Professional Documents

Culture Documents

Sensor Hall

Uploaded by

Ramiro RamirezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sensor Hall

Uploaded by

Ramiro RamirezCopyright:

Available Formats

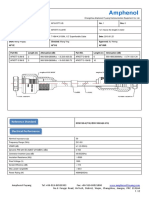

Instruction guide Sensor Hall

Description Installation

The sensor is Hall effect devices designed for use in applications where For best results, we recommend targets made from low carbon cold

ferrous edge detection/near zero speed sensing is needed. They provide rolled steel. Other factors that influence sensor performance include gear

a sinking output current. tooth height and width, space between the teeth, shape of the teeth

and thickness of the target. As a general guideline, consider a target with

minimum parameters as shown below. Note that smaller dimensions may

Features work, but testing for the application is required.

- From near zero speed um to 15 kHz sensing capability

- Plastic flange-mount housing Tooth Height 5,0 mm (.200”)

- Compatible with unregulated power supply Tooth Width 2,5 mm (.100”)

- IP67 Distance between Teeth 10 mm (.400”)

- Typical air gap of 1.5 mm Target Thickness 6,35 mm (.250”)

Environmental Specifications

Sinusoidal, 15 g max from 40 Hz

Vibration

to 2 kHz

Mechanical Shock Resistance 50 g

Maximum Speed Detection 15 kHz

Operating Temperature -40 °C to 125 °C (-40 F to 257 F)

Storage Temperature -40 °C to 125 °C (-40 F to 257 F)

Ingress Protection IP67

Electrical Specifications

Operating Supply Voltage 5 to 24 VDC

Maximum Input Voltage 30 VDC

Maximum Reverse Voltage 24 VDC

Supply Current 3 mA typ., 6 mA max

Dimensions mm (inches)

Output Sink Current 20 mA max

Mechanical Specifications

Housing Material Glass Reinforced Thermoplastic

Maximum Installation Torque

5.65 Nm (50 in lb) on threads

Limit

Operating Air Gap / Sensing

1.5 mm (0.06”)

Distance*

Sensor Orientation Not sensitive

* With recommended target type; see drawing

Pinout

A - VCC (5-32V)

B - Signal

C - GND

You might also like

- 512401Document2 pages512401tgg pNo ratings yet

- Gear Tooth Speed Sensor GS1001 GS1002 Datasheet 1075695Document3 pagesGear Tooth Speed Sensor GS1001 GS1002 Datasheet 1075695Sigit RomadhonNo ratings yet

- Gear Tooth Speed SensorsDocument3 pagesGear Tooth Speed SensorsKartik GvrNo ratings yet

- Datasheet GS1005-GS1007 Letter EN-1847814Document3 pagesDatasheet GS1005-GS1007 Letter EN-1847814lospeed01No ratings yet

- Datasheet SD101201 Letter EN 29 11 17Document2 pagesDatasheet SD101201 Letter EN 29 11 17Samuel PaulNo ratings yet

- Senturion XPR04 Proximity Probe: Condition Monitoring SolutionsDocument6 pagesSenturion XPR04 Proximity Probe: Condition Monitoring SolutionsNguyen LuanNo ratings yet

- 1GT105DC PDFDocument4 pages1GT105DC PDFIsos CellNo ratings yet

- 1GT105DC PDFDocument4 pages1GT105DC PDFIsos CellNo ratings yet

- TP1 e Start-StopDocument10 pagesTP1 e Start-Stopatila.cardellaNo ratings yet

- Ouster OS1 DatasheetDocument2 pagesOuster OS1 DatasheetHermanto ChuaNo ratings yet

- FL7M SDocument4 pagesFL7M SKapilkoundinya NidumoluNo ratings yet

- Praktek Mekatronika Klasifikasi Sensor Dan Tranduser: Dosen: Drs. Ta'ali Oleh: Muhammad Rahman 17130056Document6 pagesPraktek Mekatronika Klasifikasi Sensor Dan Tranduser: Dosen: Drs. Ta'ali Oleh: Muhammad Rahman 17130056Muhammad RahmanNo ratings yet

