Professional Documents

Culture Documents

Interior Fluid Resistant Epoxy Primer: Technical Data Sheet

Uploaded by

Pannha LangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Interior Fluid Resistant Epoxy Primer: Technical Data Sheet

Uploaded by

Pannha LangCopyright:

Available Formats

AkzoNobel

Aerospace Coatings

463-12-8

Interior Fluid Resistant Epoxy Primer

Technical Data Sheet

Product Group Epoxy primer

Characteristics - A chemically cured, two-component epoxy primer designed to provide

Product maximum protection from various chemicals, hydraulic fluids, aviation

Information fuels, phosphate ester (Skydrol®) fluids and corrosion causing media.

Components

Curing Solution Curing Solution CA-116

Thinner Thinner TR-19, TR-49, or C25/90S, as required

Specifications Boeing Long Beach DMS 1786, Ty I, Comp A

Qualified General Electric GE A50TF107-S5, Class A

Product List Messier-Dowty PCS-2500

For most recent up-date or missing specifications please check the

qualified product list (QPL) on www.akzonobel.com/aerospace

Surface Conditions

Cleaning Surface pretreatment is an essential part of the painting process.

Follow specification requirements for cleaning and application of the

required pretreatment.

Instruction for Use

Mixing Ratio 1 part Base 463-12-8

(volume) 1 part Curing Solution CA-116

0 – 0.25 parts Thinner TR-19,TR-49, or C25/90S, as needed

- Stir or Shake until all pigment is uniformly dispersed before adding

curing solution.

- Stir the catalyzed mixture thoroughly.

Page 1 of 5

AkzoNobel Aerospace Coatings

1 East Water Street, Waukegan, IL 60085, USA - Phone (847) 623 4200, Fax (847) 625 3200

Rijksstraatweg 31, 2171 AJ Sassenheim, The Netherlands - Phone (31) 71 308 2905, Fax (31) 71 308 2056

Internet: www.akzonobel.com/aerospace

AkzoNobel

Aerospace Coatings

463-12-8

Interior Fluid Resistant Epoxy Primer

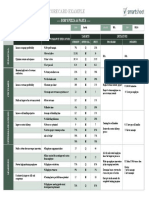

Induction Time Recommended, 30 minutes

26 – 34 seconds ISO Cup #3 @ 18°C – 22°C (64°F – 72°F) per PCS2500

Initial Spraying 26 – 36 seconds Signature Zahn Cup # 1

Viscosity 14 – 22 seconds Signature Zahn Cup # 2

(25ºC/77ºF)

The use of Signature Zahn #1 cup for viscosity is a requirement of the

referenced specification, and the ISO cup measurement is provided only

as a reference for field application. They are not provided as quality

control values.

Note Viscosity measurements are provided as guidelines only and are not to be

used as quality control parameters. Certified information is provided by

certification documentation available on request.

Pot life 8 hours minimum.

(25ºC/77ºF)

Dry Film 25 – 33 micron (m)

Thickness 1.0 – 1.3 mils

(DFT)

Application

Recommendations

Conditions Temperature: 15 – 35°C

59 – 95°F

Relative Humidity: 35 – 75%

Page 2 of 5

AkzoNobel Aerospace Coatings

1 East Water Street, Waukegan, IL 60085, USA - Phone (847) 623 4200, Fax (847) 625 3200

Rijksstraatweg 31, 2171 AJ Sassenheim, The Netherlands - Phone (31) 71 308 2905, Fax (31) 71 308 2056

Internet: www.akzonobel.com/aerospace

AkzoNobel

Aerospace Coatings

463-12-8

Interior Fluid Resistant Epoxy Primer

Note The quality of the application of all coatings will be influenced by the spray

equipment chosen and the temperature, humidity, and air flow of the paint

application area. When applying the product for the first time, it is

recommended that test panels be prepared in order to identify the best

equipment settings to be used in optimizing the performance and

appearance of the coating.

Equipment Air 1.4 mm nozzle orifice

HVLP 1.4 mm nozzle orifice

Air Assisted, Airless .28 – .33 mm nozzle orifice

Number of Spray a single uniform wet coat to recommended dry film thickness.

