Professional Documents

Culture Documents

Patente 2 - 11-05-22

Patente 2 - 11-05-22

Uploaded by

Alejandro Hurtado0 ratings0% found this document useful (0 votes)

8 views7 pagesThis document describes a method for purifying and recovering neutral and alkaline protease enzymes using cationic sulfonated phenol-formaldehyde resin. Protease is selectively adsorbed to the resin while undesirable colored materials and any amylase present are not adsorbed. Neutral protease can be recovered separately or together with alkaline protease using different elution conditions. The method provides a simple way to obtain protease free of contaminants like pigments, while also allowing for fractionation of the different protease types.

Original Description:

Original Title

Patente 2 __ 11-05-22

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document describes a method for purifying and recovering neutral and alkaline protease enzymes using cationic sulfonated phenol-formaldehyde resin. Protease is selectively adsorbed to the resin while undesirable colored materials and any amylase present are not adsorbed. Neutral protease can be recovered separately or together with alkaline protease using different elution conditions. The method provides a simple way to obtain protease free of contaminants like pigments, while also allowing for fractionation of the different protease types.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views7 pagesPatente 2 - 11-05-22

Patente 2 - 11-05-22

Uploaded by

Alejandro HurtadoThis document describes a method for purifying and recovering neutral and alkaline protease enzymes using cationic sulfonated phenol-formaldehyde resin. Protease is selectively adsorbed to the resin while undesirable colored materials and any amylase present are not adsorbed. Neutral protease can be recovered separately or together with alkaline protease using different elution conditions. The method provides a simple way to obtain protease free of contaminants like pigments, while also allowing for fractionation of the different protease types.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

United States Patent Office 3,592,738

Patented July 13, 1971

2

Okunuki, Hagihara and Ukita, U.S. Pat. 2,952,856, in

3,592,738 attempting to solve this problem with relation to protease

PURFICATION AND RECOVERY OF NEUTRAL produced by Bacillus subtilis microorganisms, found that

AND ALKALINE PROTEASE USING CATIONC adsorption-elution using Duolite C-10, a highly coarse

SULFONATED PHENOL-FORMALDEHYDE RESN 5 porous phenolic polymer having methylene sulfonic acid

Leonard Keay, Florissant, Mo., assignor to Monsanto

Company, St. Louis, Mo. groups or side chains (otherwise referred to as a Sulfo

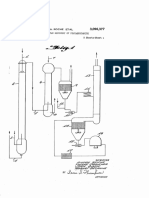

No Drawing. Filed Aug. 14, 1968, Ser. No. 752,462 nated phenol-formaldehyde resin, having omega-sulfonic

Int, C. C07g 7/02 acid groups) in the Na+ form was a satisfactory way of

U.S. C. 195-66R 13 Claims purifying and isolating protease material produced by var

O ious B. subtilis microorganisms. However, this adsorption

elution process of Okunuki et al., although not clear from

ABSTRACT OF THE DISCLOSURE the above-cited patent, was of value only in the isolation of

Aqueous solution of protease, e.g., a clarified beer from alkaline protease, as is manifest from the publication of

B. subtilis microorganism production of enzymes or redis Hagihara, Okunuki et al. appearing in J. Biochem (Tokyo)

solved enzyme mixture, is treated with sulfonated phenol 45, 185 (1958), on pages 192-193. In addition the authors

formaldehyde cationic exchange resin to eliminate unde report that the resin adsorbed a fairly large quantity of

sirable colored materials and any amylase present. Pro colored impurities, melanine-like substances having a

tease is adsorbed; amylase and most pigmented impurities dark brown color and that amylase was also partially

are not. Neutral protease can be recovered or alkaline pro adsorbed and it is clear from the said paper that purifica

tease can be recovered; both can be recovered together or 20 tion problems arose, especially toward the end of the

with fractionation when both are present. Use of neutral elution when these pigments stated to elute. Crystalliza

pH solutions for elution eliminates pigment elution prob tion of eluted protease from these pigmented solutions

lems, and use of low ionic strength solutions in prepara gave pigmented crystals from which color could not be

tion of resin and for adsorption allows recovery of maxi removed even upon repeated recrystallization. Therefore,

mum range of proteases. Fractionation is effected by use of 25 an improved process would be highly desirable, which did

moderate ionic strength solution for elution of neutral pro not suffer from the disadvantage of color contamination

tease and higher ionic strength solution for alkaline pro during the elution process. In addition, it would be highly

tease. Where fractionation is not required, elution may be desirable to have available a process of adsorption-elution

with high ionic strength solution. whereby either neutral or alkaline protease, or both to

30 gether or each individually if both are present, could be

procured substantially free from colored impurities and if

BACKGROUND OF INVENTION

desired also free from amylase, when also present in the

starting enzyme material.

(1) Field of invention It is well known that various enzymes have various dif

Enzymes; purification and isolation of protease and frac ferent activities or capacities. Protease is effective in the

tionation when both alkaline and neutral protease are digestion of protein material by hydrolysis or bond-split

present. ting activity, neutral protease being active at substantially

neutral pH's whereas alkaline protease is active at more

(2) Prior art alkaline pH's. When in combination, enzymes are fre

Production of protease and protease-containing enzyme 40 quently subject to disgestion or endogenous deterioration.

mixtures by Bacillus subtilis microorganisms is known. For this reason, and also because it is highly desirable to

When such enzyme mixtures contain amylase and colored have specific enzymes available for use in various specific

impurities in addition to protease, separation and purifica applications, the desirability of having the individual en

tion is difficult. Highly pigmented materials from the fer zymes, as well as efficient methods for the purification and

mentation are usually present, and such colored impurities separation of enzyme mixtures into their individual com

and amylase are difficulty separated from the desired pro ponents, is readily apparent.

tease. Commercial enzyme mixture products produced and SUMMARY OF THE INVENTION

sold according to U.S. Pat. 3,031,380 are undesirably The present invention involves treatment of a water

highly colored. The prior art, as represented by the cited 50 clear solution containing enzyme, e.g., protease or mix

patent, in the absence of more satisfactory procedure, has tures thereof, for example, a beer filtrate or aqueous solu

employed an aqueous beer filtrate for isolation, with salt tion of redissolved enzyme solids, with a sulfonated phe

ing out of enzymes by (NH4)2SO4 (ammonium sulfate), nol-formaldehyde cationic exchange resin, thereby to

filtration, discard of the filtrate, redissolution of the filtra Selectively adsorb the protease with substantial freedom

tion residue in water, reconversion to an (NH4)2SO4 solu from undesired coloring matter which remains in solution,

tion, raising the pH with ammonium hydroxide to precipi or on the resin upon elution with the observance of cer

tate amylase, filtration removal of amylase, and finally tain critical conditions. The process moreover permits

addition of further (NH4)2SO4 to precipitate protease by facile removal of color bodies from the protease, adsorp

downward adjustment of pH and isolation of the same. tion of both neutral and alkaline protease, and separation

