Professional Documents

Culture Documents

Masterflow 980 - Tds

Uploaded by

RadhiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Masterflow 980 - Tds

Uploaded by

RadhiCopyright:

Available Formats

MasterFlow® 980

High strength, shrinkage compensated cementitious micro concrete

DESCRIPTION equipment that can crush the aggregate but leave it in

MasterFlow 980 is a hydrogen free ready to use place. The surface must be free of oil, dust, dirt, paint,

product in powder form, which requires only the onsite curing compounds, etc. Soak area to be grouted with

addition of water to produce a shrinkage compensated water for 24 hours prior to grouting to minimize localized

micro concrete of predictable performance. absorption and to assist in the free flow of the grout.

The larger size aggregate of MasterFlow 980 permits Surfaces should be damp but free of standing water.

precision grouting of thicknesses >80mm between Particular attention should be paid to bolt holes to

bedplate and foundation and is especially suitable in ensure that these are water-free. Use oil free

high ambient temperatures. compressed air to blow out bolt holes and pockets as

necessary.

TYPICAL APPLICATIONS

Base plates, bolts, etc. must be clean and free of oil,

MasterFlow 980 is formulated for use at any

grease, paint, residual curing compound or other

consistency from fluid to damp-pack, and may be used

contaminants that could impair adhesion. Set and align

with confidence for bedding, grouting and precision

equipment. If shims are to be removed after the grout

bearing operations such as:

has set, then lightly grease them for easy removal.

- Gas or steam turbines

- Generators

Ensure formwork is secure and watertight to prevent

- Presses

movement and leaking during the placing and curing of

- Crane rails

the grout. The area should be free of excessive

- Milling machines

vibration. Shut down adjacent machinery until the grout

- Precast elements

has hardened.

- Anchor bolts

- Repair and reprofiling of bored piles

MIXING:

ADVANTAGES Damp down the inside of the grout mixer with water prior

to mixing the initial batch of MasterFlow 980. Ensure

- Shrinkage compensated.

the mixer is damp but free of standing water. Add 90%

- Formulated for deep section grouting.

of the pre-measured quantity of water. Slowly add the

- Proven and predictable performance.

MasterFlow 980 mixing continuously. Mix for two

- Excellent workability retention even at high ambient

minutes until a smooth, uniform, lump free consistency

temperatures.

is achieved, then add the remaining water and mix for a

- High bond strength to steel and concrete.

further 3 minutes.

- Early strength development even at fluid

consistency.

- Good fatigue and impact resistance. PLACING:

- Micro silica content enhances strength and durability. Lengths of metal strapping laid in the formwork prior to

- Low heat gain. placing may be necessary to assist grout flow over large

areas and in compacting and eliminating air pockets.

PACKAGING Pour the grout continuously. Maintain a constant

hydrostatic head, of at least 15 cm.

MasterFlow 980 is supplied in 25kg bags

On the side where the grout is to be poured, allow 10 cm

clearance between the side of the form and the base

APPLICATION PROCEDURE plate of the machine.

PREPARATION: On the opposite side allow at least 10cm clearance

The surface onto which the grout is to be applied should between the formwork and the base plate to allow the

be scraped to remove laitance and expose aggregate. grout to flow through without entrapping air.

Do not use bush hammers or similar preparation.

MasterFlow® 980 1/4

MasterFlow® 980

High strength, shrinkage compensated cementitious micro concrete

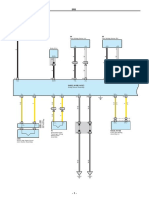

MasterFlow grouts are suitable for use with most types Diagram A illustrates the use of grout surcharge to

of pumping equipment. Immediately after placing ensure complete filling under a base.

MasterFlow 980 grout, cover all exposed grout with Diagram B shows that straps can be used to aid grout

clean damp hessian and keep moist until grout is firm flow under a wider base. A gentle “sawing” action with

enough to accept a curing membrane. We recommend the strap allows the grout to flow without segregation for

the use of a curing membrane from our MasterKure greater distances.

range.

