Professional Documents

Culture Documents

White Biotechnology: Commentaries & Analyses

Uploaded by

chitralekha pOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

White Biotechnology: Commentaries & Analyses

Uploaded by

chitralekha pCopyright:

Available Formats

www.asiabiotech.

com Commentaries & Analyses

White Biotechnology

Professor Sang Yup Lee

Dr Seh Hee Jang

I

n recent years, the crude oil price has been surging to reach over US$60 per barrel.

Crude oil is the most important energy source and many industries are heavily relying

on the use of chemicals derived from crude oil. The finite nature of oil reserves,

coupled with increasing concerns on our environmental damages, urge us to develop a

sustainable way of securing these chemicals and energy. White biotechnology, which is

a European terminology for industrial biotechnology, is thus drawing much attention as a

solution to produce energy, chemicals and other materials from renewable resources.

White biotechnology provides significant benefits over the conventional chemical

industry because it allows production of chemicals and energy from annually renewable

resources in a more energy-effective manner. Also, decreased generation of wastes,

reduced CO2 formation, and increased product yield and purity for some of the products

are additional advantages of white biotechnology. Until now, white biotechnology has

been successful in fine chemical and pharmaceutical industries leading to approximately

15% of total market (Table 1). The market portion of the current white biotechnology-

based products is approximately 5% of the total chemical market. According to McKinsey

and Company, the biotechnological feedstock will become ca. 20% and 75% of the

total chemical feedstock by 2010 and 2050, respectively, with the help of technologies

such as systems biotechnology and metabolic engineering (Fig. 1).

Table 1: Current Representative Products of White Biotechnology

Chemicals Global annual production Microrganisms (processes)

and market price

(million tons / U$ per kg)

L-Glutamic acid 1,500 / 1.44 Bacteria (aerobic)

Citric acid 1,000 / 0.96 Yeast (aerobic)

Lactic acid 150 / 2.16 Bacteria (anaerobic)

Gluconic acid 100 / 1.8 Yeast (aerobic)

L-Lysine 700 / 2.4 Bacteria (aerobic)

Vitamin C 80 / 9.6 —

The global chemical industry produced approximately US$1.9 trillion worth of

products through conventional petrochemical-based processes using more than 2 billion

barrels of crude oil in 2005. The processes are energy intensive and environmentally

unfriendly emitting about 1.5 billion tons of CO2. With the growing environmental

concerns and rapid increase in oil price, much effort is being devoted worldwide to

develop cost-competitive and energy-effective processes using renewable resources.

In particular, it is urgent to develop innovative processes for the production of bulk

chemicals, which accounts for more than 95% of all chemicals produced. Among

APBN • Vol. 10 • No. 10 • 2006 559

www.asiabiotech.com Commentaries & Analyses

(billion U$/year)

Global market

Fig. 1: Potential markets for bio-based chemicals in 2010.

the various technologies to accomplish this bio-based chemicals vision, metabolic

engineering will play the most important role as it allows development of strains that

are capable of enhanced production with less byproducts from various renewable raw

materials. Recent developments in the area of systems biology are further advancing the

strategies for metabolic engineering by providing genome-scale and holistic information

of a given organism; I prefer to call this systems biotechnology, which is the development

of biotechnological processes using systems biological approaches (Fig. 2). Among the

various chemicals that can be produced by white biotechnology (Fig. 3), some of them

are briefly described below.

Bioethanol is the best developed bio-based bulk chemical produced by white

biotechnology. Recently, the US government decided to fund additional research in

‘cutting-edge methods’ for producing ethanol (2006 U.S. President’s annual address).

The goal is to make ethanol more practical and competitive to replace the crude oil

imports. Bioethanol is commonly produced from the carbon sources from crop plants

(maize and sugar plant) by fermentation. It is one of the most cost-effective renewable

transport fuels. From a practical viewpoint, 10% ethanol can be used in modern vehicles

without any appreciable changes in performance. Traditionally, yeast has been used

for ethanol production. However, metabolically engineered bacterial strains (e.g.,

Zymomonas mobilis and Escherichia coli) have been developed to efficiently produce

bioethanol1,2.

