technical Details ENDocument2 pagesTechnical Details ENHumberto GalvezNo ratings yet

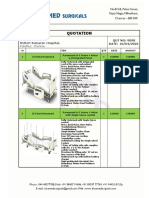

- Blue Med SurgicalsDocument6 pagesBlue Med SurgicalsRetteri KUMARANNo ratings yet

- BYD AutoDocument37 pagesBYD AutoArturo Yanez S.G.No ratings yet

- LG English For The Oil Industry 1 para EnviarDocument70 pagesLG English For The Oil Industry 1 para EnviarNOE100% (1)

- Gromax Trackstar 540Document44 pagesGromax Trackstar 540Fred WilfNo ratings yet

- Case 580n 580sn 580snwt 590sn Service ManualDocument20 pagesCase 580n 580sn 580snwt 590sn Service Manualwilliam100% (30)

- Skema FullDocument1 pageSkema FullZubaidin ChannelNo ratings yet

- CH-3 Geometric Design of HighwaysDocument146 pagesCH-3 Geometric Design of HighwaysRmesh jhaNo ratings yet

- 8293 Nissan Juke Model F15 SeriesDocument35 pages8293 Nissan Juke Model F15 SeriesEngr Ko VictorNo ratings yet

- Service Manual Trucks: Anti-Lock Brake System (ABS) Bendix VNL, VNMDocument82 pagesService Manual Trucks: Anti-Lock Brake System (ABS) Bendix VNL, VNMIB EldinNo ratings yet

- A & B Segment - 221010 - 165543Document1 pageA & B Segment - 221010 - 165543maheshgowthamNo ratings yet

- D4B8046FF16 Body ExteriorDocument422 pagesD4B8046FF16 Body ExteriorDaniel CharlesNo ratings yet

- Summer Tyre Catalogue 2018Document28 pagesSummer Tyre Catalogue 2018Krzysztof MarzecNo ratings yet