Professional Documents

Culture Documents

Benefits and Advantages:: 875E Logger

Uploaded by

tystar_21Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Benefits and Advantages:: 875E Logger

Uploaded by

tystar_21Copyright:

Available Formats

875E LOGGER

TIGERCAT 875E LOGGER

A heavy duty, purpose-built, no

compromise forestry carrier that can

be configured for heavy duty cycle

loading or processing.

BENEFITS AND ADVANTAGES:

Powerful, efficient Tigercat FPT engine Durable construction for extreme duty

• Non-certified, Tier 4f and Stage V options available • Heavy wall side bumpers and solid cast counterweight

• Upper assembly will not dent or deform from impacts

Efficient, high-capacity cooling system

• Automatic variable fan speed for improved fuel efficiency Excellent service access

• Automatic reversing cycle to clean the heat exchangers • Power operated side engine door and overhead roof

enclosure

Smooth, quiet, twin swing drive system

• Full access to engine, major components and service points

• High swing torque and reduced gear tooth loads

• Large diameter, high capacity bearing Robust, forest duty undercarriage

• Tigercat F7-150 and F7-163 undercarriage options available

Dedicated, energy recovery swing system

• Closed loop drive feeds power back to the engine when swing Spacious, elevated rear-entry cab

decelerates, reducing fuel consumption and recovering energy • Excellent operator visibility

for other machine functions • Full-length front window and additional floor windows for

• Dedicated swing system enhances machine performance clear sightline to the tracks

• Elevated cab placement provides added visibility

PURPOSE-BUILT

PURPOSE-BUILT TO ELIMINATE THE DESIGN CLOSED LOOP

COMPROMISES FOUND IN EXCAVATOR SWING DRIVE

CONVERSIONS. Closed loop swing drive feeds

power back to the engine

when swing decelerates,

reducing fuel consumption

POWER OPERATED SIDE DOOR AND ROOF ENCLOSURE. and recovering energy for

Neat, clean component layout. Thoughtful component arrangement other machine functions.

allows for optimal cooling airflow and full access to all service points Tigercat’s efficient hydraulic

with room to work. systems enhance overall

performance and productivity.

TIGERCAT FPT ENGINE TECHNOLOGY

Tigercat FPT engines offer reliability, excellent fuel economy, and lower long-term maintenance

costs - the clear power choice for forestry and off-road industrial applications.

BOOM SYSTEM

THE 875E CAN BE CONFIGURED AS A LOADER OR ROADSIDE PROCESSOR.

Variety of grapple styles including pulpwood, The log grapple configuration is available with The processing configuration can

power clam and butt-n-top grapples. or without a live heel. accommodate a maximum head weight

of 3 700 kg (8,150 lb).

UNDERCARRIAGE

The F7-150 forest duty undercarriage has excellent

tractive effort for mobility on or between decks. The

larger footprint F7-163 undercarriage provides

additional stability for heavy timber applications and

when working at extended reach.

OPERATOR’S STATION • Large touchscreen display for machine monitoring and function

adjustment

• Spacious, comfortable cab

• Auxiliary input port, Bluetooth® audio, hands-free calling and

• Full-length front window and additional floor windows Sirius ready (North America only)

provide clear sightlines

• rearVIEW camera equipped

• Air ride seat with integrated heating and ventilation

• Key FOB to remotely turn on interior and exterior cab lights

• Optimally positioned controls

PPED W

UI IT

Q

H

E

Machine data onsite

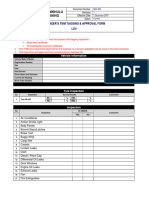

SPECIFICATIONS

875E

DIMENSIONS with standard track shoe ROTATING UPPER

WIDTH with steps 3 480 mm (137 in) SWING DRIVE 8 rpm variable speed; 360° continuous rotation

Double reduction, twin swing drive planetary

With optional F7-163 3 630 mm (143 in)

gearboxes; Twin piston swing motors

HEIGHT transport 3 430 mm (135 in)

