Professional Documents

Culture Documents

DS Series: Instruction Manual

Uploaded by

Alejandro PortilloOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DS Series: Instruction Manual

Uploaded by

Alejandro PortilloCopyright:

Available Formats

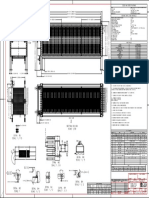

Precautions for using laser Specifications DIMENSIONAL DRAWING

Laser emission warning light • DSTA-200 • DSR-800

(unit : mm)

Digital Amplifier Detachable Photoelectronic Sensor Retro Diffuse Through beam Through beam/ 52.9 2.7 34.6

Confirmation of laser emission is available with the laser emission warning light. 36.6

• DSR-5000 21.

3.2

Model

3.2

reflection type reflection type type Length measurement type 31.65 16.1

DS Series It starts lighting after turning the power on and keeps lighting while the laser is being

2-

• DSD-100

2-

radiated. It is also possible to confirm with the exclusive amplifier unit. Cable DSR- DSD-100 DSTC-200 DSTA-200 • DSTC-200

13.4

13.4

10.6

13

13

Laser radiation warning light Emitter: DSTC-D Emitter: DSTA-D Output indicator light Output indicator light

Laser emission indicator light Laser emission indicator light

Laser Type Sensor Head DSR -800 DSTC-200-M8 (Green) 800 5000 Detector: DSTC-200 Detector: DSTA-200 52.9

DSR -5000 DSTA-200-M8 M8 Relay-type - - DSTC-200-M8 DSTA-200-M8

46.4

11.2

34.6

9.9 25.9 2.6 19.1 12.7

DSD -100 2-R R2

.6

(DSR-800/DSR-5000 Emitter M8 - - DSTC-S DSTA-S

18.6 (Optical center)

.6

DSTC-200 R2

10.6

DSD-100/DSTC-D Detector M8 - - DSTC-R DSTA-R

26.5

(DSTA-D/DSTA-S)

20.9

DSTA-200 DSTC-S)

23.5 (Optical center)

Adaptable amplifier unit DSA-M /DSA-M -M8 / DSA-S

6.5

8.2

41.4

37.4

47

Laser label

34

2.8

28.1

Light source Visible light semiconductor laser 650nm

Instruction Manual This product is classified as a Class 2 (II) Laser Product by JIS C6802 / IEC / FDA Laser

Safety Standard as this radiates the visible laser beam. The warning label and the Output max. 3mW max. 390 W

18.5 2- 3.2

Mounting hole

2.8

description label in English are attached on the side face of the sensor head indicating the IEC/JIS CLASS CLASS 2 CLASS 1 18.5 2- 3.2 1

16.1

12.35

Mounting hole 2

3

* Thank you for purchasing the DS Series. We hope you are fully satisfied with this product and enjoy CLASS 2/Class II. FDA CLASS Class II 1

4

16.1

12.35

2

its performance. * The emitters DSTC-D/DSTA-D and DSTC-S/DSTA-S of DST-200/M8 and DSTA-200/-M8 are rated 3

6

4

as Class II by the FDA standard (when exporting to the US). However, the class 1 is applied for the Detection Long 8m 0.5…50 m 1m 2m

* Carefully read this instruction manual and keep it for future reference. 6 3 2 core cable Standard length 2m (Ash) DSR/DSD : 3 4 core cable Standard length 2m

JIS/IEC standard. distance Standard 5m 0.3…35 m 0.7 m 2m Length measurement mode: 0.5 m 3 4 core cable Standard length 2m (Black) DSTC : 3 2 core cable Standard length 2m (Ash)

Exchange the label enclosed with the product. 3 4 core cable Standard length 2m (Black)

*1 Fast 2m 0.1…20 m 0.25 m (Only Long and Standard)

Approx. 2 mm Approx. 1 mm Approx. 2 mm Approx. 30 x 2.5 mm

Japan Beam size *2

Safety Precautions (Distance: 2 m) (Distance: 1 m) (Distance: 2 m) (Distance: 2 m) • DSTA-200-M8 52.9 2.7

• DSTC-200-M8 34.6

36.6 21.

3.2

Repeat accuracy *3 0.2 mm 0.2 mm 0.2 mm 0.3 mm

3.2

31.65 16.1

2-

Carefully read and understand the safety precautions before operation.

2-

Indicator light Laser radiation indictor light: Green Output indicator light: Orange

The important information is provided to protect your health and property.

13.4

10.6

13.4

13

13

Operating temperature/humidity -10 to +55°C/35 to 85 %RH (No condensation or freezing)

Do not apply any other installing or operating procedure other than that described in Laser emission indicator light Output indicator light Laser emission indicator light Output indicator light

Store temperature/humidity -25 to +70°C/35 to 85 %RH (No condensation or freezing)

this manual. 52.9

Ambient light 3,000 lx (Incandescent light) 10,000 lx (Sunlight) 9.9

46.4

11.2

34.6

25.9 2.6 19.1 12.7

Other countries (except US) Shock resistance 10 to 55 Hz Double-amplitude 1.5 mm 2 hours at each direction of X, Y and Z

2-R R2

.6

Meanings of Safety Symbols

18.6 (Optical center)

.6

R2

10.6

Protection category IP67

26.5

20.9

Indicates a possible hazard that may result in Material PC (Case, Cover) PMMA / Glass (Front glass)

23.5 (Optical center)

37.4

41.4

6.5

8.2

47

34

death, serious injury, or serious property damage

2.8

Weight (including the codes)*4 45g 90g 115g 28.1

WARNING if the product is used without observing the stated 2- 3.2

Mounting hole

instructions. * 1 DSD-100 : With white paper (90 %) of 200 x 200 mm 2- 3.2 3 2 core cable Standard length 0.15m (Ash) Tip: M8 Plug

2.8

Mounting hole 3 4 core cable Standard length 0.15m (Black) Tip: M8 Plug

DSR-800 : With the reflector MP-45 (accessory) 3 2 core cable Standard length 0.15m (Ash) Tip: M8 Plug 18.5

US 3 4 core cable Standard length 0.15m (Black) Tip: M8 Plug

DSR-5000 : With the reflector P250F (accessory) 18.5

When exporting this machine to the US, the US laser control, FDA (Food and Drug

6

Indicates a possible hazard that may result in 1

16.1

12.35

* 2 Defined with center strength 1/e2 (13.5%). There may be leak light other than the specified spot size. The sensor 2

6

Administration) is applied. This product has been already reported to CDRH (Center 1 3

16.1

CAUTION

12.35

personal injury or property damage if the product is may be damaged when there is a highly reflective object around the targets

2

3

4

used without observing the stated instructions. for Devices and Radiological Health). For details, contact our Customer Service. 4

6

3 2core cable Standard length 2m (Ash) Tip: M8 Jack

* 3 Right angle to sensing axis.(to 2m) 6 3 2core cable Standard length 2m (Ash) Tip: M8 Jack

3 4core cable Standard length 2m (Black) Tip: M8 Jack 3 4core cable Standard length 2m (Black) Tip: M8 Jack

* 4 The weights of DSTC-200 and DSTA-200 include the emitter and the ditector.

Mandatory Requirements (DSR-800/DSR-5000 Accessories and others • MP-45 • P250F

This product is not an explosion-proof construction. Do DSD-100/DSTC-D

WARNING (DSTA-D/DSTA-S)

0.2

not use the product under flammable, explosive gas or DSTC-S) Lens attachment (Model BL-W130L-1:Optional)

4.5

liquid environment. Certification label (1)

Installing the attachment to DSR-800・DSR-5000 allows two types of beam shape: Line 44.8

Use of controls or adjustments or performance of procedures FDA warning /

FDA warning / Laser open 37 2

other than those specified herein may result in hazardous / Certification label (4) beam and area beam. Attach the beam-shape lens and the optical axis to use together. 2-R3.7 23 2- 3.2

Laser open label (2)(3)

radiation exposure.

14.5

The light source of this product applies the visible light

7.4

29

23

semiconductor laser. (1) (3)

7.4

Do not disassemble or modify the product since it is not Beam shape

designed to automatically stop the laser emission when Line beam lens

4-

4-R1.2

Approx. 40 x 1 mm

C3

open. Disassembling or modifying at customer's end may Line beam

cause personal injury, fire or electric shock. (Distance: 300 mm)

Do not stare into the laser beam directly, install at eye- Approx. 35 x 35 mm

level of the people around, nor expose the beam to the Area beam lens Area beam

(Distance: 300 mm)

human body intentionally. (2) (4) ・MP-225 (Cutting type) ・BL-W130L-2 [Slit for DSTA-200]

Use the exclusive amplifier unit to connect the product.

Not doing so may result in an accident or product damage.

Wiring or disconnecting with the power ON is danger.

Never fail to turn OFF the power supply.

* The beam form may depend on the individual products.

This product cannot be used as a safety device to * Do not use for DSD-100. Uninstallable to DSTA-200, DSTA-200-M8, nor DSTA-S.

protect human body.

Operating Precautions Precautions in using DSTA-200 / DSTA-200-M8 MP-45 Reflector (attached to DSR-800・DSR-5000)

When using DSTA-200 or DSTA-200-M8 for length measurement, follow the Instruction for use

Installing in the following places may result in malfunction: instructions below. 1. When cleaning, blow off or lightly wipe with a soft cloth.

CAUTION 1. A dusty or steamy place Emitter is applied to gray cable and Receiver is applied to black one. Do not use thinner, benzene or kerosene. The product specification may change without notice for improvement.

