Professional Documents

Culture Documents

Introduction to LOPA: A Risk Assessment Method

Uploaded by

Adam MaulanaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Introduction to LOPA: A Risk Assessment Method

Uploaded by

Adam MaulanaCopyright:

Available Formats

1

Introduction to LOPA

Muhammad Raihan Syah Iman S.T, B. Eng (Hons)

PT Lebah Solusi Indonesia (LebSolution), Komplek Ruko Golden Madrid 2, Blok I-22, Banten 15310, Indonesia

+62-812-8488-7575; muhammad.iman@lebsolution.com

Wednesday, 11 May 2022

Introduction 1. Consequence Identification and Scenario

D

Screening

uring my time studying chemical engineering,

2. Scenario Selection

my exposure to the process safety industry has

3. Initiating Event Identification and Frequency

been limited to class room discussion on major

Determination

industrial accidents with extensive investigations and

4. IPL Identification and Determining Probability

media coverage. Bhopal, Piper Alpha, Buncefield, and

of Failure on Demand

Odessa are all too familiar for professionals and

5. Risk Estimation

budding engineers alike. While this has proven to be an

6. Evaluation of Risk and Decision Making

excellent approach to engaging students and inspiring

engineers such as myself, it lacks in teaching students

Step 1: Identify the consequence to screen the

about the wide range risk assessment methods

scenarios

corporations use to prevent such incidents in the first

place! LOPA begins with screening scenarios that has been

developed in a prior study, such as a HAZOP study.

As such, I would like to provide a short introduction to

These scenarios are often screened based on their

one of the many methods process safety engineers use

evaluated consequences.

to ensure that the risks imposed on us, our environment,

and our assets are kept within tolerable levels. In this Several approaches can be taken in this evaluation to

article we will discuss one such method of risk provide a semi-quantifiable result; including release

assessment, known as the Layer of Protection Analysis size/characterization, simplified injury/fatality

or LOPA. estimates, simplified injury/fatality estimates with

adjustments, or detailed injury/fatality estimates. In any

What is a LOPA? case, the method used for consequence characterization

Layer of Protection Analysis (LOPA) is a simplified should be consistent with the company’s risk

form of risk assessment that uses order of magnitude assessment methodology and risk tolerance criteria.

categories for initiating event frequencies, consequence

Step 2: Select an accident scenario

severity, and likelihood of failure of independent

protection layers (IPLs) to approximate the risk of a A scenario is defined as an unplanned event or sequence

scenario. The primary purpose of which is to determine of events that results in an undesirable consequence.

whether or not sufficient layers of protection against a Each scenario consists of at least 2 elements; the

particular scenario have been implemented. The initiating event and a consequence.

analysis builds upon information developed during a Scenario = Initiating Event + Consequence

qualitative hazard evaluation; such as a Process Hazard

Analysis (PHA), on a single cause-consequence pair Although, in addition, it may also include enabling

basis. The resulting risk estimation can be extended to events or conditions, failure of safeguards, probability

assist in making risk judgements on how much of ignition, and/or probability of human presence in the

additional risk reduction measures may be required to affected area.

reach a tolerable level of risk. In general, the LOPA

process can be broken down into 6 steps (CCPS, 2001);

2022 PT Lebah Solusi Indonesia

2

Step 3: Identify the initiating event of the This value is written in order of magnitude, e.g.

scenario and determine the initiating event 10-1, 10-2, and so on. The smaller the value, the less

frequency likely it is for the scenario to occur.

LOPA is limited to a single initiating event for each

Step 6: Evaluate the risk to reach a decision

scenario. The frequency of the initiating event is

concerning the scenario

commonly expressed in events per year, but can also be

expressed as events per 106 hours or failure per 103 Generally risk management decisions can be

demand. Acquisition of IEF from an established and categorized as either the management of risk with the

well-maintained database of the company subjected to existing systems at its current tolerable level, mitigation

the LOPA is favourable as the data better reflects actual of the risk to a tolerable level, or abandoning the risk

conditions and experiences. However, the frequency (avoid the risk entirely by altering the design and/or

data can also be obtained from varying sources operation mode) due to it being too high. The

including industry data in the Guidelines for Initiating application of a LOPA allows for a quantifiable

Events and Independent Protection Layers in Layer of comparison of the existing risk with a pre-determined

Protection Analysis (CCPS, 2015), Guidelines for risk tolerance criteria and for cost-benefit analysis of

Process Equipment Reliability Data (CCPS, 1989), and competing options of safeguards should a risk be

many more. deemed intolerable.