SWING BEARING 1 370 mm (54 in) ball circle diameter

GROUND CLEARANCE 710 mm (28 in)

ENCLOSURE Hydraulically operated roof and side engine enclosure

WEIGHT less attachment 36 820 kg (81,000 lb) with manual backup; Large air intake for cooling system

With optional F7-163 38 600 kg (84,400 lb) Vandal protection; Smooth exterior

TAIL SWING RADIUS 3 300 mm (130 in) BOOM SYSTEM butt-n-top/power clam

POWER MAXIMUM RADIUS 10 920 mm (430 in)

ENGINE, Stage V Tigercat FPT N67 210 kW (282 hp) @ 2,200 rpm HYDRAULIC BARE PIN LIFT* 8 390 kg (18,460 lb)

ENGINE, Tier 4f Tigercat FPT N67 210 kW (282 hp) @ 2,200 rpm BOOM SYSTEM processor

ENGINE, Non-certified Tigercat FPT N67 210 kW (282 hp) @ 2,200 rpm MAXIMUM RADIUS 11 230 mm (442 in)

AIR FILTRATION Precleaner, 2-stage engine air cleaner HYDRAULIC BARE PIN LIFT* 8 390 kg (18,460 lb)

COOLING Side by side radiator, oil cooler, charge air cooler BOOM SYSTEM live heel

Optional Removable intake debris screen MAXIMUM RADIUS 12 620 mm (497 in)

FAN Hydraulic driven automatic variable speed, reversible HYDRAULIC BARE PIN LIFT* 7 480 kg (16,450 lb)

FUEL CAPACITY 800 L (211 US gal) ELECTRICAL

DEF CAPACITY Tier 4f 80 L (21 US gal) BATTERY (2) 12 v

HYDRAULIC SYSTEM ALTERNATOR 110 amp, 24 v

PUMP, MAIN Piston, load sensing SYSTEM VOLTAGE 24 v

PUMP, SWING Piston, closed loop, energy recovery LIGHTING (12) High output LED; (5) LED service, engine enclosure

PUMP, ATTACHMENT Piston, load sensing O P E R AT O R ’ S S TAT I O N

PUMP, COOLING FAN Gear CAB Insulated and pressurized; A/C, heater and defroster

rearVIEW camera system; Full length polycarbonate windshield

RESERVOIR 225 L (60 US gal)

Polycarbonate side, rear, door and floor windows; Machine

FILTRATION (5) Spin-on, 7 micron full flow; (1) Water absorbing monitoring system with warning horns; AM/FM digital stereo

CYLINDERS, HOIST (2) 140 mm (5.5 in) bore with auxiliary and USB input ports; Bluetooth® audio and

hands-free calling; (2) USB and (1) 12 v power points

CYLINDER, STICK (1) 150 mm (5.9 in) bore

OPERATOR CONTROLS Hydraulic proportional boom/travel/swing; Electronic for

CYLINDER, LIVE HEEL (1) 130 mm (5.1 in) bore

horsepower/fan control; Electric switch for swing brake/speed

CYLINDER, CLAM/B-N-T (1) 110 mm (4.3 in) bore Electronic control system with LCD colour touchscreen for

HORSEPOWER CONTROL Electronic speed sensing machine monitoring and function adjustment

RESERVOIR 225 L (60 US gal) SEAT Full suspension air ride, heated, fully adjustable

Armrest mounted Tigercat joysticks

UNDERCARRIAGE

O T H E R S TA N D A R D E Q U I P M E N T

TRACK FRAMES F7-150 heavy duty forestry; Integral track guides, ramp angles

LogOn™ local wifi machine monitoring system; Fuel suction

TRACK CHAIN FH400 215 mm (8.5 in) pitch strainer Alarm for track movement; Load ticket chute