The individual enzymes then require further purification 60 of the protease with fractionation, if desired, by adhering

by dissolution in water, alkamine ion-exchanging to re to critical parameters during adsorption and elution, and

move Some pigment, and alcohol precipitation. It is appar is a Striking and unpredictable advance in the art.

ent that this is not a simple procedure and its effectiveness It has now been found that the conditions employed

leaves much to be desired, especially since protease and by Okunuki et al. can be employed to adsorb protease

amylase fractions are still cross-contaminated. 65 and pigment on the said resin, but that by eluting under

A simple method of purification by employment of an different conditions, namely, by employing neutral pH

ion exchange resin, whereby colored impurities could be Solutions, e.g., having a pH of about 6-8, preferably

removed from the desired protease, along with other unde about 6.5-7.5, such as NaCl solutions, a much cleaner

sired contaminants, such as amylase, and which would be protease product is obtained with no pigment or dis

applicable directly to a water-clear fermentation beer or 70 coloration problems such as encountered by Okunuki

Solution

desirable.

of redissolved enzyme solids, would be highly et al. using an alkaline buffer eluant. This result can be

obtained even when using a solution of the same ionic

3,592,738

3 4.

strength and pH as employed by Okunuki et al. for the parent from an inspection of the procedures employed

adsorption step. and the details of the conditions of adsorption and elution

It has further been found that, when different condi involved. Okunuki et al. prepare their resin using a buffer

tions are also employed for the adsorption step, namely, of 0.3 Normality at a pH of 6-8. To obtain adsorption.

a lower ionic strength during the adsorption and also of neutral protease and alkaline protease, the present

employment of a low ionic strength solution in prepa applicant employs much lower levels of ionic strength,

ration of the resin, neutral protease alone, alkaline pro up to about 0.05 M molar, for example 0.005 molar, or

tease alone, both neutral and alkaline protease together, even plain water.

or neutral and alkaline protease separately by fractiona Okunuki et al. prepare their resin in the same buffer

tion, can be readily obtained by the adsorption-elution IO as used for adsorption whereas, preferably after neutrali

process, depending upon the composition of the starting zation to a pH of about 7, the present applicant gen

solution initially contacted with the resin, the exact prod erally washes his resin with water to remove salts, or

uct of the elution depending upon conditions employed with 0.1% calcium acetate solution for enzyme stabili

for the elution. zation (quite in contrast with the much higher ionic

Thus, instead of using an alkaline eluting agent of strength equilibration of Okunuki et al.), especially in

Okunuki et al., but rather employing an eluting solution the case where both alkaline and neutral protease are to

having a neutral, e.g., about pH 6-8, preferably about be adsorbed before proceeding with adsorption.

pH 6.5-7.5, the following results can be obtained: Then, and most importantly, Okunuki et al. elute with

If either neutral or alkaline protease is present alone, a buffer of 0.5-0.7 Normality, employing a pH of 9-11

a high ionic strength solution can be used for the elution for their eluting solution, which comprises 0.1 M am

and will elute whichever protease is present. monium hydroxide, 0.1 M disodium phosphate, and 0.5

When both neutral and alkaline protease are present M sodium chloride, all employed together.

and it is unnecessary to fractionate them, then an eluting Again in contrast, the present applicant elutes with a

solution having a high ionic strength may be used to relatively neutral pH solution, usually a solution of high

elute both proteases from the resin at once. 25 ionic strength, i.e., above about 0.2 M, e.g., a 1 M NaCl

When both neutral and alkaline protease are present solution, to remove both neutral protease and alkaline

and it is desired to isolate them separately, they may be protease together, but without the pigmentation problem

fractionally eluted from the column by first employing experienced by Okunuki et al. when they elute with their

an eluting solution of moderate ionic strength, resulting stronger buffer solution at a higher pH. Alternatively, the

in elution of the neutral protease, followed by an eluting 30 present applicant selectively elutes the neutral protease

solution of high ionic strength, thereby eluting alkaline with a weaker solution, of more moderate ionic strength,

protease substantially free from neutral protease. for example 0.05–0.2 M, e.g., a 0.1 M phosphate buffer

When the terms "moderate ionic strength' and "high and then can, if desired, elute the alkaline protease with

ionic strength' are employed, they are respectively in a solution of higher ionic strength, for example, above

tended to describe a solution having a molarity (1) be 35 about 0.2 M and usually up to about 1 M, e.g., 1 M. NaCl,

tween about 0.05 and 0.2, and (2) greater than 0.2, but always using a relatively neutral pH solution for the

usually up to about 1.0. elution.

Thus, by in any event employing different eluting con The ionic strength of the solution from which ad

ditions than Okunuki et al., a greatly improved purifi Sorption is effected obviously plays a major role in the

cation can be effected at the elution stage. By employing 40 unpredictable adsorption phenomena, according to the

different conditions for the adsorption stage and also findings of the present invention, as well as the pH and

in preparation of the resin for the adsorption step, to ionic strength of the solution employed in the unpre

gether with varying the ionic strength of the solution dictably selective elution of the present invention.

employed for elution, which to repeat is always effected Thus, in summary, it has now been found, unpredict

with a relatively neutral pH solution rather than with the ably, that protease selectively adsorbed on a sulfonated

strongly alkaline eluting agent of Okunuki et al., the phenolformaldehyde resin can be conveniently and selec

procurement of neutral protease in addition to alkaline tively eluted therefrom free of pigment and most other

protease is rendered entirely feasible, as well as fractiona undesirable impurities, using a substantially neutral

tion of the neutral from the alkaline protease, if desired. eluant. If neutral protease is present in the starting en

The unpredictability of the effects which will be ob Zyme Solution from which adsorption is effected, neutral

tained by changing conditions in the adsorption-elution protease can also be adsorbed by using low ionic strengths

art, especially relating to enzymes, is already established, and, again by using a substantially neutral eluant and by

and is well-stated in the Okunuki et al., U.S. Patent varying the concentration of eluting solution, both pro

2,952,586, column 2, lines 19 through 44. teases can be eluted either together or separately, if both

The results of the process of the present invention are 55 are present, in any case substantially free of amylase and

therefore entirely unpredictable, first, that a cleaner highly pigmented impurities.

alkaline protease product can be obtained without pig

mentation problems by employing neutral conditions for OBJECTS

the elution, and moreover that neutral protease can also The provision of a process having any or all of the

be obtained as well as fractionation between neutral and 60 above-enumerated advantages is an object of the inven

alkaline protease by varying both the conditions of the tion. Additional objects will become apparent hereinafter,

adsorption (and also preparation of the resin) as to ionic and still others will be obvious to one skilled in the art.

strength of the solution in addition to the ionic strength

of the solution employed in the elution step, although GENERAL DESCRIPTION OF THE INVENTION

maintaining the relatively neutral pH conditions during The starting material for the process of the present in

the elution, as previously indicated. vention is a Water-clear fermentation beer, as obtained by

