Professional Documents

Culture Documents

Starting & Charging System: Section

Uploaded by

Brian BobbOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Starting & Charging System: Section

Uploaded by

Brian BobbCopyright:

Available Formats

K ELECTRICAL

B

SECTION

STARTING & CHARGING SYSTEM C

E

CONTENTS

PRECAUTIONS .......................................................... 2 DIAGNOSTIC PROCEDURE 2 ........................... 15 F

Precautions for Supplemental Restraint System MINIMUM SPECIFICATION OF CRANKING

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN- VOLTAGE REFERENCING COOLANT TEM-

SIONER” .................................................................. 2 PERATURE ......................................................... 16 G

Wiring Diagrams and Trouble Diagnosis .................. 2 Removal and Installation ........................................ 16

PREPARATION ........................................................... 3 REMOVAL ........................................................... 16

Special Service Tool ................................................. 3 INSTALLATION ................................................... 16

H

Commerical Service Tools ........................................ 3 CHARGING SYSTEM ............................................... 17

BATTERY .................................................................... 4 System Description ................................................. 17

How to Handle Battery ............................................. 4 Wiring Diagram — CHARGE — ............................. 18

METHODS OF PREVENTING OVER-DIS- Trouble Diagnoses with Battery/Starting/Charging I

CHARGE ............................................................... 4 System Tester ......................................................... 19

CHECKING ELECTROLYTE LEVEL .................... 4 DIAGNOSTIC RESULT ITEM CHART ................ 20

SPECIFIC GRAVITY CHECK ............................... 5 WORK FLOW ...................................................... 21 J

CHARGING THE BATTERY ................................. 6 DIAGNOSTIC PROCEDURE 1 ........................... 22

Trouble Diagnoses with Battery/Starting/Charging DIAGNOSTIC PROCEDURE 2 ........................... 23

System Tester .......................................................... 6 DIAGNOSTIC PROCEDURE 3 ........................... 23 SC

DIAGNOSTIC RESULT ITEM CHART .................. 8 DIAGNOSTIC PROCEDURE 4 ........................... 25

Removal and Installation .......................................... 9 DIAGNOSTIC PROCEDURE 5 ........................... 26

REMOVAL ............................................................. 9 MALFUNCTION INDICATOR .............................. 27

INSTALLATION ..................................................... 9 Removal and Installation ........................................ 27 L

STARTING SYSTEM ................................................ 10 REMOVAL ........................................................... 27

System Description ................................................ 10 INSTALLATION ................................................... 27

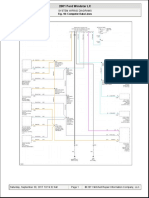

Wiring Diagram — START — ..................................11 Disassembly and Assembly .................................... 28 M

Trouble Diagnoses with Battery/Starting/Charging SERVICE DATA AND SPECIFICATIONS (SDS) ...... 29

System Tester ........................................................ 12 Battery .................................................................... 29

DIAGNOSTIC RESULT ITEM CHART ................ 12 Starter ..................................................................... 29

WORK FLOW ...................................................... 13 Generator ............................................................... 29

DIAGNOSTIC PROCEDURE 1 ........................... 14

Revision: April 2004 SC-1 2004 Titan

PRECAUTIONS

PRECAUTIONS PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER” EKS008W0

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

● To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

● Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

● Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Wiring Diagrams and Trouble Diagnosis EKS008W1

When you read wiring diagrams, refer to the following:

● GI-15, "How to Read Wiring Diagrams" .

● PG-4, "POWER SUPPLY ROUTING CIRCUIT" for power distribution circuit.

When you perform trouble diagnosis, refer to the following:

● GI-11, "HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES".

● GI-27, "How to Perform Efficient Diagnosis for an Electrical Incident".

Revision: April 2004 SC-2 2004 Titan

PREPARATION

PREPARATION PFP:00002

A

Special Service Tool EKS008W2

Tool number

Description

Tool name B

J-44373 Model 620

Battery/Starting/Charging system

tester

C

D

SEL403X

F

Commerical Service Tools EKS008W3

Tool number

Description G

Tool name

Power tool Loosening bolts and nuts

I

PBIC0190E

SC

Revision: April 2004 SC-3 2004 Titan

BATTERY

BATTERY PFP:AYBGL

How to Handle Battery EKS008W4

CAUTION:

● If it becomes necessary to start the engine with a booster battery and jumper cables, use a 12-volt

booster battery.

● After connecting battery cables, ensure that they are tightly clamped to battery terminals for good

contact.

● Never add distilled water through the hole used to check specific gravity.

METHODS OF PREVENTING OVER-DISCHARGE

The following precautions must be taken to prevent over-discharging

a battery.

● The battery surface (particularly its top) should always be kept

clean and dry.

● The terminal connections should be clean and tight.

● At every routine maintenance, check the electrolyte level.

This also applies to batteries designated as “low maintenance”

and “maintenance-free”.

MEL040F

● When the vehicle is not going to be used over a long period of

time, disconnect the negative battery terminal.

MEL041F

● Check the charge condition of the battery.

Periodically check the specific gravity of the electrolyte. Keep a

close check on charge condition to prevent over-discharge.

MEL042F

CHECKING ELECTROLYTE LEVEL

WARNING:

Do not allow battery fluid to come in contact with skin, eyes, fabrics, or painted surfaces. After touch-

ing a battery, do not touch or rub your eyes until you have thoroughly washed your hands. If acid con-

tacts eyes, skin or clothing, immediately flush with water for 15 minutes and seek medical attention.

Revision: April 2004 SC-4 2004 Titan

BATTERY

● Remove the cell plug using a suitable tool.

● Add distilled water up to the MAX level. A

MEL043F

D

Sulphation

A battery will be completely discharged if it is left unattended

for a long time and the specific gravity will become less than

1.100. This may result in sulphation on the cell plates. E

To determine if a battery has been “sulphated”, note its voltage

and current when charging it. As shown in the figure, less cur-

rent and higher voltage are observed in the initial stage of F

charging sulphated batteries.

A sulphated battery may sometimes be brought back into ser-

vice by means of a long, slow charge, 12 hours or more, fol-

G

lowed by a battery capacity test.

