Professional Documents

Culture Documents

HENRY 565 Technical Data

Uploaded by

caprater1Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HENRY 565 Technical Data

Uploaded by

caprater1Copyright:

Available Formats

The Professional’s Formula For Success™

565 FloorPro TM

Self-Leveling Underlayment

Used to smooth and flatten interior surfaces, such as concrete,

wood, ceramic tile and properly prepared adhesive residues on

concrete, prior to the installation of floor coverings.

• Walkable in 2-3 hours O

ACC RDAN

IN

CE

TESTED

• Install ceramic tile in as little as 6 hours, other floor

WITH

coverings in as little as 16 hours

ST

M C 170

8

A

• Installs up to 5” (12.7 cm) thick

• Can be tapered to meet existing elevations Y TO M

AS I

X

E

• Use to level and smooth select interior substrates prior to

installing floor coverings

R

JU

TE

T A

S

ADD W

’T FORGET

ON

D

TH

er

H

E

EN im

RY 564 Pr

®

The W.W. Henry Company

400 Ardex Park Drive

Aliquippa, PA 15001

(724) 203-8000

1-800-232-4832

www.wwhenry.com

565

can be used to sand large areas. Do not use solvents, strippers

or cleaners. Vacuum all dust and debris. Open joints should be

filled with HENRY® 549 FeatherFinish™ Underlayment Patch

and Skimcoat or HENRY® 547 UniProTM Universal Underlayment

Self-Leveling mixed with HENRY® 546 Feather Edge Additive. It is the

responsibility of the installation contractor to ensure that the

Underlayment wood subfloor is thoroughly clean and properly anchored prior to

the installation of any HENRY® material.

NOTE ON ASBESTOS-CONTAINING MATERIALS: Please note

that when removing existing flooring, any asbestos-containing

Description and Usage materials should be handled and disposed of in accordance with

Formulated from a blend of Portland cements and other applicable federal, state and local regulations.

hydraulic cements, HENRY® 565 is a self-leveling underlayment Prior to application, use 1/2’’ weather stripping or similar to

used to smooth and flatten interior surfaces, such as concrete, keep the HENRY 565 from flowing under cabinets or drywall,

wood, ceramic tile and properly prepared adhesive residues on around plumbing or into adjacent rooms. Protect wall base and

concrete, prior to the installation of floor coverings. Due to its door moldings with painter’s tape and plastic sheeting. Remove

unique leveling and drying characteristics, HENRY 565 allows this course after the product has hardened (approx. 3 hours at

floor covering installation to proceed in as little as 6 hours for 70°F/21°C).

ceramic tile and 16 hours for other floor coverings.

Recommended Tools

Substrate Preparation Mixing paddle, 5-gallon mixing drum (10-gallon mixing drum if

For each of the substrates listed below, acid etching, adhesive extending the HENRY 565 with aggregate; see below), gauge

removers, solvents and sweeping compounds are not rake, smoother, liquid measuring device (5 quarts / 4.7 L per

acceptable means for cleaning the substrate. Substrate and 40 lb. / 18 kg bag), a 1/2” (12 mm) heavy-duty drill (min. 650

ambient temperatures must be a minimum of 50°F (10°C) for the rpm), 1/2’’ (12.7 mm) weather stripping or similar, painter’s tape,

installation of HENRY® products. plastic sheeting and baseball or soccer shoes with non-metallic

cleats. For smaller installations, a steel trowel can be used in

CONCRETE: All concrete substrates must be solid, structurally

place of the gauge rake and smoother.

sound, thoroughly clean and free of oil, wax, grease, asphalt,

latex and gypsum compounds, curing compounds, sealers and Priming

any contaminant that might act as a bond breaker. If necessary,

mechanically clean the floor down to sound, solid concrete NOTE: HENRY® primers may need longer drying times with low

by shot blasting, grinding or similar. Over-watered, frozen or surface temperatures and/or high ambient humidity. Do not install

otherwise weak concrete surfaces also must be cleaned down HENRY 565 before the primer has dried thoroughly.

