Professional Documents

Culture Documents

Triple Infrared Flame Detector Manual

Uploaded by

Emre YıldırımOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Triple Infrared Flame Detector Manual

Uploaded by

Emre YıldırımCopyright:

Available Formats

FIRE ALARM & FIRE DETECTION SYSTEMS

Technical Manual

Explosion Proof Triple Infrared Flame Detector

Model No.: AS-E302-IR3

Ansorl Technology Co., Ltd.

www.ansorl.com

Technical Manual of Explosion Proof Triple Infrared Flame Detector AS-E302-IR3

1. NOTICE

Thank you for using the product from Shenzhen Ansorl Technology Co.,Ltd.

This manual detailly describes the product overview, features, specifications, installation,

wiring, testing and maintenance of AS-E302-IR3 flame detector. Make sure to read this

manual carefully before any operations of the device, which prevents the quality of product

from damaging or hurts the person.

Special Cautions:

The installation process and operation must comply with the relevant national standards.

Any operation on the interior detector must be implemented by trained personnel.

2. OVERVIEW

AS-E302-IR3 flame detector provide a new generation of fire detection capability and

technical standards.

AS-E302-IR3 flame detector adopts a newly narrow-band current infrared pyroelectric sensor,

it can effectively distinguish the real flame radiation and interference sources.

AS-E302-IR3 flame detector is built-in a 32-bit microprocessor and patented signal

processing algorithm, it can detect flame signals quickly, reduce response time, increase

detection accuracy, reduce false alarm rate.

AS-E302-IR3 flame detector maintains the performance of explosion-proof, protection,

corrosion resistance.

AS-E302-IR3 flame detector is smaller, lighter, more convenient to install comparing to our

old version detector.

3. FEATURES

Built-in 32-bit high-speed, low-power, high-performance, high-precision data

processing chip.

Adopt newly narrow-band current infrared pyroelectric sensor.

A small fire can be detected earlier.

The detection distance is 40 meters (0.33m*0.33m*0.05m n-heptane fire).

The perfect algorithm combines optimally the flame detection and false alarm

capabilities.

Detector is fit to a variety of fuels.

Apply to heavy industry applications.

Explosion-proof designs can be used in hazardous area of industrial sites.

Low maintenance cost, easy to update and improve.

Ansorl Ltd. 1 www.ansorl.com

Technical Manual of Explosion Proof Triple Infrared Flame Detector AS-E302-IR3

4. DETECTION MATERIALS AND DISTANCE

Burning Material Fire Source Size Detection Distance

n-heptane 0.1m2 flame plate 40m

gasoline 0.1m2 flame plate 35m

Detection Range diesel 0.1m2 flame plate 35m

kerosene 0.1m2 flame plate 35m

alcohol 0.1m2 flame plate 30m

paper 0.1m2 flame plate 30m

methane H0.5mxW0.2m 30m

Response time is less than 10 seconds for 0.3m×0.3m n-heptane flame plate.

5. SPECIFICATIONS

Working Voltage DC24V (range DC18V~30V)

Working Current ≤50mA

Sensitivity Level Grade one

Spectral Range IR:3.8~5.0μM

Angle Range 90°

Alarm Indicator Green(power), Red(alarm), Yellow(fault)

Relay Output Fire alarm relay, 1A@30VDC

monitoring status: normal open contact is disconnected

fire alarm status: normal open contact is closed

Fault relay, 1A@30VDC

monitoring status: normal open contact is closed

fault alarm status: normal open contact is disconnected

Operation Mode Infrared remote control

Reset Mode Power-off reset/communication protocol reset/remote control reset

Working Temperature -40℃~70℃

Storage Temperature -40℃~85℃

Working Humidity 0~96% RH (non-condensing)

Explosion-proof Mark ExdⅡC T6 Gb

Protection Grade IP66

Housing Material Cast aluminum, surface painting

6. DIMENSIONS

Ansorl Ltd. 2 www.ansorl.com

Technical Manual of Explosion Proof Triple Infrared Flame Detector AS-E302-IR3

7. INSTALLATION

8. TERMINALS

+24V

24VDC power supply

GND

FRJK

Fire alarm relay normal open contact

FRJD

FLJK

Fault relay normal closed contact

FLJD

9. Wiring Diagram

Ansorl Ltd. 3 www.ansorl.com

Technical Manual of Explosion Proof Triple Infrared Flame Detector AS-E302-IR3

10. INSTALLATION NOTICES

Before installing detector, please cut off the power supply of it.