PKIA2353E

SPECIFIC GRAVITY CHECK H

1. Read hydrometer and thermometer indications at eye level.

2. Use the following chart to correct your hydrometer reading

according to electrolyte temperature. I

SC

MEL042FA

Hydrometer Temperature Correction

L

Battery electrolyte temperature °C (°F) Add to specific gravity reading

71 (160) 0.032

66 (150) 0.028

M

60 (140) 0.024

54 (130) 0.020

49 (120) 0.016

43 (110) 0.012

38 (100) 0.008

32 (90) 0.004

27 (80) 0

21 (70) −0.004

16 (60) −0.008

10 (50) −0.012

4 (40) −0.016

−1 (30) −0.020

−7 (20) −0.024

Revision: April 2004 SC-5 2004 Titan

BATTERY

Battery electrolyte temperature °C (°F) Add to specific gravity reading

−12 (10) −0.028

−18 (0) −0.032

Corrected specific gravity Approximate charge condition

1.260 - 1.280 Fully charged

1.230 - 1.250 3/4 charged

1.200 - 1.220 1/2 charged

1.170 - 1.190 1/4 charged

1.140 - 1.160 Almost discharged

1.110 - 1.130 Completely discharged

CHARGING THE BATTERY

CAUTION:

● Do not “quick charge” a fully discharged battery.

● Keep the battery away from open flame while it is being charged.

● When connecting the charger, connect the leads first, then turn on the charger. Do not turn on the

charger first, as this may cause a spark.

● If battery electrolyte temperature rises above 55°C (131°F), stop charging. Always charge battery

at a temperature below 55°C (131°F).

Charging Rates

Amps Time

50 1 hour

25 2 hours

10 5 hours

5 10 hours

Do not charge at more than 50 ampere rate.

NOTE:

The ammeter reading on your battery charger will automatically decrease as the battery charges. This indi-

cates that the voltage of the battery is increasing normally as the state of charge improves. The charging amps

indicated above refer to initial charge rate.

● If, after charging, the specific gravity of any two cells varies more than 0.050, the battery should be

replaced.

Trouble Diagnoses with Battery/Starting/Charging System Tester EKS008W5

CAUTION:

When working with batteries, always wear appropriate eye protection.

NOTE:

● To ensure a complete and thorough diagnosis, the battery, starter and generator test segments must be

done as a set from start to finish.

● If battery surface charge is detected while testing, the tester will prompt you to turn on the headlights to

remove the surface charge.

● If necessary, the tester will prompt you to determine if the battery temperature is above or below 0°C

(32°F). Choose the appropriate selection by pressing the up or down arrow button, then press “ENTER” to

make the selection.

Revision: April 2004 SC-6 2004 Titan

BATTERY

1. Turn off all loads on the vehicle electrical system. Clean or repair

as necessary. A

2. Visually inspect the battery, battery terminals and cable ends

with ignition switch in “OFF” position.

NOTE: B

The contact surface between the battery terminals, cable ends

and tester leads must be clean for a valid test. A poor connec-

tion will prevent testing and a “CHECK CONNECTION” mes-

C

sage will appear during the test procedures. If this occurs, clean

the battery post and terminals, reconnect them and restart the

test. SEL404X

3. Connect the red tester lead clamp to the positive battery termi- D

nal, and the black to the negative terminal.

4. The tester will turn on automatically. Using the arrow keys,

select “IN-VEHICLE” on the tester and then press the “ENTER” E

key.

SEL405X

H

5. Locate the battery type and rating stamped or written on the top

case of the battery to be tested.

NOTE: I

The battery type and rating will have either of the following.

CCA: Cold Cranking Amps (490 CCA, 550 CCA, etc.)

JIS: Japanese Industrial Standard. J

Battery is stamped with a number such as:

80D26L: 80 (rank of output), D (physical size-depth), 26 (width

in cm). The last character L (post configuration) is not input into

SC

the tester.

The tester requires the rating for the battery be entered exactly SEL406X

as it is written or stamped on the battery. Do not attempt a CCA

conversion for JIS stamped batteries. JIS must be input directly. L

6. Using the arrow and “ENTER” keys alternately, select the battery type and rating.

NOTE:

The tester lists five choices; CCA, JIS, IEC, DIN, and EN. Only use CCA or JIS. M

7. Press “ENTER” to begin the test. Diagnosis results are dis-

played on the tester. Refer to SC-12, "DIAGNOSTIC RESULT

ITEM CHART" .

SEL407X

Revision: April 2004 SC-7 2004 Titan

BATTERY

8. Press “ENTER”, then test output code is displayed. Record the

test output code on the repair order.

9. Toggle back to the “DIAGNOSTIC SCREEN” for test results.

NOTE:

● If necessary, the tester will ask the user to determine if the

battery has just been charged. Choose the appropriate selec-

tion by pressing the up or down arrow button and then press

the “ENTER” button to make the selection.

● When testing a battery installed in a vehicle that has recently

been driven, select “BEFORE CHARGE”.

SEL576X

● If the battery has just been slow charged due to a “CHARGE

& RETEST” decision by the tester, and the tester asks the user “BEFORE CHARGE/AFTER

CHARGE”, select “AFTER CHARGE”.

DIAGNOSTIC RESULT ITEM CHART

Diagnostic item Service procedure

Battery is OK. Refer to SC-12, "Trouble Diagnoses with Battery/Starting/Charging System

GOOD BATTERY

Tester" .

Replace battery.

Before replacing battery, clean the battery cable clamps and battery posts. Perform battery

REPLACE BATTERY

test again with Battery/Starting/Charging system tester. If second test result is “Replace Bat-

tery”, then do so. Perform battery test again to confirm repair.

Replace the battery. Perform battery test again with Battery/Starting/Charging system tester

BAD CELL-REPLACE

to confirm repair.

Perform the slow battery charging procedure. (Initial rate of charge is 10A for 12 hours.) Per-

GOOD-RECHARGE

form battery test again with Battery/Starting/Charging system tester.

Perform the slow battery charging. (Initial rate of charge is 10A for 12 hours.)

Perform battery test again with Battery/Starting/Charging system tester to confirm repair.

CHARGE & RETEST NOTE:

If the tester asks the user “BEFORE CHARGE/AFTER CHARGE”, select “AFTER

CHARGE”.

Revision: April 2004 SC-8 2004 Titan

BATTERY

Removal and Installation EKS008W6

REMOVAL A

1. Disconnect negative battery terminal and positive battery termi-

nal.

CAUTION: B

When removing, remove negative battery terminal first.