Glycerol is another promising chemical to be produced by microbial fermentation3.

More than 600,000 tons of glycerol was produced in 2001, and used as a feedstock

for the production of various chemicals. Although glycerol had been commercially

produced by microbial fermentation during the World War I, it has been synthesized

from allyl alcohol or by the oxidation or chlorination of propylene after the World War

II. Numerous genetically modified bacterial or yeast strains have been developed by

overexpressing and/or knocking-out the genes associated with the glycerol formation

pathways to enhance the cell’s ability to produce glycerol. The best microorganism

560 APBN • Vol. 10 • No. 10 • 2006

www.asiabiotech.com Commentaries & Analyses

Fig. 2: Concept of white biotechnology: Integration of upstream (strain deveopment), midstream (fermentation)

and downstream (recovery) strategies is important for the development of successful and commercially viable

processes.

Fig. 3: Representative products of white biotechnology. Renewable raw materials are converted to various

chemicals ranging from primary to secondary metabolites.

APBN • Vol. 10 • No. 10 • 2006 561

www.asiabiotech.com Commentaries & Analyses

for the production of glycerol is an osmotolerant yeast strain, Candida glycerinogenes,

isolated from glazed fruit in southern China. As the price of crude oil rapidly increases,

more than 10,000 tons of glycerol is produced by fermentation of C. glycerinogenes in

China for the domestic usage4.

Lactic acid is also one of the main products produced by white biotechnology.

Annually, 130,000 tons of lactic acid is produced, most of which is used by the food

industry. Future demand on lactic acid is expected to increase with the introduction

of polylactic acid into the market. Polylactic acid is a biodegradable (and now more

perferably called high-performance) plastic that has the advantages, compared to the

existing plastics, of being biodegradable and manufactured from renewable resources.

Various bacteria have been reported to produce lactic acid with high yield and

productivity. By employing different strains, a desired lactic acid enantiomer such as L(+)-,

D(-)-, or DL-lactic acid can be produced5,6. The development of specialty polymers from

lactic acid has triggered increased interest in the production of specific enantiomers. The

dimers, LL , DD, and DL, can be used as building blocks of polylactic acid possessing

different physical properties. Recently, homofermentative production of lactic acid by

metabolically engineered E. coli has also been developed7.

1,3-propanediol has a wide range of applications such as composites, adhesives,

laminates, monomers of polymers, solvents and anti-freezing agent. Currently,

it is produced by chemical synthesis, but there has been growing interest for its

biotechnological production. Until now, various microorganisms including Klebsiella,

Enterobacter, Citrobacter, Lactobacilli and Clostidia have been reported to produce 1,3-

propanediol under anaerobic condition using glycerol as an carbon source8. Considering

the high price of glycerol, many researchers have considered E. coli as a host strain for

the production of 1,3-propanediol from glucose.

As mentioned earlier, the production of biodegradable polymer is one of the

main goals of white biotechnology. While lactic acid and 1,3-propanediol serve as

monomers for polymerization9, polyhydroxyalkanoates (PHAs) are a family of naturally

synthesized polymer in a wide variety of bacteria as an energy and/or carbon storage

material. PHAs possess material properties similar to various petrochemical-based

synthetic thermoplastics and elastomers currently in use. They are also completely

degradable to water and carbon dioxide (and methane under anaerobic condition)

by microorganisms in various environments10. Recent advances in our understanding

of the PHAs biosynthetic pathways, and cloning and molecular characterization of

key genes have allowed the construction of various bacterial strains for the enhanced

production of PHAs. The production cost of PHAs is still two to three times higher than

petroleum-based polymers, but this situation may change as the price of crude oil goes

up further.

Another good example of chemicals produced by white biotechnology is 3-

hydroxyproprionic acid, which is a key intermediate for several commercially important

chemicals including acrylic acid, acrylamide, and 1,3-propanediol. Codexis and Cargill

developed a microbial process which utilizes low-cost and clean agricultural feedstocks

(corn sugar) to produce 3- hydroxyproprionic acid.