Coats

Cleaning of MEK or Thinner TR-19

Equipment

Physical Properties

Drying Times Dust free 15 minutes

(25 +/- 2ºC / 77 Dry to stack 1 hour

+/- 2ºF, 55 +/- Dry through 4 hours

5% RH) Dry to topcoat 1 hour minimum and 48 hours maximum

Theoretical 8.7 m2 per liter ready to apply at 25 m dry film thickness

Coverage 357 ft2 per US gallon ready to apply at 1 mil dry film thickness

Dry Film Weight 45.19 g/m2 at 25.4 microns

.0093 lbs/ft2 at 1 mil

Page 3 of 5

AkzoNobel Aerospace Coatings

1 East Water Street, Waukegan, IL 60085, USA - Phone (847) 623 4200, Fax (847) 625 3200

Rijksstraatweg 31, 2171 AJ Sassenheim, The Netherlands - Phone (31) 71 308 2905, Fax (31) 71 308 2056

Internet: www.akzonobel.com/aerospace

AkzoNobel

Aerospace Coatings

463-12-8

Interior Fluid Resistant Epoxy Primer

Volatile Organic Max 650 g/l

Compounds Max 5.4 lb/gal

Maximum (without thinner), per ASTM D3960

Gloss (60º) 20 maximum GU

Color DN 9295 Green

Flash-point 463-12-8 -5°C (23°F)

CA-116 -5°C (23°F)

TR-19 / TR-49 -5°C (23°F)

C25/90S -4°C (25°F)

Storage Store the product dry and at a temperature between 5 and 38ºC / 40 and

100ºF per AkzoNobel Aerospace Coatings specification. Store in the

original unopened containers. Storage temperature may vary per OEM

specification requirements. Refer to container label for specific storage life

information.

Shelf life 24 months per AkzoNobel Aerospace Coatings commercial specification.

5 - 38°C Shelf life may vary due to OEM specification requirements. Refer to

(40 - 100°F) container label for specific shelf life information.

Safety Precautions Comply with all local safety, disposal and transportation regulations.

Check the Material Safety Data Sheet (MSDS) and label of the individual

products carefully before using the products. The MSDS’s are available on

request.

Page 4 of 5

AkzoNobel Aerospace Coatings

1 East Water Street, Waukegan, IL 60085, USA - Phone (847) 623 4200, Fax (847) 625 3200

Rijksstraatweg 31, 2171 AJ Sassenheim, The Netherlands - Phone (31) 71 308 2905, Fax (31) 71 308 2056

Internet: www.akzonobel.com/aerospace

AkzoNobel

Aerospace Coatings

463-12-8

Interior Fluid Resistant Epoxy Primer

Issue date: January 2015 (supersedes August 2012) - FOR PROFESSIONAL USE ONLY

IMPORTANT NOTE The information in this data sheet is not intended to be exhaustive and is based on the present state of our knowledge and on current laws: any person

using the product for any purpose other than that specifically recommended in the technical data sheet without first obtaining written confirmation from us as to the suitability

of the product for the intended purpose does so at his own risk. It is always the responsibility of the user to take all necessary steps to fulfill the demands set out in the local

rules and legislation. Always read the Material Data Sheet and the Technical Data Sheet for this product if available. All advice we give or any statement made about the

product by us (whether in this data sheet or otherwise) is correct to the best of our knowledge but we have no control over the quality or the condition of the substrate or the

many factors affecting the use and application of the product. Therefore, unless we specifically agree in writing otherwise, we do not accept any liability whatsoever for the

performance of the product or for any loss or damage arising out of the use of the product. All products supplied and technical advice given is subject to our standard terms

and conditions of sale. You should request a copy of this document and review it carefully. The information contained in this data sheet is subject to modification from time to

time in the light of experience and our policy of continuous development. It is the user's responsibility to verify that this data sheet is current prior to using the product.

Brand names mentioned in this data sheet are trademarks of or are licensed to AkzoNobel.

