Professional Documents

Culture Documents

Visit To S1 Site (Begaluru) From 16.12.2019 To 22.12.2019 For ENDURANCE Test On RADAR

Uploaded by

Sreekanth Nakka0 ratings0% found this document useful (0 votes)

10 views2 pagesOriginal Title

site visit report

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views2 pagesVisit To S1 Site (Begaluru) From 16.12.2019 To 22.12.2019 For ENDURANCE Test On RADAR

Uploaded by

Sreekanth NakkaCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

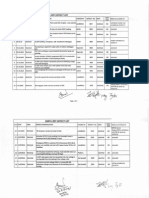

Visit to S1 site (Begaluru) from 16.12.2019 to 22.12.

2019 for ENDURANCE test on RADAR

Works Done:

1) Replaced Soft Starter for CLPU2. Tested and found the performance satisfactory

It was found Liquid Line Solenoid Valve is not getting ON.

It was rectified by arranging temporary control power supply on emergency from the

outside of CLPU2 panel (see fig. below).

(It is to be rectified by providing permanent wiring)

2) As a part of Preventive maintenance, replaced the Soft Starter of CLPU1 also

3) Since there is no load from Radar to CLPU, temporary supply given to Coolant Heaters1 and 2

to compensate the heat load on CLPU. (The temporary connection was removed after

completing the test.

WORKS TO BE DONE:

1) Compressor crank case heater wiring conduit to be replaced. It got rusted

2) Supply line pipe leakage. Necessary clamping to be provided to avoid direct load on the coupling

below the Tank.

3) Main panel door hinges got damaged completely. To be replaced immediately.

4) Permanent wiring for CLPU2 compressor start Relay

5) Main connector to be fixed to the main panel

6) 19 PIN Control connector to be replaced with new internal wiring. And to be fitted to the panel.

7) Illumination lamps to be provided in the pathway.

8) Refrigeration gauges to be provided in Suction and Discharge lines.

9)

OUR MATERIAL AT S1 SITE:

1) 5 core x 6 AWG harnessed cable – 15 mtrs length ----- 1no

2) Control cable with 19 pin Female connector- 15mtrs length ---- 1no

3) Marechal connector set (male & female) --- 1no

4) 100A MCCB ----- 1no

5) Tool kit box ( with different tools-got rusted) ------ 1no

NOTE: Communication from CLPU to PDSU is missing due to improper contact between our 19 pin male

connector & 19 pin female connector of PDSU.

Conclusion: 19 pin male connector & wiring to be changed.

You might also like

- CWPHDocument3 pagesCWPHVijay Kumar SiripurapuNo ratings yet

- Ikc2-Service Tips PDFDocument18 pagesIkc2-Service Tips PDFzoltan esteban Hrotko gonzalez100% (1)

- ES-0044 Smart Pump Repair ProcedureDocument11 pagesES-0044 Smart Pump Repair ProcedureAbdulhakim AriefNo ratings yet

- Technology 150-170-200Document12 pagesTechnology 150-170-200andtib100% (1)

- Zimbabwe Electricity Supply Authority: Internal CorrespondenceDocument3 pagesZimbabwe Electricity Supply Authority: Internal CorrespondenceArchiford NdhlovuNo ratings yet

- Failure of TRLY and TREG Card in MARK VI-OCT09pdf PDFDocument5 pagesFailure of TRLY and TREG Card in MARK VI-OCT09pdf PDFsanjeevchhabraNo ratings yet

- Instructions For EMCP IIDocument11 pagesInstructions For EMCP IIjose gregorio mata cabezaNo ratings yet

- Starting System (2Az-Fe) : InspectionDocument40 pagesStarting System (2Az-Fe) : InspectionTung Nguyen100% (1)

- GT1 GROUND FAULT RECTIFICATIONDocument9 pagesGT1 GROUND FAULT RECTIFICATIONMohamed Bin IerousNo ratings yet

- Acura 2.5TL 3.2TL (1995 - 1998) Service Manual - Part2Document200 pagesAcura 2.5TL 3.2TL (1995 - 1998) Service Manual - Part2CandieApple100% (5)

- Future Electrical Work List for 11.08.2016Document2 pagesFuture Electrical Work List for 11.08.2016Dhilip AnNo ratings yet

- Ne2180 Ne3280 PDFDocument43 pagesNe2180 Ne3280 PDFCarlos Castillo UrrunagaNo ratings yet