2. A place generating corrosive gas Install the sensor so that the sensor of flood beam is positioned in the center of the 2. Avoid strong push of the reflecting surface or direct impact. For any inquiry, please contact the manufacture/vendor below.

3. A place directly receiving scattering water or oil light receiving part. (Install so that the indication value of amplifier unit is Doing so may result in damaging the prism and deteriorating the performance.

4. A place suffered from heavy vibration or impact maximum.) 3. Avoid using outside or under the environment where oil or water scatters.

Do not use the sensor outside nor expose the detection Install the flooding/receiving device in the same direction.

surfacedirectly to ambient light (laser light, incandescent Refer to each label or indicator light as a standard. Installation procedure

light and sunlight). Refer to the figure below and use in the correct direction.

Indicator light Improper installation may cause malfunction.

Do not use the sensor in transient state after power on Indicator light

approx. 100 ms). Head office: Mitsui Seimei Kyoto Yamashina BLDG 6F, 46-1

The sensor performance may depend on the individual Takehanadounomae-cho, Yamashina-ku, Kyoto

units. 607-8085 Japan

Wipe off dirt on the emitting/receiving parts to maintain TEL: +81-(0)75-594-8123

correct detection. Also, avoid direct impact on the FAX: +81-(0)75-594-8124

product. Indicator light

Website http://www.optex-fa.com

0536692

ヘッド取説.indd 1 2006/01/24 14:32:55

Specification Each Part Two Points Teaching Teaching Transparent Object

Switch to SET. Reflection type Switch to SET. Rotating reflection type: Perform when

Digital Amplifier Detachable Photoelectronic Sensor Advanced Model (2CH) Standard Model (1CH)

1st: Perform adjustment when there is there is no object.

SET RUN an object. SET RUN

D2SA Series Model

Cable type

M8 connector type

Base unit

D2SA-M(N/P) D2SA-S(N/P) D2SA-M(N/P)3 D2SA-S(N/P)1

-

Handset

-

Base unit

D2SA-M(N/P)-M8 D2SA-S(N/P)-M8

Handset

Select the two points teaching.

Laser Type Amplifier Unit D2SA-M D2SA-M 3 Adaptable sensor head DS Series

D2SA-S D2SA-S 1 Power source, voltage 12 - 24 V DC ± 10 % including a ripple

T 1st point: Press the teaching button. T Press the teaching button.

D2SA-M -M8 D2SA-S -M8 Consumption current 45 mA or less / 24 V No. Name Function Reflection side -10%

of reflector

Response time 60µs/500µs/2ms (Fast/Standard/Long) Laser emission indicator light Turns on while the amplifier is powered.

2nd: Perform adjustment with the

1 CH output indicator light Turns on when the output of 1 CH is ON.

NPN / PNP Open collector background without object.

Control output T 2nd point: Press the teaching button.

Load current: 100 mA or less Residual voltage:1.8 V or less 2 CH output indicator light Turns on when the output of 2 CH is ON.

Instruction Manual Indicator light

Laser emission indicator light: Green, Output Indicator light: Orange (1·2CH)

Teaching indicator light: Red Channel indicator light: Green (1·2CH)

Main monitor (Red)

Sub monitor (Green)

Displays light intensity, function, and the number of counts.

Displays the threshold, function selection, and the number of counts. Threshold

Switch to RUN.

Digital display 7 segment 8 digit display Teaching mode indicator light Turns on in the Teaching mode. Set the threshold to -10 % against the

Thank you for purchasing DSA Series. We hope you are fully satisfied with this product and enjoy its SET RUN

performance. amount of received light.

Timer function OFF, On delay, Off delay, One-shot Valid channel indicator light Keeps turning ON when the monitor display value,

Carefully read this instruction manual and keep it for future reference. (1 CH) adjustment, and the function setting are valid to 1 CH.

Timer time 1 ms - 9 s

Switch to RUN. The threshold flashes and the

Mutual interference Valid channel indicator light Keeps turning ON when the monitor display value, display returns to normal.

Yes: Up to 4 machines SET RUN 1st

prevention function (2 CH) adjustment, and the function setting are valid to 2 CH.

Threshold

Safety Precautions Output method Light on / Dark on Switching type in the function UP button RUN mode: Displays or changes the threshold. 2nd

The threshold flashes and the Set the threshold at the center between

Teaching Length Measurement

Analog output Current output:4 - 20 mA - DOWN button Function mode: Selects the function or changes the numerical values.

display returns to normal. the 1st and the 2nd points. Valid only when the length measurement function is set. Allows to

Carefully read and understand the safety precautions before operation. External input setting External input setting Mode button RUN mode: Switches to the Function mode. (0.5 s )

determine the size or the length of object.

The important information is provided to protect your health and property. (teaching, synchronizing input, (teaching, synchronizing input, Function mode: Fix the selection.

* Not displayed on the teaching mode menu unless the application of length

Do not apply any other installing or operating procedure other than that described in floodlight off, counter reset) floodlight off, counter reset) Teaching button RUN mode: Switches the channel. measurement is selected in the detection mode setting.

this manual. Setting input/output Output setting * Teaching length measurement or length measurement mode does not measure the

Function mode: Returns to RUN mode or performs scaling. actual length of object accurately.

(2CH output + Alarm output) * Settable only with D2SA-M -M8

Set mode: Run the teaching.

Operating temperature/humidity *1 -25 to +55°C / 35 to 85 % RH (No freezing) Switch to SET. Transmission Type (In length

Meaning of Safety Symbols SET/RUN selection switch Switches between Teaching mode and RUN mode.

Auto Teaching SET RUN measurement)

Store temperature/humidity -40 to +70°C / 35 to 85 % RH (No condensation)

* The button function varies in each mode: RUN mode, Function mode, and SET mode. SET: Press the teaching button when

Indicates a possible hazard that may result in death, Shock resistance 10 to 55 Hz Double amplitude 1.5 mm 2 hours for each direction of X, Y, and Z * As D2SA-M 3/D2SA-S 1/D2SA-M -M8/D2SA-S -M8 are 1 output (1 CH) type, Switch to SET. there is no object with the flood light

T SET: Press the teaching button. and the light receiver facing each

serious injury, or serious property damage if the Protective category IP50 and do not turn on.The channel switching of also becomes invalid. SET RUN

WARNING product is used without observing the stated

Reflection, Transmission, Regressive

Reflection Type

other.

instructions.

Material PC: Case and cover

Adjustment Select the auto teaching.

Start and End: Perform adjustment

Weight (including the codes) Cable type: 65 g M8 connector type: 30 g while the object is passing.

The available teaching depends on "5.3 Detection Mode setting." Refer to

T IN: Press the teaching button.

below:

*1 Operating temperature may differ according to the number of connection.

Indicates a possible hazard that may result in See as follows: (Standard detection) All teachings are valid.

CAUTION personal injury or property damage if the product is 1 - 3 machine(s): -25 to +55°C T Start: Press the teaching button.

used without observing the stated instructions. 4 - 8 machines: -25 to +50°C * When not using analog output. / (Edge detection) No teaching are valid. IN: Press the teaching button when

* Base units and handsets of the advanced or standard models can be connected with any there is an object.

(Differential detection) Only one point teaching is valid.

combination.

However, some combination may be restricted. For details, contact our Customer

Service. T End: Press the teaching button.

Mandatory Requirements Setting Maximum Sensitivity Switch to RUN.

Switch to SET. SET RUN

This product is not an explosion-proof construction. SET RUN

WARNING Do not use the product under flammable, explosive gas Input/Output Schematic Transmission type The upper limit flashes and

or liquid environment. Regressive Reflection type: Perform the display returns to normal.

Select the one-point teaching. adjustment when there is an object.

NPN PNP

Do not use the product in water.

Do not disassemble, repair, or convert the product. • D2SA-MN / DSA-SN • D2SA-MP / D2SA-SP Switch to RUN.

Brown Brown

Failure to do this may cause failure, fire, or electric 12 to

24 V DC Protective Protective

12 to

24 V DC SET RUN Manual Adjustment

Load

Load

circuit circuit

Black

shock. Control output Black T Press the teaching button.

White

1 CH Control output

1 CH

White Control

Pressing the UP/DOWN button in the RUN mode flashes the threshold. It

Control output

Operate within the rated range. output

indicates that adjustment is possible. Adjust to any value using the

Main circuit

The threshold flashes and the

Main circuit

2 CH 2 CH

Load

Load

Blue

display returns to normal.

Protective Protective

0V

circuit circuit Blue

0V Black and UP/DOWN button.

Black and white Analog output

white Analog output

This product cannot be used as a safety device to Analog GND When using the zone teaching, the threshold of upper/lower limit can be set

Analog GND Gray

Gray External individually.

protect human body. External

input

input Reflection type: Perform adjustment

when there is no object.

Normal When using zone teaching

• D2SA-MN-M8 / D2SA-SN-M8 • D2SA-MP-M8 / D2SA-SP-M8

Setting Lower Limit (Far) Setting Upper Limit (Near)

Brown 1

12 to

Brown 1

12 to Switch to RUN.

Protective

24 V DC 24 V DC

Load

circuit

SET RUN

Operational Precautions Black 4

Control output Black 4

Control output

Main circuit

Main circuit

Protective

circuit Gray 2

1 CH

Gray 2

1 CH Zone Teaching

External External

input input

Use the specified sensor head to connect this product.

Load

The threshold flashes and the

CAUTION Any use other than specified will cause accident or

Blue 3

0V

Blue 3

0V

display returns to normal.