FINAL DRIVE (2) Axial piston motors; Infinitely variable speed Access light FOB

TRACTIVE EFFORT 291 kN (65,500 lbf) OPTIONAL EQUIPMENT

With optional F7-163 334 kN (75,000 lbf) Cold weather kit; High view cab mounted camera system

GEARBOX Triple reduction planetary with brake Heavy duty stick cylinder guard; Jaw/tilt control swap

Butt-n-top tilt float; RemoteLog® telematics system

FRONT IDLER Hydraulic track adjuster; Spring shock absorber F7-163 undercarriage

SLIDES, UPPER Replaceable, bolt-on

ROLLERS, LOWER (8) FH400 single/double flange excavator type *Hydraulic bare pin lift calculated at 9,14 m (30 ft) reach as per SAE J2417

With optional F7-163 (9) FH400 single/double flange excavator type

TRACK SHOE 710 mm (28 in) double grouser, tall lug

TOP SPEED 875E LOGGER

LOW RANGE 2,3 km/h (1.4 mph)

HIGH RANGE 4,5 km/h (2.8 mph)

BRAKES

5,37 m

TRACK Friction disc; Automatic spring applied, hydraulic release (17 ft 7 in)

SWING Friction disc; Manual spring applied, hydraulic release

ALL ENGINE POWER VALUES ARE QUOTED AT NET POWER, AS PER SAE J1349.

TIGERCAT RESERVES THE RIGHT TO AMEND THESE SPECIFICATIONS AT ANY TIME WITHOUT NOTICE.

WEIGHTS AND DIMENSIONS MAY VARY SUBJECT TO MACHINE OPTIONS AND CONFIGURATIONS.

FOR THE MOST CURRENT SPECIFICATIONS PLEASE REFER TO THE TIGERCAT WEBSITE OR MOBILE APP.

TIGERCAT PRODUCTS MAY BE COVERED BY ONE OR MORE OF THE FOLLOWING US OR CANADIAN

10,92 m (35 ft 10 in)

PATENTS OR CORRESPONDING PATENTS IN OTHER COUNTRIES. REFER TO VIRTUAL PATENT MARKINGS: 5,61 m (18 ft 5 in) F7-150

WWW.TIGERCAT.COM/PATENTS. 5,79 m (19 ft) F7-163

EMAIL comments@tigercat.com © 2001 - 2021 Tigercat International Inc. All Rights Reserved. TIGERCAT, WIDERANGE, TURNAROUND,

PHONE 519. 753.2000 ER, EHS, LOW-WIDE, TEC, REMOTELOG, LOGON, and their respective logos, TOUGH RELIABLE

875E 1.0 0321

PRODUCTIVE, TIGERCAT TV, “Tigercat Orange” and BETWEEN THE BRANCHES, as well as corporate and

WEBSITE www.tigercat.com

product identity, are trademarks of Tigercat International Inc., and may not be used without permission.

ADDRESS 54 Morton Ave. East, Brantford, Ontario Canada, N3R 7J7

CV652

TIGERCAT, TURNAROUND, WIDERANGE, EHS, LOW-WIDE, ER and REMOTELOG, and their respective

MAIL Box 637 N3T 5P9 logos are registered trademarks of Tigercat International Inc.

You might also like

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- 890 ENG 1.0 1019 Hi ResDocument4 pages890 ENG 1.0 1019 Hi Restystar_21No ratings yet

- Benefits and Advantages:: The 850 ProcessorDocument4 pagesBenefits and Advantages:: The 850 Processortystar_21No ratings yet

- Benefits and Advantages:: X870D/Lx870D Series Feller BunchersDocument4 pagesBenefits and Advantages:: X870D/Lx870D Series Feller Buncherstystar_21No ratings yet

- Mini Hydraulic Excavator: Engine WeightsDocument16 pagesMini Hydraulic Excavator: Engine WeightsMyint Myat LwinNo ratings yet