Page 5 of 5

AkzoNobel Aerospace Coatings

1 East Water Street, Waukegan, IL 60085, USA - Phone (847) 623 4200, Fax (847) 625 3200

Rijksstraatweg 31, 2171 AJ Sassenheim, The Netherlands - Phone (31) 71 308 2905, Fax (31) 71 308 2056

Internet: www.akzonobel.com/aerospace

You might also like

- Fluid Resistant Epoxy Primer Lead and Cadmium Free: Technical Data SheetDocument4 pagesFluid Resistant Epoxy Primer Lead and Cadmium Free: Technical Data SheetFrancisco RodríguezNo ratings yet

- (7.3) AkzoNobel Polyurethane Topcoat 24F40 Series TDSDocument4 pages(7.3) AkzoNobel Polyurethane Topcoat 24F40 Series TDSBowser DoskaNo ratings yet

- 24T3 Series TDSDocument5 pages24T3 Series TDSFernando CarmonaNo ratings yet

- Akzo Nobel - 20P20-3 - TDSDocument5 pagesAkzo Nobel - 20P20-3 - TDSDiogo José Alves NunesNo ratings yet

- 20p1-21 Fuel Tank Coating 2015Document5 pages20p1-21 Fuel Tank Coating 2015Francisco RodríguezNo ratings yet

- Interlac 1 Gris MamaparoDocument4 pagesInterlac 1 Gris Mamaparowilfran villegasNo ratings yet

- Conseal Touch-Up: Technical Data SheetDocument4 pagesConseal Touch-Up: Technical Data SheetSyilla ShopeNo ratings yet

- Formula 152 Topcoat (MILDTL-24441)Document4 pagesFormula 152 Topcoat (MILDTL-24441)Trịnh Minh KhoaNo ratings yet

- Composite Filler Putty: Technical Data SheetDocument4 pagesComposite Filler Putty: Technical Data SheetMiguel Angel Weisser RiffoNo ratings yet

- 23T3 SeriesDocument5 pages23T3 SeriesEliana FLTNo ratings yet

- Jotafloor EP SL Uni - Abrasion & Impact ResistDocument6 pagesJotafloor EP SL Uni - Abrasion & Impact Resistangelito bernalNo ratings yet

- Penguard Tiecoat 100Document5 pagesPenguard Tiecoat 100Raja SNo ratings yet

- Daylight Reflecting SystemDocument4 pagesDaylight Reflecting SystemSelva KumarNo ratings yet

- Resist 86 PDFDocument5 pagesResist 86 PDFJayaraman KamarajNo ratings yet

- Interzinc 75V: Zinc-Rich EpoxyDocument4 pagesInterzinc 75V: Zinc-Rich EpoxyTrịnh Minh KhoaNo ratings yet

- Perma-Glaze Series G435: Product ProfileDocument2 pagesPerma-Glaze Series G435: Product ProfileR. Raziel Vergara Z.No ratings yet

- Resist 86: Technical Data SheetDocument5 pagesResist 86: Technical Data SheetantonyfmNo ratings yet

- E Program Files An ConnectManager SSIS TDS PDF Interline 850 Eng A4 20160519Document4 pagesE Program Files An ConnectManager SSIS TDS PDF Interline 850 Eng A4 20160519ValentinNo ratings yet

- TDS 48342 Jotatemp 1000 Euk GBDocument5 pagesTDS 48342 Jotatemp 1000 Euk GBhenryNo ratings yet

- Amerlock 400BFDocument6 pagesAmerlock 400BFVijay KumarNo ratings yet

- Tankguard Storage: Technical Data SheetDocument5 pagesTankguard Storage: Technical Data SheetEngTamerNo ratings yet

- Jotatemp 1000 Ceramic: Technical Data SheetDocument5 pagesJotatemp 1000 Ceramic: Technical Data Sheetebastien2No ratings yet

- Jotun Resist 86Document5 pagesJotun Resist 86Ansar AliNo ratings yet

- Marathon 1000GF Technical Data SheetDocument5 pagesMarathon 1000GF Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Interline 975: Solvent Free Epoxy Tank CoatingDocument4 pagesInterline 975: Solvent Free Epoxy Tank Coatingnoto.sugiartoNo ratings yet

