Professional Documents

Culture Documents

NN-S-103 - C Stilt

NN-S-103 - C Stilt

Uploaded by

Nimish PrabhukhanolkarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NN-S-103 - C Stilt

NN-S-103 - C Stilt

Uploaded by

Nimish PrabhukhanolkarCopyright:

Available Formats

1:100 1m 2m 3m

1:50 0 0.5m 1m 1.5m

1:1 0 10mm 20mm 30mm

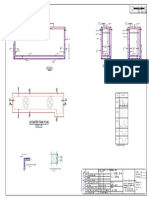

STILT FLOOR BEAM SCHEDULE

Reinforcement Stirrups Comments SLAB SCHEDULE

Label b(mm) d(mm)

Schematic Top Left Top Middle Top Right Bott. Left Bott. Middle Bott. Right S1 S2

B1,B2,B34,B35,B24, Reinforcement Comments

150 650 2 - 10 2 - 10 2 - 10 2 - 12 2 - 12 2 - 12 8 @300c/c 8 @300c/c Type 1 Label D(mm)

B25,B1A/2A/34A/35A Along short span Along Long Span

B3,B4,B32,B33 150 650 2 - 12 +2 - 10 2 - 12 2 - 12 +2 - 10 2 - 12 +2 - 10 2 - 12 +2 - 10 2 - 12 +2 - 10 8 @300c/c 8 @300c/c Type 1 S1 110 8 @150 8 @250 Two-way

B6,B7 230 650 2 - 12 2 - 12 2 - 12 +2 - 10 2 - 12 2 - 12 2 - 12 8 @300c/c 8 @300c/c Type 1 S2 100 8 @200 8 @220 Two-way

B8,B28 230 650 2 - 16 2 - 16 2 - 16 +2 - 20 2 - 12 2 - 12 2 - 12 +2 - 16 8 @250c/c 8 @300c/c Cantilever S3 100 8 @220 8 @220 Two-way

B9,B29 230 650 from B8/B28 2 - 16 2 - 16 from B8/B28 2 - 12 2 - 12 8 @200c/c 8 @250c/c Type 2 S4 110 8 @140 6 @200 One-way

B10 230 650 2 - 20 2 - 20 2 - 20 +2 - 20 2 - 12 +2 - 10 2 - 12 2 - 12 8 @150c/c 8 @150c/c Type 1 S5 100 8 @220 6 @250 One-way

B10A,B30 230 650 2 - 12 2 - 12 2 - 12 2 - 12 2 - 12 2 - 12 8 @300c/c 8 @300c/c Cantilever Note:

1 Alternate bars should be bent up.

B11 230 650 2 - 16 +2 - 12 2 - 16 2 - 16 +2 - 20 2 - 16 +2 - 12 2 - 16 2 - 16 +2 - 12 8 @300c/c 8 @300c/c Type 2

2 Top bars should be developed in adjacent spans along spanning directions. If no adjacent span,

B12 230 650 from B11 2 - 16 2 - 16 from B11 2 - 16 2 - 16 8 @300c/c 8 @300c/c Type 2 additional top L bar provided and hooked into beam.

B13,B15 150 650 2 - 12 2 - 12 2 - 12 2 - 12 2 - 12 2 - 12 8 @300c/c 8 @300c/c Type 1

FC1

650

900

B14,B16 150 650 from B13/B15 2 - 12 2 - 12 from B13/B15 2 - 12 2 - 12 8 @300c/c 8 @300c/c Type 1

B17 230 650 2 - 20 2 - 20 2 - 20 +2 - 20 2 - 16 2 - 16 2 - 16 +2 - 16 8 @250c/c 8 @250c/c Cantilever

650

B18 230 650 from B17 2 - 20 2 - 20 +2 - 16 from B17 2 - 16 2 - 16 +2 - 16 8 @200c/c 8 @250c/c Type 2