- KDL 32R305C PDFDocument57 pagesKDL 32R305C PDFKimberly SolanoNo ratings yet

- 11KV VCBDocument3 pages11KV VCBeagles1109No ratings yet

- DLP Panasonic Pt50dl54 Pt60dl54Document93 pagesDLP Panasonic Pt50dl54 Pt60dl54SonnyandDawn BerryNo ratings yet

- Emergency Stop - Test: TroubleshootingDocument14 pagesEmergency Stop - Test: TroubleshootingFLAVIO MARTINSNo ratings yet

- GMLAN Communication Issues, No Crank, Warning Lamps & More FixedDocument12 pagesGMLAN Communication Issues, No Crank, Warning Lamps & More Fixedأمجد راضي هادي /A1No ratings yet

- NEW TH 37lru20Document72 pagesNEW TH 37lru20fong99No ratings yet

- Monthly Report: OOS Gretha: OR Oskar Savo October 2016Document11 pagesMonthly Report: OOS Gretha: OR Oskar Savo October 2016Legend AnbuNo ratings yet

- Team Electrical VisitDocument2 pagesTeam Electrical VisitSubrata DeNo ratings yet

- Commissioning LT SwitchgearDocument13 pagesCommissioning LT Switchgearvikivarma147100% (1)

- Service Tips Chassis Cp90 110Document8 pagesService Tips Chassis Cp90 110Mircea AlexNo ratings yet

- User Manual IDC20KDocument12 pagesUser Manual IDC20KAnonymous m1cSnEavoNo ratings yet

- Bo Bien Doi Tan So - Huong Dan Su Dung 140444 030kVA 3X200V - ManualDocument39 pagesBo Bien Doi Tan So - Huong Dan Su Dung 140444 030kVA 3X200V - ManualVăn Xuân Nguyễn0% (1)

- Defects Captured During RRTDocument37 pagesDefects Captured During RRTdreamboy87No ratings yet

- TCL Series Solid State Tesla CoilDocument20 pagesTCL Series Solid State Tesla CoilNayanka SpringerNo ratings yet

- GFK2391 PDFDocument2 pagesGFK2391 PDFCarlos Aguilar MontemayorNo ratings yet

- Sa Akx18Document66 pagesSa Akx18Pedro Lopez Asalde100% (1)

- Sa-Akx18 SMDocument66 pagesSa-Akx18 SMFelipe L-m67% (3)

- Technical Handover Notes for Chief Electrical EngineerDocument23 pagesTechnical Handover Notes for Chief Electrical EngineerDimitrii MoisyeyevNo ratings yet

- Mark2 Kiigroundf Fault Ctif Tre Ficat TionDocument3 pagesMark2 Kiigroundf Fault Ctif Tre Ficat TionMohamed Bin IerousNo ratings yet

- 25pt4622Philips+L7 3A+AADocument48 pages25pt4622Philips+L7 3A+AAWall BrysonNo ratings yet

- Sa PM31P PDFDocument122 pagesSa PM31P PDFJose LuisNo ratings yet

- Furnace Replace Carrier 302075 304 Board Ig LIAF044 1Document2 pagesFurnace Replace Carrier 302075 304 Board Ig LIAF044 1topogigio240No ratings yet

- Philips Chasis l9Document58 pagesPhilips Chasis l9videosonNo ratings yet

- IND5Document14 pagesIND5ExperimentonomenNo ratings yet

- Hitachi Ras Rac-7!9!14gh4Document68 pagesHitachi Ras Rac-7!9!14gh4cristiangodeanuNo ratings yet

- EHV Circuit Breaker Flashover Case StudyDocument29 pagesEHV Circuit Breaker Flashover Case StudymarconchinNo ratings yet

- Colour Television Chassis: Electrical Diagram's en PWB's Diagram PWBDocument30 pagesColour Television Chassis: Electrical Diagram's en PWB's Diagram PWBSotiris IoannouNo ratings yet

- How To Repair Antminer APW12 Power SupplyDocument26 pagesHow To Repair Antminer APW12 Power Supplymurad asadov0% (1)

- CITIG 1500 DC Rev.00Document21 pagesCITIG 1500 DC Rev.00jewel1969No ratings yet

- Sony KDL-40R485A Chassis ITC2Document70 pagesSony KDL-40R485A Chassis ITC2Nico50% (4)

- AMX 4+ Error - ListDocument18 pagesAMX 4+ Error - Listmasroork_293% (15)

- Sa Ak250plDocument102 pagesSa Ak250plOmar Antonio Marrugo EspitiaNo ratings yet

