Professional Documents

Culture Documents

Astm A 664

Uploaded by

talhadikenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm A 664

Uploaded by

talhadikenCopyright:

Available Formats

Designation: A 664 – 06e1

Standard Practice for

Identification of Standard Electrical Steel Grades in ASTM

Specifications1

This standard is issued under the fixed designation A 664; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e1 NOTE—The values statement (1.3) was corrected editorially in September 2006.

1. Scope A 340 Terminology of Symbols and Definitions Relating to

1.1 This practice covers the procedure for designating Magnetic Testing

(within ASTM specifications) standard grades of flat-rolled A 677 Specification for Nonoriented Electrical Steel Fully

electrical steels made to specified maximum values of core Processed Types

loss. This practice applies to magnetically soft irons and steel A 683 Specification for Nonoriented Electrical Steel, Semi-

(low-carbon steels and alloys of iron with silicon, aluminum, processed Types

and so forth) where a core loss measurement at a stated peak A 726 Specification for Cold-Rolled Magnetic Lamination

--`,,```,,,,````-`-`,,`,,`,`,,`---

value of alternating induction and a stated frequency, such as Quality Steel, Semiprocessed Types

15 kG (1.5 T) and 60 Hz, is normally used to grade the A 840/A 840M Specification for Fully Processed Magnetic

material. This practice also applies when some other property Lamination Steel

is specified (or a different induction or frequency, or both) as A 876 Specification for Flat-Rolled, Grain-Oriented,

the limiting characteristic, provided the material also meets all Silicon-Iron, Electrical Steel, Fully Processed Types

the requirements of the ASTM specification. A 976 Classification of Insulating Coatings for Electrical

1.2 Individual specifications that are in conformity with this Steels by Composition, Relative Insulating Ability and

practice are Specifications A 677, A 683, A 726, A 840/ Application

A 840M, and A 876.

3. Terminology

1.3 The values stated in customary (cgs-emu and inch-

pound) units are to be regarded as standard. The values given 3.1 The terms and symbols used in this practice are defined

in parentheses are mathematical conversions to SI units which in Terminology A 340.

are provided for information only and are not considered 4. Procedure

standard.

1.4 This standard does not purport to address all of the 4.1 General Requirements of the Core-Loss-Type

safety concerns, if any, associated with its use. It is the Designations—The core-loss-type designations to be used for

responsibility of the user of this standard to establish appro- ordering purposes and for identification of the shipped material

priate safety and health practices and determine the applica- in ASTM specifications for electrical steels shall be a six-

bility of regulatory limitations prior to use. character identification (for example, 36F145) comprised of

the following basic elements:

2. Referenced Documents 4.1.1 First Two Digits—The first two digits of the grade

2.1 ASTM Standards: 2 designation shall represent the nominal decimal thickness of

the material in millimetres. For instance, the number 36

represents a thickness of 0.36 mm or 0.014 in. Refer to

1

This practice is under the jurisdiction of ASTM Committee A06 on Magnetic Appendix X1 for the relationship between Electrical Sheet

Properties and is the direct responsibility of Subcommittee A06.02 on Material Gauge Number and thickness.

Specifications.

Current edition approved May 1, 2006. Published May 2006. Originally

4.1.2 Code Letters—A code letter shall designate the gen-

approved in 1972. Last previous edition approved in 1999 as A 664 – 99. eral category of magnetic material and the standard sampling

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or and testing practices that apply. The precise conditions of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM sampling and testing are given in the ASTM specification

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. covering each class of material. The code letter to be used and

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International 1

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

A 664 – 06e1

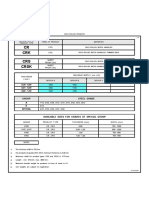

TABLE 1 Code Letters and Sampling and Testing Conditions

Code Letter ASTM Specification Class of Material and Core-Loss Testing Conditions

C A 840/A 840M Magnetic lamination steel, fully processed, with core-loss value determined at

15 kG (1.5 T) and 60 Hz on as-sheared Epstein specimens.A

D A 726 Magnetic lamination steel, semiprocessed, with core-loss value determined at

15 kG (1.5 T) and 60 Hz on Epstein specimensA after a quality development

anneal at 1450°F (790°C) with a 1-h soak period.