B10 B12

B19 230 650 from B18 2 - 20 2 - 20 +2 - 16 from B18 2 - 16 2 - 16 8 @200c/c 8 @250c/c Type 1 TB1

R/F as per

B20 230 650 from B19 2 - 20 2 - 20 from B19 2 - 16 2 - 16 8 @250c/c 8 @300c/c Type 1 schedule

C7' C6'

Column R/F as per

B21 230 650 2 - 16 +2 - 12 2 - 16 2 - 16 +2 - 20 2 - 16 2 - 16 2 - 16 +2 - 16 8 @250c/c 8 @300c/c Type 2

schedule

B22 230 650 from B21 2 - 16 2 - 16 +2 - 20 from B21 2 - 16 2 - 16 +2 - 12 8 @250c/c 8 @300c/c Type 2 Winders in 12 Section at TB1

Brick work 11 (Scale 1:50)

B23 230 650 from B22 2 - 16 2 - 16 +2 - 12 from B22 2 - 16 2 - 16 +2 - 12 8 @250c/c 8 @300c/c Type 2

10

B23A 230 650 from B23 from B23 from B23 from B23 from B23 from B23 8 @250c/c 8 @300c/c Cantilever

9

625

130

B26 230 650 2 - 16 +2 - 20 2 - 16 2 - 16 +2 - 16 2 - 12 +2 - 12 2 - 12 +2 - 12 2 - 12 +2 - 12 8 @300c/c 8 @300c/c Type 1 250

8

B27 230 650 2 - 12 +2 - 16 2 - 12 2 - 12 +2 - 10 2 - 16 2 - 16 2 - 16 8 @300c/c 8 @300c/c Type 1

B31 230 650 2 - 12 +2 - 20 2 - 12 2 - 12 +2 - 16 2 - 16 2 - 16 2 - 16 8 @300c/c 8 @300c/c Type 1 8 @ 250 c/c

130

10 @ 150 c/c

B36,B72 150 650 2 - 12 +2 - 10 2 - 12 2 - 12 +2 - 10 2 - 12 +2 - 10 2 - 12 2 - 12 +2 - 10 8 @300c/c 8 @300c/c Type 2

B37,B73 150 650 from B36/B72 2 - 12 2 - 12 +2 - 10 from B36/B72 2 - 12 2 - 12 +2 - 10 8 @300c/c 8 @300c/c Type 2

Section EE MB1

B38,B70 150 650 2 - 16 2 - 16 2 - 16 2 - 12 2 - 12 2 - 12 8 @150c/c 8 @200c/c Cantilever ( Scale 1:25)

P2 P3

B39,B71 150 650 2 - 16 2 - 16 2 - 16 2 - 12 2 - 12 2 - 12 8 @150c/c 8 @200c/c Cantilever

B40 150 650 2 - 16 2 - 16 2 - 16 2 - 12 2 - 12 2 - 12 8 @150c/c 8 @200c/c Cantilever 9

2 - 16 2 - 16 2 - 12 2 - 12 Type 1 8

B41,B42 150 650 from B40/B41 from B40/B41 8 @300c/c 8 @300c/c

7

B43 150 650 from B42 2 - 16 2 - 16 from B42 2 - 12 2 - 12 8 @150c/c 8 @200c/c Cantilever

6

B44,B64 230 650 2 - 16 +2 - 12 2 - 16 2 - 16 2 - 12 +2 - 10 2 - 12 2 - 12 8 @300c/c 8 @300c/c Type 1 20

5

19

0

13

B45,B65 230 650 2 - 16 2 - 16 2 - 16 2 - 12 2 - 12 2 - 12 +2 - 10 8 @300c/c 8 @300c/c Type 2

10 @ 150 c/c 4

18

B46,B60 230 650 2 - 16 2 - 16 +2 - 20 2 - 16 +2 - 20 2 - 16 2 - 16 2 - 16 8 @300c/c 8 @300c/c Cantilever 8 @160c/c