Switch to SET.

SET RUN Reflection type: Perform adjustment

product damage. • D2SA-MN3 / DSA-SN1 • D2SA-MP3 / D2SA-SP1 with the background without object, Automatically returns to

It is dangerous to wire or attach/remove the connector Brown 1

12 to

Brown 1

12 to

One Point Teaching and when there is an object. the normal display 5

24 V DC 24 V DC Select the zone teaching.

with the power on. Make sure to turn off the power

Protective

circuit seconds after completion of

Load

Switch to SET.

Main circuit

Main circuit

Black 4 Black 4 the setting (no operation).

before operation. Control output

1 CH

Control output

1 CH SET RUN

Make sure to use the product with the protective cover Automatically returns to the normal display 5

Load

Protective

circuit

Blue 3

0V

Blue 3

0V

Reflection type: Perform adjustment seconds after completion of the setting

attached and closed. Select the one point teaching. with the background without object. T Press the teaching button.

(no operation).

Installing in the following places may result in * D2SA-S / D2SA-S 1 of the handset do not have power wires (brown, blue) as they receive the power * No operation state for 5 seconds during setting automatically returns the display to

malfunction: supply from the base unit.

normal as well.

1. A dusty or steamy place

2. A place generating corrosive gas Pin layout T Press the teaching button.

3. A place directly receiving scattering water or oil. Near Error Display in Teaching

• D2SA-M -M8 Threshold Upper limit

4. A place suffered from heavy vibration or impact. 10% An error message is displayed in the event of error during adjustment.

Zone

• DSA-S -M8

The product is not designed for outdoor use. Switch to RUN. 10% Refer to the table below for readjustment.

Threshold Lower limit

Do not use the sensor in transient state after power on SET RUN

Indicates shortage of light intensity or no difference

External input Control output Far

(approx. 100 ms). 2 4 of light intensity.

Threshold FaSt +15%

Do not wire with the high voltage cable or the power line. Stnd +5% The threshold flashes and the Set the zone (detection range) to ±10 % Indicates a sampling error in teaching of a moving object.

1 3 Switch to RUN. against the amount of received light.

Failure to do this will cause malfunction by induction or Long +1% display returns to normal.

SET RUN Indicates a calculation error.

damage. 12 to 24 V DC 0V

Set the threshold to + % against the amount

The sensor performance or digital display values may depend of received light. Indicates that the teaching is interrupted.

on the individual units or the condition of detected product. The threshold flashes and the (Depends on the response speed setting.)

display returns to normal.

Function Setting A C B Switching Channel Connecting Sensor Head

Pressing the T button during the RUN mode allows switching. At the same time

the channel indicator light switches. Open the protective cover and plug the connector into the amplifier unit with the

Press the mode button. Set the displayed value on the main monitor of lock lever facing up.

5.1 Zero-reset setting Set the displayed value on the main monitor to "0." 5.9 All zero-reset setting connected amplifier units to 0.

T Make sure that it clicks.

Select by using and fix by . Select by using and fix by . When removing, hold down the lock lever and pull out the connector.

1. Operation setting Select an operation mode. The screen returns to the TOP of Zero reset The screen returns to the TOP of All zero-reset setting.

TOP setting. TOP

Select by using and fix by . Does not perform Zero-reset. * D2SA-M 3/D2SA-S 1/D2SA-M -M8/D2SA-S -M8 cannot be switched as they have a

The screen returns to the TOP of Operation setting. Turn off Zero reset. single output (1CH).

TOP

Performs all zero-reset.

ON when light comes in. Turn on Zero reset.

TIP The key-locked amplifier unit is not reset. Lock Lever

ON when light is blocked.

Returning to Normal Display with One Button

5.2 Display setting Select a display method of normal main sub monitor.

* The timer can be set individually for 1CH and 2CH. 5.10 All one point teaching A single unit operates the teaching of all connected Pressing the T button for 2 seconds or more in setting each function enables to

Select by using and fix by .

The screen returns to the TOP of Display setting amplifier units. return to the normal display (RUN mode) without using Eit (Exit).

2. Response speed setting Select a response speed. TOP

setting. Select by using and fix by . * Invalid while setting the timer time, number of count, or span slant.

Select by using and fix by . The screen returns to the TOP of All one-

The screen returns to the TOP of Response Displayed in numeric display. TOP

TOP point teaching setting.

speed setting.

Displayed in bar display. Does not perform teaching. CAUTION

High accuracy setting 2 ms Key Lock

Displayed in percent (%) display. Performs all one point teaching. Cancels all the operations. Useful to prevent accidental operation. • Do not attach any sensor head other than the specified one (DS Series).

Standard setting 500 µs • When removing the connector, do not pull on the cable.

Displayed in normal count display. TIP The key-locked amplifier unit does not perform

Fastest setting 60 µs teaching. Hold down the buttons for 2 seconds or more simultaneously in the RUN Failure to do so will break the cable or damage the product.

Displayed in total count display. mode. Operate in the same way to cancel as well.

5.11 Length measurement

3. Timer setting Select a timer and the time.

No display. standard value setting Select a width of flood line of sensor head. In locking When cancelled Dimensional drawing

Select by using and fix by . Select by using and fix by .

"cnt" or "tcnt" can be select only when the counter (Unit: mm)

OFF moves to the TOP of Timer setting and function is valid. The screen returns to the TOP of Length • D2SA-M

TOP TOP

others move to the Timer setting. measurement standard value setting. • D2SA-M 3

5.3 Detection mode setting Select a detection method from the list below: TIP During key lock, no command such as all teaching/copy is accepted from other sensors. • D2SA-S

Timer off Turns off the setting.

Select by using and fix by . • D2SA-S 1

Off delay timer TOP The screen returns to the TOP of Detection Sets to 3000.

mode setting. 5.12 End of Detail Setting

On delay timer (Expert mode) Valid only for DSTA-200/DSTA-200-M8. ■Reset "Peak/ Bottom hold"

Sets to the normal detection.

One shot timer

Peak/Bottom hold can be reset by operating with amplifier itself at the time of

Sets to the rising edge detection. analog output.

Timer Time Setting 1-9000 (1 ms - 9 s) Sets to the trailing edge detection.

is for time changing, T is for digit Returns to the TOP of Detail Setting (Expert mode). Confirm the position of "SET/RUN" switch is snapped to "RUN" side.

change, and is to fix. Then the screen Sets to the differential detection. SET RUN

Move the position to "SET" side and return to "Run" side again.

returns to Timer setting TOP. D ①

Detects for length measurement. ②

* Make sure to connect two amplifier units before

differential detection. 5.7.1 Analog output setting Select either read out or turn off the analog output.

* The timer can be set individually for 1CH and 2CH.

* Parallel use of On delay timer and Off delay timer in the

Select counter function ON/OFF and a increasing/ Select by using and fix by . Setting Amplifier Unit

5.4 Counter setting decreasing direction of value. The screen returns to the TOP of Analog

same channel same channel is not possible. TOP output setting.

Select by using and fix by . Attaching and Removing to/from DIN rail

4. Sensitivity correction Correct to the optimal value when sensitivity is OFF moves to the TOP of Counter setting, Turns off.

TOP and the others to number of count setting.

Attachment of Amplifier Unit

setting not enough.

Hook the claw on the connecting side of

Tune on using . The progressing status is Reads out.

Counter off sensor head to the DIN rail. Then press

displayed in bar chart. After the end, the

TOP

screen returns to the TOP of Sensitivity 5.7.2 Span setting Set the slant of output. down the hook until it locks.

Sets the count value to the increasing direction.

correction. Select by using and fix by .

Sets the count value to the decreasing direction. The screen moves to each detail setting. Removal of Amplifier Unit

Tune on the sensitivity correction. TOP

Pushing the unit to the direction of , hold

Number of count setting 0 - 9999999 Set 4 mA. up the connecting side of sensor head and

Tune off the sensitivity correction.

is for count change, T is for digit

Set 20 mA.

remove the unit.

* Settings are only for tuning on (ON) or tuning off change, and is to fix. The screen returns

(OFF). to the Timer Setting TOP.

5. Detailed setting

(Expert mode) Slant setting

is for slant change, T is for digit Expansion of Amplifier Unit

Moves to the Detailed setting menu.

TOP change, and is to fix. The screen returns

5.5 Output setting Select an output method of 1CH and 2CH. to the TOP of Span setting. Slide and hook up each amplifier units to DIN rail.

A And fix it with End units from the both sides.

Select by using and fix by .

The screen returns to the TOP of Output setting.

TOP After end of 4A setting, the screen moves to 20A setting.

6. Initialization setting As many as 8 units can be combined with the

1, 2CH: Control output * Full scale of the default is as follows:

(Initial reset) Initialize all settings. Transmission, Regressive reflection, or Reflection type:

0 - 4000 (Amount of received light) relay connector. ・D2SA-M□-M8

Select by using and fix by . 1CH: Control output, Transmission type and in setting length measurement:

The screen returns to the TOP of Initialization 2CH: Alarm output 0 - 3000 (Received light = Line width) ・D2SA-S□-M8

TOP setting.

* D2SA-M 3/D2SA-S 1/D2SA-M -M8/D2SA-S -

5.7.3 Output clamp hold Select a measurement value state when

M8 do not allow these settings. setting measurement is impossible.

Not initialize Handset

Select by using and fix by .