2. Remove battery cover.

3. Remove battery clamp bolt and battery clamp. C

4. Remove battery.

D

WKIA1385E

INSTALLATION

E

Install in the reverse order of removal.

CAUTION:

When installing, install positive battery terminal first.

F

Battery clamp bolt : 3.5 N·m (0.36 kg-m, 31 in-lb)

Battery terminal nut : 3.5 N·m (0.36 kg-m, 31 in-lb)

G

SC

Revision: April 2004 SC-9 2004 Titan

STARTING SYSTEM

STARTING SYSTEM PFP:23300

System Description EKS008W7

Power is supplied at all times:

● through 40A fusible link (letter m , located in the fuse and fusible link box)

● to ignition switch terminal B.

With the ignition switch in the START position, power is supplied:

● from ignition switch terminal ST

● to IPDM E/R terminal 21.

With the ignition switch in the ON or START position, power is supplied to IPDM E/R (intelligent power distribu-

tion module engine room) CPU.

With the selector lever in the P or N position, power is supplied:

● through A/T assembly terminal 9

● to IPDM E/R terminal 48.

Ground is supplied at all times:

● to IPDM E/R terminals 38 and 59

● from body grounds E9, E15 and E24.

Then the starter relay is turned on.

The IPDM E/R is energized and power is supplied:

● from terminal 19 of the IPDM E/R

● to terminal 1 of the starter motor windings.

The starter motor plunger closes and provides a closed circuit between the battery and the starter motor. The

starter motor is grounded to the cylinder block. With power and ground supplied, the starter motor operates.

Revision: April 2004 SC-10 2004 Titan

STARTING SYSTEM

Wiring Diagram — START — EKS008W8

SC

WKWA1150E

Revision: April 2004 SC-11 2004 Titan

STARTING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester EKS008W9

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and generator test segments must be done

as a set from start to finish.

1. Turn off all loads on the vehicle electrical system.

2. Perform battery test with Battery/Starting/Charging system

tester. Refer to SC-12, "Trouble Diagnoses with Battery/Starting/

Charging System Tester" .

3. Press “ENTER” to begin the starting system test.

SEL408X

4. Start the engine.

SEL409X

5. Diagnosis result is displayed on the tester. Refer to SC-12,

"DIAGNOSTIC RESULT ITEM CHART" .

NOTE:

● If the starter performs normally but the engine does not start,

perform engine diagnosis.

● For intermittent “NO CRANK” or “NO STARTER OPERA-

TION” incidents, refer to SC-15, "DIAGNOSTIC PROCE-

DURE 2" .

SEL410X

DIAGNOSTIC RESULT ITEM CHART

Diagnostic item Service procedure

CRANKING VOLTAGE NORMAL Go to SC-13, "WORK FLOW" .

CRANKING VOLTAGE LOW Go to SC-13, "WORK FLOW" .

Perform the slow battery charging procedure. (Initial rate of charge is 10A for 12 hours.) Per-

CHARGE BATTERY form battery test again with Battery/Starting/Charging system tester. Refer to SC-12, "Trouble

Diagnoses with Battery/Starting/Charging System Tester" .

Before replacing battery, clean the battery cable clamps and battery posts. Perform battery

test again with Battery/Starting/Charging system tester. Refer to SC-12, "Trouble Diagnoses

REPLACE BATTERY

with Battery/Starting/Charging System Tester" . If second test result is “REPLACE BAT-

TERY”, then do so. Perform battery test again to confirm repair.

Revision: April 2004 SC-12 2004 Titan

STARTING SYSTEM

WORK FLOW

A

SC

WKIA2104E

*1 SC-12 *2 SC-14 *3 SC-15

*4 SC-15

Revision: April 2004 SC-13 2004 Titan

STARTING SYSTEM

DIAGNOSTIC PROCEDURE 1

Check Terminal "2" Circuit

1. CHECK POWER SUPPLY FOR STARTER MOTOR “2” TERMINAL

1. Remove the fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

3. Turn the ignition switch OFF.

4. Check that the starter motor connector F27 connection is clean and tight.

5. Check voltage between starter motor connector F27 terminal 2

(B/R) and ground using a digital circuit tester.

Battery voltage should

exist.

OK or NG

OK >> GO TO 2.

NG >> Check harness between the battery and the starter

motor for open circuit.

WKIA2105E

2. CHECK BATTERY CABLE CONNECTION QUALITY (VOLTAGE DROP TEST)

Check voltage between starter motor connector F27 terminal 2 (B/R)

and battery positive terminal using a digital circuit tester.

Ignition switch in : Less than 0.5V

START.

OK or NG

OK >> GO TO 3.

NG >> Check harness between the battery and the starter

motor for poor continuity.

WKIA2106E

3. CHECK STARTER MOTOR GROUND CIRCUIT (VOLTAGE DROP TEST)

Check voltage between starter motor case and battery negative ter-

minal using a digital circuit tester.

Ignition switch in : Less than 0.2V

START.

OK or NG

OK >> Starter motor “2” terminal circuit is OK. Further inspec-

tion is necessary. Refer to SC-13, "WORK FLOW" .

NG >> Check harness between the starter motor case and

ground for poor continuity.

WKIA2107E

Revision: April 2004 SC-14 2004 Titan

STARTING SYSTEM

DIAGNOSTIC PROCEDURE 2

Check Terminal "1" Circuit A

1. CHECK POWER SUPPLY FOR STARTER MOTOR “1” TERMINAL

1. Remove the fuel pump fuse. B

2. Crank or start the engine (where possible) until the fuel pressure is released.

3. Turn the ignition switch OFF.

C

4. Disconnect starter motor connector F28.

5. Check voltage between starter motor connector F28 terminal 1

(W/R) and ground using a digital circuit tester.

D

Ignition switch in : Battery voltage

START.

OK or NG E

OK >> GO TO 2.

NG >> Check the following.

● 40A fusible link (letter m , located in fuse and fusible

F

link box)

WKIA2108E

● Ignition switch

G

● Starter relay [within the intelligent power distribution module engine room (IPDM E/R)]

● Harness for open or short

2. CHECK “1” TERMINAL CONNECTION QUALITY (VOLTAGE DROP TEST) H

1. Turn the ignition switch OFF.

2. Connect starter motor connector F28. I

3. Check voltage between starter motor connector F28 terminal 1

(W/R) and battery positive terminal using a digital circuit tester.

J

Ignition switch in : Less than 1V

START.