to sound, solid concrete by mechanical methods. Sanding ABSORBENT CONCRETE: Standard absorbent concrete

equipment is not an effective method to remove contaminants and ceramic tile must be primed with HENRY® 564 FloorPro™

from concrete. Underlayment Primer diluted 1:1 with water. Apply evenly with a

ADHESIVE RESIDUES ON CONCRETE: HENRY 565 also can soft bristled push broom. Do not use paint rollers, mops or spray

be installed over non-water-soluble adhesive residue on concrete equipment. Do not leave any bare spots. Brush off puddles and

only. The adhesive must first be tested to make certain it is excess primer. Allow primer to dry to a clear, thin film (min.

not water-soluble. Water-soluble adhesives must be removed 3 hours, max. 24 hours).

mechanically down to clean concrete. Extremely absorbent concrete may require two applications of

Non-water-soluble adhesives should be prepared to a thin, HENRY 564 to minimize the potential for pinholes forming in the

well-bonded residue using the wet-scraping technique as HENRY 565. Make an initial application of HENRY 564 diluted

recommended by the Resilient Floor Covering Institute with 3 parts water by volume. Let dry thoroughly (1 to 3 hours),

(www.rfci.com) to remove thick areas and adhesive build-up, and install a second application of HENRY 564 mixed 1:1 with

as well as any areas that are weak or not well bonded to the water as stated above.

concrete. Any existing patches below the adhesive must be WOOD AND ADHESIVE RESIDUE ON CONCRETE: Prime

removed completely. with HENRY 564 at full strength (do not dilute). Apply directly to

CERAMIC TILE: HENRY 565 can be applied over clean, the prepared substrate with a short-nap or sponge paint roller,

sound, solidly bonded ceramic tile. The tile must be roughened leaving a thin coat of primer. Do not use a push broom. Do not

mechanically to remove the glaze. The tile must be clean, leave any bare spots. Brush off puddles and excess primer. Allow

including the complete removal of existing dust, dirt, debris and primer to dry to a clear, thin film (min. 3 hours, max. 24 hours).

any other contaminant that may act as a bond breaker. Substrate For wood substrates, after priming, install 3.2 or 3.4 galvanized,

preparation must be by mechanical means, such as shot blasting. expanded diamond metal lath mesh (“plaster lath”) to the

WOOD: The wood subfloor either must be solid hardwood subfloor, stapling approximately every 6” (15.2 cm) to prevent

flooring; a minimum of 3/4’’ (19 mm) tongue-and-groove, the mesh from floating. Overlap adjacent pieces of mesh by

APA-rated Type 1, exterior exposure plywood; or an approved approximately 1” (2.5 cm).

OSB equivalent. The wood subfloor must be constructed

according to prevailing building codes and must be solid and

Joints and Cracks

securely fixed to provide a rigid base free of undue flex. Any Under no circumstances should HENRY 565 be installed over

boards exhibiting movement must be re-nailed. The surface of any moving joints or moving cracks. All existing expansion

the wood must be clean and free of oil, grease, wax, dirt, varnish, joints, isolation joints and construction joints, as well as all

shellac and any contaminant that might act as a bond breaker. If moving cracks, must be honored up through the underlayment

necessary, sand down to bare wood. A commercial drum sander and flooring.

As needed, dormant cracks and dormant joints can be filled Wear Surface

with HENRY 549 or HENRY 547 mixed with HENRY 546,

following the instructions in each product’s technical brochure. HENRY 565 is not to be used as a permanent wear surface,

even if coated or sealed. HENRY 565 must be covered by a

However, please be advised that while dormant control joints suitable floor covering material, such as carpet, vinyl flooring,

and dormant cracks in the slab may be filled with HENRY ceramic tile, etc.

549 or HENRY 547 mixed with HENRY 546 prior to installing

HENRY 565, this filling is not intended to act as a repair Installation of Flooring

method that will eliminate the possibility of joints and cracks HENRY 565 is walkable 2 to 3 hours after installation.

telegraphing. HENRY 549, HENRY 547 and HENRY 565 are Install moisture-insensitive tile, such as ceramic, quarry

non-structural materials and are, therefore, unable to restrain and porcelain, after a 6-hour cure. Allow a 16-hour cure

movement within a concrete slab. This means that while some for all other floor coverings. Drying time is a function of

dormant joints and dormant cracks may not telegraph through jobsite temperature and humidity conditions, as well as the

the HENRY® materials and up into the finish flooring, cracks installation thickness. Low substrate temperatures and/or

will telegraph in any area that exhibits movement, such as an high ambient humidity will extend the drying time. Adequate

active crack, an expansion or isolation joint, or an area where ventilation and heat will aid drying.