- Orissa Power Gen. Co. Ltd. 2 X 660 MW (Unit #3 & 4) Ib Thermal Power Station, BanharpaliDocument6 pagesOrissa Power Gen. Co. Ltd. 2 X 660 MW (Unit #3 & 4) Ib Thermal Power Station, BanharpaliSantoshkumar GuptaNo ratings yet

- Rmu Comment SheetDocument4 pagesRmu Comment SheetDesign and Estimation DepartmentNo ratings yet

- QRP Labs Ultimate 3S QCU Rev 3 Kit - Assembly ManualDocument22 pagesQRP Labs Ultimate 3S QCU Rev 3 Kit - Assembly ManualjohnNo ratings yet

- Paper B-E-3-2 With AnswersDocument6 pagesPaper B-E-3-2 With AnswersvidyasagNo ratings yet

- CAN Data Link (RENR5059)Document3 pagesCAN Data Link (RENR5059)PramodNo ratings yet

- Presentation - Merlin Gerin Sb6-72 Sf6 CB Failures - FinalDocument18 pagesPresentation - Merlin Gerin Sb6-72 Sf6 CB Failures - Finalfpinto69No ratings yet

- Pipeline Engineering: Type 2 Flange Mounted Signaller Installation, Operation & Maintenance ManualDocument5 pagesPipeline Engineering: Type 2 Flange Mounted Signaller Installation, Operation & Maintenance ManualEudaldo Jose Saavedra LopezNo ratings yet

- PandarosDocument9 pagesPandarosTempest_LNo ratings yet

- TM 11-5805-239-35 - Power - Supply - PP-1209 - 1966 PDFDocument27 pagesTM 11-5805-239-35 - Power - Supply - PP-1209 - 1966 PDFWurzel1946No ratings yet

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- MS3450W32-63P Amphenol Aerospace - Mouser IndiaDocument5 pagesMS3450W32-63P Amphenol Aerospace - Mouser IndiaSreekanth NakkaNo ratings yet

- MS3456W32-63S Amphenol Aerospace - Mouser IndiaDocument6 pagesMS3456W32-63S Amphenol Aerospace - Mouser IndiaSreekanth NakkaNo ratings yet

- Phoenix Contact 0790491 en Compressor Terminal BlockDocument29 pagesPhoenix Contact 0790491 en Compressor Terminal BlockSreekanth NakkaNo ratings yet

- 2CCS863001R0634 s803s c63Document4 pages2CCS863001R0634 s803s c63Sreekanth NakkaNo ratings yet

- 2CSM401043R0811-Ts-40!12!24-c Compressor 230v To 24VAc TransformerDocument3 pages2CSM401043R0811-Ts-40!12!24-c Compressor 230v To 24VAc TransformerSreekanth NakkaNo ratings yet

- Phoenix Contact 3212138 enDocument48 pagesPhoenix Contact 3212138 enSreekanth NakkaNo ratings yet

- 1SFA898106R7000 pstx60 600 70Document4 pages1SFA898106R7000 pstx60 600 70Sreekanth NakkaNo ratings yet

- S201M-C1 Miniature Circuit Breaker - 1P - C - 1 A: Product-DetailsDocument5 pagesS201M-C1 Miniature Circuit Breaker - 1P - C - 1 A: Product-DetailsrosmawanNo ratings yet

- Phoenix Contact 3212120 enDocument59 pagesPhoenix Contact 3212120 enSreekanth NakkaNo ratings yet

- 2CCS800900R0011 s800 AuxDocument3 pages2CCS800900R0011 s800 AuxSreekanth NakkaNo ratings yet

- Copeland-Stream-Series (Considered Compressor Part Number)Document77 pagesCopeland-Stream-Series (Considered Compressor Part Number)Sreekanth NakkaNo ratings yet

- Tropical Explosure TestDocument3 pagesTropical Explosure TestSreekanth NakkaNo ratings yet

- Copeland-Stream-Series (Considered Compressor Part Number)Document77 pagesCopeland-Stream-Series (Considered Compressor Part Number)Sreekanth NakkaNo ratings yet

- Stream User-ManualDocument36 pagesStream User-ManualSreekanth NakkaNo ratings yet

- Digital Inputs: DI524-1 (32 Input Module) : Description of Input Type Remarks Digital Input No. Short NameDocument13 pagesDigital Inputs: DI524-1 (32 Input Module) : Description of Input Type Remarks Digital Input No. Short NameSreekanth NakkaNo ratings yet

- LLSC-Internal WiringDocument17 pagesLLSC-Internal WiringSreekanth NakkaNo ratings yet

- Example Ac500 Ha Cs3Document93 pagesExample Ac500 Ha Cs3Sreekanth NakkaNo ratings yet