F A 677 Nonoriented electrical steel, fully processed, with core-loss value determined at

15 kG (1.5 T) and 60 Hz on as-sheared Epstein specimens.A

S A 683 Nonoriented electrical steel, semiprocessed, with core-loss value determined at

15 kG (1.5 T) and 60 Hz on Epstein specimensA after a quality development

anneal at 1550°F (845°C) with a 1-h soak period, except that the temperature

shall be 1450°F (790°C) for alloy contents less than 1.3 % silicon plus aluminum.

G A 876 Grain-oriented electrical steel, fully processed, with core-loss value determined

at 15 kG (1.5 T) and 60 Hz on Epstein specimensB stress-relief annealed usually

in the range from 1450 to 1550°F (790 to 845°C) with a 1-h soak period.

H A 876 Grain-oriented electrical steel, fully processed, with core-loss value determined

at 17 kG (1.7 T) and 60 Hz on Epstein specimensB stress-relief annealed usually

in the range from 1450 to 1550°F (790 to 845°C) with a 1-h soak period.

P A 876 Grain-oriented electrical steel, fully processed, high permeability, with core-loss

value determined at 17 kG (1.7 T) and 60 Hz on Epstein specimens,B stress-

relief annealed usually in the range from 1450 to 1550°F (790 to 845°C) with a

1-h soak period. Relative peak permeability at 10 Oe (796 A/m) typically exceeds

1880.

Q A 876 Grain-oriented electrical steel, fully processed, high permeability, laser scribed,

with core-loss value determined at 17 kG (1.7 T) and 60 Hz on an as-sheared

sheet-type test specimen. Relative peak permeability at 10 Oe (796 A/m)

typically exceeds 1880.

A

Test specimen with one half of the strips cut parallel to the rolling direction and the other half cut perpendicular to the rolling direction.

B

Test specimen with all strips cut parallel to the rolling direction.

the sampling and testing conditions associated with that letter fully processed, in a thickness of 0.35 mm with a maximum

shall be as in Table 1. core loss of 0.66 W/lb measured at 15 kG (1.5 T) and 60 Hz on

4.1.3 Last Digits—The last three digits of the grade desig- Epstein specimens with all strips cut parallel to the rolling

nation shall represent the maximum permissible core loss in direction, stress-relief annealed at 1450 to 1550°F (790 to

watts per pound for the test conditions indicated by the code 845°C) with a 1-h soak period.

letter. For instance, the 145 designation on a standard ASTM 5.2 The ASTM grade designations for electrical steel shall

specification used in conjunction with the Code Letter F be assigned only by ASTM. They shall apply only when an

represents 1.45 W/lb for the maximum value of core loss ASTM specification incorporating that grade designation has

determined at 15 kG (1.5 T) and 60 Hz on an as-sheared become effective through the normal standardizing activities of

Epstein specimen consisting of one half of the strips cut the Society. The ASTM grade designations shall be used to

parallel to the rolling direction and the other half cut perpen- identify electrical steel grades only when the material so

dicular to the rolled direction. identified complies with the requirements of the ASTM speci-

5. Use of Standard Electrical Steel Grade Designations fication of which the grade designation is a part.

5.1 The standard grade designation, formulated as described

6. Keywords

herein, shall be used together with the appropriate ASTM

specification to designate specifically the desired material. For 6.1 core loss; electrical steel; fully processed; grain-oriented

instance, a material designated ASTM Specification A 876 electrical steel; identification; laser scribed; magnetic lamina-

Type 35G066, would signify grain-oriented electrical steel, tion steel; nonoriented electrical steel; semiprocessed

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright ASTM International 2

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

A 664 – 06e1

APPENDIXES

(Nonmandatory Information)

X1. ELECTRICAL SHEET GAUGE NUMBERS

X1.1 Table X1.1 shows the relationship between Electrical TABLE X1.1 Electrical Sheet Gauge Number