5.6 External input setting Select an assignment of external input.

The screen returns to the TOP of Output Protection

Initialize TOP

Select by using and fix by . clamp hold setting. Base unit Cover

Initializing changes all settings to the factory default. The screen returns to the TOP of External

TOP input setting. Set the output to approx. 24 mA.

7. End of setting

Sets to the external teaching input. Hold just before measurement

becomes impossible.

Sets to the laser off input. Options

Sets to the synchro input.

(available only in use of length measurement function)

5.7.4 Average counter setting Select a number of times of sampling. End Unit

Select by using and fix by .

Returns to the normal display. Sets to the counter value reset The screen returns to the TOP of Average

TOP

input. counter setting. Connector BEF-BE01-W190 (2 pcs)

Sets to the hold reset input. Set. End unit

Precautions for Function Setting Average counter

*D2SA-M 3/D2SA-S 1/D2SA-S -M8 do not allow 1/4/8/16/32/64/128/256/

* Some function settings automatically delete the invalid settings or settings, of which 5.7 Analog function setting these settings. 512/ 1024/2048 CAUTION The product specification may change without notice for improvement.

concomitant use is not allowed, from the displayed items. This does not indicate any failure. *External teaching can be available in several teachings

* Some functions are not incorporated or not settable to D2SA-M 3 /D2SA-S which are chosen by appropriate adjusting methods. For any inquiry, please contact the manufacture/vendor below.

5.7.5 Hold setting Select a hold state.

1 /D2SA-M -M8 /D2SA-S -M8. TOP * Make sure to turn off the power before operation.

Moves to the analog function setting Select by using and fix by . * Make sure to use the DIN rail and the end unit (BEF-BE01-W190) in

* Hold down the operation button for approx. 0.3 seconds if not especially specified. D The screen returns to the TOP of Hold setting.

detail menu. TOP expanding the amplifier unit.

* Analog output and Analog setting is available when response time setting is

5.8 All copy setting Copy the setting to the connected amplifier units. * After expansion, make sure to check the operating temperature

"Long" or "Standard". Normal measurement

Head office: Mitsui Seimei Kyoto Yamashina BLDG 6F, 46-1

* The sub monitor starts flashing when each setting selection becomes available. Select by using and fix by . (See "Specification").

The screen returns to the TOP of All copy setting. 5.7.6 End of Analog function

Peak hold * To avoid short of connecting terminal, protection cover Takehanadounomae-cho, Yamashina-ku, Kyoto

* The monitor in use of the counter function displays "U" when the up-counter TOP setting

is selected, and displays "d" when the down-counter is selected. Does not copy. need to be attached to ones which are not in use. 607-8085 Japan

Bottom hold

* For functions other than Operation setting and Timer setting, both settings of 1 * Do not remove the combined units all together from DIN rail. TEL: +81-(0)75-594-8123

CH and 2 CH are changed when the setting of each function is modified. Makes copy. Peak to Peak hold FAX: +81-(0)75-594-8124

* The "all setting" described in 5.8 to 5.10 is reflcted only on the amplifier unit TIP The key-locked amplifier unit setting is not

connected to the right side from the cable connector of operated amplifier unit. Website http://www.optex-fa.com

C B modified.

Returns to the TOP of Analog function setting.

Specification Each Part Two Points Teaching Teaching Transparent Object

Switch to SET. Reflection type Switch to SET. Rotating reflection type: Perform when

Digital Amplifier Detachable Photoelectronic Sensor 1st: Perform adjustment when there is there is no object.

Advanced Model (2CH) Standard Model (1CH) SET RUN an object. SET RUN

D2SA Series Model

Cable type

M8 connector type

D2SA-M(N/P)S

-

D2SA-M(N/P)3S

D2SA-M(N/P)S-M8

Select the two points teaching.

Laser Type Amplifier Unit D2SA-M□S Adaptable sensor head DS Series

D2SA-M□3S Power source, voltage 12 - 24 V DC ± 10 % including a ripple

T 1st point: Press the teaching button. T Press the teaching button.

D2SA-M□S-M8 Consumption current 45 mA or less / 24 V No. Name Function Reflection side -10%

of reflector

Response time 60µs/500µs/2ms (Fast/Standard/Long) Laser emission indicator light Turns on while the amplifier is powered.

2nd: Perform adjustment with the

1 CH output indicator light Turns on when the output of 1 CH is ON.

NPN / PNP Open collector background without object.

Control output T 2nd point: Press the teaching button.

Load current: 100 mA or less Residual voltage:1.8 V or less 2 CH output indicator light Turns on when the output of 2 CH is ON.

Instruction Manual Indicator light

Laser emission indicator light: Green, Output Indicator light: Orange (1·2CH)

Teaching indicator light: Red Channel indicator light: Green (1·2CH)

Main monitor (Red)

Sub monitor (Green)

Displays light intensity, function, and the number of counts.

Displays the threshold, function selection, and the number of counts. Threshold

Switch to RUN.

Digital display 7 segment 8 digit display Teaching mode indicator light Turns on in the Teaching mode. Set the threshold to -10 % against the

Thank you for purchasing DSA Series. We hope you are fully satisfied with this product and enjoy its SET RUN

performance. amount of received light.

Timer function OFF, On delay, Off delay, One-shot Valid channel indicator light Keeps turning ON when the monitor display value,

Carefully read this instruction manual and keep it for future reference. (1 CH) adjustment, and the function setting are valid to 1 CH.

Timer time 1 ms - 9 s

Switch to RUN. The threshold flashes and the

Output method Light on / Dark on Switching type in the function Valid channel indicator light Keeps turning ON when the monitor display value, display returns to normal.

SET RUN 1st

Analog output Current output:4 - 20 mA - (2 CH) adjustment, and the function setting are valid to 2 CH.

Threshold

Safety Precautions External input setting External input setting UP button RUN mode: Displays or changes the threshold. 2nd

The threshold flashes and the Set the threshold at the center between

Teaching Length Measurement

(teaching, synchronizing input, (teaching, synchronizing input, DOWN button Function mode: Selects the function or changes the numerical values.

display returns to normal. the 1st and the 2nd points.

floodlight off, counter reset) floodlight off, counter reset) Valid only when the length measurement function is set. Allows to

Carefully read and understand the safety precautions before operation. Mode button RUN mode: Switches to the Function mode. (0.5 s )

determine the size or the length of object.

Setting input/output Output setting

The important information is provided to protect your health and property. Function mode: Fix the selection.

* Not displayed on the teaching mode menu unless the application of length

Do not apply any other installing or operating procedure other than that described in (2CH output + Alarm output) * Settable only with DSA-M□S-M8 measurement is selected in the detection mode setting.

Teaching button RUN mode: Switches the channel.

this manual. Operating temperature/humidity -25 to +55°C / 35 to 85 % RH (No freezing) * Teaching length measurement or length measurement mode does not measure the

Function mode: Returns to RUN mode or performs scaling. actual length of object accurately.

Store temperature/humidity -40 to +70°C / 35 to 85 % RH (No condensation) Set mode: Run the teaching.

Shock resistance 10 to 55 Hz Double amplitude 1.5 mm 2 hours for each direction of X, Y, and Z Switch to SET. Transmission Type (In length

Meaning of Safety Symbols SET/RUN selection switch Switches between Teaching mode and RUN mode.

Auto Teaching SET RUN measurement)

Protective category IP50

* The button function varies in each mode: RUN mode, Function mode, and SET mode. SET: Press the teaching button when

Indicates a possible hazard that may result in death, Material PC: Case and cover * D2SA-M□3S/D2SA-M□S-M8 are 1 output (1 CH) type, ③ and ⑧ do not turn on.The Switch to SET. there is no object with the flood light

serious injury, or serious property damage if the Weight (including the codes) Cable type: 65 g M8 connector type: 30 g channel switching of ⑫ also becomes invalid. SET RUN

T SET: Press the teaching button. and the light receiver facing each

WARNING product is used without observing the stated

Reflection, Transmission, Regressive

Reflection Type

other.

instructions. Adjustment Select the auto teaching.

Start and End: Perform adjustment

while the object is passing.

The available teaching depends on "5.3 Detection Mode setting." Refer to

T IN: Press the teaching button.

Input/Output Schematic below:

Indicates a possible hazard that may result in

(Standard detection) All teachings are valid.

CAUTION personal injury or property damage if the product is NPN PNP T Start: Press the teaching button.

used without observing the stated instructions. / (Edge detection) No teaching are valid. IN: Press the teaching button when

• D2SA-MNS • D2SA-MPS there is an object.

Brown Brown (Differential detection) Only one point teaching is valid.

12 to 24V 12 to 24 V

DC Protective Protective

DC

Load

Load

circuit circuit

Black

Control output

1 CH

Black

Control output T End: Press the teaching button.

Mandatory Requirements White

Control output White 1 CH

Control output Setting Maximum Sensitivity Switch to RUN.

Main circuit

Main circuit

2 CH 2 CH

Load

Load

Protective Protective Blue

circuit circuit Blue

0V Black and

0V Switch to SET. SET RUN

Black and white Analog

This product is not an explosion-proof construction. white Analog

output

output

Analog SET RUN

WARNING Do not use the product under flammable, explosive gas Gray GND

Analog

Gray

GND

External Transmission type

External input The upper limit flashes and

or liquid environment. input Regressive Reflection type: Perform the display returns to normal.

Select the one-point teaching. adjustment when there is an object.

Do not use the product in water. • D2SA-MNS-M8 • D2SA-MPS-M8

Brown 1 Brown 1

Do not disassemble, repair, or convert the product. 12 to 24 V

DC Protective

12 to 24 V

DC Switch to RUN.