Succinic acid is a four-carbon dicarboxylic acid, which can be used as a precursor of

many industrially important chemicals in food, chemical and pharmaceutical industries. It

is expected that the current petroleum-based succinic acid process will be replaced by the

fermentative succinic acid production system in the foreseeable future. Several promising

562 APBN • Vol. 10 • No. 10 • 2006

www.asiabiotech.com Commentaries & Analyses

succinic acid producers include Actinobacillus succinogenes, Anaerobiospirillum

succiniciproducens, Mannheimia succiniciproducens and recombinant Escherichia

coli.

There is no doubt in that white biotechnology will become an essential technology

paradigm for the sustainable growth using renewable materials. However, the efficiency

of the processes for the production of the diverse chemicals needs to be improved. For

the time being, the products of white biotechnology have to compete with the products

from the petroleum-based industry. This is why there is still hesitation in the global

chemical industry for actively adopting white biotechnology. However, as repeatedly

stated, white biotechnology is a key solution for the sustainable growth. As the first group

of foreseeing companies are already developing more and more bio-based processes,

there may be no second chance left for the other chemical companies in the near future.

White biotechnolgy! It is an essential technology for our future.

Acknowledgements

My work described herein was supported by the Genome-Based Integrated

Bioprocess Project from the Ministry of Science and Technology and LG Chem Chair

Professorship.

References

1. Ingram, L.O. et al. 1(998) Metabolic Engineering of bacteria for ethanol production. Biotech. Bioeng.

58:204–214.

2. Seo J.-S. et al. (2005) The genome sequence of the ethanologenic bacterium Zymomonas mobilis ZM4.

Nat. Biotechnol. 23:63–68.

3. Wang, Z-X et al. (2001) Glycerol production by microbial fermentation: A review. Biotechnol. Adv.

19:201–223.

4. Wang, Z-X et al. (1999) A new osmotolerant glycerol-highly-producing species of Candida sp. - Candida

glycerolgenesis Xhuge sp. nov. Acta. Microbiol. Sin. 39:68–74.

5. Dien, B. S. et al. (2001) Recombinant Escherichia coli engineered for production of L-lactic acid from

hexose and pentose sugars. J. Ind. Microb. Biotech. 27:259–264.

6. Zhu, J. et al. (2005) Effect of a single-gene knockout on the metabolic regulation in Escherichia coli for

D-lactate production under microaerobic condition. Met. Eng. 7:104–115.

7. Chang, D. et al. (1999) Homofermenative production of D- or L-lactate in metabolically engineered

Escherichia coli RR1. Appl. Env. Microb. 65(4):1384–1389

8. Nakamura, C. E. et al. (2003) Metabolic engineering for the microbial production of 1,3-propanediol.

Curr. Opin. Biotech. 14:454–459.

9. Lee, S. Y. et al. (2004) Fermentative production of chemicals that can be used for polymer synthesis. Macro.

Biosci. 4:157–164.

10. Lee, S.Y. (1996) Bacterial polyhydroxyalkanoates. Biotechnol. Bioeng. 49: 1–14

Contact Details:

Professor Sang Yup Lee and Dr Seh Hee Jang

Address: Department of Chemical and Biomolecular Engineering,

BioProcess Engineering Research Center,

Bioinformatics Research Center,

KAIST, Daejeon 305-701, Korea

Email: leesy@kaist.ac.kr

APBN • Vol. 10 • No. 10 • 2006 563

You might also like

- Introduction to Virology and Viral ClassificationDocument5 pagesIntroduction to Virology and Viral ClassificationmonchievaleraNo ratings yet

- Manual de Genetica Medica (2007)Document519 pagesManual de Genetica Medica (2007)Mara PitrezNo ratings yet

- Bio Ethanol I ToDocument301 pagesBio Ethanol I Togeopradhana100% (1)

- Bio EthanolDocument303 pagesBio EthanolSyed Muzamil Ahmed100% (2)

- Study of Bio-Plastics As Green & Sustainable Alternative ToDocument8 pagesStudy of Bio-Plastics As Green & Sustainable Alternative ToJesús Ariel Valenzuela HernándezNo ratings yet