Sheet Gauge Numbers and thickness. This is for information Electrical Sheet Thickness

only. Gauge Number in. mm

16 0.0625 1.59

17 0.0560 1.42

18 0.0500 1.27

19 0.0453 1.15

20 0.0375 0.952

21 0.0340 0.864

22 0.0310 0.787

23 0.0280 0.711

24 0.0250 0.635

25 0.0220 0.559

26 0.0185 0.470

27 0.0170 0.432

28 0.0155 0.394

29 0.0140 0.356

30 0.0125 0.318

31 0.0100 0.254

X2. USE OF INSULATING COATINGS DESIGNATION

X2.1 In the interest of promoting computerized databases, combination is correct since not all coatings are applicable to

the electrical steel designation contained in this practice can be a given grade of steel. Since Classification A 976 is not a

combined with the coatings designation listed in Classification specification, it is not appropriate at this time to specify

A 976 to form an identifying alphanumeric field. The user insulating coating behavior.

should consult with the steel producer to verify that the

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

--`,,```,,,,````-`-`,,`,,`,`,,`---

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

Copyright ASTM International 3

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

You might also like

- Astm A753Document6 pagesAstm A753Cristian Otivo100% (1)

- Astm A876-2003Document6 pagesAstm A876-200313564250125No ratings yet

- Astm A 683Document5 pagesAstm A 683talhadikenNo ratings yet

- Nonoriented Electrical Steel Fully Processed Types: Standard Specification ForDocument6 pagesNonoriented Electrical Steel Fully Processed Types: Standard Specification Forbenjaminverduzco4No ratings yet

- Flat-Rolled, Grain-Oriented, Silicon-Iron, Electrical Steel, Fully Processed TypesDocument6 pagesFlat-Rolled, Grain-Oriented, Silicon-Iron, Electrical Steel, Fully Processed TypesEduardoNo ratings yet

- ASTM A876 12 Standard SPC For Flat Rolled Grain Oriented Silicon Iron Elelctrical Steel PDFDocument6 pagesASTM A876 12 Standard SPC For Flat Rolled Grain Oriented Silicon Iron Elelctrical Steel PDFSilverio AcuñaNo ratings yet

- Din en Iso 9015 1 PDFDocument4 pagesDin en Iso 9015 1 PDFMarcos Verissimo Juca de PaulaNo ratings yet

- Cold-Rolled Magnetic Lamination Quality Steel, Semiprocessed TypesDocument7 pagesCold-Rolled Magnetic Lamination Quality Steel, Semiprocessed Typesist93993No ratings yet

- A 407 Â " 93 R04 QTQWNWDocument3 pagesA 407 Â " 93 R04 QTQWNWEduardo CortesNo ratings yet

- A867 PDFDocument4 pagesA867 PDFsaltbathNo ratings yet

- Nonoriented Electrical Steel, Semiprocessed Types (Metric) : Standard Specification ForDocument5 pagesNonoriented Electrical Steel, Semiprocessed Types (Metric) : Standard Specification ForProduction DepartmentNo ratings yet

- Cold-Rolled Magnetic Lamination Quality Steel, Semiprocessed TypesDocument5 pagesCold-Rolled Magnetic Lamination Quality Steel, Semiprocessed TypessamehNo ratings yet

- Astm A890 - A890m - 12Document4 pagesAstm A890 - A890m - 12Nguyen Duc Thanh (EVPC)No ratings yet

- Flat-Rolled, Grain-Oriented, Silicon-Iron, Electrical Steel, Fully Processed TypesDocument6 pagesFlat-Rolled, Grain-Oriented, Silicon-Iron, Electrical Steel, Fully Processed TypesSamir ShaikhNo ratings yet

- Martensitic Stainless Steel Bars For High-Temperature ServiceDocument4 pagesMartensitic Stainless Steel Bars For High-Temperature ServiceTatan FirmansyahNo ratings yet

- Amorphous Magnetic Core Alloys, Semi-Processed Types: Standard Specification ForDocument4 pagesAmorphous Magnetic Core Alloys, Semi-Processed Types: Standard Specification ForKeven MontgemryNo ratings yet

- F 836M - 02 - RJGZNK0Document7 pagesF 836M - 02 - RJGZNK0krutikNo ratings yet

- Astm A510Document7 pagesAstm A510Alejandro GutierrezNo ratings yet

- Steel Wire, High-Carbon Spring, For Heat-Treated ComponentsDocument3 pagesSteel Wire, High-Carbon Spring, For Heat-Treated ComponentsOMEGA CONSULTANTNo ratings yet