dissimilar substrates meet. We know of no method to prevent

this telegraphing from occurring. Notes

Mixing and Application This product is intended for interior use over dry substrates

only. Do not use in areas of constant water exposure or in

HENRY 565 is mixed one bag at a time. Mix each 40 lb. (18 kg) areas exposed to permanent or intermittent substrate moisture,

bag with 5 quarts (4.7 L) of clean water. Pour the water in the as this may jeopardize the performance of the underlayment

mixing drum first, and then add the HENRY 565 while mixing and the floor covering. This product is not a vapor barrier, and

with a mixing paddle and a 1/2” (12 mm) heavy-duty drill will allow free passage of moisture. Follow the directives of the

(min. 650 rpm). Mix thoroughly for approximately 2 to 3 floor covering manufacturer regarding the maximum allowable

minutes to obtain a lump-free mix. Do not overwater! substrate moisture content, and test the substrate prior to

Yellowish foam while mixing, or settling of the sand aggregate installing HENRY 565. Where substrate moisture exceeds the

while placing, indicates overwatering. maximum allowed, The W.W. Henry Company recommends

HENRY 565 has a flow time of 10 minutes at 70°F (21°C). the use of ARDEX Moisture Control Systems. For further

Pour the mix onto the floor, and spread with a gauge rake. information, please refer to the ARDEX technical brochures at

Immediately smooth the material with a smoother. Work in a www.ardexamericas.com.

continuous manner during the entire self-leveling installation. HENRY 565 can be used in areas exposed to intermittent

Wear baseball or soccer shoes with non-metallic cleats to topical moisture, such as bathrooms and kitchens.

avoid leaving marks in the liquid HENRY 565.

Always install an adequate number of properly located

Thickness of Application test areas, including the finish flooring, to determine the

Install HENRY 565 at a minimum thickness of 1/8’’ (3 mm) suitability of the products for the intended use. As floor

over the highest point in the floor, which typically results in coverings vary, always contact and rely upon the floor

an average thickness of 1/4’’ (6 mm) or more over the entire covering manufacturer for specific directives, such as

floor. HENRY 565 can be installed up to 1 1/2” (3.8 cm) over maximum allowable moisture content, adhesive selection

large areas neat, and up to 5’’ (12.7 cm) with the addition of and intended end use of the product.

proper aggregate. Never mix with cement or additives other than HENRY®

To match existing elevations, HENRY 565 can be tapered to approved products. Observe the basic rules of concrete work.

as thin an application as the sand in the material will allow. Do not install below 50°F (10°C) surface and air temperatures.

If a true featheredge is needed, The W.W. Henry Company Install quickly if the substrate is warm, and follow warm

recommends using HENRY 549 or HENRY 547 mixed with weather instructions available from the HENRY® Technical

HENRY 546 for transitions. Service Department.

For areas with a thickness greater than 1 1/2’’ (3.8 cm), mix Dispose of container and residue in accordance with federal,

HENRY 565 with washed and well-graded 1/8’’ to 3/8’’ (3 to state and local waste disposal regulations. Do not flush

9.5 mm) pea gravel. Please note that the aggregate size must material down drains.

not exceed 1/3 the depth of the pour. Mix the HENRY 565

with water first, and then add 1 part aggregate by volume,

mixing until the aggregate is completely coated. Do not use

sand. If the aggregate is wet, reduce the amount of water to

avoid overwatering.

The addition of aggregate will diminish the workability of the

product and may make it necessary to install a neat coat to

obtain a smooth surface. Allow the initial application to dry

for 12 to 16 hours, and then prime this layer with HENRY 564

mixed 1:1 with water. Allow the primer to dry (min. 3 hours,

max. 24 hours) before installing the neat coat of HENRY 565.

Technical Data According To W.W. HENRY

Quality Standards

All data based on a mixing ratio of 3.5 parts powder to

1 part water by volume at 70°F / 21°C and in accordance with

ASTM C1708 as applicable. Physical properties are typical

values and not specifications.