- IIS Members List 7 9 16Document39 pagesIIS Members List 7 9 16dharmender singhNo ratings yet

- Study of Bio-Plastics As Green & Sustainable Alternative To PlasticsDocument8 pagesStudy of Bio-Plastics As Green & Sustainable Alternative To PlasticsAndehNo ratings yet

- Yeast Asexual Reproduction LabDocument3 pagesYeast Asexual Reproduction LabRyan Carlo CondeNo ratings yet

- Recent Evolutionary Trends in The Production of BiofuelsDocument23 pagesRecent Evolutionary Trends in The Production of BiofuelsPrajwal KambleNo ratings yet

- Microbiology Quiz QuestionsDocument19 pagesMicrobiology Quiz QuestionsAkram NiaziNo ratings yet

- Commentaries & Analyses: AsiabiotechDocument1 pageCommentaries & Analyses: AsiabiotechWaqas MinhasNo ratings yet

- White Biotechnology Final PDFDocument4 pagesWhite Biotechnology Final PDFMayank SharmaNo ratings yet

- Commentaries & Analyses: AsiabiotechDocument1 pageCommentaries & Analyses: AsiabiotechWaqas MinhasNo ratings yet

- Biofuel Review: A Study on Biofuel as a Green Energy ResourceDocument6 pagesBiofuel Review: A Study on Biofuel as a Green Energy ResourcePradip PatelNo ratings yet

- Biofuel: Clarence Lehman See All ContributorsDocument10 pagesBiofuel: Clarence Lehman See All Contributorsmuhammad aslamNo ratings yet

- Lecture-3: Fermentation ProcessesDocument20 pagesLecture-3: Fermentation ProcessesYENUGULA DAVID VENKATNo ratings yet

- Research ProposalDocument23 pagesResearch ProposalIsabellaNo ratings yet

- Assignment 1 Che 544 - Group 6Document29 pagesAssignment 1 Che 544 - Group 6atikah hasnor100% (1)

- InTech-Biofuel Sources Extraction and DeterminationDocument28 pagesInTech-Biofuel Sources Extraction and DeterminationHadi WaisiNo ratings yet

- Biofuel Alternatives To Ethanol: Pumping The Microbial WellDocument7 pagesBiofuel Alternatives To Ethanol: Pumping The Microbial WellAshrafNamamuTeratasNo ratings yet

- Almeida 2023Document13 pagesAlmeida 2023Ingryd Mayer KrinskiNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument19 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsHassan AbidNo ratings yet

- A Novel Cell Factory For Efficient Production of Ethanol From Dairy WasteDocument11 pagesA Novel Cell Factory For Efficient Production of Ethanol From Dairy WasteVitor ArsenioNo ratings yet

- Green Chemistry Application for Sustainable Development Using Renewable FeedstocksDocument26 pagesGreen Chemistry Application for Sustainable Development Using Renewable FeedstocksAlinaCrinaCiubotariuMuresanNo ratings yet

- FermentationDocument18 pagesFermentationCrissy DionesNo ratings yet

- Discussion BiofuelDocument7 pagesDiscussion BiofuelSiti Humaira IbrahimNo ratings yet

- Microbial Production Commodity Chemicals: International Union of Pure and Applied ChemistryDocument16 pagesMicrobial Production Commodity Chemicals: International Union of Pure and Applied ChemistryzahidNo ratings yet

- Biofuels FinalDocument4 pagesBiofuels Finalapi-326166436No ratings yet

- Xylitol Production ReviewDocument21 pagesXylitol Production ReviewJISENNIA MARLENY VARA GARCIANo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument23 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For Scientistsr7525rNo ratings yet

- Jof 08 00395 With CoverDocument23 pagesJof 08 00395 With CoverVitor ArsenioNo ratings yet

- National Institute of Technology, Durgapur: Final Year Project ReportDocument24 pagesNational Institute of Technology, Durgapur: Final Year Project ReportAkashdeep Sah100% (2)

- Microbial Production of Organic Acids: Expanding The MarketsDocument9 pagesMicrobial Production of Organic Acids: Expanding The MarketsBrain Science100% (1)