Load

circuit

Black

SET RUN Manual Adjustment

4

Failure to do this may cause failure, fire, or electric Control output Black 4

Main circuit

Main circuit

1 CH Control output

1 CH

shock. Protective

circuit Gray 2 Gray 2 T Press the teaching button.

External External Pressing the UP/DOWN button in the RUN mode flashes the threshold. It

input input

Operate within the rated range.

Load

Blue 3

0V

Blue 3

0V The threshold flashes and the indicates that adjustment is possible. Adjust to any value using the

display returns to normal. UP/DOWN button.

This product cannot be used as a safety device to • D2SA-MN3S • D2SA-MP3S When using the zone teaching, the threshold of upper/lower limit can be set

Brown Brown 1

1

12 to 24 V 12 to 24 V individually.

protect human body. DC Protective

circuit

DC Reflection type: Perform adjustment

Load

when there is no object.

Normal When using zone teaching

Main circuit

Main circuit

Black 4 Black 4

Control output Control output

1 CH 1 CH Setting Lower Limit (Far) Setting Upper Limit (Near)

Switch to RUN.

Load

Protective

circuit

Blue 3 Blue 3

SET RUN

Operational Precautions 0V 0V

Zone Teaching

Use the specified sensor head to connect this product. The threshold flashes and the

CAUTION Any use other than specified will cause accident or

Pin layout display returns to normal.

Switch to SET.

SET RUN Reflection type: Perform adjustment

product damage. • D2SA-M -M8 with the background without object, Automatically returns to

It is dangerous to wire or attach/remove the connector One Point Teaching and when there is an object. the normal display 5

Select the zone teaching.

with the power on. Make sure to turn off the power seconds after completion of

Switch to SET.

the setting (no operation).

before operation. External input Control output SET RUN

Make sure to use the product with the protective cover 2 4 Automatically returns to the normal display 5

Reflection type: Perform adjustment seconds after completion of the setting

attached and closed. 1 3 Select the one point teaching. with the background without object. T Press the teaching button.

(no operation).

Installing in the following places may result in

12 to 24 V DC 0V * No operation state for 5 seconds during setting automatically returns the display to

malfunction: normal as well.

1. A dusty or steamy place

2. A place generating corrosive gas T Press the teaching button.

3. A place directly receiving scattering water or oil. Near Error Display in Teaching

Threshold Upper limit

4. A place suffered from heavy vibration or impact. 10% An error message is displayed in the event of error during adjustment.

Zone

The product is not designed for outdoor use. Switch to RUN. 10% Refer to the table below for readjustment.

Threshold Lower limit

Do not use the sensor in transient state after power on SET RUN

Indicates shortage of light intensity or no difference

Far

(approx. 100 ms). of light intensity.

Threshold FaSt +15%

Do not wire with the high voltage cable or the power line. Stnd +5% The threshold flashes and the Set the zone (detection range) to ±10 % Indicates a sampling error in teaching of a moving object.

Switch to RUN. against the amount of received light.

Failure to do this will cause malfunction by induction or Long +1% display returns to normal.

SET RUN Indicates a calculation error.

damage.

Set the threshold to + % against the amount

The sensor performance or digital display values may depend of received light. Indicates that the teaching is interrupted.

on the individual units or the condition of detected product. The threshold flashes and the (Depends on the response speed setting.)

display returns to normal.

Function Setting A C B Switching Channel Dimensional drawing

Pressing the T button during the RUN mode allows switching. At the same time

the channel indicator light switches. • D2SA-M□S (Unit: mm)

Press the mode button.

5.1 Zero-reset setting Set the displayed value on the main monitor to "0." 5.11 Length measurement • D2SA-M□3S

standard value setting Select a width of flood line of sensor head. T

Select by using and fix by .

The screen returns to the TOP of Zero reset Select by using and fix by .

1. Operation setting Select an operation mode. TOP setting. The screen returns to the TOP of Length

Select by using and fix by . TOP

measurement standard value setting. * D2SA-M□3S/D2SA-M□S-M8 cannot be switched as they have a single output (1CH).

The screen returns to the TOP of Operation setting. Turn off Zero reset.

TOP Turns off the setting.

Maximum aperture 180˚

ON when light comes in. Turn on Zero reset.

Sets to 3000.

ON when light is blocked. 5.12 End of Detail Setting Returning to Normal Display with One Button

5.2 Display setting Select a display method of normal main sub monitor. (Expert mode) Valid only for DSTA-200/DSTA-200-M8.

* The timer can be set individually for 1CH and 2CH. Pressing the T button for 2 seconds or more in setting each function enables to

Select by using and fix by .

The screen returns to the TOP of Display

return to the normal display (RUN mode) without using Eit (Exit).

2. Response speed setting Select a response speed. TOP

setting. * Invalid while setting the timer time, number of count, or span slant.

Select by using and fix by .

The screen returns to the TOP of Response Displayed in numeric display.

TOP Returns to the TOP of Detail Setting (Expert mode).

speed setting.

Displayed in bar display.

High accuracy setting 2 ms D Key Lock

Displayed in percent (%) display. Cancels all the operations. Useful to prevent accidental operation.

Standard setting 500 µs

• D2SA-M□S-M8

Displayed in normal count display. 5.7.1 Analog output setting Select either read out or turn off the analog output.

Fastest setting 60 µs Hold down the buttons for 2 seconds or more simultaneously in the RUN

Displayed in total count display. Select by using and fix by . mode. Operate in the same way to cancel as well.

The screen returns to the TOP of Analog

3. Timer setting Select a timer and the time. TOP output setting.

No display. In locking When cancelled

Select by using and fix by .

"cnt" or "tcnt" can be select only when the counter Turns off.

OFF moves to the TOP of Timer setting and function is valid.

TOP

others move to the Timer setting.

Reads out.

5.3 Detection mode setting Select a detection method from the list below:

Timer off

Select by using and fix by . 5.7.2 Span setting Set the slant of output.

Off delay timer The screen returns to the TOP of Detection ■Reset "Peak/ Bottom hold"

TOP Select by using and fix by .

mode setting. The screen moves to each detail setting. Peak/Bottom hold can be reset by operating with amplifier itself at the time of

On delay timer TOP

Sets to the normal detection. analog output. Options

Set 4 mA.

One shot timer

Sets to the rising edge detection. Set 20 mA.

Confirm the position of "SET/RUN" switch is snapped to "RUN" side.

SET RUN End Unit

Timer Time Setting 1-9000 (1 ms - 9 s) Sets to the trailing edge detection. Move the position to "SET" side and return to "Run" side again.

①

is for time changing, T is for digit Slant setting ②

change, and is to fix. Then the screen Detects for length measurement.

is for slant change, T is for digit

returns to Timer setting TOP.

change, and is to fix. The screen returns

BEF-BE01-W190 (2 pcs)

Select counter function ON/OFF and a increasing/

5.4 Counter setting decreasing direction of value. to the TOP of Span setting.

Select by using and fix by .

Setting Amplifier Unit

OFF moves to the TOP of Counter setting,

* The timer can be set individually for 1CH and 2CH. TOP and the others to number of count setting.

After end of 4A setting, the screen moves to 20A setting. Attaching and Removing to/from DIN rail

* Parallel use of On delay timer and Off delay timer in the

* Full scale of the default is as follows:

same channel same channel is not possible. Transmission, Regressive reflection, or Reflection type: Attachment of Amplifier Unit

Counter off 0 - 4000 (Amount of received light)

Transmission type and in setting length measurement:

Hook the claw on the connecting side of

4. Sensitivity correction Correct to the optimal value when sensitivity is

setting not enough. Sets the count value to the increasing direction. 0 - 3000 (Received light = Line width) sensor head to the DIN rail. Then press

5.7.3 Output clamp hold Select a measurement value state when down the hook until it locks.

Tune on using . The progressing status is Sets the count value to the decreasing direction. setting measurement is impossible.

displayed in bar chart. After the end, the

TOP Select by using and fix by . Removal of Amplifier Unit

screen returns to the TOP of Sensitivity Number of count setting 0 - 9999999 The screen returns to the TOP of Output

correction. TOP Pushing the unit to the direction of , hold

is for count change, T is for digit clamp hold setting.

up the connecting side of sensor head and

Tune on the sensitivity correction. change, and is to fix. The screen returns

to the Timer Setting TOP. Set the output to approx. 24 mA. remove the unit.

Tune off the sensitivity correction. Hold just before measurement

* Settings are only for tuning on (ON) or tuning off becomes impossible.

(OFF).

5. Detailed setting

(Expert mode) 5.5 Output setting Select an output method of 1CH and 2CH.

5.7.4 Average counter setting Select a number of times of sampling.

Select by using and fix by . Select by using and fix by . Connecting Sensor Head

Moves to the Detailed setting menu. The screen returns to the TOP of Output setting.

TOP TOP The screen returns to the TOP of Average

TOP counter setting. Open the protective cover and plug the connector into the amplifier unit with the

A 1, 2CH: Control output

lock lever facing up.

Set.

1CH: Control output, Make sure that it clicks.

Average counter

2CH: Alarm output When removing, hold down the lock lever and pull out the connector.

6. Initialization setting 1/4/8/16/32/64/128/256/

(Initial reset) Initialize all settings. * D2SA-M□3S/D2SA-M□S-M8 do not allow these 512/ 1024/2048

settings.

Select by using and fix by .