Mixing Ratio: 5 quarts (4.7 L) of water per 40 lb. (18 kg) bag

Approximate

Coverage: 22 sq. ft. per bag at 1/4’’ (2 sq. m at 6 mm)

44 sq. ft. per bag at 1/8’’ (4 sq. m at 3 mm)

Coverage will vary depending on the texture

of the surface being smoothed.

Flow Time: 10 minutes

Initial Set

(ASTM C191): Approx. 30 minutes

Final Set

(ASTM C191): Approx. 90 minutes

Compressive

Strength (ASTM

C109/mod – Air

cure only): 4,100 psi (287.0 kg/cm2) at 28 days

Flexural Strength

(ASTM C348): 1,000 psi (70 kg/cm2) at 28 days

Walkable: 2 to 3 hours

Install Flooring: 6 hours for moisture-insensitive tile, such as

ceramic, quarry and porcelain; 16 hours for

all other floor coverings

VOC: 0

Packaging: 40 lb. (18 kg) bag

Storage: Store in a cool, dry area. Do not leave bags

exposed to sun.

Cleanup: Before the product dries, clean tools with a

coarse, clean cloth dampened with warm,

soapy water.

Shelf Life: 1 year, if unopened

Warranty: HENRY® Standard Limited Warranty applies.

Made in the USA by The W.W. Henry Company, Aliquippa, PA 15001

© 2013 The W.W. Henry Company, L.P. All rights reserved.

05-28-2013

The W.W. Henry Company

400 Ardex Park Drive

Aliquippa, PA 15001

(724) 203-8000

1-800-232-4832

HR046 (06/15) www.wwhenry.com

You might also like

- Emotion WheelDocument1 pageEmotion WheelJose Luis Florez Castro100% (1)

- Subaru Engines Ex13 Ex17 Ex21 Ex27 sp170 sp210 Ex21efi Service PDFDocument113 pagesSubaru Engines Ex13 Ex17 Ex21 Ex27 sp170 sp210 Ex21efi Service PDFCristiano FerreiraNo ratings yet

- Subaru Engines Ex13 Ex17 Ex21 Ex27 sp170 sp210 Ex21efi Service PDFDocument113 pagesSubaru Engines Ex13 Ex17 Ex21 Ex27 sp170 sp210 Ex21efi Service PDFCristiano FerreiraNo ratings yet

- B737max8 Corrected FaclivDocument9 pagesB737max8 Corrected FaclivNGUYỄN BìnhNo ratings yet

- HY006Document23 pagesHY006electronisicstimesNo ratings yet

- Petronas Technical Standards: The Design of Glycol ContactorsDocument47 pagesPetronas Technical Standards: The Design of Glycol ContactorsadamNo ratings yet

- Creative Habits of The MindDocument2 pagesCreative Habits of The MindmuscdalifeNo ratings yet

- Bco Grade 8 English First Quarter PDFDocument4 pagesBco Grade 8 English First Quarter PDFAudhrey BravoNo ratings yet

- Cable TieDocument64 pagesCable TieSanthosh Nerlige Sundar RajNo ratings yet

- Chapter 3. One-Compartment Open Model Intravenous Bolus AdministrationDocument23 pagesChapter 3. One-Compartment Open Model Intravenous Bolus AdministrationbencleeseNo ratings yet

- Coiled Tubing Acid Stimulation: The Case of Awi 8-7 Production Well in Salak Geothermal Field, IndonesiaDocument7 pagesCoiled Tubing Acid Stimulation: The Case of Awi 8-7 Production Well in Salak Geothermal Field, IndonesiaHafiizhNurrahmanNo ratings yet

- Gpa 2286-95 PDFDocument22 pagesGpa 2286-95 PDFaidanNo ratings yet

- Solar 255Lc-V Solar 255Lc-V Solar 255Lc-V Solar 255Lc-VDocument35 pagesSolar 255Lc-V Solar 255Lc-V Solar 255Lc-V Solar 255Lc-VErick AlejandroNo ratings yet

- TLF - 3 BHK Elegant Luxury Floors SEC-63ADocument21 pagesTLF - 3 BHK Elegant Luxury Floors SEC-63Asandeep.dhupalNo ratings yet