Step 4: Identify IPLs and estimate the Summary

probability of failure on demand of each IPL A Layer of Protection Analysis or LOPA is a form of

A safeguard is a device, system, or action that is capable risk assessment used by corporations to provide a

of preventing a scenario from proceeding to its reproducible assessment of the risk imposed by a given

undesired consequence and/or reduce the severity of its scenario based on estimations of the likelihood for the

consequences. In the context of a LOPA only preventive initiating event to occur and the probability that of the

safeguards are taken into account, as the desired independent layers of protection will fail.

outcome is an evaluation of the likelihood of a scenario The resulting value can then be used to assess whether

and how the safeguard affects it and not how it mitigates additional layers of protection are required to reduce the

the consequences. This safeguard is considered an risk to a tolerable level.

Independent Protection Layer (IPL) when it is

independent of the initiating event or the action of any References

other layer of protection associated with the scenario. 1. CCPS, 1989. Guidelines for Process Equpment

Remember: All IPLs are safeguards but not all Reliability Data. New York: AIChE.

safeguards are IPLs!

2. CCPS, 2001. Layer of Protection Analysis:

The effectiveness of an IPL is quantified in terms of its Simplified Process Risk Assessment. New

probability of failure on demand (PFD). The smaller the York: AIChE.

value of the PFD, the larger the reduction in frequency

3. CCPS, 2015. Guidelines for Initiating Events

of the consequence for a given initiating event.

and Independent Protection Layers in Layer of

Step 5: Estimate the risk of the scenario by Protection Analysis. New York: Wiley.

mathematically combining the consequence,

initiating event and IPL data

The risk and frequency of a given scenario can be

quantified by multiplying the initiating event frequency

with the multiplication product of all the existing IPL’s

PFD. This value can be expanded upon by incorporating

the probability of ignition (flammable release),

probability of human presence in the affected area,

and/or probability of injury.

2022 PT Lebah Solusi Indonesia

You might also like

- Layer of Protection AnalysisDocument23 pagesLayer of Protection AnalysisAnurag BajpaiNo ratings yet

- Opcion 9Document5 pagesOpcion 9LAURA LUC�A ATENCIA CASTILLONo ratings yet

- Using Layers of Protection Analysis To Evaluate Fire and Gas SystemsDocument6 pagesUsing Layers of Protection Analysis To Evaluate Fire and Gas SystemsStevenNo ratings yet

- NMISHRAG AppendicesDocument48 pagesNMISHRAG Appendicesapi-3733731No ratings yet

- Journal of Loss Prevention in The Process Industries: Paul BaybuttDocument9 pagesJournal of Loss Prevention in The Process Industries: Paul BaybuttEfari BahchevanNo ratings yet

- McaDocument9 pagesMcaamit singhNo ratings yet

- Layers of Protection AnalysisDocument5 pagesLayers of Protection AnalysisInstrumentation ToolsNo ratings yet

- Layer of Protection AnalysisDocument6 pagesLayer of Protection AnalysismkkNo ratings yet

- Safety Integrity Level For Issues Methodologies: ProcessesDocument6 pagesSafety Integrity Level For Issues Methodologies: ProcessesjackrzysNo ratings yet

- Process of Identifying and Analyzing Potential Issues That Could Negatively Impact Key Business Initiatives or ProjectsDocument47 pagesProcess of Identifying and Analyzing Potential Issues That Could Negatively Impact Key Business Initiatives or ProjectsRolie EsclamadoNo ratings yet

- LOPA CCPS Short NotesDocument7 pagesLOPA CCPS Short NotesFarhan AhmedNo ratings yet

- Borrador Paper Stochastic Fuzzy LOPA 2Document19 pagesBorrador Paper Stochastic Fuzzy LOPA 2Ennio PicenoNo ratings yet