The screen returns to the TOP of Initialization 5.6 External input setting Select an assignment of external input. 5.7.5 Hold setting Select a hold state.

TOP setting.

Select by using and fix by . Select by using and fix by .

The screen returns to the TOP of External The screen returns to the TOP of Hold setting.

Not initialize TOP TOP

input setting.

Normal measurement Lock Lever

Initialize Sets to the external teaching input. 5.7.6 End of Analog function

Peak hold

Initializing changes all settings to the factory default. setting

Sets to the laser off input.

Bottom hold

7. End of setting

Sets to the synchro input.

(available only in use of length measurement function) Peak to Peak hold

Sets to the counter value reset

input.

Returns to the TOP of Analog function setting. CAUTION

Sets to the hold reset input.

Returns to the normal display. * D2SA-M□3S 1 do not allow these settings.

• Do not attach any sensor head other than the specified one (DS Series).

* External teaching can be available in several teachings • When removing the connector, do not pull on the cable.

5.7 Analog function setting

which are chosen by appropriate adjusting methods. Failure to do so will break the cable or damage the product. The product specification may change without notice for improvement.

Precautions for Function Setting

Moves to the analog function setting For any inquiry, please contact the manufacture/vendor below.

* Some function settings automatically delete the invalid settings or settings, of which detail menu.

concomitant use is not allowed, from the displayed items. This does not indicate any failure. TOP

* Some functions are not incorporated or not settable to D2SA-M□3S /D2SA-M□ D

S-M8.

* Hold down the operation button for approx. 0.3 seconds if not especially specified.

* Analog output and Analog setting is available when response time setting is

"Long" or "Standard".

C B

Head office: Mitsui Seimei Kyoto Yamashina BLDG 6F, 46-1

* The sub monitor starts flashing when each setting selection becomes available.

* The monitor in use of the counter function displays "U" when the up-counter Takehanadounomae-cho, Yamashina-ku, Kyoto

is selected, and displays "d" when the down-counter is selected. 607-8085 Japan

* For functions other than Operation setting and Timer setting, both settings of 1

TEL: +81-(0)75-594-8123

CH and 2 CH are changed when the setting of each function is modified.

FAX: +81-(0)75-594-8124

Website http://www.optex-fa.com

レーザ使用に関する注意事項 仕様 外形寸法図

(単位:mm)

デジタルアンプ分離型光電センサ ■レーザ放射警告灯 ・DSTA‑200

52.9 2.7

・DSR‑800 34.6

同軸回帰反射型 同軸反射型 透過型 透過/測長型 ・DSR‑5000

DSシリーズ

36.6 21.

レーザ放射がされていることをレーザ放射警告灯で確認していただけます、電

3.2

2

31.65 16.1

3.

2‑φ

φ

源を入れたあと点灯し、放射されている間常時点灯します。また、専用アンプ 型式 ケーブル DSD‑100 DSTC‑200 DSTA‑200 ・DSD‑100

2‑

DSR‑

ユニット側でも確認できます。 ・DSTC‑200

13.4

13.4

10.6

投光器:DSTC‑D 投光器:DSTA‑D

13

13

レーザ放射警告灯 800 5000 受光器:DSTC‑200 受光器:DSTA‑200 レーザ放射表示灯 出力表示灯 レーザ放射表示灯 出力表示灯

レーザタイプセンサヘッド DSR ‑800 DSTC‑200‑M8 (緑点灯) M8中継型 ‑ ‑ DSTC‑200‑M8 DSTA‑200‑M8 52.9

46.4 34.6

DSR ‑5000 DSTA‑200‑M8 投光器M8 ‑ ‑ DSTC‑S DSTA‑S

9.9 25.9 2.6 11.2 19.1 12.7

2‑R R2

.6

DSD ‑100 受光器M8 ‑ ‑ DSTC‑R DSTA‑R .6

(DSR‑800/DSR‑5000 R2

10.6

18.6(光軸中心)

DSTC‑200

26.5

20.9

DSD‑100/DSTC‑D/DSTC‑S) (DSTA‑D/DSTA‑S) 適合アンプユニット DSA‑M□□ /DSA‑M□‑M8 / DSA‑S□□

DSTA‑200

37.4

6.5

8.2

41.4

34

光源 可視光半導体レーザ 650nm

47

23.5(光軸中心)

2.8

■レーザラベルについて 出力 最大出力 3mW 最大出力 390μW

28.1

取扱い説明書

2‑φ3.2

この商品は可視光レーザビームを放射しており、JIS C6802 / IEC / FDAレーザ IEC/JIS CLASS CLASS 2 CLASS 1

18.5

取付け穴

2‑φ3.2

2.8

安全規格のクラス2(Ⅱ)に相当します、センサヘッド側面にはCLASS2/ClassⅡ 18.5

取付け穴 1

16.1

FDA CLASS Class Ⅱ

12.35

2

を示す警告、説明ラベル(英文)をそれぞれ貼付済みです。

3

4

1

16.1

検出距離 Long 8m 0.5…50m 1m 2m

12.35

2

● お買い上げいただきありがとうございます、ご希望どおりの製品であることをご確認して下さい。 DSR/DSD :φ3 4芯 ケーブル 標準長 2m

*DSTC‑200/‑M8・/DSTA‑200/‑M8の投光器DSTC‑D/DSTA‑D及びDSTC‑S/DSTA‑SはFDA規格(米国 3

4 6

DSTC :φ3 2芯 ケーブル 標準長 2m(灰)

● 取扱い説明書は、ご使用前によくお読みいただき大切に保管して下さい。 へ輸出される場合)ではクラスⅡですがJIS/IEC規格ではクラス1が適用されますので *1 Standard 5m 0.3…35m 0.7m 2m 測長モード;0.5m 6 φ3 2芯 ケーブル 標準長 2m(灰) φ3 4芯 ケーブル 標準長 2m(黒)

φ3 4芯 ケーブル 標準長 2m(黒)

同梱されているラベルを張り替えて使用してください。 Fast 2m 0.1…20m 0.25m (Long ,Standardのみ)

約φ2mm 約φ1mm 約φ2mm 約30x2.5mm

ビームサイズ *2

(距離2m) (距離1m) (距離2m) (距離2m)

安全にご使用いただくために ●日本国内 ・DSTA‑200‑M8 ・DSTC‑200‑M8

繰り返し精度 *3 0.2mm 0.2mm 0.2mm 0.3mm 36.6

52.9 2.7

21.

34.6

3.2

2

31.65 16.1

3.

表示灯 レーザ放射表示灯:緑色 出力表示灯:橙色

2‑φ

φ

2‑

取扱い説明書に記載されている注意事項をよくお読みになり、内容を理解され 使用周囲温度・湿度 ‑10~+55℃/35~85%RH (氷結・結露しないこと)

13.4

13.4

10.6

13

13

るまではお使いにならないでください。 保管周囲温度・湿度 ‑25~+70℃/35~85%RH (氷結・結露しないこと) レーザ放射表示灯 出力表示灯 レーザ放射表示灯 出力表示灯

取扱い説明書には、お客様の健康や財産を守るための注意事項が記載されてい

使用周囲照度 3,000 lx (白熱ランプ) 10,000 lx (太陽光)

ますので記載の無い据付け・操作方法ではご使用にならないで下さい。 52.9

46.4 34.6

耐振動 10~55Hz 複振幅1.5mm X,Y,Z各方向2時間 9.9 25.9 2.6 11.2 19.1 12.7

2‑R .6

●諸外国(米国を除く) R2

保護構造 IP67 .6

R2

■記号表記について

18.6(光軸中心)

10.6

材質 PC (ケース,カバー) PMMA / ガラス(前面窓)

26.5

20.9

質量(コード含む)*4 45g 90g 115g

41.4

6.5

8.2

37.4

この表示を無視して誤った取り扱いをすると、人が死亡

23.5(光軸中心)

47

34

2.8

28.1

または重症を負う可能性が想定される内容を示します。 2‑φ3.2

*1 DSD‑100 :200x200mm 白紙(90%)にて 取付け穴

また、重大な物的損害を受ける恐れがあります。 2‑φ3.2 φ3 2芯 ケーブル 標準長 0.15m(灰) 先端M8プラグ

DSR‑800 :MP‑45リフレクタ(付属)にて

2.8

取付け穴 φ3 4芯 ケーブル 標準長 0.15m(黒) 先端M8プラグ

DSR‑5000 :P250Fリフレクタ(付属)にて φ3 2芯 ケーブル 標準長 0.15m(灰) 先端M8プラグ

●米国 φ3 4芯 ケーブル 標準長 0.15m(黒) 先端M8プラグ

18.5

*2 中心強度の1/e2(13.5%)で定義しています。規定のスポットサイズ以外にも漏れ光が 18.5

この表示を無視して誤った取り扱いをすると、人が負傷 機器搭載して米国へ輸出する場合、米国のレーザ規制FDA (Food and Drug

6

1

16.1

12.35

2

あり対象物の周囲に反射率の高いものがある場合その影響を受ける場合があります。

6

Administration)を受けます。この商品はCDRH (Center for Devices and 1 3

する可能性が想定される内容、および物的損害の発生が

16.1

12.35

2 4

3

*3 検出軸に直角方向(2mまで)

