Professional Documents

Culture Documents

Iso 7040

Iso 7040

Uploaded by

Ahmet HamamcıoğluOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Iso 7040

Iso 7040

Uploaded by

Ahmet HamamcıoğluCopyright:

Available Formats

Nylon Insert Lock Nuts

Nuts METRIC - Regular Pattern

H F

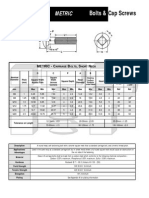

METRIC - NYLON INSERT STOP NUTS , REGULAR PATTERN, CLASS 8 S TYLE 1 ISO 7040

F G H I

Width Across Wrenching

Nominal Size Thread Pitch Width Across Flats Thickness

Corners Height

Max Min Min Max Min Min

M3 0.5 5.50 5.32 6.01 4.5 4.02 1.72

M4 0.7 7.00 6.78 7.66 6.00 5.52 2.32

M5 0.8 8.00 7.78 8.79 6.80 6.22 3.52

M6 1 10.00 9.78 11.05 8.00 7.42 3.92

M8 1.25 13.00 12.73 14.38 9.50 8.92 5.15

M10 1.5 16.00 15.73 17.77 11.9 11.2 6.43

M12 1.75 18.00 17.73 20.03 14.9 14.2 8.3

M16 2 24.00 23.67 26.75 19.1 17.8 11.28

M20 2.5 30.00 29.16 32.95 22.8 20.7 13.52

M24 3 36 35 39.55 27.1 25.0 16.16

M30 3.5 46 45 50.85 32.6 30.1 19.44

M36 4 55.0 53.8 60.79 38.9 36.4 23.52

Hex nut with a metric thread pitch and a nylon-filled collar at its back end. Class 8, style 1 nuts of a basic diameter greater than M16

Description are quenched and tempered. When a screw reaches the collar, the threads and nylon form a tight, frictional fit, restricting movement

of the screw when it is subjected to vibration. The nylon insert comes in various colors.

Class 8 metric nylon insert lock nuts are to be used with screw of a Class 8.8 or less. It is able to be reused more times than a two-

Applications/

way reversible nut. It is less expensive than a Grade-C automation lock nut. Nylon insert lock nuts are designed for use in

Advantages temperatures from -73°C to +120°C.

Class 8 metric nylon insert lock nuts shall be made of a steel which conforms to the following chemical composition--

Material

Carbon: 0.58% maximum; Manganese: 0.25% minimum; Phosphorus: 0.060% maximum; Sulfur: 0.150% maximum.

M3 - M4: HV 180 - 302 (Rockwell B 87.1 - C 30)

Hardness M5 - M16: HV 200 - 302 (Rockwell B 91.5 - C 30)

M20 - M36: HV 233 - 353 (Rockwell C 18 - C 36)

M3 - M4: 800

M5 - M7: 855

Proof Load (N/mm2 ) M8 - M10: 870

M12 - M16: 880

M20 - M36: 920

Plating See Appendix-A for plating information

This page prints with a watermark

You might also like

- Hondata S300 Wideband Setup Guide: Wiring InformationDocument2 pagesHondata S300 Wideband Setup Guide: Wiring InformationSimson Anson100% (1)

- Forging of CrankshaftDocument4 pagesForging of Crankshaftkhor_yin_1No ratings yet

- Alloy-Steel and Stainless Steel Bolting For Low-Temperature ServiceDocument8 pagesAlloy-Steel and Stainless Steel Bolting For Low-Temperature ServiceGian SennaNo ratings yet

- Stainless Steel Socket-Set Screws: Standard Specification ForDocument5 pagesStainless Steel Socket-Set Screws: Standard Specification FormsbarretosNo ratings yet

- Model SG-100 Plasma Spray Gun Operators Manual Rev HDocument69 pagesModel SG-100 Plasma Spray Gun Operators Manual Rev HAdamNo ratings yet

- BS 21 - Pressure Tight Pipe Thread JointsDocument8 pagesBS 21 - Pressure Tight Pipe Thread JointsHARSHANo ratings yet