- Castings, Iron-Nickel-Chromium and Nickel Alloys, Specially Controlled For Pressure Retaining Parts For Corrosive ServiceDocument6 pagesCastings, Iron-Nickel-Chromium and Nickel Alloys, Specially Controlled For Pressure Retaining Parts For Corrosive ServiceOdyzeus PingolNo ratings yet

- Norma Astm A1007Document9 pagesNorma Astm A1007Alfredo RangelNo ratings yet

- Astm A 401 - A 401M - 03 - Qtqwms9bndaxtqDocument4 pagesAstm A 401 - A 401M - 03 - Qtqwms9bndaxtqEjat IS100% (1)

- Wrought Nickel-Iron Soft Magnetic Alloys (UNS K94490, K94840, N14076, N14080)Document6 pagesWrought Nickel-Iron Soft Magnetic Alloys (UNS K94490, K94840, N14076, N14080)Tomy lee youngNo ratings yet

- ASTM A886-02 Standard Specification For Steel Strand, Indented, Seven-Wire Stress Relieved For Prestressed ConcreteDocument5 pagesASTM A886-02 Standard Specification For Steel Strand, Indented, Seven-Wire Stress Relieved For Prestressed Concretebenedick barquinNo ratings yet

- Flex Gabion Standard ASTM A975-97Document7 pagesFlex Gabion Standard ASTM A975-97Moh Ragil SodikinNo ratings yet

- Astm A 653Document13 pagesAstm A 653Anonymous LQdcbfAEYNNo ratings yet

- Astm A510mDocument7 pagesAstm A510mÖZGÜRNo ratings yet

- Astm 653Document13 pagesAstm 653Alejandro Garza100% (1)

- ASTM A580 2006 Standard Specification For Stainless Steel WireDocument5 pagesASTM A580 2006 Standard Specification For Stainless Steel WireEidrish Shaikh100% (2)

- ASTM A976-2003 - Insulating Coating StandardDocument4 pagesASTM A976-2003 - Insulating Coating StandardBobby PoonNo ratings yet

- Astm 325MDocument8 pagesAstm 325MCPA BTKNo ratings yet

- A653.1501849-1 - Hot Dipped Steel GalvanizationDocument13 pagesA653.1501849-1 - Hot Dipped Steel Galvanizationsubhaschandranath1No ratings yet

- ASTM A 488-01 Standard Practice For Steel Castings, Welding, Qualifications of Procedures and PersonnelDocument18 pagesASTM A 488-01 Standard Practice For Steel Castings, Welding, Qualifications of Procedures and PersonnelAlex VillegasNo ratings yet

- Astm A240Document11 pagesAstm A240Thuc Quyen TranNo ratings yet

- A732 PDFDocument6 pagesA732 PDFMiguel TovarNo ratings yet

- General Requirements For Wire Rods and Coarse Round Wire, Carbon Steel (Metric)Document6 pagesGeneral Requirements For Wire Rods and Coarse Round Wire, Carbon Steel (Metric)Jesús Luis Arce GuillermoNo ratings yet

- Astm A 407-07Document3 pagesAstm A 407-07Ramsi Ankzi100% (1)

- F 879M - 02 - Rjg3ou0Document6 pagesF 879M - 02 - Rjg3ou0krutikNo ratings yet

- ASTM A682 2002 Standard Specification For Steel Strip High Carbon Cold Rolled General Requirements PDFDocument8 pagesASTM A682 2002 Standard Specification For Steel Strip High Carbon Cold Rolled General Requirements PDFNooruddin SadruddinNo ratings yet

- Astm A653 15 PDFDocument13 pagesAstm A653 15 PDFDaniel Vasquez100% (2)

- Astm A801 A801m 99Document2 pagesAstm A801 A801m 99SHANKARNo ratings yet

- Stainless Steel Wire: Standard Specification ForDocument4 pagesStainless Steel Wire: Standard Specification Forhailander castañeda martinezNo ratings yet

- A 976 - 13 PDFDocument5 pagesA 976 - 13 PDFflpNo ratings yet

- Astm A653a 653M 1Document1 pageAstm A653a 653M 1Barbado BlancoNo ratings yet

- A510MDocument7 pagesA510MIlka RaffaelliNo ratings yet

- Specification For High-Temperature Bolting Materials With Expansion Coefficients Comparable To Austenitic SteelsDocument10 pagesSpecification For High-Temperature Bolting Materials With Expansion Coefficients Comparable To Austenitic SteelsJay GaneshNo ratings yet