- A Method for Barrier-Based Incident Investigation Links Facility Risk AssessmentsDocument15 pagesA Method for Barrier-Based Incident Investigation Links Facility Risk AssessmentsMoroko69No ratings yet

- Intelie Ebook Dra 2022Document15 pagesIntelie Ebook Dra 2022Mariana BoninaNo ratings yet

- Layer of Protection Analysis Effectivetool in PHA PDFDocument13 pagesLayer of Protection Analysis Effectivetool in PHA PDFkenoly123No ratings yet

- 4 Hazard and Risk Controls: 4.1 The Hazard Control ProcessDocument7 pages4 Hazard and Risk Controls: 4.1 The Hazard Control ProcessSultan Al-SaiariNo ratings yet

- Introduction To Layer of Protection Analysis: KeywordsDocument6 pagesIntroduction To Layer of Protection Analysis: KeywordsAquiles_voyNo ratings yet

- Layer of Protection AnalysisDocument6 pagesLayer of Protection Analysishmatora72_905124701No ratings yet

- Selection of Hazard Evaluation Techniques in Oil & Gas and Petrochemical Industries For Risk AssessmentDocument8 pagesSelection of Hazard Evaluation Techniques in Oil & Gas and Petrochemical Industries For Risk AssessmentMohammad NadimNo ratings yet

- HP LOPA A Comprehensive Analytical ToolDocument6 pagesHP LOPA A Comprehensive Analytical Toolaegean227No ratings yet

- Addressing Enablers in LOPADocument14 pagesAddressing Enablers in LOPAluneallanNo ratings yet

- Three Knights Presents Risk-Based InspectionDocument20 pagesThree Knights Presents Risk-Based InspectionAMLO45No ratings yet

- Credible Accident ScenariosDocument9 pagesCredible Accident Scenariosbaaziz2015No ratings yet

- Impacts of Process Safety Time on Layer of Protection Analysis (LOPADocument6 pagesImpacts of Process Safety Time on Layer of Protection Analysis (LOPATukang Nasgor100% (1)

- Risk Assessment Techniques (IEC 31010Document9 pagesRisk Assessment Techniques (IEC 31010kanchana rameshNo ratings yet

- Faq Layers of Protection Analysis (Lopa)Document6 pagesFaq Layers of Protection Analysis (Lopa)OSIIQPGRISNo ratings yet

- AeSolutions Risk Criteria Selection and The Impacts On LOPA ResultsDocument13 pagesAeSolutions Risk Criteria Selection and The Impacts On LOPA ResultsAnonymous bHh1L1No ratings yet

- Risk Assessment Third Dimension 1Document27 pagesRisk Assessment Third Dimension 1geosherif72No ratings yet

- System Safety Process StepsDocument3 pagesSystem Safety Process Stepsmazen_229No ratings yet

- 4.2 BRA PROCEDURE WITH METHODOLOGYDocument4 pages4.2 BRA PROCEDURE WITH METHODOLOGYaceNo ratings yet

- Nirma University Study Comparing PHA TechniquesDocument6 pagesNirma University Study Comparing PHA TechniquesDHAVALESH AMNo ratings yet

- Iec 61508Document14 pagesIec 61508Pandhu DewantoNo ratings yet

- SHM - Practical 12 - Risk Assessment MethodsDocument8 pagesSHM - Practical 12 - Risk Assessment MethodsBhaliya AadityaNo ratings yet

- Risk AnalysisDocument8 pagesRisk AnalysisFatma HelalNo ratings yet

- 1 s2.0 S0925753522002570 MainDocument14 pages1 s2.0 S0925753522002570 MainneckitoNo ratings yet

- Consistent Consequence Severity Estimation: Keywords: LOPA, Risk Analysis, Consequence, QuantitativeDocument15 pagesConsistent Consequence Severity Estimation: Keywords: LOPA, Risk Analysis, Consequence, Quantitativeyasir543No ratings yet

- How to perform LOPA analysis for process safetyDocument5 pagesHow to perform LOPA analysis for process safetykumar_chemical100% (1)