In addition, amylase is removed as a contaminant by filtration or centrifugation, or an aqueous extract of the

the present adsorption-elution procedure, since it is not enzyme or enzyme mixture. The latter is obtained by re

adsorbed to any substantial extent under the conditions dissolving a crude Solid precipitated enzyme or enzyme

employed according to the invention and can be washed mixture, as may be obtained by precipitation of the en

out, as with water or extremely low ionic strength solu Zyme-containing solids from a clarified fermentation beer

tions, so as not to contaminate subsequent protease using an excess of water-miscible organic solvent in which

fractions. the enzyme is insoluble, with further clarification if neces

The distinctions between the process of the present Sary. The solvent employed for such precipitation is pref

invention and that of Okunuki et al. are immediately ap 5 erably a polar Solvent selected from the group consisting

3,592,788

5 6

of lower-alkanols, e.g., isopropanol, lower-alkyl ketones, If it is desired to wash the adsorbent, after protease

e.g., acetone, and cyclic ethers, e.g., tetrahydrofuran has been adsorbed thereon, for further removal of un

and dioxane. Isopropyl alcohol and acetone are preferred desired impurities, whether in column form or otherwise,

solvents. Hereinafter the starting material will some Water, aqueous organic Solvent, e.g., acetone solutions,

times be referred to as the "solution.' In either case, 5 or a dilute solution of a soluble calcium salt, for ex

the starting material should be a water-clear fluid, which ample an about 0.02% solution of a calcium salt, pref

will ordinarily not contain solids visible to the naked eye, erably calcium acetate, may advantageously be employed.

hence the designation "water-clear.” The invention can Such solutions as are employed for washing of the column

also be applied to any other water-clear aqueous solution containing the adsorbed protease should be at or about

of protease together with undesirable colored impurities, O a neutral pH and of low ionic strength such that protease

whether of natural or synthetic origin. is not eluted. Elution of the protease from the column

The first essential step in the process of the invention, may then be effected employing a solution of somewhat

as already stated, is the selective adsorption of protease, greater ionic strength, also at or about neutral pH, as

including both neutral and alkaline protease, if desired, further disclosed in detail hereinafter.

as produced by fermentation culture of a protease-pro The Second essential step in the process involves elu

ducing strain of B. subtilis, employing a sulfonated tion of the adsorbed protease. Elution of protease from

phenol-formaldehyde cation exchange resin as the ad the resin is effected by means of an eluting solution

sorbent. The protease is adsorbed and subsequently comprising an aqueous buffer, at an ionic strength greater

eluted, whereas the colored impurities are unadsorbed or, than about 0.05 M but below the point where crystalliza

to the extent adsorbed, uneluted under the conditions of 20 tion of the buffer occurs. Advantageously, aqueous buffer

the elution. of ionic strength greater than 0.2 M is employed. Usually

According to the invention, if amylase is also present a solution of up to about 1.0 M is employed when no

in the starting solution, this is not adsorbed or, to the ex fractionation of protease is involved. However, when

tent adsorbed, not eluted under the conditions of the both neutral and alkaline protease are present, and frac

elution. The pigment which is adsorbed to a certain ex tionation is desired, use of moderate ionic strength (0.05

tent, even though considerable may be removed earlier 0.2 M) to elute the neutral protease, followed by a

in the overall process as by adsorption using DEAE Solution of high ionic strength (greater than 0.2 M, usu

Cellulose or other anion exchange agent, is definitely not ally up to about 1.0 M) to elute alkaline protease is

eluted under the conditions of the elution. If amylase is mandatory. For this purpose, 0.1 M phosphate buffer

removed at an earlier stage of the total process, then it 30 followed by a 1.0 M sodium chloride solution have been

does not enter into the adsorption-elution step at all. found optimum, although other solutions of moderate

Sulfonated phenol-formaldehyde cation exchange and high ionic strengths may be used instead. These may

resins are readily available commercially. They may be follow washing with water in case amylase is present,

used according to the invention in a batch, continuous, or if it is desired to eliminate any adsorbed amylase prior

column process, or in similar manner, according to the 35 to the protease elution. In any event, however, the elu

established art of adsorption-elution and chromatography. tion is with a relatively neutral pH solution, one having

The resin, e.g., column, may advantageously be adjusted a pH of about 6-8, and preferably about 6.5-7.5, to

to a neutral pH and washed with water or dilute calcium avoid contamination with highly colored impurities. The

acetate solution, e.g., 0.1% aqueous solution, or with a elution pH may frequently advantageously be slightly

very dilute buffer, e.g., the adsorbing solution, prior to 40 higher than that employed during adsorption.

adsorption therewith. Precipitation of the protease from the eluted fractions

The protease is adsorbed onto the resin by bringing it may be effected using solid ammonium sulfate or other

into contact therewith, in the form of an aqueous Solu Suitable precipitant, e.g., sodium sulfate or, if phosphate

tion thereof. The conditions of the adsorption may be buffer is used as the eluting agent, the eluted protease

those of the prior art when adsorption of alkaline pro Solution may be further treated with a calcium salt, for

tease alone is of interest, but where neutral protease is example, calcium acetate, in an amount up to about 2%

present and is to be adsorbed as well as alkaline protease, by weight, in such case with adjustment of pH slightly

the solution should have a low ionic strength, below upwardly to about 7.5 to produce a precipitate of calcium

about 0.05 molarity, to enable adsorption of the neutral phosphate, which may then be removed by physical means

as well as the alkaline protease on the resin. The pH Such as filtration or centrifugation. Dialysis of the pro

should preferably be between about 6 and 8, and advan 50 tease-containing supernatant, recentrifugation or filtra

tageously about 6-7.5, especially where neutral protease tion, and lyophilization further increases the purity of

is present and its adsorption is desired. The pH of the the protease or proteases, as will be apparent.

starting enzyme-containing solution will usually be be Although cooling to any temperature below room tem

tween about 5.5 and 7, preferably 6 to 6.5, and thus the perature has been found advantageous, it is desirable that,

desired starting pH range is readily obtainable if not a for best results, both the eluting solution and the starting

normal pH range for the starting enzyme-containing enzyme-containing solution be chilled to 10 centigrade

solution. or below, and about 5 centigrade has been found an

The solution may be stabilized by the addition of extremely useful, attainable, and operative temperature

calcium acetate or other suitable soluble calcium salt, for carrying out the method of the invention. If the

for example, the gluconate, the chloride, or the like. 60 eluting and adsorbing solutions are not cooled, as pre

Preferably the stabilizing amount of calcium Salt is up viously described, less satisfactory purification, separa

to about 0.2%, and the preferred form is an about 0.1% tions, and yields of desired protease fractions are obtained.

calcium acetate aqueous solution. Such solutions are When operating in the foregoing manner, recoveries

readily obtained by redissolving the solid obtained by of colorless protease are usually between fifty and sixty

solvent precipitation of the enzyme or enzyme mixture, 65 percent of the protease adsorbed by the resin, and fre

and filtering or centrifuging the resulting solution, or by quently as high as 70% or even greater percentages of

directly filtering or centrifuging the fermentation beer, the protease originally adsorbed on the resin. The process

and adding the necessary buffer or salt to the concentra of the invention allows a clear, efficient fractionation of

tion desired. neutral from alkaline protease in a simple and convenient

The adsorption is preferably conducted employing a 70 manner, if desired, and gives a colorless protease product

solution containing up to about 2.5% of dissolved solids, which is additionally purified of other impurities and

preferably about 1% of dissolved solids, or an enzyme pigments which are not adsorbed, or not eluted, the final

level not greater than about 50,000 enzyme units per purity and composition of the protease product depending

milliliter as determined by the Anson variation of the upon the additional steps employed at an earlier stage

well-known Kunitz casein digestion method. in the overall process, as already stated.