OK or NG SC

OK >> Starter motor “1” terminal circuit is OK. Further inspec-

tion is necessary. Refer to SC-13, "WORK FLOW" .

NG >> Check harness between the battery and the starter

L

motor “1” terminal for poor continuity.

WKIA1792E

Revision: April 2004 SC-15 2004 Titan

STARTING SYSTEM

MINIMUM SPECIFICATION OF CRANKING VOLTAGE REFERENCING COOLANT TEMPERA-

TURE

Engine coolant temperature Voltage V

−30°C to −20°C (−22°F to −4°F) 8.4

−19°C to −10°C (−2°F to 14°F) 8.9

−9°C to 0°C (16°F to 32°F) 9.3

More than 1°C (More than 34°F) 9.7

Removal and Installation EKS008WA

REMOVAL

1. Remove the intake manifold. Refer to EM-15, "REMOVAL" .

2. Disconnect the starter harness connectors.

3. Remove the two starter bolts, using power tools.

4. Remove the starter.

WKIA1388E

INSTALLATION

To install, reverse the removal procedure.

CAUTION:

Be sure to tighten terminal "2" nut carefully.

Terminal "2" nut : 10.8 N·m (1.1 kg-m, 8 ft-lb)

Revision: April 2004 SC-16 2004 Titan

CHARGING SYSTEM

CHARGING SYSTEM PFP:23100

A

System Description EKS008WB

The generator provides DC voltage to operate the vehicle's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator. B

Power is supplied at all times to generator terminal 4 through:

● 10A fuse (No. 30, located in the fuse and fusible link box).

Terminal 1 supplies power to charge the battery and operate the vehicle's electrical system. Output voltage is C

controlled by the IC regulator at terminal 4 detecting the input voltage. The charging circuit is protected by the

140A fusible link (letter a , located in the fusible link box).

Ground is supplied:

D

● to generator terminal 2

● through body ground E203.

With the ignition switch in the ON or START position, power is supplied: E

● through 10A fuse [No. 14, located in the fuse block (J/B)]

● to combination meter terminal 24 for the charge warning lamp.

Ground is supplied to terminal 13 of the combination meter through terminal 3 of the generator. With power F

and ground supplied, the charge warning lamp will illuminate. When the generator is providing sufficient volt-

age with the engine running, the ground is opened and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a fault is indicated. G

SC

Revision: April 2004 SC-17 2004 Titan

CHARGING SYSTEM

Wiring Diagram — CHARGE — EKS008WC

WKWA1140E

Revision: April 2004 SC-18 2004 Titan

CHARGING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester EKS008WD

A

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and generator test segments must be done

as a set from start to finish.

1. Turn off all loads on the vehicle electrical system. B

2. Perform battery and starting system test with Battery/Starting/

Charging system tester.

C

3. Press “ENTER” to begin the charging system test.

4. Start engine.

D

E

SEL417X

5. Press “ENTER” until “LOADS OFF REV ENGINE 5 SEC” is dis-

played. F

6. Raise and hold the engine speed at 1,500 to 2,000 rpm for about

5 seconds, then return the engine to idle.

Once the increase in engine rpm is detected, press “ENTER” to G

continue.

NOTE:

● If after 30 seconds an increase in engine idle speed is not H

detected, “RPM NOT DETECTED” will display.

● Some engines may have a higher idle initially after starting,

particularly when the engine is cold. The tester may detect SEL418X

I

this without any other action being taken. If this occurs, con-

tinue on with the testing process. The final results will not be affected.

7. The tester now checks the engine at idle and performs the J

DIODE/RIPPLE check.

8. When complete, the tester will prompt you to turn on the follow-

ing electrical loads.

SC

● Heater fan set to highest speed. Do not run the A/C or wind-

shield defroster.

● Headlamp high beam

L

● Rear window defogger

NOTE:

Do not run the windshield wipers or any other cyclical loads. SEL419X

M

9. Press “ENTER” to continue.

SEL420X

Revision: April 2004 SC-19 2004 Titan

CHARGING SYSTEM

10. Raise and hold the engine speed at 1,500 to 2,000 rpm for about

5 seconds, then return the engine to idle. Once the increase in

engine rpm is detected, press “ENTER” to continue.

NOTE:

If after 30 seconds an increase in engine idle speed is not

detected, “RPM NOT DETECTED” will be displayed. Press

“ENTER” to restart the test.

SEL421X

11. Diagnostic result is displayed on the tester. Refer to SC-20,

"DIAGNOSTIC RESULT ITEM CHART" .

SEL422X

12. Press “ENTER” then test output code is displayed. Record the

test output code on the repair order.

13. Toggle back to the “DIAGNOSTIC SCREEN” for test results.

SEL577X

DIAGNOSTIC RESULT ITEM CHART

Diagnostic item Service procedure

CHARGING SYSTEM NORMAL Charging system is normal and will also show DIODE RIPPLE test result.

NO CHARGING VOLTAGE Go to SC-21, "WORK FLOW" .

LOW CHARGING VOLTAGE Go to SC-21, "WORK FLOW" .

HIGH CHARGING VOLTAGE Go to SC-21, "WORK FLOW" .

DIODE RIPPLE NORMAL Diode ripple is OK and will also show CHARGING VOLTAGE test result.

Replace the generator. Perform “DIODE RIPPLE” test again using Battery/Starting/Charging

EXCESS RIPPLE DETECTED

system tester to confirm repair.

DIODE RIPPLE NOT DETECTED Go to SC-21, "WORK FLOW" .

Revision: April 2004 SC-20 2004 Titan

CHARGING SYSTEM

WORK FLOW

A

SC

WKIA2109E

Revision: April 2004 SC-21 2004 Titan

CHARGING SYSTEM

DIAGNOSTIC PROCEDURE 1

Check Terminal "3" Circuit

1. CHECK “3” TERMINAL CONNECTION

1. Turn the ignition switch OFF.

2. Check to see if “3” terminal is clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair “3” terminal connection. Confirm repair by performing complete Battery/Starting/Charging

system test.

2. CHECK “3” TERMINAL CIRCUIT

1. Disconnect E205 connector from generator.

2. Apply ground to connector E205 terminal 3 (BR/W) with the igni-

tion switch in the ON position.

CHARGE lamp should light up.

OK or NG

OK >> GO TO SC-21, "WORK FLOW" .

NG >> Check the following.