- A 568A 568M Steel, Sheet, Carbon, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, General RequirementsforDocument28 pagesA 568A 568M Steel, Sheet, Carbon, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, General RequirementsforleandroschroederNo ratings yet

- Astm A510 6 PDFDocument7 pagesAstm A510 6 PDFNafiou KamelNo ratings yet

- Carbon and Alloy Nuts (Metric) : Standard ForDocument8 pagesCarbon and Alloy Nuts (Metric) : Standard Forpramod wattamwarNo ratings yet

- Flat-Rolled, Grain-Oriented, Silicon-Iron, Electrical Steel, Fully Processed TypesDocument5 pagesFlat-Rolled, Grain-Oriented, Silicon-Iron, Electrical Steel, Fully Processed TypesProduction DepartmentNo ratings yet

- A345 PDFDocument4 pagesA345 PDFaxis inspection solutionsNo ratings yet

- Norma Astm A-123 InglesDocument8 pagesNorma Astm A-123 InglesMarilu' CrNo ratings yet

- Astm A407Document3 pagesAstm A407AlbertoNo ratings yet

- Astm A 653 PDFDocument9 pagesAstm A 653 PDFAdán Vera GoNo ratings yet

- Astm 358Document7 pagesAstm 358Willy SastraleksanaNo ratings yet

- A325m 14 PDFDocument8 pagesA325m 14 PDFAquino0% (1)

- Astm A743 PDFDocument6 pagesAstm A743 PDFzafarbadal100% (2)

- Chromium, Chromium-Nickel, and Silicon Alloy Steel Bars and Shapes For Corrosion and Heat-Resisting ServiceDocument2 pagesChromium, Chromium-Nickel, and Silicon Alloy Steel Bars and Shapes For Corrosion and Heat-Resisting ServiceProduction DepartmentNo ratings yet

- ASTM A194 NutsDocument13 pagesASTM A194 NutsDan ClarkeNo ratings yet

- Standart No Document Name Kabul TarihiDocument1 pageStandart No Document Name Kabul TarihitalhadikenNo ratings yet

- Astm A 681Document14 pagesAstm A 681talhadikenNo ratings yet

- CR CRK CRS CRSK: Group Steel GradeDocument6 pagesCR CRK CRS CRSK: Group Steel GradetalhadikenNo ratings yet

- Astm A677Document6 pagesAstm A677EduardoNo ratings yet

- Astm A 659Document3 pagesAstm A 659talhadikenNo ratings yet

- Üretim Akış Şeması Ve Nihai Ürünler IngDocument8 pagesÜretim Akış Şeması Ve Nihai Ürünler IngtalhadikenNo ratings yet

- ASTM A387 Pressure Vessel Plates Material - Alloy Steel Cr-MoDocument6 pagesASTM A387 Pressure Vessel Plates Material - Alloy Steel Cr-Monse mcxNo ratings yet

- Abs EuropeDocument3 pagesAbs EuropetalhadikenNo ratings yet

- Organ Izasyo N Standart No Document Name Kabul TarihiDocument4 pagesOrgan Izasyo N Standart No Document Name Kabul TarihitalhadikenNo ratings yet

- ASTM A 435 A 435M 1990 (Reapproved 2007)Document2 pagesASTM A 435 A 435M 1990 (Reapproved 2007)Paulo MoroNo ratings yet

- A 530 - A 530M - 02 Qtuzmc0wmgDocument8 pagesA 530 - A 530M - 02 Qtuzmc0wmgtalhadikenNo ratings yet

- Astm A283Document2 pagesAstm A283Kevin ChurchillNo ratings yet

- Catalog Metals Solid WebDocument212 pagesCatalog Metals Solid WebtalhadikenNo ratings yet

- İngilizce Dilbilgisi - Yusuf Buz PDFDocument544 pagesİngilizce Dilbilgisi - Yusuf Buz PDFGokhan BaranNo ratings yet

- UntitledDocument1 pageUntitledtalhadikenNo ratings yet

- Electronics Repair ManualDocument957 pagesElectronics Repair Manuallfloryn96% (27)