- Chinese To DinDocument7 pagesChinese To Dindnageshm4n244No ratings yet

- Clerkship ManualDocument132 pagesClerkship ManualasdfasdfNo ratings yet

- Asme B18.6.1 1997Document12 pagesAsme B18.6.1 1997Jesse ChenNo ratings yet

- TOEFLDocument25 pagesTOEFLDiah Dwi UtamiNo ratings yet

- CBSE Class 3 Moral Science Question Paper SA 1 2010 - 2Document3 pagesCBSE Class 3 Moral Science Question Paper SA 1 2010 - 2Anonymous 9WyPyism100% (1)

- DIN 915 EN-1980 Hexagon Socket Set Screws With Dog PointDocument4 pagesDIN 915 EN-1980 Hexagon Socket Set Screws With Dog Pointthachpn100% (1)

- Metric Fasteners - DIN 985 Nylon Insert Stop Nuts - DimensionsDocument1 pageMetric Fasteners - DIN 985 Nylon Insert Stop Nuts - DimensionssnorklingmonkeyNo ratings yet

- Din 13-51Document1 pageDin 13-51anks_raNo ratings yet

- Din 439Document1 pageDin 439Oleh SmolovyiNo ratings yet

- Asme Section II A Sa-276Document10 pagesAsme Section II A Sa-276Anonymous GhPzn1xNo ratings yet

- JCB 3cx Manual TallerDocument4 pagesJCB 3cx Manual TallerCONSORCIO MEJORAMIENTO VIAL0% (2)

- Acceleration and Vibration SensorDocument28 pagesAcceleration and Vibration Sensoramirul lexNo ratings yet

- ISO-10664Document10 pagesISO-10664leandrobsousaNo ratings yet

- Din 8140-1Document5 pagesDin 8140-1main46prairieNo ratings yet

- Iso 3601 1 2008 en FR PDFDocument11 pagesIso 3601 1 2008 en FR PDFOscar Morello0% (1)

- Experiment 1Document4 pagesExperiment 1Kim Joy CoronelNo ratings yet

- Foreword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BDocument4 pagesForeword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BMarcelo KleinNo ratings yet

- ISO 2341-1986 EN 22341-1992 Clevis Pins With Head PDFDocument6 pagesISO 2341-1986 EN 22341-1992 Clevis Pins With Head PDFAddul Omman NailNo ratings yet

- GB T 1804 200Document7 pagesGB T 1804 200dreamingscientist3393No ratings yet

- Material Standard Equivalent PDFDocument5 pagesMaterial Standard Equivalent PDFpicnarukNo ratings yet

- F879MDocument6 pagesF879MmsbarretosNo ratings yet

- DIN 7349 - Arruela Plana PDFDocument1 pageDIN 7349 - Arruela Plana PDFpierocarnelociNo ratings yet

- Din 434Document1 pageDin 434RaduZapciroiuNo ratings yet

- Astm A31 (1995)Document4 pagesAstm A31 (1995)gsb2100% (1)

- Uncertainty in MeasurementDocument58 pagesUncertainty in MeasurementDijo PaulNo ratings yet

- Metric DIN 439 Spec PDFDocument4 pagesMetric DIN 439 Spec PDFHasib SejdinovicNo ratings yet

- Maryland Metrics - Fastener Technical DataDocument92 pagesMaryland Metrics - Fastener Technical Dataserzo75100% (1)

- Ipil Ipil Leaf Meal As Supplements To Soybean and Fish MealDocument6 pagesIpil Ipil Leaf Meal As Supplements To Soybean and Fish MealInternational Aquafeed magazine100% (4)

- Iso 4162 1990Document9 pagesIso 4162 1990lokesh prakashNo ratings yet

- TSH7702GDocument8 pagesTSH7702GEmir AkçayNo ratings yet

- BS en 14399-3 PDFDocument7 pagesBS en 14399-3 PDFClaudia Dutu100% (2)

- Astm A216 PDFDocument4 pagesAstm A216 PDFilliasuddinNo ratings yet

- Iso 14582 - Hexalobular Socket Countersunk Flat Head Screws, High Head PDFDocument5 pagesIso 14582 - Hexalobular Socket Countersunk Flat Head Screws, High Head PDFMitesh MakvanaNo ratings yet

- Alloy Steel Socket Button and Flat Countersunk Head Cap ScrewsDocument5 pagesAlloy Steel Socket Button and Flat Countersunk Head Cap ScrewsAhmed AbdelazizNo ratings yet