● 10A fuse [No. 14, located in fuse block (J/B)]

● CHARGE lamp

● Harness for open or short between combination WKIA2110E

meter and fuse

● Harness for open or short between combination meter and generator

Revision: April 2004 SC-22 2004 Titan

CHARGING SYSTEM

DIAGNOSTIC PROCEDURE 2

Check Terminal "1" Circuit A

1. CHECK “1” TERMINAL CONNECTION

1. Turn the ignition switch OFF. B

2. Check to see if “1” terminal is clean and tight.

OK or NG

C

OK >> GO TO 2.

NG >> Repair “1” terminal connection. Confirm repair by performing complete Battery/Starting/Charging

system test.

D

2. CHECK GENERATOR “1” TERMINAL CIRCUIT

Check voltage between generator connector E206 terminal 1 (B/R) E

and ground using a digital circuit tester.

Battery voltage should exist.

OK or NG F

OK >> GO TO 3.

NG >> Check the following.

● 140A fusible link (letter a , located in fusible link box) G

● Harness for open or short between generator and fus-

ible link

WKIA2111E H

3. CHECK “1” TERMINAL CONNECTION QUALITY (VOLTAGE DROP TEST)

Check voltage between generator connector E206 terminal 1 (B/R) I

and battery positive terminal using a digital circuit tester.

With engine running : Less than 0.2V

at idle and warm. J

OK or NG

OK >> Replace the generator. Refer to SC-27, "Removal and

SC

Installation" . Confirm repair by performing complete

Battery/Starting/Charging system test.

NG >> Check harness between the battery and the generator

for poor continuity. WKIA2112E

L

DIAGNOSTIC PROCEDURE 3

Check Terminal "3" Circuit M

1. CHECK “3” TERMINAL CONNECTION

1. Turn the ignition switch OFF.

2. Check to see if “3” terminal is clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair “3” terminal connection. Confirm repair by performing complete Battery/Starting/Charging

system test.

Revision: April 2004 SC-23 2004 Titan

CHARGING SYSTEM

2. CHECK “3” TERMINAL CIRCUIT

1. Disconnect E205 connector from generator.

2. Apply ground to connector E205 terminal 3 (BR/W) with the igni-

tion switch in the ON position.

CHARGE lamp should light up.

OK or NG

OK >> Replace the generator. Refer to SC-27, "Removal and

Installation" . Confirm repair by performing complete

battery/starting/charging system test.

NG >> Check the following.

● 10A fuse [No. 14, located in fuse block (J/B)]

WKIA2110E

● CHARGE lamp

● Harness for open or short between combination meter and fuse

● Harness for open or short between combination meter and generator

Revision: April 2004 SC-24 2004 Titan

CHARGING SYSTEM

DIAGNOSTIC PROCEDURE 4

Check Terminal "1" Circuit A

1. CHECK “1” TERMINAL CONNECTION

1. Turn the ignition switch OFF. B

2. Check to see if “1” terminal is clean and tight.

OK or NG

C

OK >> GO TO 2.

NG >> Repair “1” terminal connection. Confirm repair by performing complete Battery/Starting/Charging

system test.

D

2. CHECK GENERATOR “1” TERMINAL CIRCUIT

Check voltage between generator connector E206 terminal 1 (B/R) E

and ground using a digital circuit tester.

Battery voltage should exist.

OK or NG F

OK >> GO TO 3.

NG >> Check the following.

● 140A fusible link (letter a , located in fusible link box) G

● Harness for open or short between generator and fus-

ible link

WKIA2111E H

3. CHECK “1” TERMINAL CONNECTION QUALITY (VOLTAGE DROP TEST)

1. Start the engine. I

2. Check voltage between generator connector E206 terminal 1 (B/

R) and battery positive terminal using a digital circuit tester.

J

With engine running : Less than 0.2V

at idle and warm.

OK or NG SC

OK >> GO TO 4.

NG >> Check harness between the battery and the generator

for poor continuity. L

WKIA2112E

4. CHECK GENERATOR DRIVE BELT TENSION M

1. Turn the ignition switch OFF.

2. Check generator drive belt tension. Refer to EM-12, "DRIVE BELTS" .

OK or NG

OK >> Replace the generator. Refer to SC-27, "Removal and Installation" . Confirm repair by performing

complete Battery/Starting/Charging system test.

NG >> Readjust drive belt tension. Refer to EM-12, "Tension Adjustment" .

Revision: April 2004 SC-25 2004 Titan

CHARGING SYSTEM

DIAGNOSTIC PROCEDURE 5

Check Terminal "4" Circuit

1. CHECK “4” TERMINAL CONNECTION

1. Turn the ignition switch OFF.

2. Check to see if “4” terminal is clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair “4” terminal connection. Confirm repair by performing complete Battery/Starting/Charging

system test.

2. CHECK GENERATOR “4” TERMINAL CIRCUIT

Check voltage between generator connector E205 terminal 4 (Y/B)

and ground using a digital circuit tester.

Battery voltage should exist.

OK or NG

OK >> GO TO 3.

NG >> Check the following.

● 10A fuse (No. 30, located in fuse and fusible link box)

● Harness for open or short between generator and

fuse

WKIA2113E

3. CHECK “4” TERMINAL CONNECTION QUALITY (VOLTAGE DROP TEST)

1. Start the engine.

2. Check voltage between generator connector E205 terminal 4 (Y/

B) and battery positive terminal using a digital circuit tester.

With engine running : Less than 0.2V

at idle and warm.

OK or NG

OK >> Replace the generator. Refer to SC-27, "Removal and

Installation" . Confirm repair by performing complete

Battery/Starting/Charging system test.

NG >> Check harness between the battery and the generator

for poor continuity. WKIA2114E

Revision: April 2004 SC-26 2004 Titan

CHARGING SYSTEM

MALFUNCTION INDICATOR

The IC regulator warning function activates to illuminate “CHARGE” warning lamp, if any of the following A

symptoms occur while generator is operating:

● Excessive voltage is produced.

● No voltage is produced. B

Removal and Installation EKS008WE

REMOVAL C

1. Disconnect the negative battery terminal.

2. Remove the fan shroud. Refer to CO-13, "REMOVAL" .

3. Remove the drive belt. Refer to EM-12, "Removal" . D

4. Remove lower bracket, using power tools.

5. Remove the generator upper bolt, using power tools.

6. Disconnect the generator harness connectors. E

7. Remove the generator.

G

WKIA1390E

INSTALLATION

H

Installation is in the reverse order of removal.