- Benefits and Advantages:: Lx830D Feller BuncherDocument4 pagesBenefits and Advantages:: Lx830D Feller Bunchertystar_21No ratings yet

- Benefits and Advantages:: Lsx870D Shovel LoggerDocument4 pagesBenefits and Advantages:: Lsx870D Shovel Loggertystar_21No ratings yet

- Mini Hydraulic Excavator: Engine WeightsDocument16 pagesMini Hydraulic Excavator: Engine Weightsariyanto -No ratings yet

- D475a 5SDDocument14 pagesD475a 5SDzlNo ratings yet

- Wheel Loader: Engine Gross Power Operating Weight Bucket CapacityDocument16 pagesWheel Loader: Engine Gross Power Operating Weight Bucket CapacityAbo Achraf LaalawiNo ratings yet

- Multi Terrain Loaders: Cat C3.3B DIT (Turbo) Engine 257D 277D 287D Weights Operating SpecificationsDocument16 pagesMulti Terrain Loaders: Cat C3.3B DIT (Turbo) Engine 257D 277D 287D Weights Operating SpecificationsAkhmad SebehNo ratings yet

- 930G Engl (30c)Document28 pages930G Engl (30c)AbdelbagiNo ratings yet

- 924 GZDocument20 pages924 GZMilton DaniloNo ratings yet

- Wheel LoaderDocument16 pagesWheel LoaderRyan AliNo ratings yet

- 430E/ 430E IT: Backhoe LoaderDocument32 pages430E/ 430E IT: Backhoe Loadercameron_froeseNo ratings yet

- Retro Excavadora - 430E-430EITDocument32 pagesRetro Excavadora - 430E-430EITAndrés lyricsNo ratings yet

- The Tigercat 855E Is A High Performance, Fuel Efficient Feller BuncherDocument6 pagesThe Tigercat 855E Is A High Performance, Fuel Efficient Feller Bunchertystar_21No ratings yet

- DL300A EspecificacionesDocument20 pagesDL300A EspecificacionesRuiz D. AntonioNo ratings yet

- Cat 307 PDFDocument16 pagesCat 307 PDFAndy WeiNo ratings yet

- Caterpillar 854G - Specifications - AEHQ5308-01 (12-1999) PDFDocument20 pagesCaterpillar 854G - Specifications - AEHQ5308-01 (12-1999) PDFmarioNo ratings yet

- WA400-5 GB SceenDocument16 pagesWA400-5 GB SceenAngel UmánNo ratings yet

- Backhoe Loader Brochure 201910Document16 pagesBackhoe Loader Brochure 201910Blytzx GamesNo ratings yet

- Camion Articulado D400EDocument16 pagesCamion Articulado D400Edarwin100% (1)

- TG Series Compact TractorsDocument12 pagesTG Series Compact Tractorsحسن الديب hassan eldeebNo ratings yet

- Bobcat E37 Mini ExcavatorDocument12 pagesBobcat E37 Mini ExcavatorPiyumi HasanthikaNo ratings yet

- CS563EDocument16 pagesCS563ELuis Fernando Vasquez RamosNo ratings yet

- Captura de Pantalla 2023-07-31 A La(s) 4.09.25 P. M.Document12 pagesCaptura de Pantalla 2023-07-31 A La(s) 4.09.25 P. M.Ronny HernandezNo ratings yet

- pl83 87 Tier 4f - Aehq7482 00 - EnglishDocument20 pagespl83 87 Tier 4f - Aehq7482 00 - EnglishRahmat RiskiNo ratings yet

- Motoniveladora 120m-Awd (b86)Document12 pagesMotoniveladora 120m-Awd (b86)Sara Veronica Florentin CuencaNo ratings yet

- 345b II Specalog (Aehq5390)Document28 pages345b II Specalog (Aehq5390)suwarjitechnicNo ratings yet