- Ch-7 - Risk AnalysisDocument32 pagesCh-7 - Risk AnalysisDebayanbasu.juNo ratings yet

- Hazards and Risks Assessment MethodsDocument20 pagesHazards and Risks Assessment Methodsapi-3733731100% (8)

- Risk Tolerance Criteria and The IEC 61511/ISA 84 Standard On Safety Instrumented SystemsDocument4 pagesRisk Tolerance Criteria and The IEC 61511/ISA 84 Standard On Safety Instrumented SystemsjackrzysNo ratings yet

- Process Safety Capability Studies PDFDocument51 pagesProcess Safety Capability Studies PDFmaurya888No ratings yet

- Experiences Using Risk Graph & LOPADocument6 pagesExperiences Using Risk Graph & LOPASonco Suwa100% (2)

- Use Maximum-Credible Accident Scenarios For Realistic and Reliable Risk AssessmentDocument9 pagesUse Maximum-Credible Accident Scenarios For Realistic and Reliable Risk AssessmentArman MohammadiNo ratings yet

- 2 Unit 5 - Security - Risk ManagementDocument16 pages2 Unit 5 - Security - Risk ManagementGayathri DhanaNo ratings yet

- Introduction To LOPADocument3 pagesIntroduction To LOPAchayan83No ratings yet

- Risk Assessment Methodology To Support Shutdown Plant DecisionDocument9 pagesRisk Assessment Methodology To Support Shutdown Plant DecisionDiovinyl KartilNo ratings yet

- RISK MANAGEMENT AssignmentDocument9 pagesRISK MANAGEMENT AssignmentANNIE NACHEMBENo ratings yet

- Guidance On Human Factor Critical Task AnalysisDocument8 pagesGuidance On Human Factor Critical Task Analysisjiaolei9848No ratings yet

- Health & Safety Lectures: Risk AssessmentDocument25 pagesHealth & Safety Lectures: Risk Assessmenteladio30No ratings yet

- Simplified Risk Analysis (LOPA)Document8 pagesSimplified Risk Analysis (LOPA)hmatora72_905124701No ratings yet

- Lopa SilDocument10 pagesLopa Silkhali54No ratings yet

- A New Approach For Information Security Risk Assessment: Value at RiskDocument10 pagesA New Approach For Information Security Risk Assessment: Value at RiskFilipe Felix-LingNo ratings yet

- Proactive Safety ArticleDocument6 pagesProactive Safety ArticleLUIS ALEJANDRO CUERVO GALVISNo ratings yet

- Reliability Engineering and System Safety: Chu Guanquan, Wang JinhuiDocument9 pagesReliability Engineering and System Safety: Chu Guanquan, Wang JinhuiVanco AdziskiNo ratings yet

- CompTIA CASP+ Certification The Ultimate Study Guide To Master the Advanced Security Practitioner ExamFrom EverandCompTIA CASP+ Certification The Ultimate Study Guide To Master the Advanced Security Practitioner ExamNo ratings yet

- Security Leader Insights for Business Continuity: Lessons and Strategies from Leading Security ProfessionalsFrom EverandSecurity Leader Insights for Business Continuity: Lessons and Strategies from Leading Security ProfessionalsNo ratings yet

- CompTIA CySA+ Certification The Ultimate Study Guide to Practice Questions With Answers and Master the Cybersecurity Analyst ExamFrom EverandCompTIA CySA+ Certification The Ultimate Study Guide to Practice Questions With Answers and Master the Cybersecurity Analyst ExamNo ratings yet

- Aircraft System Safety: Assessments for Initial Airworthiness CertificationFrom EverandAircraft System Safety: Assessments for Initial Airworthiness CertificationNo ratings yet

- Reliability and Probabilistic Safety Assessment in Multi-Unit Nuclear Power PlantsFrom EverandReliability and Probabilistic Safety Assessment in Multi-Unit Nuclear Power PlantsRating: 5 out of 5 stars5/5 (1)

- FAQs of Retail ManagementDocument3 pagesFAQs of Retail Managementtanishque patraNo ratings yet