- MeasurIT KTek LM80 0812Document4 pagesMeasurIT KTek LM80 0812cwiejkowskaNo ratings yet

- Velomitor Piezo-Velocity Sensor Datasheet - 141632Document11 pagesVelomitor Piezo-Velocity Sensor Datasheet - 141632Mehtab AhmedNo ratings yet

- Datasheet For: Relay OutputDocument3 pagesDatasheet For: Relay OutputGiang LêNo ratings yet

- Rugged & Compact CompactDocument2 pagesRugged & Compact CompactAnjum DuttaNo ratings yet

- FLX Datasheet A201 RevHDocument2 pagesFLX Datasheet A201 RevHDavidNo ratings yet

- Application: Your Partner For Airflow Sensing & ControlsDocument2 pagesApplication: Your Partner For Airflow Sensing & ControlsSaravanabhavan ChandrasekarNo ratings yet

- Flat Capacitive Sensor With A Thickness of Only 10 MMDocument5 pagesFlat Capacitive Sensor With A Thickness of Only 10 MMpercetakan zhafirahNo ratings yet

- Senscient ELDS - Hydrogen Sulphide - Data Sheet Rev6Document2 pagesSenscient ELDS - Hydrogen Sulphide - Data Sheet Rev6Vincent GabrielNo ratings yet

- Bro Ufp 20Document2 pagesBro Ufp 20Aimee chaconNo ratings yet

- 2700588Document6 pages2700588steam100deg8229No ratings yet

- Data Sheet: SpecificationsDocument3 pagesData Sheet: SpecificationsStéphane DUMALINNo ratings yet

- Single Channel Hall Effect Speed Sensor: Product IDDocument3 pagesSingle Channel Hall Effect Speed Sensor: Product IDpayman baharehNo ratings yet

- FLX Datasheet A201 RevIDocument2 pagesFLX Datasheet A201 RevIMARIA DE JESUSNo ratings yet

- Isb Datasheet enDocument3 pagesIsb Datasheet endiacochemicalsNo ratings yet

- Product Brief: Positive Stop™ ConnectorsDocument4 pagesProduct Brief: Positive Stop™ ConnectorsThắng TrầnNo ratings yet

- AFK577-3-xxM-B 4310SM-DMDocument2 pagesAFK577-3-xxM-B 4310SM-DMMinh DucNo ratings yet

- TI-45NA: Check LineDocument2 pagesTI-45NA: Check LineINMETRO SACNo ratings yet

- Velomitor Piezo-Velocity Sensor Datasheet - 141632Document11 pagesVelomitor Piezo-Velocity Sensor Datasheet - 141632Trong Hung NguyenNo ratings yet

- Technical Specification: DescriptionDocument2 pagesTechnical Specification: DescriptionAnonymous RcxX0FcNo ratings yet

- Con A Ocd Caa1b 0013 B150 PRMDocument4 pagesCon A Ocd Caa1b 0013 B150 PRMFaiz BajwaNo ratings yet

- Ams 3125 Bearing Vibration Monitor en 39920Document3 pagesAms 3125 Bearing Vibration Monitor en 39920EyuNo ratings yet

- Ams 3125 Bearing Vibration Monitor en 39920Document3 pagesAms 3125 Bearing Vibration Monitor en 39920EyuNo ratings yet

- Dse 1610.15 Ahz & Dse 1810.35 SHZDocument2 pagesDse 1610.15 Ahz & Dse 1810.35 SHZTaller ManttoNo ratings yet

- Osisense Xs & XT - Xs630b1mal2Document5 pagesOsisense Xs & XT - Xs630b1mal2knightfelix12No ratings yet

- Sitransl Lu150 Fi01 enDocument5 pagesSitransl Lu150 Fi01 enErnesto Nestum MendesNo ratings yet

- Catalogo de Transductores de PresionDocument13 pagesCatalogo de Transductores de PresionAnthony ZamoraNo ratings yet

- Dual Laterolog: 2 " Product LineDocument1 pageDual Laterolog: 2 " Product LineAbyanNo ratings yet

- Eddy Current Datasheet - eddyNCDT - turboSPEED - 135 - enDocument4 pagesEddy Current Datasheet - eddyNCDT - turboSPEED - 135 - enJuan P. EscuderoNo ratings yet

