Professional Documents

Culture Documents

Designing and Maintenance of Control

Designing and Maintenance of Control

Uploaded by

VenomOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Designing and Maintenance of Control

Designing and Maintenance of Control

Uploaded by

VenomCopyright:

Available Formats

190513109009 Designing and Maintenance of Control

➢ We’ve created this guide to provide an overview of the key design considerations

applicable to industrial control panel design, including schematics, relevant

regulatory standards, and design considerations relating to every facet of

effective control panel design for industrial equipment and machinery.

➢ A variety of design considerations must be weighed throughout the design

process in order to design a control panel that meets functional requirements,

application specifications, and regulatory standards. The following design

decisions represent the primary design considerations in developing an industrial

control panel, although additional considerations specific to individual

applications may apply.

Gujarat Technological University 22 Alpha College of Eng. & Tech.

190513109009 Designing and Maintenance of Control

Chapter 5

WIRING OF STAR-DELTA STARTER

2.1 Introduction of Star-Delta Starter

➢ A star delta starter is a type of reduced voltage starter. We use it to reduce the

starting current of the motor without using any external device or apparatus. This

is a big advantage of a star delta starter, as it typically has around 1/3 of the

inrush current compared to a DOL starter.

Fig. 4.1 Star delta starter

Fig. 4.2 Star connection

Fig. 4.3 Delta connection

Gujarat Technological University 23 Alpha College of Eng. & Tech.

190513109009 Designing and Maintenance of Control

2.2 Why we use Star-Delta Starter?

➢ Most induction motors are started directly on line, but when very large motors

are started that way, they cause a disturbance of voltage on the supply lines

due to large starting current surges.

2.3 Working Principle of Star-Delta Starter

➢ This is the reduced voltage starting method. Voltage reduction during star-delta

starting is achieved by physically reconfiguring the motor windings as

illustrated in the figure below. During starting the motor windings are

connected in star configuration and this reduces the voltage across each

winding 3. This also reduces the torque by a factor of three.

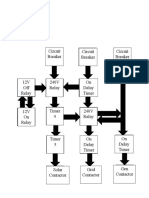

➢ The Star/Delta starter is manufactured from three contactors, a timer and a

thermal overload. The contactors are smaller than the single contactor used in

a Direct on Line starter as they are controlling winding currents only. The

currents through the winding are 1/root 3 (58%) of the current in the line .

Fig. 4.4 Star Delta 2

Gujarat Technological University 24 Alpha College of Eng. & Tech.

190513109009 Designing and Maintenance of Control

2.4 3 Phase VFD Diagram with Motor

FD wiring can be made in two ways:-

➢ Power wiring

➢ Control wiring

➢ Power wiring – Power wiring refers to the distribution of power. In the case of

VFD flow of power from VFD to the motor. As you know that we are making

the wiring of the 3 phase VFD and motor. Therefore 3 wires carry 3 phases i.e

(R, Y, & B) from the circuit breaker to the input terminal of the VFD and 3 wires

from VFD to the motor. This figure also helps you to understand the power

wiring of a VFD.

➢ Control wiring – control wiring is used for controlling purposes. They are used

to give commands to the control devices or communication between electrical

devices. In control wiring, there is no use of heavy voltage and therefore gauge

of wire is thinner. In control wiring normally standard 24vdc is used.

Fig 4.5 3 Phase VFD Wiring

Diagram

Gujarat Technological University 25 Alpha College of Eng. & Tech.

190513109009 Designing and Maintenance of Control

➢ Various automation processes in the industry need control of AC induction

motors using AC drives. Presented here is a robust system for switching on/off,

varying the speed and direction of rotation of an industrial 3 Phase Induction

Motor using VFD and PLC. We use here Delta AC motor drive for its operation

➢ The first stage of a VFD is the converter, which comprises six diodes, which are

similar to check valves used in plumbing systems. These allow current to flow

in only one direction; the direction shown by the arrow in the diode symbol. For

example, whenever A-phase voltage (voltage is similar to pressure in plumbing

systems) is more positive than B- or C-phase voltages, that diode opens and

allows current to flow.