3

17 Top Starter

B47,B61 230 650 from B46/B60 2 - 16 2 - 16 from B46/B60 2 - 16 2 - 16 8 @300c/c 8 @300c/c Type 1 2 Parking Floor

16 8 @ 250 c/c Level

B48,B62 230 650 from B47/B61 2 - 16 2 - 16 +2 - 12 from B47/B61 2 - 16 2 - 16 8 @300c/c 8 @300c/c Type 1 1

15

B49,B63 230 650 from B48/B62 from B48/B62 from B48/B62 from B48/B62 from B48/B62 from B48/B62 8 @300c/c 8 @300c/c Cantilever 14

10 @ 150 c/c

B50,B56 230 650 2 - 16 2 - 16 +2 - 20 2 - 16 +2 - 20 2 - 16 2 - 16 2 - 16 8 @250c/c 8 @250c/c Cantilever 13

8 @160c/c

B51,B57 230 650 from B50/B56 2 - 16 2 - 16 from B50/B56 2 - 16 +2 - 20 2 - 16 8 @200c/c 8 @250c/c Type 1 12 Bottom Starter

8 @ 250 c/c

11

B52,B58 230 650 from B51/B57 2 - 16 2 - 16 +2 - 20 from B51/B57 2 - 12 2 - 12 8 @200c/c 8 @250c/c Type 1 PB9

Section CC

B53,B59 230 650 2 - 12 +2 - 10 2 - 12 +2 - 10 2 - 12 +2 - 10 2 - 12 2 - 12 2 - 12 8 @250c/c 8 @300c/c Cantilever

( Scale 1:25)

B54 230 650 2 - 12 2 - 12 2 - 12 2 - 12 2 - 12 +2 - 10 2 - 12 8 @300c/c 8 @300c/c Type 1

B66 230 650 2 - 16 2 - 16 +2 - 20 2 - 16 +2 - 20 2 - 16 2 - 16 2 - 16 8 @300c/c 8 @300c/c Cantilever Section DD

( Scale 1:25)

B67 230 650 from B66 2 - 16 2 - 16 from B66 2 - 16 2 - 16 8 @300c/c 8 @300c/c Type 1 MB1

B68 230 650 from B67 2 - 16 2 - 16 +2 - 12 from B67 2 - 16 2 - 16 8 @300c/c 8 @300c/c Type 1

B69 230 650 from B68 from B68 from B68 from B68 from B68 from B68 8 @300c/c 8 @300c/c Cantilever

TB1,TB3 300 900 4 - 20 4 - 20 4 - 20 07 - 32 07 - 32 07 - 32 10 @150c/c 10 @150c/c Type 1

L

Top Left Top Right

TB2 600 800 8 - 16 8 - 16 8 - 16 16 - 20 16 - 20 16 - 20 10 @200c/c 10 @200c/c Type 1 L/3 Top Center

MB1 150 625 2 - 12 +2 - 10 2 - 12 2 - 12 +2 - 12 2 - 12 2 - 12 +2 - 12 2 - 12 8 @300c/c 8 @300c/c Type 1

MB2 150 625 2 - 16 +2 - 12 2 - 16 2 - 16 2 - 12 2 - 12 2 - 12 8 @250c/c 8 @250c/c Type 1 C D

MB1 S1 S1

Bottom S2

MB3 150 625 2 - 16 +2 - 12 2 - 16 2 - 16 2 - 12 2 - 12 2 - 12 8 @250c/c 8 @250c/c Type 1

MB3

Type 2-Beam

MB2

E

E

B44A/45A,B64A/65A 150 650 2 - 16 +2 - 12 2 - 16 2 - 16 2 - 12 2 - 12 2 - 12 8 @250c/c 8 @250c/c Cantilever

Note: At ends, the top and bott. bars must be bent inside the column

to get an anchorage length of atleast 50 db from face of column

10

11 13 14 15 16 17 18 19

9 7 6 5 4 3 2 1

12

NOTE: Underlines values represent extra bars in inner layer.