All wiring must comply with relevant standards and regulations.

Detectors are installed in explosion proof areas, the wiring of detector should be

connected by power limit and be controlled.

Before wiring, check whether the external cable is open circuit, short circuit fault or not.

Install the detector as instructed, adjust appropriately the detector view angle in terms of

the scope of protection.

All connections adopt more than 1.0 square wire, the end of connections cut about 6mm

Isolation jacket, then connect to the terminal blocks of flame detectors.

Warning: expose lead wire too much or too less may cause wrong connection.

11. TESTING

Before testing, announce the related management department that fire detector system is

testing that need to cut off the maintenance area or the systemic logic control functions

in order to avoid unnecessary alarm linkage.

The flame detector must be tested after installation and maintenance.

Detector executes initializing setting after powering on, the green lamp is always on, then

ends after 30 seconds.

Before testing, examine whether the LED flashes or not, if not flash, the detector is not

powered on (check the connections), or damaged (return to repair).

Field test tool is alcohol lamp or flame simulator, simulate fire situation until the detector

alarms.

After the test, announce the related management department that the system returns to

normal status.

Note: The flame detector does not have any internal parts which user can debug.

Replacing any components or adjusting circuits are likely to damage the performance of

the device without the manufacturer’s agreement.

12. MAINTENANCE

Flame detector must be regular tested and maintained in accordance with the national

standards and the related regulations.

Each detector must be cleaned at least once a year and be tested and maintained each

month.

Before cleaning, announce the related management department that the system of flame

detector will stop working for temporarily.

Cut off the area which will be maintained or the systemic logic control functions in order

to avoid unnecessary alarm linkage.

Clean dust and impurities on the front of the detector by vacuum suction or compressed

air.

If the lens has dirt, use the alcoholic cotton to wipe the lens, prohibit scratching the lens

by hard object.

Follow the above procedure to test the detector after the cleaning of the detectors.

Ansorl Ltd. 4 www.ansorl.com

You might also like

- Ir3-Flame-Sensor-2-Page KopyasıDocument7 pagesIr3-Flame-Sensor-2-Page KopyasıNazim YesilkayaNo ratings yet

- Installation Manual EnUS 16566339211Document6 pagesInstallation Manual EnUS 16566339211Hoằng PhạmNo ratings yet

- Explosion-Proof Smoke Detector: GeneralDocument2 pagesExplosion-Proof Smoke Detector: GeneralBambang Sigit PriyantoNo ratings yet

- Notifier Explosion Proof Smoke Detector 30 3003Document2 pagesNotifier Explosion Proof Smoke Detector 30 3003Tee RixNo ratings yet

- 5200236-00A - Salwico AC-IR-3Fq - Addressable-Conventional IR Flame DetectorDocument4 pages5200236-00A - Salwico AC-IR-3Fq - Addressable-Conventional IR Flame DetectorcembozNo ratings yet

- Data Sheet enUS 2700120843Document3 pagesData Sheet enUS 2700120843Forward MyanmarNo ratings yet

- I-9101 Intelligent Combination Heat and Smoke Detector Issue 1.01Document2 pagesI-9101 Intelligent Combination Heat and Smoke Detector Issue 1.01HiteshgangeleNo ratings yet

- 601P Install ManualDocument2 pages601P Install ManualDanut Stefan100% (2)

- ApolloFire XP95 MultisensorDocument2 pagesApolloFire XP95 MultisensorfasiwiNo ratings yet

- Sensor Anti Chamas Hosokawa PDFDocument1 pageSensor Anti Chamas Hosokawa PDFCristiano FariasNo ratings yet

- Flameproof Flame Detector Ex d TitleDocument3 pagesFlameproof Flame Detector Ex d TitleionutenacheNo ratings yet

- PP 2070 XP Multi PinDocument2 pagesPP 2070 XP Multi PinManuel RiNo ratings yet

- Gsti 9104Document2 pagesGsti 9104aditgroupNo ratings yet

- Fixed Gas Detector Operation ManualDocument8 pagesFixed Gas Detector Operation ManualpcatruongNo ratings yet