- RB NotesDocument35 pagesRB NotesmyokhinewinNo ratings yet

- Best Safety Practices in The Philippine Construction PDFDocument16 pagesBest Safety Practices in The Philippine Construction PDFDione Klarisse GuevaraNo ratings yet

- Unlimited FundingDocument46 pagesUnlimited FundingObrienFinancial88% (8)

- Chapter 2 - Analyzing External Environment: Minglana, Mitch T. BSA 201Document2 pagesChapter 2 - Analyzing External Environment: Minglana, Mitch T. BSA 201Mitch Tokong MinglanaNo ratings yet

- Car Rental Business PlanDocument12 pagesCar Rental Business Plansemuty9250% (2)

- Disadvantages of Online ShoppingDocument3 pagesDisadvantages of Online ShoppingVineet tiwariNo ratings yet

- K08340 - Managing Risk - How To Use A Process Classification FrameworkDocument4 pagesK08340 - Managing Risk - How To Use A Process Classification FrameworkR ALSHEHRINo ratings yet

- Facilities Layout Design and Facilities LocationDocument8 pagesFacilities Layout Design and Facilities LocationBunty EvolNo ratings yet

- CA. Ranjay Mishra (FCA)Document14 pagesCA. Ranjay Mishra (FCA)ZamanNo ratings yet

- Inova Corporate Brochure WEBDocument15 pagesInova Corporate Brochure WEBDang Tran HoangNo ratings yet

- HRM Project (Pak Suzuki Motors)Document25 pagesHRM Project (Pak Suzuki Motors)Shaam Ul Haq83% (6)

- Information Security ManagerDocument2 pagesInformation Security Managermirrayhan08No ratings yet

- Catálogo HombreDocument50 pagesCatálogo Hombrediana isabelNo ratings yet

- Subramanyam Chapter07Document34 pagesSubramanyam Chapter07Saras Ina Pramesti100% (2)

- Class 12th Accountancy NotesDocument9 pagesClass 12th Accountancy Notesadarshkumar12040% (1)

- Sop 1Document3 pagesSop 1elnionlineNo ratings yet

- 03 - Analyzing The Marketing EnvironmentDocument38 pages03 - Analyzing The Marketing EnvironmentMuskaan RathiNo ratings yet

- LebronDocument5 pagesLebronRobert oumaNo ratings yet

- SAP Procurement CertificationDocument6 pagesSAP Procurement CertificationFerhanMalik0% (1)

- BIM For Civil and Structural Engineers: Tom Bartley, Senior Engineer, WSPDocument15 pagesBIM For Civil and Structural Engineers: Tom Bartley, Senior Engineer, WSPMartinNo ratings yet

- Steps in Selling Process PDFDocument12 pagesSteps in Selling Process PDFWaseem Raja MallahNo ratings yet

- Data Migration GuideDocument7 pagesData Migration GuideMax GxNo ratings yet

- Nepal Taxation Guide 2018 - 20180801041445 - 20181126030832Document25 pagesNepal Taxation Guide 2018 - 20180801041445 - 20181126030832its4krishna3776No ratings yet

- Quality ManagementDocument17 pagesQuality ManagementAnkit SahniNo ratings yet

- Skill Development, Theories of Learning, Technology IntelligenceDocument7 pagesSkill Development, Theories of Learning, Technology IntelligencePankajNo ratings yet

- Level II 2020 IFT Mock Exam SampleDocument12 pagesLevel II 2020 IFT Mock Exam SampleRuda Thales Lins MeirelesNo ratings yet

- Agile Vs. Lean: What's the DifferenceDocument2 pagesAgile Vs. Lean: What's the DifferenceEd Phénix le PrinceNo ratings yet

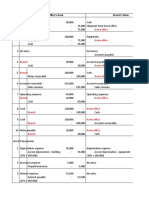

- Home Office and Branch financial records combinedDocument16 pagesHome Office and Branch financial records combinedNatalia ErvinaNo ratings yet

- Preference Over ELSS V/s Other Section 80C Investment OptionsDocument53 pagesPreference Over ELSS V/s Other Section 80C Investment OptionsKrina N DwivediNo ratings yet