➢ When B phase becomes more positive than A phase, B-phase diode opens and

A-phase diode closes. The same is true for the three diodes on the negative side

of the bus. Thus, we get six current pulses as each diode opens and closes. This

is called a 6-pulse VFD, which is the standard configuration for current VFDs.

Gujarat Technological University 26 Alpha College of Eng. & Tech.

190513109009 Designing and Maintenance of Control

Chapter 6

ROLES AND RESPONSIBILITIES DURING INTERNSHIP

4.1 DAILY TASK AND RESPONSIBILITIES

➢ My work in the company is Wiring of the Panel and Purchase Engineer.

➢ My work in the company is to ensure continuous Production and as a Production

Engineer.

➢ I must check every Panel Weekly that Panel is working normally or not.

➢ Servicing and replacing old or faulty equipment.

➢ Troubleshooting equipment malfunctions.

➢ If any Panel has defect or stop working, I must repair it and ensure continuous

production.

➢ Evaluating performance and providing feedback of workers.

Gujarat Technological University 27 Alpha College of Eng. & Tech.

190513109009 Designing and Maintenance of Control

4.2 ROLES AND RESPONSIBILITIES

➢ I must monitor all the workers is doing their job properly.

➢ If any worker is not doing, it is work properly I must tell owner about that or

manage him by myself.

➢ I must build a healthy co-ordination between worker and owners.

➢ I must ensure continuous production and do maintenance when it is required.

➢ One of a supervisor’s most important responsibilities is managing a team.

➢ Evaluating performance and providing feedback of workers.

➢ Helping to resolve worker issues and disputes.

Gujarat Technological University 28 Alpha College of Eng. & Tech.

You might also like

- Rover 25 MG ZR Electrical LibraryDocument306 pagesRover 25 MG ZR Electrical LibraryLuis Brás100% (5)

- AVR Operation ManualDocument26 pagesAVR Operation ManualRamon Palacios100% (2)

- Course "EEM 2 DC Machines": WWW - Lucas-Nuelle - deDocument17 pagesCourse "EEM 2 DC Machines": WWW - Lucas-Nuelle - desifuszNo ratings yet

- Automatic Door Slider Using ArduinoDocument45 pagesAutomatic Door Slider Using ArduinoNayan Bhattad100% (2)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Electrical Machines Lab Manual - 2014-15 - Cycle I-11!08!2014Document52 pagesElectrical Machines Lab Manual - 2014-15 - Cycle I-11!08!2014Abuturab MohammadiNo ratings yet

- TW500A Linear Amplifier - Operator and Technical ManualDocument33 pagesTW500A Linear Amplifier - Operator and Technical ManualAlexander J Rokowetz100% (2)

- Electrical Drives and Control - Unit-I (MECHANICAL ENGINEERING)Document83 pagesElectrical Drives and Control - Unit-I (MECHANICAL ENGINEERING)Thivya PrasadNo ratings yet

- Brake Board ManualDocument17 pagesBrake Board ManualMohamedElsawiNo ratings yet

- 1.1 Introduction of Company: 190513109009 Designing and Maintenance of ControlDocument17 pages1.1 Introduction of Company: 190513109009 Designing and Maintenance of ControlVenomNo ratings yet

- Protection of Three-Phase Induction MotorDocument9 pagesProtection of Three-Phase Induction Motoryisakabera123No ratings yet

- PLC Based Star - Delta Starter For Three Phase Squirrel Cage Induction MotorDocument10 pagesPLC Based Star - Delta Starter For Three Phase Squirrel Cage Induction MotorTana AzeezNo ratings yet

- 3 Phase Motor Starters DDocument15 pages3 Phase Motor Starters DManishmanniaNo ratings yet

- Daudi EstomihDocument5 pagesDaudi Estomihmujtaba samaduNo ratings yet

- Variable Frequency Drive and Faults Detection Using MicrocontrollerDocument4 pagesVariable Frequency Drive and Faults Detection Using MicrocontrollerMohammad Safdar SadatNo ratings yet