- PIR Sensor Manual: D203B ModelDocument6 pagesPIR Sensor Manual: D203B Modelabdurrahim_tNo ratings yet

- PIR Sensor Manual: Dual Element Pyroelectric Infrared Radial Sensor Model D204BDocument6 pagesPIR Sensor Manual: Dual Element Pyroelectric Infrared Radial Sensor Model D204BEdward YanezNo ratings yet

- Fuente Fcps 24s6eDocument12 pagesFuente Fcps 24s6eGuido RuizNo ratings yet

- AW-FD702E-IR2 Datasheet - 202000807Document2 pagesAW-FD702E-IR2 Datasheet - 202000807mohammed ayedNo ratings yet

- Installation & Operating Manual Fire Detection Unit Itx 6340Document13 pagesInstallation & Operating Manual Fire Detection Unit Itx 6340erode els erodeNo ratings yet

- K85001-0560 - Reflective Beam DetectorDocument4 pagesK85001-0560 - Reflective Beam DetectorDauXuan HuynhNo ratings yet

- Instruction Manual: Temperature Transducer For Pt100 Sensor With 4 - 20 Ma OutputDocument8 pagesInstruction Manual: Temperature Transducer For Pt100 Sensor With 4 - 20 Ma OutputBayu Dwi Rizkyadha PutraNo ratings yet

- The Flamegard Series of Flame Detectors: Fast, Reliable Flame DetectionDocument4 pagesThe Flamegard Series of Flame Detectors: Fast, Reliable Flame DetectionSandika JayaputraNo ratings yet

- PSD DatasheetDocument2 pagesPSD Datasheetmetal_dung2No ratings yet

- D7050 Addressable Photoelectric Smoke and Smoke Heat Detector HeadsDocument3 pagesD7050 Addressable Photoelectric Smoke and Smoke Heat Detector HeadsBrillit RuizNo ratings yet

- NOVA-5000 Flame Detection & Control SystemDocument2 pagesNOVA-5000 Flame Detection & Control Systemmrsmith733No ratings yet

- Smoke DetectorDocument2 pagesSmoke DetectoratharvawazurkarNo ratings yet

- Smart Home Design and Control Using LabVIEWDocument26 pagesSmart Home Design and Control Using LabVIEWSiva BadrinathNo ratings yet

- Depliant Iris Enea Inim 1.10 ENGDocument4 pagesDepliant Iris Enea Inim 1.10 ENGKnjigescribdNo ratings yet

- IR3 Data Sheet enUS 11803977227Document3 pagesIR3 Data Sheet enUS 11803977227Charles DublinNo ratings yet

- C 9104Document1 pageC 9104aditgroupNo ratings yet

- 74-5070 TC840C1000 CoptirDocument2 pages74-5070 TC840C1000 Coptirlopez.garyjavierNo ratings yet

- IQA-WLPR110 Product Manual en v6 - 161230Document1 pageIQA-WLPR110 Product Manual en v6 - 161230Vigilancia VISORNo ratings yet

- IRD 1020 Infra-Red Flicker Detector: Flame Detection Device For Oil and Gas FlamesDocument4 pagesIRD 1020 Infra-Red Flicker Detector: Flame Detection Device For Oil and Gas FlamesJorge Gustavo GoyecheaNo ratings yet

- Detector Humo Direccionable D7050Document2 pagesDetector Humo Direccionable D7050Mario Javier CNo ratings yet

- User Manual of Explosion Proof Smoke Detector AS-SD801EXDocument5 pagesUser Manual of Explosion Proof Smoke Detector AS-SD801EXEmre YıldırımNo ratings yet

- Https Hochiki - VN Uploads Plugin File 135 1590594717-270100149-Soc-24v-Photoelectric-Smoke-DetectorDocument2 pagesHttps Hochiki - VN Uploads Plugin File 135 1590594717-270100149-Soc-24v-Photoelectric-Smoke-DetectorTráng Nguyễn VănNo ratings yet

- Soc-24V Conventional Photoelectric Smoke Detector: ApplicationsDocument2 pagesSoc-24V Conventional Photoelectric Smoke Detector: Applicationsuygar öztürkNo ratings yet

- Fs10 R, RN Spec (Sp330c)Document5 pagesFs10 R, RN Spec (Sp330c)theloniussherekNo ratings yet