想定される内容を示します。 Radiological Health) に届出済みです。詳細は別途お問い合わせください。 4

6

φ3 2芯 ケーブル 標準長 2m(灰) 先端M8ジャック

*4 DSTC‑200・DSTA‑200は投・受光器込みの質量です。 6 φ3 2芯 ケーブル 標準長 2m(灰) 先端M8ジャック

φ3 4芯 ケーブル 標準長 2m(黒) 先端M8ジャック φ3 4芯 ケーブル 標準長 2m(黒) 先端M8ジャック

* M8中継型は投光器・受光器のみの交換が可能です。

(DSR‑800/DSR‑5000

安全上必ずお守りください DSD‑100/DSTC‑D 付属品・その他 ・MP‑45 ・P250F

DSTC‑S) (DSTA‑D/DSTA‑S)

0.2

●この商品は防爆構造ではありませんので、引火性または爆 証明ラベル(1) ■レンズアタッチメント(型式 BL‑W130L‑1:オプション)

4.5

発性ガス、液体の環境下では使用しないで下さい。 DSR‑800・DSR‑5000 にアタッチメントを取り付けて、ラインビーム・エリアビ 44.8

37 2

●この商品の光源は可視光半導体レーザを使用しています。 FDA警告/ FDA警告/レーザ開口 ームの2種で検出が可能です、ご使用になるビーム形状レンズと光軸をあわせ 2‑R3.7

23 2‑φ3.2

●この商品は分解したときに自動的にレーザ放射を停止する レーザ開口ラベル(2)(3) 証明ラベル(4) て取り付けてください。

14.5

機能を備えておりませんので、分解・改造をしないで下

7.4

29

(3)

23

さい。 (1)

7.4

ラインビーム ビーム形状

人体への障害・火災・感電の原因になります。 レンズ 約40 x 1mm

4‑

4‑R1.2

C3

●レーザビームを直接覗き込んだり、周囲の人の目線高さに ラインビーム

(距離300mm)

設置・故意に人体にむけて照射するなどはしないで下さい。

●この商品の接続には専用アンプユニットを使用して下さい、 エリアビーム 約35 x 35mm

エリアビーム

他のものを接続しますと事故・商品破損の原因となります。 レンズ (距離300mm)

(2) (4)

●電源が入ったままの配線作業・コネクタの脱着は危険です、

・MP-225(フリーカット) ・BL-W130L-2[DSTA-200用スリット]

必ず電源を切ってから行ってください。

*製品個々のばらつきによりビーム形状に違いが生じることがあります。

この商品は人体保護を目的とした安全機器としては *DSD‑100には適しません、またDSTA‑200・M8/DSTA‑Sに

ご使用いただけません。 取り付けることはできません。

使用上の注意 ■DSTA‑200/DSTA‑200‑M8使用時の注意 ■MP‑45リフレクタ(DSR‑800・DSR‑5000に付属)

DSTA‑200・‑M8を測長用途で使用される場合は次のことに注意して下さい。 ●使用上の注意

●次のような場所への設置は誤動作の原因となる事がありま 1. 清掃される場合はエアで吹き飛ばすかやわらかい布で軽くふき取ってください。

すのでご注意ください。 ●投光器は灰色ケーブル、受光器は黒色ケーブルに対応しています。

シンナー、ベンジン、灯油類は使用しないでください。

1. ホコリ・蒸気等の多い場所。 ●センサの取付けは、投光ビーム中心が受光部中心に来るように設置してくだ

2. 反射面を強く押したり、直接衝撃を与えたりしますと、プリズムが破損し

2. 腐食性ガスの発生する場所。 さい。

性能の低下が起こる恐れがあります。

3. 水・油等が直接飛散する場所。 (アンプユニットの表示値が最大になるように設置してください。)

3. 屋外や油・水が飛散する環境下での使用は避けてください。

4. 振動・衝撃等の激しい場所。 ●投・受光器の設置は同一方向になるようにしてください。各ラベルや表示灯

● 製品の仕様は改良のため予告なく変更する事があります。

を基準にしてください。 ●取り付け方法

●屋外・強い外乱光(レーザ光・太陽光・白熱ランプ)が ● 製品に関するお問い合わせ、御意見等は製造・発売元の下記まで御連絡下さい。

取り付けは下図を参考に正しい方向で使用してください、誤った取り付けを行

直接受光面にあたる場所での使用は避けて下さい。 表示灯

表示灯

うと誤動作の原因となります。

●電源投入時(約100ms)の過度状態でのご使用は避けて下

さい。

●商品個々のばらつきや、対象物の状態によって検出特性に

違いが生じることがあります。

●投受光面にゴミ・ほこり等の汚れがありますと正しく検出

できない場合があります、また直接衝撃を与えないで下

さい。 表示灯

オプテックス・エフエーホームページ http://www.optex-fa.jp

0536692

ヘッド取説.indd 2 2006/01/24 14:33:06

You might also like

- M5N Civ SHP 125 601 BD 4307 2 - R0Document1 pageM5N Civ SHP 125 601 BD 4307 2 - R0Tarek AbulailNo ratings yet

- MQ13 600 DR 5840 SS3282Document1 pageMQ13 600 DR 5840 SS3282David Borja HuarachiNo ratings yet

- Lay Out - SLD App MLG 2016-1Document1 pageLay Out - SLD App MLG 2016-1Woro AmbarwulanNo ratings yet

- M5N Civ SHP 125 601 BD 4308 2 - R0Document1 pageM5N Civ SHP 125 601 BD 4308 2 - R0Tarek AbulailNo ratings yet

- M5N Civ SHP 125 601 BD 4310 2 - R0Document1 pageM5N Civ SHP 125 601 BD 4310 2 - R0Tarek AbulailNo ratings yet

- M5N Civ SHP 125 601 BD 4311 2 - R0Document1 pageM5N Civ SHP 125 601 BD 4311 2 - R0Tarek AbulailNo ratings yet

- 2010 Census - Census Block Map (Index) : La Paz County, Az: MILFORD 47500 Davis 18100Document1 page2010 Census - Census Block Map (Index) : La Paz County, Az: MILFORD 47500 Davis 18100Igor SemenovNo ratings yet

- Low Pressure Low Pressure: Hydraulic Hoses OverviewDocument1 pageLow Pressure Low Pressure: Hydraulic Hoses OverviewNaseema SulaimanNo ratings yet

- BB BB: Code and SpecificationsDocument1 pageBB BB: Code and SpecificationsandersonNo ratings yet

- 2010 CENSUS - CENSUS BLOCK MAP (INDEX) : Choctaw County, AL: MILFORD 47500 Davis 18100Document1 page2010 CENSUS - CENSUS BLOCK MAP (INDEX) : Choctaw County, AL: MILFORD 47500 Davis 18100Igor SemenovNo ratings yet

- Parent: Customer Name: Project Name: 9281D4ASSEM 09281 D4 Certified: Approved For Construction Assy. WTDocument9 pagesParent: Customer Name: Project Name: 9281D4ASSEM 09281 D4 Certified: Approved For Construction Assy. WTmoneyphotocopyshopNo ratings yet

- P&ID For Air CoolersDocument9 pagesP&ID For Air CoolersAvinash ShuklaNo ratings yet

- 14M Motor Grader Electrical System: Harness and Wire Electrical Schematic SymbolsDocument6 pages14M Motor Grader Electrical System: Harness and Wire Electrical Schematic Symbolsmanu luvungaNo ratings yet

- ManualDocument4 pagesManualcristianNo ratings yet

- Detail 1: SL OP E1 %Document1 pageDetail 1: SL OP E1 %Tri SuhartantoNo ratings yet

- Caracter Is T IceDocument1 pageCaracter Is T IceVlad AlexandruNo ratings yet

- 14M Motor Grader Electrical System: Harness and Wire Electrical Schematic SymbolsDocument6 pages14M Motor Grader Electrical System: Harness and Wire Electrical Schematic SymbolsTekooMohamedNo ratings yet

- 966H Diagrama Electrico 1Document4 pages966H Diagrama Electrico 1Florencio MaximilianoNo ratings yet

- 38 1 MLR Line&Load Reactors MarcusDocument2 pages38 1 MLR Line&Load Reactors MarcuskarlosNo ratings yet

- 3 - Detection of ARP Spoofing Attacks in Software Defined Networks - 2023 IeeexploreDocument5 pages3 - Detection of ARP Spoofing Attacks in Software Defined Networks - 2023 IeeexploreMahmoud ElzoghbiNo ratings yet

- 60019gb8 PDFDocument6 pages60019gb8 PDFbnNo ratings yet

- Wlan Ez1100 DownloadDocument1 pageWlan Ez1100 Downloadc85320d9ddb90c13f4a215f1f0a87b531ab33310No ratings yet

- Plan 3Document4 pagesPlan 3rnz mrnNo ratings yet

- KEYPLANTDocument1 pageKEYPLANTGunawan MsjrNo ratings yet

- 2010 CENSUS - CENSUS BLOCK MAP (INDEX) : Baldwin County, AL: MILFORD 47500 Davis 18100Document1 page2010 CENSUS - CENSUS BLOCK MAP (INDEX) : Baldwin County, AL: MILFORD 47500 Davis 18100Igor SemenovNo ratings yet

- DMBOKv1 ImagesDocument10 pagesDMBOKv1 ImagesFabrice Van HoedNo ratings yet

- 14M Electric System B9J 1-UPDocument6 pages14M Electric System B9J 1-UPIndi100% (1)

- Ficha J2zzpv4tt5818pxf4ohmm8312xuihlDocument15 pagesFicha J2zzpv4tt5818pxf4ohmm8312xuihlJulio Cruzado SolanoNo ratings yet