- Ccum 21Document4 pagesCcum 21Hari Krishna.MNo ratings yet

- Transformer Testing by Afees Ahamed Egger IndiaDocument27 pagesTransformer Testing by Afees Ahamed Egger IndialrpatraNo ratings yet

- Manual Ats ZenithDocument18 pagesManual Ats ZenithGILBERTOPERDOMONo ratings yet

- Testing of Large Electric Generators For Suitability of ServiceDocument32 pagesTesting of Large Electric Generators For Suitability of ServiceDany KanNo ratings yet

- Procedure Field Inspection & Testing Electrical EquipmentDocument21 pagesProcedure Field Inspection & Testing Electrical Equipmentarifadha446100% (5)

- Tap ChangerDocument33 pagesTap ChangerMadhavasrinivasan Sathiamoorthy100% (2)

- GTJZ Manual 201907Document42 pagesGTJZ Manual 201907saiful.laku2No ratings yet

- Rotating Rectifier - TestDocument10 pagesRotating Rectifier - TestDjebali Mourad100% (1)

- 3-Phase Ac Motor Monitoring and Parameter Calculation Using Labview and DaqDocument13 pages3-Phase Ac Motor Monitoring and Parameter Calculation Using Labview and DaqahmetNo ratings yet

- Chapter 3. Alternator: 1. DescriptionDocument21 pagesChapter 3. Alternator: 1. DescriptionGabriel QuijadaNo ratings yet

- Conductor Resistance MTO106 An enDocument6 pagesConductor Resistance MTO106 An enkamran719No ratings yet

- Sharp Lc32le155d2 Service ManualDocument73 pagesSharp Lc32le155d2 Service Manualhellxide ofmeNo ratings yet

- Chapter 4Document7 pagesChapter 4MaxwellNo ratings yet

- SOLAR PV EMULATOR NEW MANUAL - Rev 1 PDFDocument33 pagesSOLAR PV EMULATOR NEW MANUAL - Rev 1 PDFSatyaraj SharmaNo ratings yet

- Basic Electrical Machines (Eceg132) Laboratory Manual: Department of Electrical and Computer EngineeringDocument158 pagesBasic Electrical Machines (Eceg132) Laboratory Manual: Department of Electrical and Computer EngineeringRonan Rojas100% (1)

- Harmonic Filter InstallationDocument18 pagesHarmonic Filter Installationagus triprasetyo100% (1)

- ABB ACS800 11 Regenerative InverterDocument146 pagesABB ACS800 11 Regenerative InverterGabo RamirezNo ratings yet

- YASKAWA L7 Manual PDFDocument242 pagesYASKAWA L7 Manual PDFangustiohNo ratings yet

- PSQ 1.2. Voltage Sags & InterruptionsDocument56 pagesPSQ 1.2. Voltage Sags & InterruptionsSeid EndrisNo ratings yet

- DC Generator Report 1Document7 pagesDC Generator Report 1ricky fluor50No ratings yet

- Owner'S Manual For Travel Frequency Control System: BPP6-2QM4V3-76J0Document21 pagesOwner'S Manual For Travel Frequency Control System: BPP6-2QM4V3-76J0jorgemegok1860No ratings yet

- 03 - ACS 5000AD TC SW Commissioning ManualDocument76 pages03 - ACS 5000AD TC SW Commissioning ManualserkalemtayeNo ratings yet

- Sine Wave Inverter With PICDocument50 pagesSine Wave Inverter With PICmtrapkNo ratings yet

- Breaker Timing - ZensolDocument20 pagesBreaker Timing - ZensolIsmail Azad100% (1)

- Anexo 1Document110 pagesAnexo 1rhusseinpos4765No ratings yet

- User's Manual: Transformer OhmmeterDocument20 pagesUser's Manual: Transformer Ohmmetermnrk 1997No ratings yet