- Computer Science Project FileDocument21 pagesComputer Science Project FileVidya SajitNo ratings yet

- OptiSystem 7.0 Release NotesDocument3 pagesOptiSystem 7.0 Release NotesRonald SaavedraNo ratings yet

- SCAP Workshop Coursebook v2Document42 pagesSCAP Workshop Coursebook v2davodmNo ratings yet

- E Waste Recyclers in GurgaonDocument2 pagesE Waste Recyclers in Gurgaonewaste gurgaonNo ratings yet

- 3 - Basics of Electronic CircuitsDocument23 pages3 - Basics of Electronic CircuitsAlisNo ratings yet

- Gardner Denver Rotary Screw Compressors: History, Stability, & DependabilityDocument4 pagesGardner Denver Rotary Screw Compressors: History, Stability, & DependabilitySpark ElectricNo ratings yet

- Thesis Final Ch. 1-3Document50 pagesThesis Final Ch. 1-3Gjenerrick Carlo Mateo100% (1)

- ProjectGenerator V1 4Document80 pagesProjectGenerator V1 4Hasan SAYINNo ratings yet

- Air Separators - How To Size (B&G)Document2 pagesAir Separators - How To Size (B&G)Ben SyNo ratings yet

- Azure Fundamentals Path (May 2019)Document1 pageAzure Fundamentals Path (May 2019)AmitPatilNo ratings yet

- Mobility-Online: User Guide For Degree StudentsDocument7 pagesMobility-Online: User Guide For Degree StudentsNurdin HefniNo ratings yet

- Abb GCDocument105 pagesAbb GCMarthen TangkeNo ratings yet

- GY-HM250SP SPORTS PRODUCTION STREAMING CAMCORDER ManualDocument200 pagesGY-HM250SP SPORTS PRODUCTION STREAMING CAMCORDER ManualAnonymous 84ArHkK6d100% (1)

- 9852 1007 01d Maintenance Instr COP 1840HE, HEXDocument19 pages9852 1007 01d Maintenance Instr COP 1840HE, HEXButnariu CristianNo ratings yet

- ST315A Kiln Temperature ControllerDocument2 pagesST315A Kiln Temperature ControllerDave WalkerNo ratings yet

- PLC Exercises PDFDocument28 pagesPLC Exercises PDFzoulouweNo ratings yet

- FMEA Tree DiagramDocument2 pagesFMEA Tree DiagramJosephNo ratings yet

- Nate Holt's Blog On Electrical CAD, Etc enDocument51 pagesNate Holt's Blog On Electrical CAD, Etc enMario FriscoNo ratings yet

- Iffco Application FormDocument2 pagesIffco Application FormNur SkNo ratings yet

- SD310 User Manual DraftDocument53 pagesSD310 User Manual DraftErick HidalgoNo ratings yet

- Assembly Language Programming 16 31Document16 pagesAssembly Language Programming 16 31RupalNo ratings yet

- Student Handbook - Tech Course IDocument4 pagesStudent Handbook - Tech Course I5129 SRI RAM SNo ratings yet

- IRIS EN Sports Long Audio Transcription Project: Platform Introduction ForDocument10 pagesIRIS EN Sports Long Audio Transcription Project: Platform Introduction ForRaihan UmranNo ratings yet

- BillDocument5 pagesBillnewo arcegaNo ratings yet

- Quality Engineer Control Manager Manufacturing-CVDocument7 pagesQuality Engineer Control Manager Manufacturing-CVabdulyunus_amirNo ratings yet

- Job Description: Data Architect / Data Modeler Requisition ID: 15001465Document11 pagesJob Description: Data Architect / Data Modeler Requisition ID: 15001465Simon BoyoNo ratings yet

- Internship ReportDocument69 pagesInternship ReportAnn WeissNo ratings yet

- Midea Mdf3 20den3Document14 pagesMidea Mdf3 20den3Vladimir StakićNo ratings yet

- Certificate: of ConformityDocument3 pagesCertificate: of ConformityGerson SouzaNo ratings yet

- Digital Content Manager Version 21.00 Installation GuideDocument48 pagesDigital Content Manager Version 21.00 Installation Guideandlee74No ratings yet