- 6300 Series AE Sensors DatasheetDocument6 pages6300 Series AE Sensors DatasheetPablo ToscanoNo ratings yet

- Analog Sensors AssignmentDocument7 pagesAnalog Sensors AssignmentPathum SudasingheNo ratings yet

- 1200g PDFDocument2 pages1200g PDFEstrella LopezNo ratings yet

- Osisense XX Xx518a3nam12-1792380Document3 pagesOsisense XX Xx518a3nam12-1792380api-548237900No ratings yet

- Digital Flow Transmitter For Continuous Flow MeasurementDocument7 pagesDigital Flow Transmitter For Continuous Flow MeasurementChemikal EngineerNo ratings yet

- Low Cost String PotDocument2 pagesLow Cost String PotmelquicedecNo ratings yet

- Spesifikasi Flow MeterDocument4 pagesSpesifikasi Flow MeterMUH ILHAM MARZUKINo ratings yet

- Data Sheet: SpecificationsDocument3 pagesData Sheet: Specificationsrizky nurmansyahNo ratings yet

- 2014 Product Catalog-Rev5Document9 pages2014 Product Catalog-Rev5Rashed KaiserNo ratings yet

- Datenblatt Lecksuchgert LD Basic ENDocument2 pagesDatenblatt Lecksuchgert LD Basic ENHilina MedferNo ratings yet

- Ac 122Document1 pageAc 122avikbhaiNo ratings yet

- Spectrophotometer Importer5Document22 pagesSpectrophotometer Importer5Maurice AbdullahiNo ratings yet

- Ac102 1a PDFDocument1 pageAc102 1a PDFHector Jose Murillo CordobaNo ratings yet

- ULTRAFLOW U1000 Ultrasonic Flowsensor: FeaturesDocument4 pagesULTRAFLOW U1000 Ultrasonic Flowsensor: FeaturesleoNo ratings yet

- RH103 Technical Specification - Small SizeDocument2 pagesRH103 Technical Specification - Small SizeKONAN Narcisse AdiahNo ratings yet

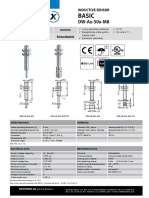

- Basic: DW-Ax-50x-M8Document2 pagesBasic: DW-Ax-50x-M8Oscar Esau Garcia RajzNo ratings yet

- Product Data Sheet: M-Series® M5000Document4 pagesProduct Data Sheet: M-Series® M5000Carlos GilNo ratings yet

- + DS2000-ExdDocument3 pages+ DS2000-Exdmarcello_oliveiraNo ratings yet

- Modmag M-Series m5000 Product Data Sheet Mag-Ds-00175-EnDocument4 pagesModmag M-Series m5000 Product Data Sheet Mag-Ds-00175-EnNAHASALI11No ratings yet

- SD50MTSW01EI SW Manual Eng RevE SW2 3 WDocument99 pagesSD50MTSW01EI SW Manual Eng RevE SW2 3 WAmr N KhNo ratings yet

- 2 DR BTM FRZR - cs1400Document40 pages2 DR BTM FRZR - cs1400Marcella RossiNo ratings yet

- Voice Controlled Robot Through AndroidDocument103 pagesVoice Controlled Robot Through Androidsamar0% (1)

- CW-4T SpeakerDocument2 pagesCW-4T SpeakerDavid CurkanNo ratings yet

- Samsung UN40D5003BFDocument79 pagesSamsung UN40D5003BFJose Barroso GuerraNo ratings yet

- 30RQ17-40 Cat ItDocument9 pages30RQ17-40 Cat ItinkblueNo ratings yet

- Tech Net Bus Info Volvo CanBUSDocument11 pagesTech Net Bus Info Volvo CanBUSalfe20001120No ratings yet

- Elite Wireless Microphones Revolabs Executive: The Gold Standard in Next Generation Wireless MicrophonesDocument2 pagesElite Wireless Microphones Revolabs Executive: The Gold Standard in Next Generation Wireless MicrophonesMuhammad Naveed AshrafNo ratings yet