● Install the generator and check tension of drive belt. Refer to EM-12, "Tension Adjustment" .

CAUTION: I

Be sure to tighten terminal "1" nut carefully.

″1″ terminal nut : 10.8 N·m (1.1 kg-m, 8 ft-lb)

J

SC

Revision: April 2004 SC-27 2004 Titan

CHARGING SYSTEM

Disassembly and Assembly EKS008WF

WKIA1391E

1. Screws 2. Bearing retainer 3. Front bearing

4. Front cover 5. Pulley 6. Pulley nut

7. Bolts 8. Fan guide 9. Rivets

10. IC regulator assembly 11. Diode assembly 12. Packing

13. Rear cover 14. Nut 15. Insulator bushing

16. Bushing 17. B terminal 18. Nuts

19. Bolts 20. Stator 21. Rotor assembly

Revision: April 2004 SC-28 2004 Titan

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS) PFP:00030

A

Battery EKS008WG

Standard battery Heavy duty battery

Type Gr. 24 Gr. 27 B

Capacity (20 HR) minimum V-AH 72 80

Cold cranking current A

650 710 C

(For reference value)

Starter EKS008WH

D

Application All models

Mitsubishi

Manufacturer

M002T85571ZCKD

E

Type Reduction gear type

System voltage 12V

Terminal voltage 11V F

No-load Current Less than 145A

Revolution More than 3,300 rpm

G

Minimum diameter of commutator 31.4 mm (1.236 in)

Minimum length of brush 11.0 mm (0.433 in)

Brush spring tension 26.7-36.1 N (2.72 - 3.68 kg, 5.93 - 8.02 lb) H

Clearance between pinion front edge and

0.5 - 2.0 mm (0.020 - 0.079 in)

pinion stopper

Generator EKS008WI

I

LR1130-701

Type

Hitachi J

Nominal rating 12V-130A

Ground polarity Negative

SC

Minimum revolution under no-load (When 13.5 volts is applied) 1,200 rpm

More than 78A/1,800 rpm

Hot output current (When 13.5 volts is applied) More than 108A/2,500 rpm

More than 130A/5,000 rpm L

Regulated output voltage 14.1 - 14.7V @ 25°C

Minimum length of brush 6 mm (0.24 in)

M

Brush spring pressure 1.0 - 3.432 N (0.102 - 0.3501 kg, 0.22 - 0.7715 lbs)

Slip ring minimum outer diameter 26 mm (1.02 in)

Rotor (Field coil) resistance 2.1 ohms

Revision: April 2004 SC-29 2004 Titan

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: April 2004 SC-30 2004 Titan

You might also like

- Ford Manual for Owners and Operators of Ford Cars and Trucks (1919)From EverandFord Manual for Owners and Operators of Ford Cars and Trucks (1919)No ratings yet

- Engine Control SystemDocument694 pagesEngine Control Systemthar tharNo ratings yet

- Rebuilding Nippon Denso Alternator 00-01 A - JeepForumDocument14 pagesRebuilding Nippon Denso Alternator 00-01 A - JeepForumejen_glNo ratings yet

- Coleman RV 12 Volt Thermistat ACDocument18 pagesColeman RV 12 Volt Thermistat ACsthoma20100% (1)

- Kelsey Hayes 5.1Document116 pagesKelsey Hayes 5.1Isack LeonardoNo ratings yet

- Inyo County, California (CA) Scanner Frequencies and Radio Frequency ReferenceDocument2 pagesInyo County, California (CA) Scanner Frequencies and Radio Frequency ReferencemaxartoneNo ratings yet

- Power Probe 3 ManualDocument15 pagesPower Probe 3 Manualjim100% (1)

- BOSSDocument99 pagesBOSScamohunter71No ratings yet

- FORD EEC-III Tester Manual - VisioneerDocument161 pagesFORD EEC-III Tester Manual - VisioneerСтефан Цанев100% (1)

- Ford 7.3L IDM Box InsertDocument2 pagesFord 7.3L IDM Box InsertAlberto GutierrezNo ratings yet

- 2011 Mad PogDocument81 pages2011 Mad PogBruno Pilieci100% (1)

- ENGINE MECHANICAL SECTIONDocument140 pagesENGINE MECHANICAL SECTIONEuclides Adao100% (1)

- Technical Service Information: FORD 4R70E/4R75EDocument5 pagesTechnical Service Information: FORD 4R70E/4R75EMario MastronardiNo ratings yet

- XXXX 1997 Chevrolet Pickup K1500: I - System/Component Tests - 5.0L XXXX Highlighted Article TextDocument28 pagesXXXX 1997 Chevrolet Pickup K1500: I - System/Component Tests - 5.0L XXXX Highlighted Article TextJose Gabriel Diaz100% (1)

- 1 5 0 0 / 2 5 0 0 / 3 5 0 0 2 0 1 6 Ram Truck: Owner'S ManualDocument914 pages1 5 0 0 / 2 5 0 0 / 3 5 0 0 2 0 1 6 Ram Truck: Owner'S ManualKorey BradleyNo ratings yet

- Ford Motorcraft CarburationDocument40 pagesFord Motorcraft CarburationjohnvandurenNo ratings yet

- Polaris Predator 90 Parts Manual 2005Document36 pagesPolaris Predator 90 Parts Manual 2005birddog06100% (1)

- On An 4000 Maintenance ManualDocument158 pagesOn An 4000 Maintenance ManualMiles TetlockNo ratings yet

- Honda Gx160 5.5 HP Quick RefDocument2 pagesHonda Gx160 5.5 HP Quick RefNivedanSahayNo ratings yet

- 2004 f150 3v and 4r100 Heritage 5.4 Reference ValuesDocument12 pages2004 f150 3v and 4r100 Heritage 5.4 Reference Valuesjr100100100% (2)

- Electrical Wiring Power Take-Off Circuit Installation: Return To Body Builders Layout Book INDEXDocument1 pageElectrical Wiring Power Take-Off Circuit Installation: Return To Body Builders Layout Book INDEXvixentdNo ratings yet

- 1996 Dakota Gas Powertrain DiagnosticsDocument917 pages1996 Dakota Gas Powertrain DiagnosticscatlinmwagnerNo ratings yet

- Wiring PDFDocument136 pagesWiring PDFEnrique Arevalo Leyva100% (2)