8

L

Top Left Top Right

L/3 Top center

B1 B1A B2A B2

MB1

B45A

B65A

MB3

B49

B59

B53

B6 C2 B3 B4 B7 S5

B71

B63

B69

B39

B43

S5 S1 S1

P1 B10 FC1 B10A Bottom

C1 C3 C4 S2 Bottom Right

Bottom left

B8 C5 B9 C D

C7' TB1 C6'

B45

Type 1-Beam

B65

P2

P3

P4

B48

S3 S1 S3

S5 S5 Staircase Midlanding Lvl.

B62

B12 S1 Note: At ends, the top and bott. bars must be bent inside the column

B73

B37

B68

B42

B13 B14 B15 B16 to get an anchorage length of atleast 50 db from face of column

S2 S2 Scale 1:50

UP B11

B17 B18 S5 S5 B20 B21 S5 B22 S5 B23 B23A

B52

B58

C8 C9 B19 C10 S4 C11 C12 C13

S5 C14 B26 C15 S5

B44

B64

B67

B24 Slab reinf't

B41

B72

B25

B36

B47

B61

S2 S3 S3 S5 S2

B51

B57

S5 S1 FC2 C17'

B54

C16 S1 C23' 6 dia @250 c/c

B28 C18 B29 TB3 FC3 C19'

C20 C21 S3 S3 C22 8 @ 200 top

B27

C23 TB2 B30 beam reinf't

B66

B44A

B38

B40

B70

B50

B46

B56

B60

S5 B32 B33

B64A

B31 S5

Design Complaint to the foll. Codes Drawing Title:

150

STRUCTURAL

IS 456-2000 Drawn: JT/PSR

B34 B34A B35A B35 Notes:

STILT LEVEL RCC Checked: JSS/NP

Chajja outline Refer General Notes for Concrete

DETAILS

Correct Paper Size: A1

FIRST FLOOR LAYOUT Chajja Slab Detail & General Specifications

Designed: PSR

SCALE - 1:100 (Scale 1:25)

Only written dimensions to be used. Agami Engineering

Project: Drawing No.:

38/1997 Vakratunda Soc.,

B 18.06.16 IFC. NEETA NIWAS GandhiNagar, Bandra (E), NN - S - 103

A 16.06.16 Client: Mumbai 400 051 Project No.:

P: +91-22-26432068

Date: Description: C. H. PATIL & SONS --

W: www.agamiengineering.com

Revision History

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- S-105-Third Floor.BDocument1 pageS-105-Third Floor.BNimish PrabhukhanolkarNo ratings yet

- Ug Water Tank Plan: Section B-B Section C-CDocument1 pageUg Water Tank Plan: Section B-B Section C-CNimish PrabhukhanolkarNo ratings yet

- Typical Floor (5Th - 7Th) Beam Schedule (1of1)Document1 pageTypical Floor (5Th - 7Th) Beam Schedule (1of1)Nimish PrabhukhanolkarNo ratings yet

- NN-S-109 - O.H TankDocument1 pageNN-S-109 - O.H TankNimish PrabhukhanolkarNo ratings yet

- Fourth Floor Beam Schedule (1of1)Document1 pageFourth Floor Beam Schedule (1of1)Nimish PrabhukhanolkarNo ratings yet

- Foundation Layout: Agami EngineeringDocument1 pageFoundation Layout: Agami EngineeringNimish PrabhukhanolkarNo ratings yet

- NN S 104 Second Floor.CDocument1 pageNN S 104 Second Floor.CNimish PrabhukhanolkarNo ratings yet

- Foundation Layout: Agami EngineeringDocument1 pageFoundation Layout: Agami EngineeringNimish PrabhukhanolkarNo ratings yet