- 2004.03 Salmonella en Alimentos ELFADocument3 pages2004.03 Salmonella en Alimentos ELFAJavier muñozNo ratings yet

- Cafeteria Design PDFDocument7 pagesCafeteria Design PDFShruti JhaNo ratings yet

- Autos - Paper LC100 PDFDocument2 pagesAutos - Paper LC100 PDFPablo CarreñoNo ratings yet

- B15 GB Environmental and Municipal TechnologyDocument24 pagesB15 GB Environmental and Municipal TechnologyThinker OctansNo ratings yet

- Solar 500Lc-V Solar 500Lc-V Solar 500Lc-V Solar 500Lc-V Giant Giant Giant GiantDocument27 pagesSolar 500Lc-V Solar 500Lc-V Solar 500Lc-V Solar 500Lc-V Giant Giant Giant GiantErick AlejandroNo ratings yet

- 106c - Pmc-E BulletinDocument24 pages106c - Pmc-E BulletinAbu SyafieqNo ratings yet

- Bancs BostromDocument2 pagesBancs BostromSébastien DionNo ratings yet

- APART Air Panas-ModelDocument1 pageAPART Air Panas-ModelTwrk IncNo ratings yet

- Process Steels BrochureDocument8 pagesProcess Steels Brochure970186csNo ratings yet

- ANALYSISDocument1 pageANALYSISShruti JhaNo ratings yet

- M1 Pacific Motorway Extension To Raymond TerraceDocument4 pagesM1 Pacific Motorway Extension To Raymond TerraceSimon McCarthyNo ratings yet

- D80190GC20 Les04Document40 pagesD80190GC20 Les04Revankar B R ShetNo ratings yet

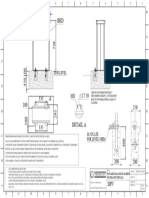

- JN1399 - JSA-01-01 - R1 - Option-1Document1 pageJN1399 - JSA-01-01 - R1 - Option-1Riyan EsapermanaNo ratings yet

- Architectural Portfolio - Vishal Infant Raj.TDocument30 pagesArchitectural Portfolio - Vishal Infant Raj.Tvishal infantraj100% (1)

- Outdoor-Eats CM 0722Document14 pagesOutdoor-Eats CM 0722John FoxNo ratings yet

- FFB BrochureDocument4 pagesFFB Brochureprashant_mahitkar4532No ratings yet

- SeminopolyDocument1 pageSeminopolyfararaNo ratings yet

- D80190GC20 Les02Document32 pagesD80190GC20 Les02Revankar B R ShetNo ratings yet

- Structure Details - Cooling Tower - J244Document1 pageStructure Details - Cooling Tower - J244vishnutryNo ratings yet

- Gen Pigpro-Flange InstallguideDocument1 pageGen Pigpro-Flange InstallguideMuhammad Ashabul YZNo ratings yet

- FUJIPRE2400304-ZGF01 W24030468-J400-07 (1720×1200,1100×900,M750) (2CO) 钢带 英文 ModelDocument1 pageFUJIPRE2400304-ZGF01 W24030468-J400-07 (1720×1200,1100×900,M750) (2CO) 钢带 英文 ModelTakumina ServicesNo ratings yet

- PDF Created With Fineprint Pdffactory Pro Trial VersionDocument103 pagesPDF Created With Fineprint Pdffactory Pro Trial Versionlii liiNo ratings yet

- DPV Foundation HB50Document1 pageDPV Foundation HB50rusiru.dpvNo ratings yet

- Merchants' Academy Learner Profile Passport: ThinkersDocument6 pagesMerchants' Academy Learner Profile Passport: Thinkersbonda_1234No ratings yet

- Pen Type PH MeterDocument1 pagePen Type PH Metersuman dasNo ratings yet

- Kursi ChairmanDocument99 pagesKursi ChairmanptexitamaNo ratings yet

- 3010 100lb TransducerDocument2 pages3010 100lb TransducerLouie FernandezNo ratings yet

- THE RISE Brochure 13 - Small Brochure-250124Document16 pagesTHE RISE Brochure 13 - Small Brochure-250124raja babuNo ratings yet