- D475A-5 Super Dozer Aess725!00!46551 - Folha de Esp.Document12 pagesD475A-5 Super Dozer Aess725!00!46551 - Folha de Esp.João MariaNo ratings yet

- BulldozerDocument12 pagesBulldozerCarolina Olivares AlfaroNo ratings yet

- E 6 SKIDDERS 1.4 0517 WebDocument8 pagesE 6 SKIDDERS 1.4 0517 WebdavidNo ratings yet

- Asphalt PaverDocument16 pagesAsphalt Paverzae nurdinNo ratings yet

- Crawler Dozer: Engine Power 268 KW / 359 HP at 1.900 RPM Operating Weight 39.500 KGDocument20 pagesCrawler Dozer: Engine Power 268 KW / 359 HP at 1.900 RPM Operating Weight 39.500 KGagensaNo ratings yet

- Wheel LoaderDocument16 pagesWheel Loaderalsief1951No ratings yet

- Vibratory Soil Compactor: Stage II CompliantDocument12 pagesVibratory Soil Compactor: Stage II Compliantguillermo springNo ratings yet

- 307e - Cat - C10216006 PDFDocument16 pages307e - Cat - C10216006 PDFJorge CarvajalNo ratings yet

- Dresta TD-20M EnglishDocument8 pagesDresta TD-20M EnglishjddiazmNo ratings yet

- Ficha Tecnica Cat Cs-433eDocument16 pagesFicha Tecnica Cat Cs-433eJavier Hernandez AbrilNo ratings yet

- Caracteristicas Ap600dDocument12 pagesCaracteristicas Ap600dJulio MezaNo ratings yet

- GD535-5 CEN00731-01 English PDFDocument20 pagesGD535-5 CEN00731-01 English PDFPachacuticCartuche67% (3)

- Tier 4 Interim Engine: Net Horsepower Gross Horsepower Maximum GVWDocument16 pagesTier 4 Interim Engine: Net Horsepower Gross Horsepower Maximum GVWdeadbirdsNo ratings yet

- CAT SpecalogDocument36 pagesCAT SpecalogBen GottmanNo ratings yet

- 695SR 26061062GBDocument16 pages695SR 26061062GBwalk111No ratings yet

- Horsepower GROSS 241 KW 323 HP NET 235 KW 316 HP Max. Gross Vehicle Weight 47525 KG 104,770 LBDocument5 pagesHorsepower GROSS 241 KW 323 HP NET 235 KW 316 HP Max. Gross Vehicle Weight 47525 KG 104,770 LBAOUAR SofianeNo ratings yet

- GrapoDocument2 pagesGrapoSERGUINo ratings yet

- IT14GDocument20 pagesIT14GBilal VURALNo ratings yet

- 914G It14g PDFDocument20 pages914G It14g PDFMA TotalforkliftNo ratings yet

- LHD R1300G Cargador de Bajo Perfil CaterpillarDocument16 pagesLHD R1300G Cargador de Bajo Perfil CaterpillarCesar Chu AcevedoNo ratings yet

- Putting People First: A Reach-Type Forklift Designed for Comfort and SavingsDocument12 pagesPutting People First: A Reach-Type Forklift Designed for Comfort and SavingsThiên PhúcNo ratings yet

- Shinko Reach10 30 PDFDocument12 pagesShinko Reach10 30 PDFThiên PhúcNo ratings yet

- Shinko Reach10 - 30Document12 pagesShinko Reach10 - 30api-19987138100% (2)

- DX700LC PDFDocument24 pagesDX700LC PDFDadanNo ratings yet

- IT24F Integrated Toolcarrier: Versatile Machine for Many ApplicationsDocument20 pagesIT24F Integrated Toolcarrier: Versatile Machine for Many ApplicationsCecilia Adasme PerezNo ratings yet

- Series: Wheel LoadersDocument12 pagesSeries: Wheel LoadersHandoko Dwi raharjoNo ratings yet