3,592,738

7 8

Thus, the neutral protease produced by a protease DESCRIPTION OF THE PREFERRED

producing strain of Bacillus subtilis, for example B. subtilis EMBODIMENTS

strain AM, can be isolated essentially free of alkaline The following examples are given by way of illustra

protease, or vice versa, or together, and in any case, tion only, and are not to be construed as limiting.

free of amylase and pigment-free, from a starting Source 5

of clarified fermentation beer or redissolved crude Solids General outline of preparation of fermentation beer

precipitated from a fermentation beer by solvent addi A culture of Bacillus subtilis AM is inoculated into

tion, depending upon the exact conditions employed dur a sterile slurry of grains and other nutrient material (such

ing adsorption of the protease and subsequent elution as rice bran, corn meal, fish meal, wheat bran, Enzose

from the resin. () TM-about 50-80% dextrose and the balance higher

Starting enzyme-containing beers can be obtained saccharides, being the dried mother liquor remaining

from microorganism fermentation, e.g., production of from dextrose manufacture by enzymatic hydrolysis of

enzymes by bacteria, using well-known fermentation corn starch), distillers solubles, corn steep liquor, etc.)

methods such as those generally described in Kirk containing protein, carbohydrate, minerals, and growth

Othmer, Encyclopedia of Chemical Technology, 8, factors. The vessel is agitated and aerated by bubbling

173-204. sterile air through the inoculated slurry. The pH may be

The exact activity of the enzymes employed as start controlled or left to achieve its own natural pH. Aliquots

ing material depends on the method of preparation and of the beer are removed for assay at various times and,

is not critical to the present invention providing only when enzyme production is apparently a maximum, the

that the starting solution has the desired protease activity. fermentation beer is then centrifuged and/or filtered

Various analytical methods are available to determine prior to enzyme isolation.

the activity of enzymatically active material, for exam Some details and examples of this type of enzyme

ple, the protease activity of proteolytic enzymes can be production method are given generally in U.S. Patents

determined by well-known casein digestion methods. 2,530,210 of C. V. Smythe, B. B. Drake and C. E.

According to such tests, a protease catalyzes the hy 25 Neubeck (to Rohm & Haas Company, Nov. 14, 1950),

drolysis of casein for a certain period of time and tem and 2,549,465 of J. C. Hoogerheide and E. G. Laughery

perature and at a certain pH, the reaction is stopped by (to Pabst Brewing Company), Apr. 17, 1951) and par

the addition of trichloroacetic acid, and the Solution is ticularly in U.S. Patent 3,031,380 of Apr. 24, 1962.

filtered. The color of the filtrate is developed by Folin The foregoing procedure, especially that of U.S. Patent

phenol reagent, and the level of enzyme activity is meas 30 3,031,380, is productive of a fermentation beer contain

ured spectrophotometrically in units of casein tyrosine. ing the desired enzyme mixture. For clarification pur

This method is more fully described in the Journal of poses to give a water-clear beer for use as starting ma

General Physiology, 30, 291 (1947) and in Methods of terial, this fermentation beer may merely be centrifuged

Enzymology, 2, 33 by Academic Press N.Y. (1955). and/or filtered. Alternatively, the solid enzyme mixture

Amylase activity is generally determined by the Well may be precipitated by adding an excess of Solvent, e.g.,

known dinitrosalicylic acid method of Bernfeld. isopropanol or acetone, to the fermentation beer either

A particularly effective source of mixed enzymes which without prior filtration or centrifugation or after a prior

can be used as starting material in the present invention centrifugation and/or filtration, which is productive of

is a mutated Bacillus subtilis organims. The process for a solid precipitate comprising an enzyme mixture, which

producing this organism and enzymes therefrom is de 40 may then be readily redissolved in water to give a water

scribed in U.S. Patent 3,031,380. A culture of this clear enzyme solution which may be used as starting

Bacilius subtilis (strain AM) organism has been de material in the process of the invention. Obviously, the

posited with the United States Department of Agricul starting solution, by whichever procedure procured, may

ture, Agricultural Research Service, Northern Utilization be subjected to additional centrifugation and/or filtra

Research and Development Division, 1815 North Uni tion if desired to upgrade the quality of the starting

versity St., Peoria, Ill. 61604, and has been assigned No. enzyme Solution.

NRRL B-3411. The enzymatically active material pro EXAMPLE 1.

duced by this organism has been found generally to Con

sist of two proteases, approximately 65–75% neutral Preparation of B. subtilis AM alkaline protease by chro

protease (activity at a pH of 7.0–7.5) and about 25-35% matography on Duolite C-10 ion exchange resin (ad

alkaline protease (activity at a pH of 9-10). A significant sorption conditions of Hagihara)

amount of amylase is also present. There are generally Preparation of C-10 resin.-500 g. Duolite C-10 resin

about 700 thousand to about 1.2 million units of neutral (TM-Diamond Alkali Co., a coarse, highly porous Sul

protease activity per gram and about 250 thousand to fonated phenol-formaldehyde resin) was ground in a pes

about 400 thousand units of alkaline protease activity 55 tle and mortar and stirred in 8 liters of N/1 NaOH for

per gram of precipitated Solids as determined by Anson's one hour, then allowed to settle and the fines and wash

variation of the Kunitz. “Casein' method. There are gen ings removed by decantation. The resin was washed 3

erally about 300 thousand to 350 thousand units of times by decantation with tap water and then retreated

amylase activity per gram as determined by the Bernfeld with NA1 NaOH and rewashed 4 times with distilled

method. As pointed out in the cited patent, the relative 60 water. The resin was converted to the H-- form by wash

proportions of protease to amylase will vary depend ing with excess 2 N HCl for one hour, followed by 3

ing on the exact conditions of growth of the microor distilled water rinses. The resin was then suspended in

ganism, bu we have found that the neutral and alkaline 0.2 M sodium phosphate buffer pH 6.5 and, while stir

protease and the amylase will be produced, in at east ring, the pH was raised to 7.0 by addition of 50% NaOH.

some amounts, almost regardless of changes in the cul After 2 hours, the liquid was removed by decantation and

ture medium and other conditions of growth of the micro the resin resuspended in 0.2 M phosphate pH 6.5 and

organism. allowed to stand overnight and the pH rechecked and

Another source of enzymes which can be used as start adjusted to 7.0 if necessary.

ing material in accord with the present invention is Isolation of alkaline protease according to the present