- DSPX - Almb - A014 - Factory Buildings Ground FloorDocument1 pageDSPX - Almb - A014 - Factory Buildings Ground FloorAshwini ShettyNo ratings yet

- A R C H: Lodging Sports Entertainment Shopping Hotel CondominiumDocument1 pageA R C H: Lodging Sports Entertainment Shopping Hotel CondominiumjashndeepNo ratings yet

- Vadacha Mala L SectionDocument1 pageVadacha Mala L SectionPrashant GaradNo ratings yet

- Compact Dehumidifiers FFB Series BrochureDocument4 pagesCompact Dehumidifiers FFB Series Brochurelogicgates2002No ratings yet

- Lifting Plan DrawingDocument1 pageLifting Plan DrawingPintu kumarNo ratings yet

- 10 - 02 - 16 - Temporary Single Line DiagramDocument1 page10 - 02 - 16 - Temporary Single Line Diagrammudassir mNo ratings yet

- Springfield Citywide Systemic Safety Interventions ProjectDocument4 pagesSpringfield Citywide Systemic Safety Interventions ProjectRyan TrowbridgeNo ratings yet

- CA Trodat 2023 GB MasterDocument55 pagesCA Trodat 2023 GB MasterRomel Remolacio AngngasingNo ratings yet

- 1000 Series Fire Hose CabinetsDocument2 pages1000 Series Fire Hose CabinetsPARIETALNo ratings yet

- Topic School Rules: Da y Remark SDocument4 pagesTopic School Rules: Da y Remark SKayè Sy PiansayNo ratings yet

- Creating Videos With Confidence WorkbookDocument29 pagesCreating Videos With Confidence Workbookvero baudensNo ratings yet

- Engr. Ramon A. Orbita Engineering Utilities 2 Tan, Maria Francheska ZDocument1 pageEngr. Ramon A. Orbita Engineering Utilities 2 Tan, Maria Francheska ZBalte, Richard F.No ratings yet

- Contour Garden: T O IL E T T O IL E T 1s TF LO O R T O IL E T 1s TF LO O R T O IL E TDocument1 pageContour Garden: T O IL E T T O IL E T 1s TF LO O R T O IL E T 1s TF LO O R T O IL E Tpramod vikramNo ratings yet

- VT-2023-WMS-1563 (006) VishnuHariKumarDocument1 pageVT-2023-WMS-1563 (006) VishnuHariKumarprakashNo ratings yet

- Anderson County Sheriff's Office: Tall OaksDocument7 pagesAnderson County Sheriff's Office: Tall Oaksalpca8615No ratings yet

- Electric Potters WhelDocument1 pageElectric Potters WhelGajsNo ratings yet

- Trolley Aera: Concrete Road New Proposed TST RoadDocument1 pageTrolley Aera: Concrete Road New Proposed TST RoadulfatNo ratings yet

- Sectores A, B, C, D, E, F, I Puertas de Madera: Aulas Asesorías SH. MujeresDocument1 pageSectores A, B, C, D, E, F, I Puertas de Madera: Aulas Asesorías SH. MujeresAmdi Astochado MondragonNo ratings yet

- Pol808 3Document4 pagesPol808 3robert.leon007No ratings yet

- En Rhel 7 Server Datasheet 12182617Document4 pagesEn Rhel 7 Server Datasheet 12182617Zacarias VillanuevaNo ratings yet

- 17041aa108 DWG PDF-modeldDocument1 page17041aa108 DWG PDF-modeldVishnu ThipparthiNo ratings yet

- Australian Motorcycle News - April 15, 2021Document118 pagesAustralian Motorcycle News - April 15, 2021Mou MoiraNo ratings yet

- ERO 15569 Effective School Evaluation June16 FULL WEB 002Document44 pagesERO 15569 Effective School Evaluation June16 FULL WEB 002William J ElliottNo ratings yet

- Acu5050a r2Document28 pagesAcu5050a r2princesa762No ratings yet

- Pcuk Pricelist 2018Document36 pagesPcuk Pricelist 2018Erwin FernándezNo ratings yet

- Feral Hog Buying Stations in TexasDocument4 pagesFeral Hog Buying Stations in Texascaprater1No ratings yet