- We-5 VESS081101 0404 EngDocument12 pagesWe-5 VESS081101 0404 EngmhommdNo ratings yet

- Underground Mining Loader: Engine Operating SpecificationsDocument20 pagesUnderground Mining Loader: Engine Operating SpecificationsFabian MorquechoNo ratings yet

- PC700-8 Uess15301 1208Document24 pagesPC700-8 Uess15301 1208LTATECNICONo ratings yet

- Tren ScoopDocument16 pagesTren ScoopHugoRamosMamaniNo ratings yet

- Brochure-Model 1895 SBLDocument2 pagesBrochure-Model 1895 SBLtystar_21No ratings yet

- Dvigateli JD 6.8 8.1 LitraDocument474 pagesDvigateli JD 6.8 8.1 Litraкостя костяNo ratings yet

- 597 Series PDFDocument52 pages597 Series PDFtystar_21No ratings yet

- Valmet 911.3 ENDocument8 pagesValmet 911.3 ENtystar_21No ratings yet

- Data Sheets 1510 1910 en (df4) PDFDocument16 pagesData Sheets 1510 1910 en (df4) PDFPaulo GodinhoNo ratings yet

- Ind Catalog enDocument128 pagesInd Catalog entystar_21No ratings yet

- 597 Series PDFDocument52 pages597 Series PDFtystar_21No ratings yet

- 2020 Browning Safe Brochure PDFDocument36 pages2020 Browning Safe Brochure PDFtystar_21No ratings yet

- Indian Scout Rider's Manual 2018Document129 pagesIndian Scout Rider's Manual 2018tystar_21No ratings yet

- H855D/Lh855D Harvester: Benefits and AdvantagesDocument4 pagesH855D/Lh855D Harvester: Benefits and Advantagestystar_21No ratings yet

- The Quick, Efficient, High Performance H845E HarvesterDocument6 pagesThe Quick, Efficient, High Performance H845E Harvestertystar_21No ratings yet

- The H822D Series. Powerful, Compact and Built For The OperatorDocument6 pagesThe H822D Series. Powerful, Compact and Built For The Operatortystar_21No ratings yet

- Benefits and Advantages:: H250D ProcessorDocument4 pagesBenefits and Advantages:: H250D Processortystar_21No ratings yet

- Service Manual: Tigercat H250B HarvesterDocument180 pagesService Manual: Tigercat H250B Harvestertystar_21No ratings yet

- Tigercat Drive-To-Tree Feller Bunchers Lead The Industry in Productivity, Reliability and DurabilityDocument8 pagesTigercat Drive-To-Tree Feller Bunchers Lead The Industry in Productivity, Reliability and Durabilitytystar_21No ratings yet

- Service 822C enDocument366 pagesService 822C entystar_21100% (1)

- Etx®-Cd: Up To Intel® Core™2 Duo ProcessorDocument2 pagesEtx®-Cd: Up To Intel® Core™2 Duo Processortystar_21No ratings yet

- 47085a Pump PVWJDocument24 pages47085a Pump PVWJtystar_21No ratings yet

- The Tigercat 855E Is A High Performance, Fuel Efficient Feller BuncherDocument6 pagesThe Tigercat 855E Is A High Performance, Fuel Efficient Feller Bunchertystar_21No ratings yet

- The Efficient and Agile, Mid-Sized 845E Feller Buncher.: T H E 8 4 5 EDocument6 pagesThe Efficient and Agile, Mid-Sized 845E Feller Buncher.: T H E 8 4 5 Etystar_21No ratings yet

- 855D/L855D Feller Buncher: Benefits and AdvantagesDocument4 pages855D/L855D Feller Buncher: Benefits and Advantagestystar_21No ratings yet

- D5 ControlSystem Brochure CV659-EN-1.0 PrintDocument8 pagesD5 ControlSystem Brochure CV659-EN-1.0 Printtystar_21No ratings yet