- SX-1250 Service Manual (Hi-Res)Document94 pagesSX-1250 Service Manual (Hi-Res)MrWasabihead0% (1)

- At ArmadaDocument330 pagesAt ArmadaOscar GonzálezNo ratings yet

- 05 TitanDocument344 pages05 TitanDavid ChalkerNo ratings yet

- TitanDocument345 pagesTitansesentorodriguezNo ratings yet

- Diagnostic Procedures Manual GuideDocument32 pagesDiagnostic Procedures Manual Guidejohansen05100% (2)

- 2003 GMC TAC ConnectorsDocument29 pages2003 GMC TAC ConnectorsfenkensteinNo ratings yet

- 2014-Nissan-Pathfinder POWER CONTROL SYSTEMDocument85 pages2014-Nissan-Pathfinder POWER CONTROL SYSTEMgerardogmoralesNo ratings yet

- Body, Lock and Security System Troubleshooting GuideDocument222 pagesBody, Lock and Security System Troubleshooting GuideAriel Mercocha100% (1)

- Heavy Duty DatalinkDocument1 pageHeavy Duty DatalinkBonnieHachey-PorterNo ratings yet

- 2001 Camaro 3800 PCM Pin OutsDocument5 pages2001 Camaro 3800 PCM Pin OutsRashid JuarezNo ratings yet

- B Series Valve AdjustmentDocument5 pagesB Series Valve Adjustmentsasa oljacaNo ratings yet

- Operating Instructions and Owner'S Manual Mr. Heater HeatstarDocument8 pagesOperating Instructions and Owner'S Manual Mr. Heater HeatstarcjmNo ratings yet

- Manual Honda Gx270 Gx340 Gx390Document96 pagesManual Honda Gx270 Gx340 Gx390PriourNo ratings yet

- 3123 93-0102 RevD Manual English Final Downloadable PDFDocument52 pages3123 93-0102 RevD Manual English Final Downloadable PDFAlberto ChavezNo ratings yet

- Xneon Connectores 334Document324 pagesXneon Connectores 334Roger Mirabet RuizNo ratings yet

- 2014 Mustang Power DistributionDocument5 pages2014 Mustang Power DistributionRuben100% (1)

- 2011 LD ElectricalPickupsChassisCabs 100813 PDFDocument240 pages2011 LD ElectricalPickupsChassisCabs 100813 PDFZak CarriganNo ratings yet

- View Active Fault Codes on Blue Bird School Bus Dash DisplaysDocument7 pagesView Active Fault Codes on Blue Bird School Bus Dash DisplaysJaider Cruz CruzNo ratings yet

- 2001 Ford Windstar Computer Data LinesDocument1 page2001 Ford Windstar Computer Data LinesRubenNo ratings yet

- Alldata - Suburban - ServiceDocument1,121 pagesAlldata - Suburban - ServiceАлександра Палиенко100% (2)

- ARP - Bolt Catalogue (Bolting Information) - Cat03Document82 pagesARP - Bolt Catalogue (Bolting Information) - Cat03petermorgan74931No ratings yet

- 2010 Corvette Professional PDFDocument395 pages2010 Corvette Professional PDFDavid BaylissNo ratings yet

- Ec PDFDocument2,751 pagesEc PDFDaniel Aguirre100% (1)

- Acadia 2012 3.6LDocument285 pagesAcadia 2012 3.6LCarlos Eduardo Baylon FloresNo ratings yet

- 2001 Buick Lesabre Factory Service ManualDocument6,539 pages2001 Buick Lesabre Factory Service ManualKJ CARGO50% (2)

- Ac System General Diagnostic ProceduresDocument5 pagesAc System General Diagnostic ProceduresToua YajNo ratings yet

- 2007 Nissan Xterra 16Document18 pages2007 Nissan Xterra 16Roma Roma100% (1)

- Manual de ServicioDocument183 pagesManual de ServicioDiego SotoNo ratings yet

- Nissan Xterra 2008 Engine Control PDFDocument690 pagesNissan Xterra 2008 Engine Control PDFManuales De Maquinaria Jersoncat100% (1)

- Service Vehicle Replacement PartsDocument31 pagesService Vehicle Replacement PartsEmilio CortesNo ratings yet

- A B D e F G H I J K L M N PDocument6 pagesA B D e F G H I J K L M N PMuruganNo ratings yet

- 1994 Chevrolet SuburbanDocument385 pages1994 Chevrolet SuburbanCharles DeBlanc50% (2)

- Articles 1 10 PDFDocument32 pagesArticles 1 10 PDFLuisYFer1No ratings yet

- Minn Kota Repair ManualDocument113 pagesMinn Kota Repair Manualjeriperi100% (1)

- Starting & Charging System: SectionDocument32 pagesStarting & Charging System: SectionLino Bello RezamanoNo ratings yet

- SC PDFDocument32 pagesSC PDFLino Bello RezamanoNo ratings yet

- EL150GY-NB - GM BrochureDocument2 pagesEL150GY-NB - GM BrochureBrian BobbNo ratings yet

- EL125-CB3 - GM BrochureDocument2 pagesEL125-CB3 - GM BrochureBrian BobbNo ratings yet

- GTH-5519 GTH-5519 S: Serial Number RangeDocument172 pagesGTH-5519 GTH-5519 S: Serial Number RangeBrian BobbNo ratings yet

- LF150-13 Motorcycle SpecsDocument2 pagesLF150-13 Motorcycle SpecsBrian BobbNo ratings yet

- 340 Da 0Document2 pages340 Da 0Brian BobbNo ratings yet

- Diagrama DDF482RFEDocument3 pagesDiagrama DDF482RFEBrian BobbNo ratings yet

- TA35 & TA40 Articulated Dumptruck Maintenance Manual: Click Here For Table ofDocument488 pagesTA35 & TA40 Articulated Dumptruck Maintenance Manual: Click Here For Table ofKot878100% (2)

- Ta 35 HorDocument36 pagesTa 35 HorBrian BobbNo ratings yet

- Makita Genuinebatterystatement Public 09dec14Document1 pageMakita Genuinebatterystatement Public 09dec14Brian BobbNo ratings yet

- KTR PD Type Alternator ConnectionDocument1 pageKTR PD Type Alternator ConnectionBrian BobbNo ratings yet