- Unit-3: (This Unit Covers Criteria P4, P5, P7, D2) Motor StartersDocument15 pagesUnit-3: (This Unit Covers Criteria P4, P5, P7, D2) Motor StartersMuhja AljaserNo ratings yet

- Railway WorkshopDocument38 pagesRailway WorkshopPrateek SabharwalNo ratings yet

- SL 8Document7 pagesSL 8thierry troveroNo ratings yet

- Industrial Drives & PLC: Lab Manual For Academic Session Spring 2020Document18 pagesIndustrial Drives & PLC: Lab Manual For Academic Session Spring 2020Saima Aman KhanNo ratings yet

- Troubleshooting VF DDocument7 pagesTroubleshooting VF DRichard BakerNo ratings yet

- Ip 16 12 1Document12 pagesIp 16 12 1DhanushNo ratings yet

- SOP MAINTENANCE FINAL - Part4Document50 pagesSOP MAINTENANCE FINAL - Part4Arslan AhmadNo ratings yet

- Xe2 e DC Current Relay For Loss of Exciation ProtectionDocument16 pagesXe2 e DC Current Relay For Loss of Exciation ProtectionUdara AmilaNo ratings yet

- Danger Warning Caution: Safety InformationDocument7 pagesDanger Warning Caution: Safety InformationcombaheeNo ratings yet

- Drivecon XT Series Instruction ManualDocument120 pagesDrivecon XT Series Instruction ManualHochimidNo ratings yet

- 15ee752 PDFDocument41 pages15ee752 PDFkoushith gowda0% (1)

- Megger Transformer WindingDocument13 pagesMegger Transformer Windingjuanete29No ratings yet

- Annex-7 - 6.6 KV Breakers Testing ReportDocument20 pagesAnnex-7 - 6.6 KV Breakers Testing ReportZafar ArshadNo ratings yet

- Separately Excited DC Motor Speed Control Using Four Quadrant ChopperDocument3 pagesSeparately Excited DC Motor Speed Control Using Four Quadrant ChopperJay S PatelNo ratings yet

- Project Reprt333Document49 pagesProject Reprt333dhirajsingh_avit83% (6)

- 14 Test de GénératriceDocument3 pages14 Test de GénératriceAliHabesNo ratings yet

- 3RW30 Sirius System Manual 3RW3 CH 8 52 PgsDocument52 pages3RW30 Sirius System Manual 3RW3 CH 8 52 PgsMarcelo BMNo ratings yet

- Surface Vehicle Standard: Reaf. DEC89Document4 pagesSurface Vehicle Standard: Reaf. DEC89gharba putraNo ratings yet

- Chapater 1: Overview of The CompanyDocument5 pagesChapater 1: Overview of The CompanyVenomNo ratings yet

- 1.1 Introduction of Company: 190513109009 Designing and Maintenance of ControlDocument17 pages1.1 Introduction of Company: 190513109009 Designing and Maintenance of ControlVenomNo ratings yet

- Designing and Maitenance of Control Panel: Rajput Dipendra SinghDocument38 pagesDesigning and Maitenance of Control Panel: Rajput Dipendra SinghVenomNo ratings yet

- Designing and Maitenance of Control PanelDocument40 pagesDesigning and Maitenance of Control PanelVenomNo ratings yet

- KGF CH 2Document18 pagesKGF CH 2VenomNo ratings yet

- Engineering Training Review: Alpha College of Engineering and Technology, Kalol, GandhinagarDocument6 pagesEngineering Training Review: Alpha College of Engineering and Technology, Kalol, GandhinagarVenomNo ratings yet

- KGF CH 1Document10 pagesKGF CH 1VenomNo ratings yet

- Task 4: Figure 1 Speed-Torque Curve For Ideal DC MotorDocument19 pagesTask 4: Figure 1 Speed-Torque Curve For Ideal DC MotoraqeelNo ratings yet

- Lista de Componentes JBL Jblpro - Alpha 2Document18 pagesLista de Componentes JBL Jblpro - Alpha 2Nelson Baldini JuniorNo ratings yet