- ChemflakeDocument5 pagesChemflakeManohar SeetharamNo ratings yet

- TDS 11480 Pilot ACR Euk GBDocument5 pagesTDS 11480 Pilot ACR Euk GBeeng gilangNo ratings yet

- TDS Penguard Tie Coat 100 Euk GBDocument6 pagesTDS Penguard Tie Coat 100 Euk GBIliyan PetrovNo ratings yet

- Jotatemp 540 Zinc Technical Data SheetDocument5 pagesJotatemp 540 Zinc Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Tankguard 412 Jotun PaintDocument6 pagesTankguard 412 Jotun PaintGurdeep Sungh AroraNo ratings yet

- Turbo-Coat Acrylic Conformal Coating: Product# 2108Document5 pagesTurbo-Coat Acrylic Conformal Coating: Product# 2108Compras MareinsaNo ratings yet

- Hardtop CA PDFDocument5 pagesHardtop CA PDFBiju_PottayilNo ratings yet

- Hardtop CA: Technical Data SheetDocument5 pagesHardtop CA: Technical Data SheetBiju_PottayilNo ratings yet

- Tankguard SF: Technical Data SheetDocument5 pagesTankguard SF: Technical Data SheetRifki ArifinNo ratings yet

- Interbond 600 PDFDocument4 pagesInterbond 600 PDFTrịnh Minh KhoaNo ratings yet

- Penguard Express ZP: Technical Data SheetDocument5 pagesPenguard Express ZP: Technical Data Sheetinfospinster0% (1)

- Tankguard 412: Technical Data SheetDocument6 pagesTankguard 412: Technical Data SheetMuneer ahmedNo ratings yet

- Pilot ACR: Technical Data SheetDocument4 pagesPilot ACR: Technical Data SheetBiju_PottayilNo ratings yet

- Triflex ™ 3-Layer Combinations: Technical Data SheetDocument2 pagesTriflex ™ 3-Layer Combinations: Technical Data SheetSantosh JayasavalNo ratings yet

- TDS 2920 Penguard Express ZP Eng USDocument5 pagesTDS 2920 Penguard Express ZP Eng USnatig samedovNo ratings yet

- Jotatemp 1000 Ceramic Technical Data SheetDocument5 pagesJotatemp 1000 Ceramic Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Interline 982+ds+eng PDFDocument4 pagesInterline 982+ds+eng PDFMohamed NouzerNo ratings yet

- Tankguard StorageDocument5 pagesTankguard StorageBiju_PottayilNo ratings yet

- Hardtop XP Alu: Technical Data SheetDocument5 pagesHardtop XP Alu: Technical Data SheetargaNo ratings yet

- TDS Stainless Steel Paint Jotamastic 70Document5 pagesTDS Stainless Steel Paint Jotamastic 70rndsb.aopNo ratings yet

- Intertuf 5003Document4 pagesIntertuf 5003Trịnh Minh KhoaNo ratings yet

- Aerodur Finish c21 100Document5 pagesAerodur Finish c21 100Javier PargaNo ratings yet

- Soft Natural Rubber Lining: Technical Data SheetDocument2 pagesSoft Natural Rubber Lining: Technical Data SheetSantosh JayasavalNo ratings yet

- Jotachar JF750: Technical Data SheetDocument6 pagesJotachar JF750: Technical Data SheetPeter PetersenNo ratings yet

- Barrier SmartpackDocument5 pagesBarrier SmartpackMhd EbalNo ratings yet

- Barrier 80 PDFDocument5 pagesBarrier 80 PDFBalaji GuruNo ratings yet

- Jotafloor EP SLDocument4 pagesJotafloor EP SLEduardo Vera portocarreroNo ratings yet

- TDS 429 Conseal Touch-Up Euk GBDocument4 pagesTDS 429 Conseal Touch-Up Euk GBGalih WicaksonoNo ratings yet

- Datasheet Jotun-Tankguard StorageDocument5 pagesDatasheet Jotun-Tankguard Storagebudi handoyoNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- Balncing KitDocument4 pagesBalncing KitRul RtNo ratings yet

- IKO968959021 Auth LetterDocument3 pagesIKO968959021 Auth LetterGero0412No ratings yet