- Bioethanol Production From Renewable Raw Materials and Its Separation and Purification - A ReviewDocument38 pagesBioethanol Production From Renewable Raw Materials and Its Separation and Purification - A Reviewnabeelkhaliq323No ratings yet

- Iofuels: Why Do We Need Biofuels?Document2 pagesIofuels: Why Do We Need Biofuels?rockingtwo07No ratings yet

- Biofuels Defined: Liquid Fuels from Living OrganismsDocument11 pagesBiofuels Defined: Liquid Fuels from Living OrganismsK.D. PatelNo ratings yet

- Bioethanol Production As A Renewable Energy Source From Algal Biomass & Corn StalkDocument6 pagesBioethanol Production As A Renewable Energy Source From Algal Biomass & Corn StalkDilay RıdvanNo ratings yet

- J Renene 2011 04 031Document9 pagesJ Renene 2011 04 031antonio tellezNo ratings yet

- Biotechnology For Biofuels-EditedDocument4 pagesBiotechnology For Biofuels-EditedKARTHIK VINODNo ratings yet

- A REPORT ON BIO-ETHANOL PRODUCTIONDocument13 pagesA REPORT ON BIO-ETHANOL PRODUCTIONbukidaNo ratings yet

- Comparative Study of Bioethanol and Commercial EthanolDocument21 pagesComparative Study of Bioethanol and Commercial Ethanolanna sophia isabelaNo ratings yet

- 2ndpaper PDFDocument7 pages2ndpaper PDFaysha ghazyNo ratings yet

- Complet ProDocument64 pagesComplet ProGabriel AyauNo ratings yet

- Cellulosic EthanolDocument15 pagesCellulosic EthanolSuryaNo ratings yet

- EthanolDocument2 pagesEthanolJulissa SantisNo ratings yet

- Fermentation 07 00314Document18 pagesFermentation 07 00314ArvindNo ratings yet

- Algal Bio PlasticsDocument4 pagesAlgal Bio PlasticsBala JiNo ratings yet

- Proposal On Food Waste To Energy Conversion (Biodiesel)Document17 pagesProposal On Food Waste To Energy Conversion (Biodiesel)Abdulaziz Khalil100% (1)

- Bio Fuels - WORD 03Document22 pagesBio Fuels - WORD 03vineeththedominatorNo ratings yet

- Economic Power of MicrobeDocument16 pagesEconomic Power of MicrobeAbhishek MuleNo ratings yet

- TK 4009 Bioproses Industrial 3 Maret 2015Document30 pagesTK 4009 Bioproses Industrial 3 Maret 2015Ryan Fitrian Sofwan FauzanNo ratings yet

- Bioalcohol Production: SeminarDocument16 pagesBioalcohol Production: SeminarNeelima ThakurNo ratings yet

- Bioethanol Journal 1Document14 pagesBioethanol Journal 1Muhammad Hafizh HibatullahNo ratings yet

- 2G Ethanol ConversionDocument26 pages2G Ethanol Conversionsarim rizviNo ratings yet

- Biofuels 1Document17 pagesBiofuels 1Wajd NasserNo ratings yet

- Tutorial 2Document3 pagesTutorial 2Lê PhươngNo ratings yet

- Algae FinalDocument8 pagesAlgae FinalbennyksNo ratings yet

- Alok Kumar Singh, Et AlDocument11 pagesAlok Kumar Singh, Et AlKavinNo ratings yet

- 2nd Generation BioFuel in IndiaDocument19 pages2nd Generation BioFuel in IndiaAlok YadavNo ratings yet

- Accepted Manuscript: Bioresource TechnologyDocument37 pagesAccepted Manuscript: Bioresource TechnologyLuminita AndronicNo ratings yet

- (Biol 12) Grade 10 Unit 1, 3 and 5Document31 pages(Biol 12) Grade 10 Unit 1, 3 and 5mintesnot berisaNo ratings yet

- Rausch 2006Document40 pagesRausch 2006Marco Antonio Guerrero RoblesNo ratings yet

- Md. Mesbah Uddin Khulna University, Bangladesh: SpeakerDocument18 pagesMd. Mesbah Uddin Khulna University, Bangladesh: Speakerapi-26998277No ratings yet