- Canon PIXMA Ip8720Document149 pagesCanon PIXMA Ip8720Brian BobbNo ratings yet

- Ip8720 LSSDocument2 pagesIp8720 LSSBrian BobbNo ratings yet

- Data Entry Form For Direct and Mobile Banking 1Document1 pageData Entry Form For Direct and Mobile Banking 1Brian BobbNo ratings yet

- Techtip 25Document7 pagesTechtip 25Brian BobbNo ratings yet

- Lister Diesel Engine Service Manual SLDocument1 pageLister Diesel Engine Service Manual SLBrian BobbNo ratings yet

- Samsung Finance Plus Terms and ConditionsDocument1 pageSamsung Finance Plus Terms and ConditionsBrian BobbNo ratings yet

- GTH 1056Document153 pagesGTH 1056Brian BobbNo ratings yet

- Engine B fuel system guideDocument16 pagesEngine B fuel system guideBrian BobbNo ratings yet

- Labour ActDocument27 pagesLabour ActVD GraphixNo ratings yet

- BOSL Schedule of Banking FeesDocument6 pagesBOSL Schedule of Banking FeesBrian BobbNo ratings yet

- Old Fashioned Silky Creamy Custard Pie - Small Town WomanDocument2 pagesOld Fashioned Silky Creamy Custard Pie - Small Town WomanBrian BobbNo ratings yet

- Massey FergussonDocument58 pagesMassey Fergussonjulienjulien17No ratings yet

- Switches Fluid Level Hi Lo Coolant Oil DieselDocument4 pagesSwitches Fluid Level Hi Lo Coolant Oil DieselBrian BobbNo ratings yet

- Foton Auman BJ 1093 SeDocument113 pagesFoton Auman BJ 1093 SeBrian BobbNo ratings yet

- Savings-Account-Form Local BankDocument2 pagesSavings-Account-Form Local BankBrian BobbNo ratings yet

- Cssna Insite Form FilledDocument1 pageCssna Insite Form FilledBrian BobbNo ratings yet

- 350 Series Broce Broom PartsDocument168 pages350 Series Broce Broom Partsjuan apaza100% (1)

- Back To Table ofDocument2 pagesBack To Table ofBrian BobbNo ratings yet

- 800A, 800AJ SN 0300183033 To PresentDocument612 pages800A, 800AJ SN 0300183033 To PresentBrian BobbNo ratings yet

- Fish Processing CGDocument41 pagesFish Processing CGmelisasumbilon100% (1)

- Internship Report On UBLDocument62 pagesInternship Report On UBLbbaahmad89No ratings yet

- DH 201 To 300 Bedded Revised Draft PDFDocument158 pagesDH 201 To 300 Bedded Revised Draft PDFAmit Kumar MishraNo ratings yet

- Solid Phase ExtractionDocument16 pagesSolid Phase ExtractionDAVID VELEZNo ratings yet

- Sea Cliff Zanzibar E Fact SheetDocument6 pagesSea Cliff Zanzibar E Fact SheetBenedict MuringakumweNo ratings yet

- Drugs MnemonicsDocument6 pagesDrugs MnemonicsDarrylJavier100% (1)

- Product Data Sheet GC 120 LDocument5 pagesProduct Data Sheet GC 120 LYohanes Meinata PermanaNo ratings yet

- EKS 17 Miniature Piston Pump SpecificationsDocument1 pageEKS 17 Miniature Piston Pump SpecificationsdujobozinovicNo ratings yet

- A Study On Employee Absenteeism at TVS Sundaram Fasteners Limited, Chennai, TamilnaduDocument7 pagesA Study On Employee Absenteeism at TVS Sundaram Fasteners Limited, Chennai, TamilnaduIJRASETPublicationsNo ratings yet

- 9 Types of Maintenance - How To Choose The Right Maintenance StrategyDocument10 pages9 Types of Maintenance - How To Choose The Right Maintenance StrategydejanNo ratings yet

- Monnal T50 VentilatorsDocument2 pagesMonnal T50 VentilatorsInnovate IndiaNo ratings yet

- Basic Concepts On Laboratory Biosafety and BiosecurityDocument3 pagesBasic Concepts On Laboratory Biosafety and BiosecurityGwynneth EuriccaNo ratings yet

- Acidified Foods Guidance 2010-08-02 (Clean)Document39 pagesAcidified Foods Guidance 2010-08-02 (Clean)Victor SchneiderNo ratings yet

- Literature Review Sustainable DevelopmentDocument5 pagesLiterature Review Sustainable DevelopmentJade NelsonNo ratings yet

- UntitledDocument10 pagesUntitledVeneta GizdakovaNo ratings yet

- AISC Design Guide 27 - Structural Stainless SteelDocument159 pagesAISC Design Guide 27 - Structural Stainless SteelCarlos Eduardo Rodriguez100% (1)

- Cranes & Hoists ProgramDocument28 pagesCranes & Hoists ProgramImtiyaz AkhtarNo ratings yet

- Brick AssDocument12 pagesBrick AssInaf NafiNo ratings yet

- Ia On Solubility EquilibriumDocument8 pagesIa On Solubility Equilibriumapi-235913605100% (1)

- Standard QAPDocument9 pagesStandard QAPsivaNo ratings yet

- 2 Second Grade English Diagnostic Test (Autoguardado)Document5 pages2 Second Grade English Diagnostic Test (Autoguardado)MELISSA KARENTH MONTES PINTONo ratings yet

- Measuring Blood Pressure AccuratelyDocument2 pagesMeasuring Blood Pressure AccuratelyxmantestNo ratings yet

- ZHINENG Qigong Breathing Exercises ZBEDocument12 pagesZHINENG Qigong Breathing Exercises ZBELong Le100% (4)

- Manitowoc Cff-90 PartsDocument13 pagesManitowoc Cff-90 PartsDaren FerreiraNo ratings yet

- Swancor 901 Data SheetDocument2 pagesSwancor 901 Data SheetErin Guillermo33% (3)

- TDS - Rheofinish 288 FDDocument2 pagesTDS - Rheofinish 288 FDVenkata RaoNo ratings yet

- PFC Katalog PPDocument128 pagesPFC Katalog PPbmsinghNo ratings yet

- Axell Wireless Cellular Coverage Solutions BrochureDocument8 pagesAxell Wireless Cellular Coverage Solutions BrochureBikash ShakyaNo ratings yet

- Breast CancerDocument1 pageBreast CancerAdang FirmansyahNo ratings yet

- ReportDocument1 pageReportRanjan Mano100% (1)