- Greisinger OXY 3690 MP User ManualDocument4 pagesGreisinger OXY 3690 MP User ManualesatpehlivanNo ratings yet

- BS-690-691_ENDocument5 pagesBS-690-691_ENThanosEleftheroudisNo ratings yet

- PIR Sensor Manual Explains Infrared DetectionDocument6 pagesPIR Sensor Manual Explains Infrared DetectionMarian GlonteNo ratings yet

- Gsti 9105Document2 pagesGsti 9105aditgroupNo ratings yet

- Flame Detector System: PurchaserDocument2 pagesFlame Detector System: PurchaserDenis JimenezNo ratings yet

- Dettronics Flame Detetor MANUALDocument27 pagesDettronics Flame Detetor MANUALNanu PatelNo ratings yet

- SPEC. FGS Rev.2 - 11-15Document5 pagesSPEC. FGS Rev.2 - 11-15kepuren loro0% (1)

- C 9102Document1 pageC 9102aditgroupNo ratings yet

- Detector Notifier PDFDocument2 pagesDetector Notifier PDFJoni EfwanNo ratings yet

- Detector UVIR X5200Document2 pagesDetector UVIR X5200chicle60No ratings yet

- 2U Rack Mount Novec 1230 DataSheet 1.5Document5 pages2U Rack Mount Novec 1230 DataSheet 1.5prakistaoNo ratings yet

- Instructions: Dual Frequency Infrared Detector/Controller U7099Document9 pagesInstructions: Dual Frequency Infrared Detector/Controller U7099Prem SagarNo ratings yet

- 601P (En)Document2 pages601P (En)Radu BucuresteanuNo ratings yet

- fsb-200 Install Sheeti56-2424-04rDocument18 pagesfsb-200 Install Sheeti56-2424-04rcarlos yepezNo ratings yet

- System Sensor 2151 & 2151T - Installation ManualDocument2 pagesSystem Sensor 2151 & 2151T - Installation ManualAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- Apollo Serie 60Document19 pagesApollo Serie 60Luis Walter LeoneNo ratings yet

- Informatsiya Drager Polytron Ir PDFDocument4 pagesInformatsiya Drager Polytron Ir PDFSandip JoardarNo ratings yet

- Polytron FX - Old, Obsolete DatasheetDocument2 pagesPolytron FX - Old, Obsolete DatasheetMohamed NaserNo ratings yet

- RF 360 Advanced Ceiling Mount PIR Installation Manual-1Document2 pagesRF 360 Advanced Ceiling Mount PIR Installation Manual-1Imi Michał SmulskiNo ratings yet

- Intelligent Photoelectric Smoke Detector Features Twin LED DetectionDocument2 pagesIntelligent Photoelectric Smoke Detector Features Twin LED DetectionSeagull MarineNo ratings yet

- Aleksis Carrel - DuaDocument8 pagesAleksis Carrel - DuaEmre YıldırımNo ratings yet

- 1.A-DQ BN SR 2Y 1.200N CT-General-2021.04.07-03Document7 pages1.A-DQ BN SR 2Y 1.200N CT-General-2021.04.07-03Emre YıldırımNo ratings yet

- Crown Extra Lighting Co., Ltd marine safety exit lighting specificationDocument4 pagesCrown Extra Lighting Co., Ltd marine safety exit lighting specificationEmre YıldırımNo ratings yet

- User Manual of Explosion Proof Smoke Detector AS-SD801EXDocument5 pagesUser Manual of Explosion Proof Smoke Detector AS-SD801EXEmre YıldırımNo ratings yet

- Employee Leave Management System: FUDMA Journal of Sciences July 2020Document7 pagesEmployee Leave Management System: FUDMA Journal of Sciences July 2020MOHAMMED ASHICKNo ratings yet

- PDF DocumentDocument10 pagesPDF DocumentNIKHIL DASARINo ratings yet

- Mapeh-7pe Q2 Summative-TestDocument2 pagesMapeh-7pe Q2 Summative-TestVhannie AcquiatanNo ratings yet

- Careers at FEWA-DubaiDocument8 pagesCareers at FEWA-DubaiJnanamNo ratings yet

- Logging Levels in Log4j - Tutorialspoint ExamplesDocument3 pagesLogging Levels in Log4j - Tutorialspoint ExamplesJai PannuNo ratings yet