- Trim Components: Steel Building & Residential Metal RoofingDocument32 pagesTrim Components: Steel Building & Residential Metal Roofingcaprater1No ratings yet

- Alkenes and Alkynes I: Properties and Synthesis. Elimination Reactions of Alkyl HalidesDocument95 pagesAlkenes and Alkynes I: Properties and Synthesis. Elimination Reactions of Alkyl HalidesRoby PadillaNo ratings yet

- ESD Tape ApplicationsDocument6 pagesESD Tape Applicationslordycarlos8588No ratings yet

- Effect of The Tilt Angle of Natural Convection in A Solar Collector With Internal Longitudinal FinsDocument5 pagesEffect of The Tilt Angle of Natural Convection in A Solar Collector With Internal Longitudinal FinsInternational Journal of Science and Engineering InvestigationsNo ratings yet

- SSI AFD270 9in DiscDiff 012210Document2 pagesSSI AFD270 9in DiscDiff 012210Chris HdezNo ratings yet

- Periodic LawDocument2 pagesPeriodic LawenzoNo ratings yet

- Major Plant of NirmaDocument3 pagesMajor Plant of NirmaAnndy TrivediNo ratings yet

- HT Solved NumericalsDocument56 pagesHT Solved NumericalsKiran AkkoliNo ratings yet

- ENITV21D 1 Intervention For ChemistryDocument8 pagesENITV21D 1 Intervention For ChemistryMateo HernandezNo ratings yet

- Classes of CompoundsDocument12 pagesClasses of CompoundsReynaldo VirtucioNo ratings yet

- The Complexometric Determination of Calcium and Magnesium in The Same SampleDocument3 pagesThe Complexometric Determination of Calcium and Magnesium in The Same SampleRieska foni YuniarNo ratings yet

- Automated Plate Load Test: Aplt CapabilitiesDocument2 pagesAutomated Plate Load Test: Aplt CapabilitiesjoseriquNo ratings yet

- Identifying Minerals Lab ActivityDocument3 pagesIdentifying Minerals Lab ActivityJasmine ButteryNo ratings yet

- NSTSE Class 7 Solved Paper 2009Document23 pagesNSTSE Class 7 Solved Paper 2009swainanjanNo ratings yet

- Assay of Chloroquine Phosphate Experiment No.: Date: Aim: To Perform The Assay of Chloroquine Phosphate. Reference: RequirementsDocument3 pagesAssay of Chloroquine Phosphate Experiment No.: Date: Aim: To Perform The Assay of Chloroquine Phosphate. Reference: RequirementsDinesh ThakkarNo ratings yet

- Unit V BIO-CHEMICAL MEASUREMENTDocument8 pagesUnit V BIO-CHEMICAL MEASUREMENTAleeshaNo ratings yet

- Export Promotion Council (EPC) For LeatherDocument25 pagesExport Promotion Council (EPC) For Leathersiddharthjain9149No ratings yet

- Non Condensable GasDocument4 pagesNon Condensable GasSherwin AgootNo ratings yet

- Protein-Synthesis WorksheetDocument5 pagesProtein-Synthesis WorksheetAme RealNo ratings yet

- Journal of Radiation Research and Applied Sciences: Abdullah Al Naim, Nisrin Alnaim, Sobhy S. Ibrahim, S.M. MetwallyDocument7 pagesJournal of Radiation Research and Applied Sciences: Abdullah Al Naim, Nisrin Alnaim, Sobhy S. Ibrahim, S.M. MetwallySarifatul HidayahNo ratings yet

- GR 12 Biology Moddel ExamDocument8 pagesGR 12 Biology Moddel ExamDawit MarkosNo ratings yet

- Phosgenation A Handbook Hal 20 EnglishDocument3 pagesPhosgenation A Handbook Hal 20 EnglishPriska Dewi AnjarsariNo ratings yet

- Classical ExperimentsDocument2 pagesClassical ExperimentsShane Cagas AcaoNo ratings yet

- Housekeeping-G11-Module-Lesson 3Document13 pagesHousekeeping-G11-Module-Lesson 3clarencesangatNo ratings yet

- Notes On Q M C Delta TDocument2 pagesNotes On Q M C Delta TDing30180No ratings yet