SHOULDERS TYPICAL PROPERTIES

Due to differences in temperature between the grout STRENGTH DEVELOPMENT:

under the base plate, and exposed shoulders that are The strength of grout is dependent on many factors

subject to more rapid temperature changes, debonding which include mixing, water addition, curing,

and / or cracking can occur. Avoid shoulders wherever temperature and humidity. The table below gives typical

possible. If shoulders are required they should be firmly average strengths of MasterFlow 980 at 25°C, when

anchored with reinforcing to the substrate to prevent mixed with 2.8 ltrs (flowable) & 3.5 liters (fluid) per 25kg

debonding. bag.

TYPICAL WATER REQUIREMENTS Compressive Fluid Flexural

Strength N/mm² Strength

Application Consistency Flow Mix Water Time Flowable N/mm2 Fluid N/mm²

Table$ liters/ 25kg

1 day 40 25 -

min max

3 days 55 35 -

Grouting Fluid - 3.25 3.5

machinery 7 days 65 45 7

Grouting Flowable 130 2.8 3.25 28 days 80 60 9

machinery

*Properties listed are based on laboratory controlled

Bedding Plastic 60 2.0 2.5 tests.

Precast

Filling Tie Dry pack - 1.5 1.75 BLEED WATER:

bar voids No bleed water is apparent (ASTM C-232) at

recommended water addition rates

$:ASTMC230/ASTMC827

EXPANSION:

Tests were made following both ASTM Standard C- 878,

SHOULDERS on the use of expansive cements and Corps of

Engineers Standard for grout. Tests made as prescribed

by ASTM Standard C-878 show an expansion value of

about 0.05%. Tests in conformity with Corps of

Engineers show an expansion value of 0.3% that is

lower than the maximum value (0.4%) fixed by the same

standards. Moreover, MasterFlow 980 expansion

occurs

both in the plastic and in the early hardened state.

However, the expansion action of MasterFlow 980

exhausts mainly during the first 12 hours of curing.

MODULUS OF ELASTICITY

The static modulus of elasticity, measured by applying a

load corresponding to 1/3 of the strength, is

approximately 30,000 N/mm² at 28 days.

MasterFlow® 980 2/4

MasterFlow® 980

High strength, shrinkage compensated cementitious micro concrete

FATIGUE RESISTANCE: result in premature deterioration of the product or

Cube samples, produced with MasterFlow 980 and packaging. For specific storage advice consult Master

cured 28 days, underwent fatigue tests of 2,000,000 Builders Solutions's Technical Services Department.

pulsing stresses ranging between 20 and 50 N/mm² at a

frequency of 500 cycles/min. Tested specimens were PRECAUTIONS

undamaged and their compressive strength was higher The temperature of both the mixed grout and elements

than that of similar specimens that were not subjected to coming into contact with the grout should be in the range

fatigue tests of +5°C to <35°C. Do not use water in an amount or at a

temperature that will produce a consistency more than

BOND TO CONCRETE fluid or cause mixed grout to bleed or segregate.

Typical direct tensile “pull off” testing indicates a bond to

concrete in the region of 2-4Mpa. MasterFlow 980 is formulated for thicknesses above

80mm, however it is suitable for use at a minimum

WORKABILITY thickness of 15mm. For applications below 80mm

consider the use of MasterFlow 928 and for

Tests were made using ASTM C-230 apparatus and

applications below 10mm consult Master Builders

compliance with CRD-C-611 was exceeded within

Solutions’s Technical Services Department for advice.

recommended water addition rates for plastic and

flowable consistencies.

To simulate on-site conditions it is necessary to restrain

cubes for the first 24 hours immediately after casting.

CAPILLARY PORES AND PERMEABILITY

Even under a pressure of 20 atm, water does not DO NOT OVERWORK AND AVOID USING

penetrate MasterFlow 980 specimens. The permeability MECHANICAL VIBRATION. UNDER NO

factor is calculated to be therefore lower than 1.10 -12 CIRCUMSTANCES SHOULD MasterFlow® 980HF BE

cm/sec. RETEMPERED BY THE LATER ADDITION OF

WATER.

RESISTANCE TO CHEMICAL ATTACK

Due to its water tightness, MasterFlow 980 grout is It is essential that a mechanically powered grout mixer is

protected against environmental aggressive agents in used to obtain the optimum properties.

solution.

YIELD / CONSUMPTION

RESISTANCE TO HIGH TEMPERATURE: 12.6 liters / 25kg bag at 3.5 liters water addition.

MasterFlow 980 grouts can withstand high temperature 79 x 25kg bags / m³.