- The Tigercat 855D Is A High Performance, Fuel Efficient Feller BuncherDocument6 pagesThe Tigercat 855D Is A High Performance, Fuel Efficient Feller Bunchertystar_21No ratings yet

- Ac16 Articulating Carrier: Benefits and AdvantagesDocument2 pagesAc16 Articulating Carrier: Benefits and Advantagestystar_21No ratings yet

- Benefits and Advantages:: 220E LoaderDocument2 pagesBenefits and Advantages:: 220E Loadertystar_21No ratings yet

- Revised GST Process for Physically Disabled CustomersDocument7 pagesRevised GST Process for Physically Disabled CustomersNeeraj SharmaNo ratings yet

- TS501 V6.26 FunctionList AUDocument36 pagesTS501 V6.26 FunctionList AURichie YeNo ratings yet

- Architectural Design 3 Computations Professor: Date:: NameDocument13 pagesArchitectural Design 3 Computations Professor: Date:: Namejohnfrancis nonsolNo ratings yet

- Workshop Manual: TF SeriesDocument94 pagesWorkshop Manual: TF SeriesmailforspamNo ratings yet

- Stationary Portable Compressors: MOBILAIR M 57 Utility / M 58 UtilityDocument5 pagesStationary Portable Compressors: MOBILAIR M 57 Utility / M 58 UtilityIan EvansNo ratings yet

- 5700 Operator's Manual (ID0238832 - 01 - SVC)Document152 pages5700 Operator's Manual (ID0238832 - 01 - SVC)William PeeleNo ratings yet

- Chapter-Ii Geo-Historical Background of Madurai EnvironDocument25 pagesChapter-Ii Geo-Historical Background of Madurai EnvironCHALLA MOUNICANo ratings yet

- Stocks Price Movment: By:-Varshini Kumar 11-CDocument14 pagesStocks Price Movment: By:-Varshini Kumar 11-CVarshini KNo ratings yet

- Material Item Specification Fill CapacityDocument151 pagesMaterial Item Specification Fill CapacityHenry SilvaNo ratings yet

- Transportation: Keith Academy Live Lesson NotesDocument12 pagesTransportation: Keith Academy Live Lesson NotesCandra SilalahiNo ratings yet

- Tabela de Preços Janeiro 2013Document57 pagesTabela de Preços Janeiro 2013Paulo De Tarso FeitosaNo ratings yet

- 018 1968 Sir Alfred Beit Mar 2018yygfhhgdxDocument8 pages018 1968 Sir Alfred Beit Mar 2018yygfhhgdxandrew MhakaNo ratings yet

- New C Class Saloon+EstateDocument99 pagesNew C Class Saloon+EstateFloyd ElgarNo ratings yet

- 171 PDFDocument242 pages171 PDFSantosh PatilNo ratings yet

- BISAG-N Workshop Output - v3Document59 pagesBISAG-N Workshop Output - v3Rakesh SheteNo ratings yet

- Nov23 Coaching Engr. Besavilla 01 06 Nov. 2023Document14 pagesNov23 Coaching Engr. Besavilla 01 06 Nov. 2023Rhowelle TibayNo ratings yet

- HSEQ-HQ-06-08-00 Transportation StandardDocument15 pagesHSEQ-HQ-06-08-00 Transportation StandardAHMED AMIRANo ratings yet

- Delta Panel Engineering BookDocument72 pagesDelta Panel Engineering BookMitchell MulveyNo ratings yet

- Olympian Generator Set Engine FiltersDocument6 pagesOlympian Generator Set Engine FiltersJavier Méndez100% (1)

- Scania Opticruise GearboxDocument4 pagesScania Opticruise GearboxAJHAY BABU J KNo ratings yet

- Fortis® H80, H90, H100, H110, H120FT (P005) : 1698691 ©2009 Hyster Company 02/2009Document678 pagesFortis® H80, H90, H100, H110, H120FT (P005) : 1698691 ©2009 Hyster Company 02/2009José SilvaNo ratings yet