B. subtilis strain NRRL 644, B. subtilis strain NRRL 941, invention.-180 g. crude enzyme mixture was stirred in

and B. subtilis strain IAM 1523 (Japanese Culture Col 1800 m. distilled water at 5° C. for 20 minutes. 1800

lection). Still other B. subtilis and additional microor ml. cold (5 C.) acetone was added slowly with stirring

ganisms are available which produce protease or a mix followed by 36 g. calcium acetate and the mixture stirred

ture of proteases or protease and amylase, at least to a for 20 minutes at 5°. The precipitate was removed by

limited if not optimum extent. centrifugation and a further 1800 ml. acetone added to

3,592,788

10

the Supernatant and the precipitate collected by centrifu which had been pretreated as in Example 1, but equil

gation and redissolved in 750 ml. distilled water. 40 g. ibrated in distilled water to pH 6.5 instead of in 0.2 M

DEAE-Cellulose (adjusted to pH 6.5 with acetic acid) phosphate buffer. The column was washed with distilled

Was added and the mixture stirred for 20 minutes and Water and the colorless amylase-free proteases then eluted

filtered. The DEAE-Cellulose treatment was repeated to with 1 M NaCl. The recovery of neutral protease was

give a pale yellow solution. 55% and of alkaline protease 67%.

220 ml. of solution was applied to a 20 x 320 mm. EXAMPLE 4

column of Duolite C-10 at 6 C. The column was washed

with 100 ml. distilled water, 150 ml. 20% acetone, 100 ml. Separation of alkaline and neutral protease by

distilled water, and the protease eluted with 1 M NaCl. O chromatography on Duolite C-10

The protein was precipitated by addition of ammonium 200 mg. partly purified B. subtilis AM enzyme mixture

sulfate to 0.6 saturation, the protein redissolved in 0.1% in 25 ml. 0.2 M phosphate pH 6.5 as in Example 3 was

calcium acetate solution, dialyzed against distilled water applied to a 2 x 20-cm. column of Duolite C-10 as in

for 2 hours, and lyophilized. Weight of colorless amylase Example 3 except that the column had been equilibrated

free, pigment-free product=640 mg. Protease activity:

3.12 x 106 u/g. at pH 7; 3.20x106 u/g. at pH 10. with 0.2 M phosphate pH 6.5. The column was washed

Isolation of alkaline protease according to Hagihara with 0.2 M phosphate pH 6.5. After the first protein

et al. (comparative).-180 g. enzyme mixture was stirred peak had eluted, the column was eluted with 1 M NaCl.

at 5° C. for 20 minutes in 1800 ml. distilled water. which gave a second elution peak. The first elution peak

1800 ml. cold (5) acetone was added with stirring, 20 contained 56% of the neutral protease with 22% of the

followed by the addition of 36 g. calcium acetate. After alkaline protease and the second peak contained 52% of

stirring for a further 20 minutes, the precipitate was re the alkaline protease with 10% of the neutral protease.

moved by centrifugation. A further 1800 ml. acetone was The protease solutions were colorless and amylase-free.

added to the supernatant and the precipitate collected by EXAMPLE 5

decantation and redissolved in about 750 ml. distilled .

water, 40 g. DEAE-Cellulose (previously adjusted to pH Separation of B. subtilis amylase, neutral protease and

6.5 with acetic acid) was added and the mixture stirred alkaline protease by chromatography on Duolite C-10

at pH 6.5 for 20 minutes then filtered to give 660 ml. ion exchange resin

yellow filtrate. 120 mg. partly purified B. subtilis enzyme mixture (see

220 ml. yellow filtrate was applied to a 15 x 280 mm. 30

Example 3) and 10 mg. B. subtilis amylase were dis

column of Duolite C-10 in 0.2 M phosphate pH 6.5. solved in 12 ml. water and applied to a 2.0 x 15 cm. col

The column was then washed with distilled water, 20% lumn of Duolite C-10 equilibrated in water (see Example

aqueous acetone, distilled water and then the protease 3). The column was washed with distilled water until

eluted with 0.1 M NaHPO, 0.5 M NaCl, 0.1 M NH4OH. the first protein peak (yellow colored) eluted. The col

The recovery of alkaline protease was about 33%, but umn was then washed with 0.1 M phosphate pH 6.5 until

about one quarter of this was contaminated by yellow another peak eluted, then washed with 1 M NaCl until

green pigment. a further peak eluted. The first peak contained all of the

EXAMPLE 2 amylase with no neutral protease and just a trace of

Isolation of B. subtilis alkaline protease by chromatog 40 alkaline protease. The second peak contained 45% of

raphy on Duolite C-10 (adsorption conditions of the neutral protease with a little alkaline protease, while

Hagihara) the third peak contained 94% of the alkaline protease

200 g. crude B. subtilis AM enzyme mixture was stirred with a little neutral protease. The protease solutions were

in 2 liters water at 5 C. for 30 minutes. 2 liters cold colorless and amylase-free.

(5) acetone was added slowly with stirring, followed 45 EXAMPLE 6

by 40 g. calcium acetate. After stirring at 5 for 20 min

utes the precipitate was removed by centrifugation and Isolation of alkaline and neutral protease mixture from

a further 2 liters of acetone was added slowly. The gummy B. subtilis enzyme mixture by chromatography on

precipitate was allowed to settle and was collected by Duolite C-10 resin

decantation. The precipitate was dissolved in 1500 ml. 50

0.1% calcium acetate and treated with 100 g. DEAE A crude precipitated B. subtilis AM enzyme mixture

Cellulose (adjusted to pH 6.4 with acetic acid) for 30 (net weight about 30 grams) was dissolved in 1 liter

minutes and filtered. The DEAE-Cellulose treatment was distilled water at 5° C. 900 ml. cold (5) acetone was

repeated. The pale yellow solution had a volume of added slowly with stirring, followed by addition of 20

1560 m. g. solid Ca acetate. After stirring at 5 for 20 minutes,

Elution according to the invention.-780 ml. of solu the solids were removed by centrifugation. A further 1

tion was applied to a 30 x 350 mm. Duolite C-10 col liter of cold (5 C.) acetone was added to the supernatant

umn (prepared as in Example 1). The column was washed with stirring. The precipitate thus formed was collected

with 600 ml. distilled water, 600 ml. 20% acetone, 1. by centrifugation and redissolved in 1 liter 0.1% Ca

liter distilled water and the enzyme eluted with 1 MNaCl. 60 acetate. The deep yellow solution was treated with

The enzyme was precipitated with ammonium sulfate, DEAE-Cellulose (adjusted to pH 7.0 with acetic acid) at

redissolved in 400 ml. 0.01% calcium acetate, dialyzed pH 7.0 for 20 minutes at 5, whereafter the resin was

overnight at 5° against 0.01% calcium acetate (16 liters) removed by filtration.

and lyophilized. Weight of colorless product: 1920 g. The solution was applied to a 7.0 x 30 cm. column of

Assay, protease: pH 7-4.05 x 106 u/g.; pH 10-4.32X.10 Duolite C-10 adjusted to pH 6.5 in distilled water (see

pl/g. Example 3). The column was washed with distilled water

EXAMPLE 3 (2 liters), then with 1 liter 20% acetone followed by

Isolation of B substilis neutral and alkaline protease 2 liters distilled water. The proteases were eluted with

1 M. NaCl. The enzymes were precipitated from the

by chromatography on Duolite C-10 70 eluate by addition of ammonium sulfate (600 g. /liter),

200 mg. partly purified B. subtilis AM enzyme mixture redissolved in 0.1% Ca acetate, dialyzed against 0.1%

(with amylase and some pigment removed by Ca. acetate/ calcium acetate at 5° and then lyophilized. Weight=4.00

isopropanol or acetone fractionation and DEAE-Cellu g. of an about equal mixture of colorless amylase-free

lose treatment respectively) was dissolved in 20 ml. Water neutral and alkaline proteases. Assay: 7.2X 106 protease

and applied to a 2 x 20 cm. column of Duolite C-10 75 units at pH 7; 4.1 x 106 protease units at pH 10.