(+400°C) for very long periods without substantial

deterioration. NOTE

The fatigue and impact resistance of MasterFlow 980

RESISTANCE TO LOW TEMPERATURE: grout is exceeded only by the metallic reinforced, non-

After 300 freezing and thawing cycles, the modulus of catalyzed MasterFlow 4800 grout. The specially

elasticity decreases only 5%. This indicates that prepared metallic aggregate in this product contributes

MasterFlow 980 is highly resistant to the disrupting to impact resistance, a desirable property of grout to be

action of frost. subjected to severe dynamic operating forces and

repetitive loading such as found in steel and aluminum

STORAGE rolling mills, crane rails, heavy presses, etc.

Store out of direct sunlight, clear of the ground on pallets

protected from rainfall. Avoid excessive compaction.

Shelf life is 12 months when stored as above. Failure to

comply with the recommended storage conditions may

MasterFlow® 980 3/4

MasterFlow® 980

High strength, shrinkage compensated cementitious micro concrete

When a very rapid set is required in areas subject to QUALITY AND CARE

chemical spillage or contamination, use epoxy grouts All Master Builders Solutions Products are manufactured

MasterFlow 400 or MasterFlow 648. For additional under a management system independently certified to

information on MasterFlow 980 grout or other shrinkage conform to the requirements of the quality,

compensated grouting materials, contact your Master environmental and occupational health and safety

Builders Solutions representative. standards of ISO 9001 and Master Builders Solutions

ESHQ recommendations.

SAFETY PRECAUTIONS * Properties listed are based on laboratory controlled

As with all chemical products, care should be taken tests.

during use and storage to avoid contact with eyes, ® = Registered trademark of the MBCC-Group in many

mouth, skin and foodstuffs (which may also be tainted countries

with vapor until product is fully cured). Treat splashes to

eyes and skin immediately. If accidentally ingested, seek CONTACT

immediate medical attention. For further information, Should you require any further information, please do

refer to material safety data sheet. not hesitate to contact us:

NOTE www.master-builders-solutions.com/en-sa

Field service, where provided, does not constitute enquirycc.saudi@mbcc-group.com

supervisory responsibility. For additional information M: +966 13 853 8600

contact your local Master Builders Solutions

representative. Master Builders Solutions Saudi Arabia for

Master Builders Solutions reserves the right to have the Manufacturing LLC.

true cause of any difficulty determined by accepted test P.O. Box 1884, Al Khobar, KSA

methods.

The technical information and application advice given in this Master Builders Solutions publication are based on the present state of

our best scientific and practical knowledge. As the information herein is of a general nature, no assumption can be made as to a

STATEMENT OF

product's suitability for a particular use or application and no warranty as to its accuracy, reliability or completeness either expressed

RESPONSIBILITY

or implied is given other than those required by law. The user is responsible for checking the suitability of products for their intended

use.

Disclaimer:

In view of widely varying site conditions and fields of application of our All descriptions, drawings, photographs, data, ratios, weights i.e. stated

products, this technical data sheet is meant to provide general herein can be changed without advance notice and do not represent the

application guidelines only. This information is based on our present condition of the product as stipulated by contract. It is the sole

knowledge and experience. The customer is not released from the responsibility of the recipient of our products to observe possible

obligation to conduct careful testing of suitability and possible proprietary rights as well as existing laws and provisions. The reference

application for the intended use. The customer is obliged to contact the of trade names of other companies is no recommendation and does not

technical help-line for fields of application not expressly stated in the exclude the use of products of similar type. Our information only

technical data sheet under "Fields of Application". Use of the product describes the quality of our products and services and is no warranty.

beyond the fields of application as stated in the technical data sheet Liability is accepted for incomplete or incorrect particulars in our data

without previous consultation with Master Builders Solutions and sheets only in the event of intent or gross negligence, without prejudice

possible resulting damages are in the sole responsibility of the to claims under product liability laws.

customer.