- Din 976-1 1995Document6 pagesDin 976-1 1995Charmaine DrafkeNo ratings yet

- Din 936Document2 pagesDin 936Adam GordonNo ratings yet

- High Tensile: Hexagon Head Setscrews Fine Pitch EN ISO 8676 (DIN 961)Document2 pagesHigh Tensile: Hexagon Head Setscrews Fine Pitch EN ISO 8676 (DIN 961)jaison jacobNo ratings yet

- Hexagon Socket Button Head Screw With Flange - IsO 7380-2Document9 pagesHexagon Socket Button Head Screw With Flange - IsO 7380-2Corneliu VilcuNo ratings yet

- Din 1705Document2 pagesDin 1705Anurag Jain50% (2)

- Din 6915 PDFDocument3 pagesDin 6915 PDFa.tabkhi1980100% (3)

- Wagons On StockDocument10 pagesWagons On Stockserzo75100% (1)

- ASTM A194 A194M 2022 InglesDocument3 pagesASTM A194 A194M 2022 InglesErickNo ratings yet

- Asme Section II A Sa-351 Sa-351mDocument8 pagesAsme Section II A Sa-351 Sa-351mAnonymous GhPzn1x100% (1)

- Din 580Document1 pageDin 580safaozhanNo ratings yet

- ISO 14583-01 - Hexalobular Socket Pan Head ScrewsDocument8 pagesISO 14583-01 - Hexalobular Socket Pan Head ScrewsGuillermo TorresNo ratings yet

- Metric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityDocument4 pagesMetric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityRodrigoNo ratings yet

- Din 975 PDFDocument1 pageDin 975 PDFThiago CurvoNo ratings yet

- Din 7623Document2 pagesDin 7623Racha Amel100% (1)

- Din 319Document3 pagesDin 319Horváth VivienNo ratings yet

- Nylock Nut TDocument2 pagesNylock Nut Taiyubi2No ratings yet

- Ansi B1.20.7Document24 pagesAnsi B1.20.7gxbxb100% (2)

- 14H, 22H DetailsDocument1 page14H, 22H DetailsmshNo ratings yet

- Iso Metric 32Document2 pagesIso Metric 32rahul caddNo ratings yet

- Is 1862Document4 pagesIs 1862mangesh sandavNo ratings yet

- Steel Wire For Mechanical Springs DIN: European Standard EN 10270-1: 2001 Has The Status of A DIN StandardDocument27 pagesSteel Wire For Mechanical Springs DIN: European Standard EN 10270-1: 2001 Has The Status of A DIN StandardDiego CamargoNo ratings yet

- 2370 Ed1 ENDocument5 pages2370 Ed1 ENanhthoNo ratings yet

- Asme B 446Document5 pagesAsme B 446Ramon AraujoNo ratings yet

- Astm A325Document8 pagesAstm A325Nacer KisyNo ratings yet

- Iso 10684 Hot Dip Galvanized Fasteners PDFDocument27 pagesIso 10684 Hot Dip Galvanized Fasteners PDFcilacapNo ratings yet

- Metric DIN 127 SpecDocument5 pagesMetric DIN 127 SpecmahfuzNo ratings yet

- Material Specifications Forged Products Manufactured With The Forging Rev.04Document13 pagesMaterial Specifications Forged Products Manufactured With The Forging Rev.04Emre TekinNo ratings yet

- Porca Din 439 BDocument7 pagesPorca Din 439 BFrank NunesNo ratings yet

- Standard Specification For: Designation: B574 17Document6 pagesStandard Specification For: Designation: B574 17raulNo ratings yet

- Iso 68-1 PDF - Google SearchDocument2 pagesIso 68-1 PDF - Google SearchDeniz Tuncbilek0% (1)

- ISO 4033 Class 12 NutsDocument1 pageISO 4033 Class 12 NutssubsubtwoNo ratings yet

- Metric Carriage ShortneckDocument1 pageMetric Carriage ShortneckStefan StereaNo ratings yet

- Sect 08 Rail Freight Vehicle Underframe and Body Structures Incl New As Id1Document9 pagesSect 08 Rail Freight Vehicle Underframe and Body Structures Incl New As Id1serzo75No ratings yet