3,592,738

11 12

EXAMPLE 7 tively eluting the protease from the resin using an eluant

Isolation of B. subtilis neutral and alkaline proteases solution having a relatively neutral pH between about 6

from a fermentation beer by chromatography on Duo and about 8, colored impurities being left behind in the

lite C-10 resin process.

A. B. subtilis AM fermentation beer was clarified by 2. Process of claim 1, wherein the eluting solution has

a pH between about 6.5 and 7.5.

filtration using Hyflo-Supercel (TM-diatomaceous earth) 3. Process of claim 2, wherein protease is eluted from

as a filter aid. Two liters of the filtered beer were ad the resin using an eluting solution with a high ionic

justed to pH 7.0, centrifuged to remove a faint precip strength greater than about 0.2 molarity.

itate, and then applied at 5 to a 7 x 22 cm. column of O 4. Process of claim 1, further characterized in that the

Duolite C-10 at pH 7.0 in distilled water (see Example starting water-clear aqueous solution contains both neutral

3). The column was then washed successively with 1500 protease and alkaline protease and wherein the protease is

ml. distilled water, 2 liters 20% acetone, and 2 liters adsorbed on the resin from a solution thereof having a low

distilled water. The proteases were then eluted with 1 M ionic strength up to about 0.05 molarity, whereby both

NaCl, precipitated from the eluate with ammonium sul neutral and alkaline protease are adsorbed on the resin.

fate (600 g./liter), redissolved in 0.1% Ca acetate, and 5. Process of claim 4, wherein the adsorption is effected

lyophilized. Weight of colorless amylase-free product was at a relatively neutral pH between about 6 and 7.5.

680 mg.; protease assay 5.9X 106 u/g. at pH 7; 2.6X 106 6. Process of claim 4, wherein protease is eluted from

p/g. at pH 10. the resin using an eluting solution having a high ionic

EXAMPLE 8 strength greater than about 0.2 molarity, both neutral and

Isolation and separation of B. subtilis neutral and alkaline alkaline protease being eluted together.

protease by chromatography on Duolite C-10 resin 7. Process of claim 4, wherein neutral protease is eluted

Two g. crude B. subtilis AM enzyme mixture was dis from the resin using an eluting solution having a moderate

solved in 200 ml. cold distilled water, pH adjusted to ionic strength between about 0.05 and 0.2 molarity, and

7.0, and then solution applied to a 5.0X20.0 cm. column wherein alkaline protease is subsequently eluted from the

of Duolite C-10 resin adjusted to pH 7.0 in distilled resin using an eluting solution having a relatively high

water. The column was washed with water and then ionic strength greater than about 0.2 molarity.

eluted first with 0.12 M phosphate pH 6.5 and then with 8. Process of claim 7, wherein the ionic strength of the

1 M NaCl. The material eluted by the phosphate buffer relatively high ionic strength solution is between about 0.2

30 and about 1 molarity.

contained no amylase or pigment and had 24% of the 9. Process of claim 7, wherein neutral protease is eluted

neutral protease together with very little alkaline pro from the resin with an eluting solution comprising about

tease. The material eluted by the sodium chloride solu 0.1 M phosphate buffer solution and wherein alkaline pro

tion contained 59% alkaline protease with only a little tease is eluted from the resin with an eluting solution com

neutral protease and was also pigment-free and amylase prising about 1 M sodium chloride solution.

free.

EXAMPLE 9 10. Process of claim 1, wherein the starting solution is

a clarified fermentation beer from the fermentation pro

A clarified fermentation beer from the fermentation duction of enzyme by a protease-producing strain of a

of B. subtilis var. amylosacchariticus, a known producer Bacillus species or a clarified aqueous solution of previous

of neutral protease, is treated in the manner of Example 40 ly-precipitated and redissolved solids from such Bacillus

3. Similar results are obtained. species fermentation beer.

The same results are obtained using water-clear fer 11. Process of claim 1, wherein the starting solution is

mentation beers from the other B. subtilis strains previ a clarified fermentation beer from the fermentation pro

ously mentioned. duction of enzyme by a neutral and alkaline protease-pro

EXAMPLE 10 ducing strain of a Bacillus species, or a clarified aqueous

solution of previously-precipitated and redissolved solids

A synthetic mixture comprising a water-clear solution from such Bacillus species fermentation beer.

of neutral protease and alkaline protease is prepared and 12. Process of claim 1, wherein the starting solution is

adjusted to a pH of approximately 6.5. The product is a clarified fermentation beer from the fermentation pro

treated in accord with the procedure of Example 5. Frac duction of enzyme by a protease-producing strain of

tionation of the solution into its neutral and alkaline pro Bacillus subtilus or a clarified aqueous solution of pre

tease fractions is readily effected. viously-precipitated and redissolved solids from such

It is to be understood that the invention is not to be Bacillus subtilis strain fermentation beer.

limited to the exact details of operation or exact com 13. Process of claim 1, wherein the starting solution is

pounds, compositions, or procedures shown and de 55 a clarified fermentation beer from the fermentation pro

scribed, as obvious modifications and equivalents will be duction of enzyme by a neutral and alkaline protease-pro

apparent to one skilled in the art, and the invention is ducing strain of Bacillus subtilis, or a clarified aqueous

therefore to be limited only by the full scope of the ap solution of previously-precipitated and redissolved Solids

pended claims, including the application of the doctrine from such Bacillus subtilis strain fermentation beer.

of equivalents thereto. 60

I claim: References Cited

1. Process for the isolation of substantially colorless UNITED STATES PATENTS

protease from a water-clear aqueous solution containing

protease together with colored impurities, which comprises 2,952,586 9/1960 Okunuki et al. ------

the step of adsorbing the protease on a sulfonated phenol

formaldehyde resin, characterized by the step of selec LIONEL M. SHAPIRO, Primary Examiner

UNITED STATES PATENT OFFICE

CERTIFICATE OF CORRECTION

Patent No. 3,592,738 Dated July 13, 1971

Inventor(s) Leonard Keay

It is certified that error appears in the above-identified patent

and that said Letters Patent are hereby corrected as shown below:

Column 1, line 47, 'difficulty' should read -- difficultly

- - . Column 2, line l, '2,952,856' should read - - 2,952, 586 - -;

line 21, 'Stated" should read -- started --. Column 7, line 39,

"organims' should read -- organism --. Column 9, 1ine 68,

"B Substilis'

'then' should-- read

should read -- B. subtilis --. Column 11, line 26,

the --.