MasterFlow® 980 4/4 Master Builders Solutions Saudi / 02-95/ 09-14 / 04-17 / 01-20

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- WA500-1 10001-UpDocument933 pagesWA500-1 10001-UpRavinder Singh100% (5)

- Retrofit Assessment ChecklistDocument8 pagesRetrofit Assessment ChecklistPrakash SIngh RawalNo ratings yet

- Mit 185UD5Document2 pagesMit 185UD5Pakito ChocolateroNo ratings yet

- Section I 2015Document33 pagesSection I 2015ferds2599No ratings yet

- Wind Turbine Installation-ManualDocument23 pagesWind Turbine Installation-Manualויליאם סן מרמיגיוסNo ratings yet

- SRSDocument7 pagesSRSCLC 18C4No ratings yet

- 1800cpb2 Series Regulators American MeterDocument11 pages1800cpb2 Series Regulators American Meterultron2099ultronNo ratings yet

- GATE Metallurgical Engineering 2008 PDFDocument12 pagesGATE Metallurgical Engineering 2008 PDFdrashokyvuceNo ratings yet

- Flame HardeningDocument2 pagesFlame Hardenings_manikandanNo ratings yet

- Hydrogen Gas Dryer - AspxDocument2 pagesHydrogen Gas Dryer - AspxtpplantNo ratings yet

- Company Profile CBP-2019Document17 pagesCompany Profile CBP-2019sunanNo ratings yet

- Automation of Boiler Gas Burner Management System Using PLC: P. K. Bhowmik, S.K. DharDocument5 pagesAutomation of Boiler Gas Burner Management System Using PLC: P. K. Bhowmik, S.K. DharAkoKhalediNo ratings yet

- Gear Manufacturing Methods: Prepared by Kaushal PatelDocument42 pagesGear Manufacturing Methods: Prepared by Kaushal Patelashoku24007No ratings yet

- Tarea 3 CalorDocument3 pagesTarea 3 CalorLuis AngelNo ratings yet

- Bosch PCS7A5B90A Installation and Users GuideDocument20 pagesBosch PCS7A5B90A Installation and Users Guidesam huangNo ratings yet

- NYYHYDocument1 pageNYYHYCiwa DoankNo ratings yet

- Cetiol CC (OPP)Document1 pageCetiol CC (OPP)paromanikNo ratings yet

- Kobelco Eco-Solutions VNDocument20 pagesKobelco Eco-Solutions VNPhu PhuocNo ratings yet

- Power Source CharacteristicsDocument22 pagesPower Source CharacteristicsKyNo ratings yet

- SDS Gyproc SoundBloc MR 015 03Document2 pagesSDS Gyproc SoundBloc MR 015 03fgfdgfdgdfgNo ratings yet

- VS1 (ZN63A) - 12 Indoor AC High Voltage Vacuum Circuit BreakerDocument2 pagesVS1 (ZN63A) - 12 Indoor AC High Voltage Vacuum Circuit BreakerVinod KumarNo ratings yet

- Engineering Failure Analysis: S. Barella, M. Boniardi, S. Cincera, P. Pellin, X. Degive, S. GijbelsDocument8 pagesEngineering Failure Analysis: S. Barella, M. Boniardi, S. Cincera, P. Pellin, X. Degive, S. GijbelsGholamreza MahmoodiNo ratings yet

- 03-Senr3130!08!01-All Torque SpecificationsDocument16 pages03-Senr3130!08!01-All Torque Specificationsgustavoespinosam100% (1)

- 3 Quick Closing Valve SystemsDocument13 pages3 Quick Closing Valve SystemsrsalvasanNo ratings yet

- Muzaffarpur Thermal Power Project (2 X 195 MW) : Sr. Description by by No Vendor BHEL A MechanicalDocument3 pagesMuzaffarpur Thermal Power Project (2 X 195 MW) : Sr. Description by by No Vendor BHEL A MechanicalHimadri SNo ratings yet

- 1000SR Brochure 2017 EN PDFDocument1 page1000SR Brochure 2017 EN PDFmarceloaav1No ratings yet

- 05 4roisumDocument13 pages05 4roisumductoan32No ratings yet

- Eirez Vibratory Feeders and Conveyors BrochureDocument20 pagesEirez Vibratory Feeders and Conveyors BrochureJay Ryan SantosNo ratings yet

- Odiong Bridge FinalDocument18 pagesOdiong Bridge Finaljenor delatorreNo ratings yet

- First Stop Second Stop: Date: 2/17/2023 HAWB#: Reference No: 13771Document1 pageFirst Stop Second Stop: Date: 2/17/2023 HAWB#: Reference No: 13771Jatinder SinghNo ratings yet