- Electric Traction - ReferenceDocument19 pagesElectric Traction - ReferenceShrestha SanjuNo ratings yet

- Communications Systems - LBD8921/02 Wall Mounting Handset StationDocument3 pagesCommunications Systems - LBD8921/02 Wall Mounting Handset StationShreyaNo ratings yet

- Unit-Iv Gate Level DesignDocument34 pagesUnit-Iv Gate Level DesignsahithikocharlakotaNo ratings yet

- PCB HelpDocument207 pagesPCB HelpRaraNo ratings yet

- 12 Volt Gel Cell Charger by N1Hfx: Parts ListDocument3 pages12 Volt Gel Cell Charger by N1Hfx: Parts Listsa920189No ratings yet

- SCE27. .IoT Based Real-Time Residential Energy MeterDocument3 pagesSCE27. .IoT Based Real-Time Residential Energy MeterCrispNo ratings yet

- Audio, Visual & Telephone System: SectionDocument16 pagesAudio, Visual & Telephone System: SectionDozer KamilNo ratings yet

- BN208-Networked Applications - T1 2020 - Assessment PaperDocument9 pagesBN208-Networked Applications - T1 2020 - Assessment PaperMuhammad YousafNo ratings yet

- Electrical EnggDocument965 pagesElectrical EnggkrcdewanewNo ratings yet

- Motors DataDocument17 pagesMotors DataMuhammad Zargham AliNo ratings yet

- Electrical Works SpecificationsDocument131 pagesElectrical Works SpecificationsGnabBang100% (2)

- Project Based Multimedia BTLED IA 3ADocument22 pagesProject Based Multimedia BTLED IA 3AJoevan VillaflorNo ratings yet

- Best EEE Job Preparation Syllabus 2020 - EEE Job PreparationDocument6 pagesBest EEE Job Preparation Syllabus 2020 - EEE Job PreparationchristopherNo ratings yet

- Brosur Perangkat Home TheaterDocument14 pagesBrosur Perangkat Home TheaterAlfina MafaNo ratings yet

- Low Voltage Alternator - 4 Pole: 410 To 660 kVA - 50 HZ / 510 To 825 kVA - 60 HZ Electrical and Mechanical DataDocument12 pagesLow Voltage Alternator - 4 Pole: 410 To 660 kVA - 50 HZ / 510 To 825 kVA - 60 HZ Electrical and Mechanical DataMohamedOsmanNo ratings yet

- HS-100 Accelerometer: AC Acceleration Output Via FEP Cable With Protective ConduitDocument1 pageHS-100 Accelerometer: AC Acceleration Output Via FEP Cable With Protective ConduitTrie WahyudiNo ratings yet

- Panasonic NV Gs24 NV Gs26 NV Gs27 NV Gs37 NV Gs47 NV Gs57 NV Gs58Document97 pagesPanasonic NV Gs24 NV Gs26 NV Gs27 NV Gs37 NV Gs47 NV Gs57 NV Gs58Guillermo RNo ratings yet

- Gaasbi/Gaas Multi-Quantum Well Led Grown by Molecular Beam Epitaxy Using A Two-Substrate-Temperature TechniqueDocument9 pagesGaasbi/Gaas Multi-Quantum Well Led Grown by Molecular Beam Epitaxy Using A Two-Substrate-Temperature TechniqueIsmael AnconaNo ratings yet

- Basic Electronics Lab: Dr. Devlina Adhikari PHD (Iit Kharagpur) Assistant Professor, IctDocument45 pagesBasic Electronics Lab: Dr. Devlina Adhikari PHD (Iit Kharagpur) Assistant Professor, IctYash BhavaniNo ratings yet

- Integrated - Power - Designs SRP 30A 2005 DatasheetDocument5 pagesIntegrated - Power - Designs SRP 30A 2005 DatasheetJorge Andres SantistebanNo ratings yet

- Smart SYS N1540180R48 - Datasheet - 180222Document2 pagesSmart SYS N1540180R48 - Datasheet - 180222Will F AlvesNo ratings yet

- Gallium: Professional Paper 1802-HDocument48 pagesGallium: Professional Paper 1802-HPaula GeorgianaNo ratings yet