Signed and sealed this 25th day of July 1972.

(SEAL)

Attest:

EDWARD M. FLETCHER, JR. ROBERT GOTTSCHALK

Attesting Officer Commissioner of Patents

ForM Po-1 O50 (10-69)

USCOMMs oc 803 sess

U.S. Goy ERNMENT PRNTING OFFce : 1989 o-366-33s.

You might also like

- Modern Experimental Biochemistry 3d Ed - Rodney F. BoyerDocument480 pagesModern Experimental Biochemistry 3d Ed - Rodney F. BoyerTatiana Moreira92% (48)

- Gel FiltrationDocument5 pagesGel FiltrationRüveyda AkçinNo ratings yet

- US2565067Document3 pagesUS2565067Danyal2222No ratings yet

- ElutionDocument3 pagesElutionRex BanggawanNo ratings yet

- Enzyme Purification NotesDocument23 pagesEnzyme Purification NotesMadan Rajan100% (1)

- Column ChromatographyDocument22 pagesColumn ChromatographyAzeem ChaudharyNo ratings yet

- Applications of Enzyme ImmobilizationDocument15 pagesApplications of Enzyme Immobilizationamrita_azam92% (13)

- The Separation and Isolation of Proteins: a Laboratory Manual of Analytical Methods of Protein Chemistry (Including Polypeptides)From EverandThe Separation and Isolation of Proteins: a Laboratory Manual of Analytical Methods of Protein Chemistry (Including Polypeptides)No ratings yet

- Exp1&2 - Chem 40Document5 pagesExp1&2 - Chem 40Denise CedeñoNo ratings yet

- Adsorption ChromatographyDocument2 pagesAdsorption Chromatographyaparnayadav100% (12)

- Patente 3 - 11-05-22Document9 pagesPatente 3 - 11-05-22Alejandro HurtadoNo ratings yet

- Hernandez 1995Document6 pagesHernandez 1995Ifan Delapan TigaNo ratings yet

- Ergot AlkaloidsDocument8 pagesErgot AlkaloidsHofman HofmannNo ratings yet

- Of Basal MediumDocument2 pagesOf Basal MediumSandeep Kumar SaklaniNo ratings yet

- US5625109 Liquid Phase Dehydration of Tertiary Butyl AlcoholDocument6 pagesUS5625109 Liquid Phase Dehydration of Tertiary Butyl AlcoholNuzulina FitriNo ratings yet

- Groot1990 PDFDocument14 pagesGroot1990 PDFJadafNo ratings yet

- Purification and Characterization of An Organic Solvent and Detergent-Tolerant Novel Protease Produced by Bacillus Sp. RKY3Document8 pagesPurification and Characterization of An Organic Solvent and Detergent-Tolerant Novel Protease Produced by Bacillus Sp. RKY3سید حسین عارفیNo ratings yet

- Case 1982Document4 pagesCase 1982Sebastian Ortiz BuitragoNo ratings yet

- Ethanol Extraction Membrane During Supported Liquid Ferment at IonDocument8 pagesEthanol Extraction Membrane During Supported Liquid Ferment at Ionapi-26678889No ratings yet

- US3361521Document6 pagesUS3361521Vinod AvNo ratings yet

- Eudragit Coated CapsuleDocument7 pagesEudragit Coated CapsuleADVOCATE ASHUTOSH SHARMANo ratings yet

- BCH 415-Lecture Note 2023Document23 pagesBCH 415-Lecture Note 2023Saheed DanielNo ratings yet

- Us3957579 PDFDocument7 pagesUs3957579 PDFZDENKO SEBASTIAN CHAMERY CUEVASNo ratings yet

- United States Patent (19) : (21) Appl. No.: 273,440Document9 pagesUnited States Patent (19) : (21) Appl. No.: 273,440julioNo ratings yet

- Analysis of Protein ConformationDocument36 pagesAnalysis of Protein ConformationNikka Mia AbadiesNo ratings yet

- 109-Article Text-110-1-10-20131101 PDFDocument3 pages109-Article Text-110-1-10-20131101 PDFKassandra ParenNo ratings yet

- Plntphys00211 0097Document7 pagesPlntphys00211 0097yasmineat29No ratings yet

- LIGNANESDocument4 pagesLIGNANESzohra benouadahNo ratings yet

- Accelerated Desalting and Purification of Silk Fibroin in A CaCl2-EtOH-H2O Ternary System by Excess Isopropanol ExtractionDocument17 pagesAccelerated Desalting and Purification of Silk Fibroin in A CaCl2-EtOH-H2O Ternary System by Excess Isopropanol ExtractionHozefa DhilaNo ratings yet

- 1 s2.0 S1570023211007112 MainDocument6 pages1 s2.0 S1570023211007112 MainyasserNo ratings yet

- By Swill 39Re-A-2J: July 2, 1963 A. Roche Etal 3,096,377Document5 pagesBy Swill 39Re-A-2J: July 2, 1963 A. Roche Etal 3,096,377Ruchita PoilkarNo ratings yet

- US4028217Document3 pagesUS4028217paulNo ratings yet

- Rumen ADocument11 pagesRumen AnazkasihNo ratings yet

- ChemDocument20 pagesChemSaksham BajpayiNo ratings yet

- Yeast NaohDocument9 pagesYeast NaohffwwfNo ratings yet

- Chapter 5 Q.ADocument14 pagesChapter 5 Q.ADawlat SlamaNo ratings yet

- Purification and Characterization of PerDocument7 pagesPurification and Characterization of PerWilayit Ali SaediNo ratings yet

- ArtigosDocument2 pagesArtigosAmanda AraújoNo ratings yet

- Supercritical Fluid Extraction of Lovastatin From The Wheat Bran Obtained After Solid-State FermentationDocument7 pagesSupercritical Fluid Extraction of Lovastatin From The Wheat Bran Obtained After Solid-State FermentationHrithik BaradiaNo ratings yet

- lịch sử, cấu trúc cảu kinetinDocument6 pageslịch sử, cấu trúc cảu kinetinBá Hiệp LêNo ratings yet

- How To Isolate Proteins FinalDocument9 pagesHow To Isolate Proteins Finalmukeshsriwastva14No ratings yet

- Protease EnzymeDocument22 pagesProtease Enzymeامنة احمد زيدNo ratings yet

- Analysisi of Catechin in Grape Seed ExtractDocument4 pagesAnalysisi of Catechin in Grape Seed ExtractGopalaKrishnan SivaramanNo ratings yet

- 3.purificación de CatalasaDocument15 pages3.purificación de CatalasaSergio Alexander Torres PalomaresNo ratings yet

- Fujita Et Al.. 2000. Characterization of A Bioflocculant Produced by Citrobacter Sp. TKF04 From Acetic and Propionic AcidsDocument7 pagesFujita Et Al.. 2000. Characterization of A Bioflocculant Produced by Citrobacter Sp. TKF04 From Acetic and Propionic AcidsAzb 711No ratings yet