- ESP MicroProjectDocument10 pagesESP MicroProjectOmkar KhopadeNo ratings yet

- Half Wave RectifiersDocument7 pagesHalf Wave RectifiersVed PrakashNo ratings yet

- Ordering Information: Solid State RelayDocument6 pagesOrdering Information: Solid State RelayNickyibNo ratings yet

- Es1107 Assignment-01Document6 pagesEs1107 Assignment-01K. BHANU PRAKASH REDDYNo ratings yet

- Instruction Manual: EN IWDocument42 pagesInstruction Manual: EN IWJátékra CsakNo ratings yet

- Introducing The Family of "Sen" Transformers: A Set of Power Ow Controlling TransformersDocument10 pagesIntroducing The Family of "Sen" Transformers: A Set of Power Ow Controlling TransformersShadNo ratings yet

- Specification: Constant Current Discharge Characteristics: A (25)Document2 pagesSpecification: Constant Current Discharge Characteristics: A (25)GeorgeNo ratings yet

- TPA3138D2 10-W, 3.5-V To 14.4-V, Inductor Free, Stereo Class-D Speaker AmplifierDocument37 pagesTPA3138D2 10-W, 3.5-V To 14.4-V, Inductor Free, Stereo Class-D Speaker AmplifierAdrianNo ratings yet

- LOADMASTER X5 8665 Front Symphony - 'Lightship'Document7 pagesLOADMASTER X5 8665 Front Symphony - 'Lightship'yagyabajpaiNo ratings yet

- 10000Document4 pages10000Artur KołodziejNo ratings yet

- Isc 2SC5949: Silicon NPN Power TransistorDocument3 pagesIsc 2SC5949: Silicon NPN Power TransistorJuan RamírezNo ratings yet

- MIC2920A/29201/29202/29204: Features General DescriptionDocument9 pagesMIC2920A/29201/29202/29204: Features General DescriptionSenen ArchilaNo ratings yet

- ELTR 353 Power Electronics - 1Document1 pageELTR 353 Power Electronics - 1Engr Shehzad HaneefNo ratings yet

- Research PaperDocument11 pagesResearch PaperChristopher EnriquezNo ratings yet

- Newsletter July 2012 - Institution of Engineers MauritiusDocument5 pagesNewsletter July 2012 - Institution of Engineers MauritiusYashveer TakooryNo ratings yet

- Formative Assessment in TLE-EIM 2Document3 pagesFormative Assessment in TLE-EIM 2juzNo ratings yet

- BS en 60512-21-1-2010Document8 pagesBS en 60512-21-1-2010Rachid MounirNo ratings yet

- Voltage Relay SUA145Document2 pagesVoltage Relay SUA145Txema GarciaNo ratings yet

- ICT - CHS G8 L02 - Use Appropriate Hand Tools & Test EquipmentDocument27 pagesICT - CHS G8 L02 - Use Appropriate Hand Tools & Test EquipmentRuel Carballo100% (4)

- GC1602N0SHN1B 5Document10 pagesGC1602N0SHN1B 5ccuenin777No ratings yet

- MCQ On Special Purpose Diode and ApplicationsDocument18 pagesMCQ On Special Purpose Diode and Applicationskhan adilNo ratings yet

- An Instrument For Audiophile Speaker Builders: Sergej KoschuchDocument8 pagesAn Instrument For Audiophile Speaker Builders: Sergej KoschuchAlessandro BiliottiNo ratings yet

- Conveyor ExDocument1 pageConveyor Extdkhiem02No ratings yet

- Design and Fabrication Mini Lathe MachineDocument17 pagesDesign and Fabrication Mini Lathe MachineBrij Bhushan Monu86% (7)

- Physics Classes: Topic: - Current ElectricityDocument3 pagesPhysics Classes: Topic: - Current Electricitydnyanada patankarNo ratings yet

- Bluesky UserManualDocument6 pagesBluesky UserManualRenatoFariasNo ratings yet