- Fungi and Lignocellulosic BiomassFrom EverandFungi and Lignocellulosic BiomassChristian P KubicekNo ratings yet

- Alpha CRS+ Product Information PageDocument5 pagesAlpha CRS+ Product Information PageAllegra AmiciNo ratings yet

- Chakraborty Anticancer Drugs Marine OrganismDocument10 pagesChakraborty Anticancer Drugs Marine OrganismDeisy OctavianiNo ratings yet

- Reverse Vaccinology Basics and Applications 2157 7560.1000194Document5 pagesReverse Vaccinology Basics and Applications 2157 7560.1000194Yooobsan Nii barriitiNo ratings yet

- Subjects and Topics in Basic Medical Science: A Imhotep Virtual Medical School PrimerDocument168 pagesSubjects and Topics in Basic Medical Science: A Imhotep Virtual Medical School PrimerMarc Imhotep Cray, M.D.100% (3)

- What Was The Human Genome Project?Document12 pagesWhat Was The Human Genome Project?tonxasNo ratings yet

- Genetic Engineering AnswersDocument2 pagesGenetic Engineering AnswersVirginia MorleyNo ratings yet

- BME111 Engineering Perspectives on BiologyDocument3 pagesBME111 Engineering Perspectives on BiologypamoraleNo ratings yet

- AP Biology: Evolution & Hardy-Weinberg EquilibriumDocument14 pagesAP Biology: Evolution & Hardy-Weinberg EquilibriumJessica AguilarNo ratings yet

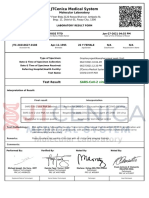

- Diagnostic Report Reveals Positive SARS-CoV-2 ResultDocument2 pagesDiagnostic Report Reveals Positive SARS-CoV-2 Resultpranav chauhanNo ratings yet

- Jtcenica Medical System: Test ResultDocument1 pageJtcenica Medical System: Test ResultAprilNo ratings yet

- Chapter 1. Cell Division: MeiosisDocument16 pagesChapter 1. Cell Division: Meiosisankurbiology100% (1)

- Final PROTOZOADocument24 pagesFinal PROTOZOAjamilaNo ratings yet

- Pengantar Farmasi IndustriDocument14 pagesPengantar Farmasi IndustriNorma YunitaNo ratings yet

- General Biology 2 PDFDocument56 pagesGeneral Biology 2 PDFReyvie SainesNo ratings yet

- Lecture 12' - Structural Transitions in Nucleic Acids IIDocument39 pagesLecture 12' - Structural Transitions in Nucleic Acids IIcurlicueNo ratings yet

- Chromosome Theory of InheritanceDocument8 pagesChromosome Theory of Inheritanceneeru.bhagatNo ratings yet

- Biology B: Pearson Edexcel Level 3 GCEDocument184 pagesBiology B: Pearson Edexcel Level 3 GCEaliceNo ratings yet

- MBI 2017 DeVentura Etal2 1Document12 pagesMBI 2017 DeVentura Etal2 1Ana Paula BertãoNo ratings yet

- Worksheet Biological MoleculesDocument5 pagesWorksheet Biological MoleculesЕгор БиндерNo ratings yet

- Brochure Biology & Medicine 03 2022 - CompressedDocument40 pagesBrochure Biology & Medicine 03 2022 - CompressedMerida Bertrand Alex PodgaNo ratings yet

- Chapter 1 Data InterpretationDocument22 pagesChapter 1 Data InterpretationRodrigo100% (1)

- PlasmidDocument5 pagesPlasmidMinahil ImranNo ratings yet

- NTA NEET Biology Syallabus 2021 2022Document6 pagesNTA NEET Biology Syallabus 2021 2022Shridansh TripathiNo ratings yet

- Classifying Living Things Clickview VideoDocument3 pagesClassifying Living Things Clickview VideoMuskaan Saini25% (8)

- Polymerase Chain Reaction 1Document8 pagesPolymerase Chain Reaction 1Ye Htut AungNo ratings yet