- Darlington: Silicon NPN Triple Diffused Planar TransistorDocument2 pagesDarlington: Silicon NPN Triple Diffused Planar TransistorGilberto DiazNo ratings yet

- D7H Series II Tractor Electrical SystemDocument2 pagesD7H Series II Tractor Electrical SystemAnonymous KOtSfT6q100% (1)

- Us Wallchart 2006Document1 pageUs Wallchart 2006vallamtroNo ratings yet

- Situasi Kontur TowerDocument1 pageSituasi Kontur TowerIlhamNo ratings yet

- HCC DLB PIER 44.687 Final Approved 301106 ModelDocument1 pageHCC DLB PIER 44.687 Final Approved 301106 ModelRama KrishnaNo ratings yet

- 2010 CENSUS - CENSUS BLOCK MAP (INDEX) : Colbert County, AL: MILFORD 47500 Davis 18100Document1 page2010 CENSUS - CENSUS BLOCK MAP (INDEX) : Colbert County, AL: MILFORD 47500 Davis 18100Igor SemenovNo ratings yet

- 2sd2560 Ds enDocument1 page2sd2560 Ds enMarius IggyNo ratings yet

- BC-5600&5800 NewDocument2 pagesBC-5600&5800 Newsamuel debebeNo ratings yet

- Sistema Electrico 2Document6 pagesSistema Electrico 2julio peña limaNo ratings yet

- Silicon NPN Epitaxial Planar Transistor (Complement To Type 2SA1386/A)Document1 pageSilicon NPN Epitaxial Planar Transistor (Complement To Type 2SA1386/A)isaiasvaNo ratings yet

- SANS10163 2 Looseleaf PDFDocument32 pagesSANS10163 2 Looseleaf PDFSiphelele SimelaneNo ratings yet

- 159 210 S84 Q4 004R5Document1 page159 210 S84 Q4 004R5Yahya Ateeni100% (1)

- General Notes:: 00ENB20BB003 Treated Co Storage TankDocument1 pageGeneral Notes:: 00ENB20BB003 Treated Co Storage Tankmustafa1989ocNo ratings yet

- Motoniveladora 140KDocument2 pagesMotoniveladora 140KAbraão Silva100% (5)

- D9T Electrical SystemDocument4 pagesD9T Electrical SystemPablo PorrasNo ratings yet

- Officer South Employment PSP Infrastructure Contributions Plan Draft For Consultation Appendix 3 Part 4Document13 pagesOfficer South Employment PSP Infrastructure Contributions Plan Draft For Consultation Appendix 3 Part 4zihan1chenNo ratings yet

- 02.1 Retaining Wall (12-15)Document2 pages02.1 Retaining Wall (12-15)WILIAMNo ratings yet

- Longitudinal Section Transverse Section Bay Section A: A C B C' 1 1 3 2Document1 pageLongitudinal Section Transverse Section Bay Section A: A C B C' 1 1 3 2Jem CapistranoNo ratings yet

- Noblex: PLL Synthesizer Stereo Radio With Compact Disc Player DigitalDocument14 pagesNoblex: PLL Synthesizer Stereo Radio With Compact Disc Player DigitalHernánSchusterNo ratings yet

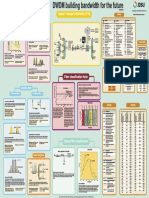

- DWDM Impairments Optical Transport Networks (OTN) : Linear EffectsDocument1 pageDWDM Impairments Optical Transport Networks (OTN) : Linear Effectskapil dev pandeyNo ratings yet

- DWDM PosterDocument1 pageDWDM Posterapi-3806249100% (1)

- Plano ElectricoDocument2 pagesPlano Electricomauricio suarezNo ratings yet

- Price List of Automobile in NepalDocument1 pagePrice List of Automobile in NepalSaroj Acharya0% (1)

- 14M - R9J SchematicDocument6 pages14M - R9J SchematicDiki PurwandiNo ratings yet

- Cat12k ElectricoDocument2 pagesCat12k ElectricoAlexis CentuNo ratings yet

- Electrical System With EMCP 3 C9 Generator Set: Engine Top ViewDocument2 pagesElectrical System With EMCP 3 C9 Generator Set: Engine Top Viewمهدي شقرونNo ratings yet

- 385C Waw1-UpDocument4 pages385C Waw1-UpJUNA RUSANDI SNo ratings yet

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- Project Management 1Document85 pagesProject Management 1Eko Fujisyah MaulwantoNo ratings yet

- HJM-22Q-G User Manual (Brief)Document14 pagesHJM-22Q-G User Manual (Brief)Alejandro PortilloNo ratings yet

- Met Averse Roadmap OverviewDocument28 pagesMet Averse Roadmap OverviewscribdlokiNo ratings yet

- Teaching Computer-Based Data Acquisition and Analysis Research Skills Using LabviewDocument26 pagesTeaching Computer-Based Data Acquisition and Analysis Research Skills Using LabviewAlejandro PortilloNo ratings yet

- Roman Empire Revived TheoryDocument173 pagesRoman Empire Revived TheoryBrenoliNo ratings yet

- Mirage Probationary EmploymentDocument3 pagesMirage Probationary EmploymentIsrael FortoNo ratings yet

- Kitty GenoveseDocument2 pagesKitty GenoveseRachael BartlettNo ratings yet

- Mark Magazine#64Document197 pagesMark Magazine#64Андрей КанищевNo ratings yet

- Barnum Distributors Wants A Projection of Cash Receipts and CashDocument1 pageBarnum Distributors Wants A Projection of Cash Receipts and CashAmit PandeyNo ratings yet

- Perilaku Ibu Hamil Dan KariesDocument22 pagesPerilaku Ibu Hamil Dan KarieshariyaniNo ratings yet

- Deed of Donation BicycleDocument2 pagesDeed of Donation BicycleCharlemagne PapioNo ratings yet

- Magic Maze: Props IncludedDocument4 pagesMagic Maze: Props IncludedarneuhüdNo ratings yet

- PUP College of Law - FAQsDocument15 pagesPUP College of Law - FAQsAlvin ClaridadesNo ratings yet

- Arnold Böcklin Was Born in Basel, Switzerland inDocument6 pagesArnold Böcklin Was Born in Basel, Switzerland inDragos PlopNo ratings yet

- IT ParksDocument12 pagesIT ParksDivam Goyal0% (1)

- Method Statement For Touch-Up Paint and Repair of Unitized Curtain WallDocument6 pagesMethod Statement For Touch-Up Paint and Repair of Unitized Curtain WallNESTOR YUMULNo ratings yet

- Operant Conditioning of RatsDocument7 pagesOperant Conditioning of RatsScott KaluznyNo ratings yet

- Finance Management Individual AssDocument33 pagesFinance Management Individual AssDevan MoroganNo ratings yet

- History of Sultan KudaratDocument9 pagesHistory of Sultan Kudaratjimmy_andangNo ratings yet

- Action Plan in Edukasyong Pantahanan at Pangkabuhayan School Year 2017-2018Document3 pagesAction Plan in Edukasyong Pantahanan at Pangkabuhayan School Year 2017-2018MERLINDA PACQUIAONo ratings yet

- SJAJ ANTICKIH GRKA Keramicke Posude SlikeeDocument563 pagesSJAJ ANTICKIH GRKA Keramicke Posude SlikeeAjdin Arapović100% (1)

- Acordes para GuitarraDocument12 pagesAcordes para GuitarraLucas Sebastian MuñozNo ratings yet

- Special Power of Attorney 2017-Michael John Dj. OpidoDocument2 pagesSpecial Power of Attorney 2017-Michael John Dj. OpidoJhoanne BautistaNo ratings yet

- UWI St. Augustine Student Wireless Network - Instruction / Setup GuideDocument2 pagesUWI St. Augustine Student Wireless Network - Instruction / Setup GuideBrendan B. MastayNo ratings yet

- Art of CharacterizationDocument4 pagesArt of CharacterizationAli RazaNo ratings yet

- Sample Annotated BibliographyDocument1 pageSample Annotated Bibliographyfcrocco100% (1)

- Calibration Form: This Form Should Be Filled Out and Sent With Your ShipmentDocument1 pageCalibration Form: This Form Should Be Filled Out and Sent With Your ShipmentLanco SANo ratings yet

- Gesc 112Document10 pagesGesc 112Kalpavriksha1974No ratings yet

- Unit 9 Performance Planning and Review: ObjectivesDocument16 pagesUnit 9 Performance Planning and Review: ObjectivesSatyam mishra100% (2)

- Grade 12 Mathematical Literacy: Question Paper 1 MARKS: 150 TIME: 3 HoursDocument53 pagesGrade 12 Mathematical Literacy: Question Paper 1 MARKS: 150 TIME: 3 HoursOfentse MothapoNo ratings yet

- Constraining Timing and P-T Conditions of Continental Collision and Late Overprinting in The Southern Brasília Orogen (SE-Brazil) - U-Pb Zircon PDFDocument23 pagesConstraining Timing and P-T Conditions of Continental Collision and Late Overprinting in The Southern Brasília Orogen (SE-Brazil) - U-Pb Zircon PDFAllissonNo ratings yet

- Polaris Ranger 500 ManualDocument105 pagesPolaris Ranger 500 ManualDennis aNo ratings yet

- Module 6:market Segmentation, Market Targeting, and Product PositioningDocument16 pagesModule 6:market Segmentation, Market Targeting, and Product Positioningjanel anne yvette sorianoNo ratings yet

- Walt Disney OutlineDocument9 pagesWalt Disney Outlineapi-234693246No ratings yet