- US2745840 Purify SaccharinDocument3 pagesUS2745840 Purify SaccharinHerdian PebiNo ratings yet

- Biocatalysts Based On Immobilized Cells of Microorganisms in The Production of Bioethanol and BiobutanolDocument6 pagesBiocatalysts Based On Immobilized Cells of Microorganisms in The Production of Bioethanol and BiobutanolYisela Escobar CortésNo ratings yet

- Tetrahedron: Asymmetry: Annamaria Varga, Valentin Zaharia, Mihály Nógrádi, László PoppeDocument6 pagesTetrahedron: Asymmetry: Annamaria Varga, Valentin Zaharia, Mihály Nógrádi, László PoppeJames TerryNo ratings yet

- Cao - From Sucrose To Fructo-Oligosaccharides - 2022 (Ingles)Document11 pagesCao - From Sucrose To Fructo-Oligosaccharides - 2022 (Ingles)NATALIA SALAZAR OROZCONo ratings yet

- Isolation of Protease Enzyme From Chayote Fruit (Sechium Edule (Jacq.) SW.) With Ammonium Sulfate Fractination MethodDocument5 pagesIsolation of Protease Enzyme From Chayote Fruit (Sechium Edule (Jacq.) SW.) With Ammonium Sulfate Fractination MethodNhư QuỳnhNo ratings yet

- I. The Role of Pyruvate As An Intermediate Bruno Rosenfeld Ernst SimonDocument11 pagesI. The Role of Pyruvate As An Intermediate Bruno Rosenfeld Ernst SimonreynaldiNo ratings yet

- Isolation and Purification of CellulaseDocument6 pagesIsolation and Purification of CellulaseMeshal NoorNo ratings yet

- Techniques For Protein PurificationDocument14 pagesTechniques For Protein PurificationTauqeer IqbalNo ratings yet

- TarpaulinDocument1 pageTarpaulinZhu Chen ChuanNo ratings yet

- Amylase Production - SSF - Purification - 2022Document13 pagesAmylase Production - SSF - Purification - 2022saeema nakhudaNo ratings yet

- Extraction and Analysis of Eugenol From Cloves: Jdefrancesco@luc - EduDocument9 pagesExtraction and Analysis of Eugenol From Cloves: Jdefrancesco@luc - Edu01Syafira Khairunissa M100% (1)

- Study of The Factors Affecting The Extraction of Soybean Protein by Reverse MicellesDocument8 pagesStudy of The Factors Affecting The Extraction of Soybean Protein by Reverse MicelleselokwaziirohNo ratings yet

- Us 4608340Document6 pagesUs 4608340akhwaNo ratings yet

- Purification and Properties of Alkaline Phosphatase From Bacillus CereusDocument6 pagesPurification and Properties of Alkaline Phosphatase From Bacillus CereusHoque SajidulNo ratings yet

- Durgapur Institute of Advanced Technology and ManagementDocument7 pagesDurgapur Institute of Advanced Technology and ManagementChemical Engg Evensem2021No ratings yet

- Uamerica 23 01025Document7 pagesUamerica 23 01025Rimy Cruz GambaNo ratings yet

- J Institute Brewing - 2012 - Kocher - Comparative Production of Sugarcane Vinegar by Different Immobilization TechniquesDocument3 pagesJ Institute Brewing - 2012 - Kocher - Comparative Production of Sugarcane Vinegar by Different Immobilization TechniquesJezzel O. NatividadNo ratings yet

- Pemurnian ProteinDocument22 pagesPemurnian Proteinzamakhsyarifattah100% (2)

- Practical Aspects of Normal-Phase Chromatography: Seth R. AbbottDocument11 pagesPractical Aspects of Normal-Phase Chromatography: Seth R. Abbottkir223No ratings yet

- 2.2 Separation of Mixtures - 0Document25 pages2.2 Separation of Mixtures - 0Arch Chellis OrongNo ratings yet

- Concentration-Purification of Uranium From An Acid Leaching SolutionDocument7 pagesConcentration-Purification of Uranium From An Acid Leaching SolutionKhairul ScNo ratings yet

- In The Name of Allah: COURSE:-626Document48 pagesIn The Name of Allah: COURSE:-626Noor AlamNo ratings yet

- A Review On High Performance Liquid Chromatography HPLCDocument19 pagesA Review On High Performance Liquid Chromatography HPLCValery FujitaNo ratings yet

- Problem Set 6 Fall 2018Document3 pagesProblem Set 6 Fall 2018rickNo ratings yet

- Qualification of A Chromatographic ColumnDocument8 pagesQualification of A Chromatographic ColumnStefan ŽivanovićNo ratings yet

- UNIT-V Lecture Notes BP205T Computer Applications in Pharmacy-Updated 14.08.2020Document32 pagesUNIT-V Lecture Notes BP205T Computer Applications in Pharmacy-Updated 14.08.2020B.MAHAALAKSHMINo ratings yet

- Adsorptiona Partition ChromatographyDocument20 pagesAdsorptiona Partition ChromatographySATYA SRIVASTAVANo ratings yet

- TN 107 Automated in Needle Derivatization Lpn2849 enDocument6 pagesTN 107 Automated in Needle Derivatization Lpn2849 enHendy Dwi WarmikoNo ratings yet

- Estimation of Neurotransmitters in The BrainDocument8 pagesEstimation of Neurotransmitters in The Brainapi-3846255100% (2)

- SCH 410 Lecture Iii 2023Document21 pagesSCH 410 Lecture Iii 2023Samuel MutisyaNo ratings yet

- Chromatography IMA IDocument35 pagesChromatography IMA ImadhavanssnNo ratings yet

- Column ChromatographyDocument3 pagesColumn ChromatographyRochelle Anne C. BurataNo ratings yet

- IEXDocument11 pagesIEXRizky RamadhaniNo ratings yet

- PDFDocument913 pagesPDFOki NurpatriaNo ratings yet

- 24장 연습문제 풀이Document8 pages24장 연습문제 풀이전찬이No ratings yet

- FPLC y CromatografiaDocument9 pagesFPLC y CromatografiaDavid García DíazNo ratings yet

- Analysis QBDocument167 pagesAnalysis QBChethan PrabhuNo ratings yet

- Florey Vol 32, 2005Document282 pagesFlorey Vol 32, 2005Fadli NugrahaNo ratings yet

- Arima Et Al 1968Document7 pagesArima Et Al 1968harisankarhsNo ratings yet

- Tramadol HCLDocument2 pagesTramadol HCLRiska Nurul HaqueNo ratings yet

- CarbamazepineDocument28 pagesCarbamazepineJuan PerezNo ratings yet

- Cefadroxil MonohydrateDocument3 pagesCefadroxil MonohydrateSyamsul ArifinNo ratings yet

- HPLC 137.1Document9 pagesHPLC 137.1Rehana LebbeNo ratings yet

- How Develop - Validate MethodsDocument554 pagesHow Develop - Validate MethodsAdriana CiroNo ratings yet