- Rail Lexicon Mk24Document60 pagesRail Lexicon Mk24serzo75No ratings yet

- Annex CDocument101 pagesAnnex Cserzo75No ratings yet

- Tech List enDocument17 pagesTech List enserzo75No ratings yet

- S235J0Document1 pageS235J0serzo75No ratings yet

- Grade S275JRDocument1 pageGrade S275JRserzo75No ratings yet

- Mazalice: Mazalice I Kuglice Januar 2013Document1 pageMazalice: Mazalice I Kuglice Januar 2013serzo75No ratings yet

- Non Alloy Structural Steels S275J2 NDocument1 pageNon Alloy Structural Steels S275J2 Nserzo75No ratings yet

- Rivkle: Stainless Steel Blind Rivet Nuts Hexagonal Body, Extra-Small Countersunk Head AdvantagesDocument1 pageRivkle: Stainless Steel Blind Rivet Nuts Hexagonal Body, Extra-Small Countersunk Head Advantagesserzo75No ratings yet

- Msds - Mol Calton G 3 - GBDocument8 pagesMsds - Mol Calton G 3 - GBserzo75No ratings yet

- S355J0Document1 pageS355J0serzo75No ratings yet

- RIVKLEDocument56 pagesRIVKLEserzo75No ratings yet

- Uputstvo Central 17 23 24 28 24M 28MDocument19 pagesUputstvo Central 17 23 24 28 24M 28Mserzo75100% (1)

- Tablica-1-Celicni Livovi PDFDocument1 pageTablica-1-Celicni Livovi PDFserzo75No ratings yet

- Pojedini Tipovi VijakaDocument4 pagesPojedini Tipovi Vijakaserzo75No ratings yet

- Citroen SaxoDocument2 pagesCitroen Saxoserzo75100% (1)

- Personality: Unit B (Topic 3)Document47 pagesPersonality: Unit B (Topic 3)REHANRAJNo ratings yet

- H105RBDocument12 pagesH105RBironwilukuNo ratings yet

- PPPoE (PPP Over Ethernet)Document20 pagesPPPoE (PPP Over Ethernet)ebinVettuchirayilNo ratings yet

- 4 20 20 Personal IdentificationDocument59 pages4 20 20 Personal IdentificationMary Rose BaluranNo ratings yet

- Trends in Computer ArchitectureDocument30 pagesTrends in Computer ArchitectureDileep KarpurNo ratings yet

- 08 Chapter 2Document39 pages08 Chapter 2Anonymous qybiMQwNo ratings yet

- Auditing ObjectivesDocument12 pagesAuditing ObjectivesAjay KaundalNo ratings yet

- POLS 0825 Syllabus Fall 2019Document7 pagesPOLS 0825 Syllabus Fall 2019MilesErohsNo ratings yet

- NotesDocument3 pagesNotesRaquel Bona ViñasNo ratings yet

- 02 Simple Random SamplingDocument35 pages02 Simple Random SamplingMahesa ElfikraNo ratings yet

- This Study Resource Was: InstructionsDocument3 pagesThis Study Resource Was: InstructionsRama fauziNo ratings yet

- List of Hospitals For Udyogasri PDFDocument15 pagesList of Hospitals For Udyogasri PDFNarayana SwamyNo ratings yet

- Klinger SealexDocument2 pagesKlinger Sealexdarsh2001patelNo ratings yet

- Chem 432 Practice Exam #3 Key S18Document6 pagesChem 432 Practice Exam #3 Key S18marksteve160No ratings yet

- Ekman - Universals and Cultural Differences in The Judments of Facial Expressions of EmotionDocument7 pagesEkman - Universals and Cultural Differences in The Judments of Facial Expressions of EmotionEsteban Benjamin Droguett VizcarraNo ratings yet

- 49676-Article Text-171137-2-10-20220826Document9 pages49676-Article Text-171137-2-10-20220826Bossman TrapapaNo ratings yet

- RM Group 9 - Research PaperDocument25 pagesRM Group 9 - Research Paperakash advisorsNo ratings yet

- German Universities234wrefwerfgDocument3 pagesGerman Universities234wrefwerfgAnsat JartybayevNo ratings yet

- Autonomously. The Guide Is Divided in 4 StagesDocument14 pagesAutonomously. The Guide Is Divided in 4 StagesLESLIE LUCIA FLOREZ AVILANo ratings yet