- Session 5 Airport Design - AirsideDocument47 pagesSession 5 Airport Design - AirsideHarmandeep AhluwaliaNo ratings yet

- Iveco Stralis ATAD. Manual - Part 306Document1 pageIveco Stralis ATAD. Manual - Part 306timNo ratings yet

- Parts Catalogue: '19 EX400 GKF (ID) (Ninja 400)Document97 pagesParts Catalogue: '19 EX400 GKF (ID) (Ninja 400)Harry BNo ratings yet

- Specs For Quotation Machine Room Less Type Elevators For Corales Blue Resort in Dominican RepublicDocument2 pagesSpecs For Quotation Machine Room Less Type Elevators For Corales Blue Resort in Dominican RepublicCarlos PrietoNo ratings yet

- MZK003 - LVD Tagging InspectionDocument4 pagesMZK003 - LVD Tagging InspectionNorman CoetzeeNo ratings yet

- Caterpillar d8k Parts BookDocument20 pagesCaterpillar d8k Parts BookHassie100% (51)

- Notice Inviting Bid: Signature Not VerifiedDocument1 pageNotice Inviting Bid: Signature Not VerifiedBhavesh Patel100% (1)

- Utilities, Road Reinstatement and Traffic Management at Road WorksDocument12 pagesUtilities, Road Reinstatement and Traffic Management at Road WorksGILBERTO POZZINo ratings yet

- BASIS IN PROPOSING A PEDESTRIAN BRIDGE IN Tuyan Naga CityDocument22 pagesBASIS IN PROPOSING A PEDESTRIAN BRIDGE IN Tuyan Naga CityPedmaship 18No ratings yet

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Incidents That Define Process SafetyFrom EverandIncidents That Define Process SafetyNo ratings yet

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeFrom EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNo ratings yet

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- 3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionFrom Everand3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionArnaud PerrotNo ratings yet

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Safety Fundamentals and Best Practices in Construction IndustryFrom EverandSafety Fundamentals and Best Practices in Construction IndustryNo ratings yet

- Radium Girls: Women and Industrial Health Reform, 1910-1935From EverandRadium Girls: Women and Industrial Health Reform, 1910-1935Rating: 4.5 out of 5 stars4.5/5 (4)

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- Autophagy in Health and DiseaseFrom EverandAutophagy in Health and DiseaseBeverly RothermelNo ratings yet

- Safety Critical Systems Handbook: A Straight forward Guide to Functional Safety, IEC 61508 (2010 EDITION) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 and ISO 13849From EverandSafety Critical Systems Handbook: A Straight forward Guide to Functional Safety, IEC 61508 (2010 EDITION) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 and ISO 13849Rating: 4 out of 5 stars4/5 (5)

- Safety and Intelligent Transport Systems Development in the People’s Republic of ChinaFrom EverandSafety and Intelligent Transport Systems Development in the People’s Republic of ChinaNo ratings yet

- One Health: Integrated Approach to 21st Century Challenges to HealthFrom EverandOne Health: Integrated Approach to 21st Century Challenges to HealthJoana C. PrataNo ratings yet

- The Invisible Rainbow: A History of Electricity and LifeFrom EverandThe Invisible Rainbow: A History of Electricity and LifeRating: 4.5 out of 5 stars4.5/5 (21)

- Exercise, Sport, and Bioanalytical Chemistry: Principles and PracticeFrom EverandExercise, Sport, and Bioanalytical Chemistry: Principles and PracticeNo ratings yet

- Fire Protection Engineering in Building DesignFrom EverandFire Protection Engineering in Building DesignRating: 4.5 out of 5 stars4.5/5 (5)

- The Construction Safety Guide: Injury and Illness Prevention through DesignFrom EverandThe Construction Safety Guide: Injury and Illness Prevention through DesignRating: 4 out of 5 stars4/5 (6)