- Active Shooter Incidents in The Us 2021 052322Document30 pagesActive Shooter Incidents in The Us 2021 052322ABC News PoliticsNo ratings yet

- Tomb Kings 8E RUS 2014Document102 pagesTomb Kings 8E RUS 2014Александр ФоминNo ratings yet

- Marketing Revision BookletDocument18 pagesMarketing Revision BookletGodfreyFrankMwakalinga0% (1)

- Examples of Geographic SegmentationDocument2 pagesExamples of Geographic SegmentationLucas satosNo ratings yet

- Newman's Apologia and The Drama of Faith and Reason - Draft5Document131 pagesNewman's Apologia and The Drama of Faith and Reason - Draft5Sancrucensis100% (6)

- Nyaa Student Handbook PDFDocument63 pagesNyaa Student Handbook PDFAntonio UngureanNo ratings yet

- Behaviorism and The Cognitive ModelDocument2 pagesBehaviorism and The Cognitive ModelShadai MéndezNo ratings yet

- Zenit Compact Setup Manual En3Document26 pagesZenit Compact Setup Manual En3Garage Lifestyle BVGNo ratings yet

- IMT - Supply Chain MGMT - Session 11&12Document49 pagesIMT - Supply Chain MGMT - Session 11&12Himanish BhandariNo ratings yet

- Surat Pengenalan Fakulti FirstSolarDocument4 pagesSurat Pengenalan Fakulti FirstSolarMohd Izzat Abd GhaniNo ratings yet

- Language Analysis Part 1: The BasicsDocument20 pagesLanguage Analysis Part 1: The BasicsLevi LiuNo ratings yet

- Ars Quatuor Coronatorum v21 1000057345Document496 pagesArs Quatuor Coronatorum v21 1000057345Δημητρης Ιατριδης0% (1)

- EMILE DURKHEIM On The Division of Labor in SocietyDocument23 pagesEMILE DURKHEIM On The Division of Labor in Societymalamati007100% (1)

- TuckerTurtle StoryDocument15 pagesTuckerTurtle StoryjbonvierNo ratings yet

- Morality: How Black Is The Night?: Moral Option 1: A Worthy OpponentDocument8 pagesMorality: How Black Is The Night?: Moral Option 1: A Worthy OpponentmpotatoNo ratings yet

- Skin Studio Powerpoint RevisedDocument8 pagesSkin Studio Powerpoint RevisedAngelo Jay MacaraegNo ratings yet

- Unleash The Warrior WithinDocument217 pagesUnleash The Warrior WithinIbis12100% (1)

- Justification of StorytellingDocument3 pagesJustification of StorytellingJoanne Lian Li FangNo ratings yet

- ISO 9001 High Level Structure 1 NewDocument6 pagesISO 9001 High Level Structure 1 NewTony SinambelaNo ratings yet

- Lecture 1 - Part 1 - Introduction To ECE 105Document12 pagesLecture 1 - Part 1 - Introduction To ECE 105homamhomarNo ratings yet

- Chapter-3 PTD NewDocument34 pagesChapter-3 PTD NewGODNo ratings yet

- Hydraulic Pump Front 1 2Document2 pagesHydraulic Pump Front 1 2eshopmanual baruNo ratings yet

- Posting+0051-2023 +Resolution+No +01,+series+of+2023+ (E) + (HVB+SGD)Document6 pagesPosting+0051-2023 +Resolution+No +01,+series+of+2023+ (E) + (HVB+SGD)Carolyn VillagraciaNo ratings yet

- Class 7 Science July Monthly TestDocument3 pagesClass 7 Science July Monthly TestPugalmeena PugalmeenaNo ratings yet

- Assignment 2 T1 2022Document2 pagesAssignment 2 T1 2022Munawwar MohamedNo ratings yet

- CanalesDocument9 pagesCanalesHector Hernandez EurozaNo ratings yet

- Probability Problem SetDocument2 pagesProbability Problem Setsympatico81No ratings yet

- IC Restaurant Balanced Scorecard ExampleDocument1 pageIC Restaurant Balanced Scorecard Examplemuscdalife100% (1)