- Case3: What's in A Car 1. What Kind of Research Study Should Shridhar Undertake? Define TheDocument2 pagesCase3: What's in A Car 1. What Kind of Research Study Should Shridhar Undertake? Define TheRoshan kumar Rauniyar0% (3)

- Interrogating Texts: Six Reading Habits To Develop in Your First Year at HarvardDocument2 pagesInterrogating Texts: Six Reading Habits To Develop in Your First Year at HarvardS I ZahidNo ratings yet

- 7306 31980 1 PBDocument10 pages7306 31980 1 PBRaihan Aditiya JuniorNo ratings yet

- CV of Dr. Mohammad TahirDocument12 pagesCV of Dr. Mohammad TahirMuhammad FayyazNo ratings yet

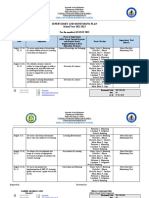

- Supervisory Plan 2022 2023Document4 pagesSupervisory Plan 2022 2023Jesieca Bulauan100% (12)

- Review Relative Clauses, Articles, and ConditionalsDocument10 pagesReview Relative Clauses, Articles, and ConditionalsNgoc AnhNo ratings yet

- Hoshizaki IM-500SAA Icemaker Service ManualDocument39 pagesHoshizaki IM-500SAA Icemaker Service ManualBenjamin DoverNo ratings yet

- The Management of Productivity and Technology in Manufacturing PDFDocument333 pagesThe Management of Productivity and Technology in Manufacturing PDFmythee100% (2)

- Strength and Serviceability of Hanger ConnectionsDocument12 pagesStrength and Serviceability of Hanger ConnectionsVitor OlivettiNo ratings yet

- Text 1 Is For No 1 - 4 The Rabbit Revenge: I. Pilihlah Salah Satu Jawaban Yang Benar!Document4 pagesText 1 Is For No 1 - 4 The Rabbit Revenge: I. Pilihlah Salah Satu Jawaban Yang Benar!Diandra MomentNo ratings yet

- 1Document5 pages1qweqweNo ratings yet

- 2 Corinthians: Workbook OnDocument18 pages2 Corinthians: Workbook OnJhon Ray OtañesNo ratings yet

- EL FILI CHAPTER 13Document9 pagesEL FILI CHAPTER 13Eduardo Sismundo JrNo ratings yet

- Use of Passive VoiceDocument13 pagesUse of Passive VoiceLuciana DicieroNo ratings yet

- Journal of Materials Processing Technology: Jun Cao, Michael A. Gharghouri, Philip NashDocument11 pagesJournal of Materials Processing Technology: Jun Cao, Michael A. Gharghouri, Philip NashJesus Ismael Jimenez GarciaNo ratings yet

- 1 SMDocument9 pages1 SMhasanuddinnst1No ratings yet

- DOE V Rhodes College Ammended Motion For TRODocument19 pagesDOE V Rhodes College Ammended Motion For TROSouwesterdocs100% (1)

- Service Training: Vorsprung Durch Technik WWW - Audi.deDocument15 pagesService Training: Vorsprung Durch Technik WWW - Audi.depuncimanNo ratings yet

- Piata de Publicitate 2012-2020 - Prezentare RezumativaDocument5 pagesPiata de Publicitate 2012-2020 - Prezentare RezumativamanageranticrizaNo ratings yet

- O & M Manual TemplateDocument11 pagesO & M Manual Templatesooriya_82No ratings yet

- Enquiries: 1. Enquiry From A Retailer To A Foreign ManufacturerDocument7 pagesEnquiries: 1. Enquiry From A Retailer To A Foreign ManufacturerNhi Hoàng Lê NguyễnNo ratings yet

- Last Lesson: How Did Franz Feelings About M Hamel and School Change ?Document4 pagesLast Lesson: How Did Franz Feelings About M Hamel and School Change ?RitikaNo ratings yet

- GARAM ModelDocument40 pagesGARAM ModelprasunmathurNo ratings yet

- Pharmacist Licensing Requirements by StateDocument21 pagesPharmacist Licensing Requirements by StateBio DataNo ratings yet

- Marketing Strategies Audit On Hewlett Packard (HP)Document19 pagesMarketing Strategies Audit On Hewlett Packard (HP)auraNo ratings yet