Professional Documents

Culture Documents

Non-Metallic Optical Strain Gage - Os3200: Key Features Description

Uploaded by

Yi-jen Chan0 ratings0% found this document useful (0 votes)

12 views2 pagesOriginal Title

os3200_1512

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views2 pagesNon-Metallic Optical Strain Gage - Os3200: Key Features Description

Uploaded by

Yi-jen ChanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Non-Metallic Optical Strain Gage | os3200

Description Key Features

The os3200 is a small, non-metallic optical, epoxy-mounted strain gage based Rugged, permanent weldable package.

on fiber Bragg grating (FBG) technology. Armored cable integrated with sensor package for fiber protection and strain

relief.

The os3200 is based on fiber Bragg grating (FBG) technology. It has a self

adhesive backing that holds the sensor body in place and protects the FBG while Fast, simple, repeatable installation

epoxy is injected. The epoxy encapsulates the FBG and bonds it to a structure’s Double ended design supports multiplexing of many sensors on one fiber.

surface. Installation time is just a few minutes. Measurements can be taken after Qualified to same rigorous standards used for comparable electronic gages.

the epoxy cures in 24 hours at room temperature.

Gage installation and protection achieved with same methods as conventional

In side by side comparisons with foil strain gages, the os3200 is equally sensitive electronic gages.

and accurate, while providing for greater strain range and 100 times more fatigue Micron Optics’ patented micro opto-mechanical technology.

life. The os3200 strain gage is qualified for use in mild environments and delivers Included in ENLIGHT’s sensor templates - allows for quick and easy

the many advantages inherent to all FBG based sensors. optical to mechanical conversions.

This sensor can be used alone or in series as a part of an FBG sensor

array. Installation and cabling for such arrays is much less expensive

and cumbersome than comparable electronic gage networks.

Multiple optical strain gages can be arranged in close proximity

at 0, 45 and 90 degrees for strain rosette measurements. With

each sensor, Micron Optics provides a Sensor Information

Sheet listing the gage factor and calibration coefficients

needed to convert wavelength information into

engineering units. Micron Optics’ ENLIGHT Sensing

Software provides a utility to calculate and then

record, display, and transmit data for large

networks of sensors. Installation,

qualification and other sensor

information is available at:

http://www.micronoptics.com/

support_downloads/Sensors/.

Deployments

Structures (bridges, dams, tunnels, mines, buildings, oil platforms)

Energy (wind turbines, oil wells, pipelines, nuclear reactors, generators)

Transportation (railways, trains, roadways, specialty vehicles, cranes)

Marine vessels (hull, deck, cargo containers)

Aerospace (airframes, composite structures, wind tunnels, static and dynamic tests).

Homeland security (perimeter intrusion, heat detection, security gate monitoring)

Non-Metallic Optical Strain Gage | os3200

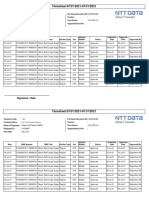

Performance Properties1 os3200 Ordering Information

Strain Sensitivity2 ~ 1.2 pm/με os3200-wwww-1xx-1yy

Gage Length 10 mm wwww Wavelengths for (+/- 1nm)

Standard - 1512 to 1588 nm in 4 nm

Operating Temperature Range3 -40 to 60° C (80°C Max) intervals

Extended - 1460 to 1620 nm

Strain Limits ± 5,000 με

xx Termination type

Maximum Drift4 50 με 1xx Cable 1, Length & Connector

1 1 m Standard, Cable Length

Physical Properties UT Unterminated

FC FC/APC Connector

Dimensions, Weight See Diagram Below, 1.0 g LC LC/APC Connector

yy Termination type

Carrier Material SantopreneTM 1yy Cable 1, Length & Connector

1 1 m Standard, Cable Length

Cable Length 1 m (± 10 cm), each end

UT Unterminated

FC FC/APC Connector

Fiber Type SMF28-Compatible

LC LC/APC Connector

Cable Type 1 mm Fiberglass Braid

Ordering Information Example

Connectors FC/APC optional

Cable Bend Radius ≥ 17 mm o3200-1552-1FC-1FC

Fastening Methods5 Epoxy

Notes

Optical Properties

Beta product. For more details see http://

1 www.micronoptics.com/products/product_designations/.

Peak Reflectivity (Rmax) > 70%

2 Actual gage factor provided with gage.

FWHM (- 3 dB point) 0.25 nm (± .05 nm) Prolonged exposure to maximum temperature could reduce

3 performance.

Isolation > 15 dB (@ ± 0.4 nm around center wavelength)

4 40 temperature cycles -40 to 60° C.

See http://www.micronoptics.com/support_downloads/

5 Sensors/ for installation details.

1852 Century Place NE

Atlanta, GA 30345 USA Copyright © 2015, os3200-1512. All rights reserved.

www.micronoptics.com Specifications subject to change without further notice.

You might also like

- Optical Strain Gage - Os3100: Key Features DescriptionDocument2 pagesOptical Strain Gage - Os3100: Key Features DescriptionYi-jen ChanNo ratings yet

- Optical Strain Gage - Os3150: Key Features DescriptionDocument2 pagesOptical Strain Gage - Os3150: Key Features DescriptionYi-jen ChanNo ratings yet

- Automated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsFrom EverandAutomated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsNo ratings yet

- Module 4-Fiber Optic Sensing: Dr. Samir MustaphaDocument38 pagesModule 4-Fiber Optic Sensing: Dr. Samir MustaphaMohamad Abed AlkaderNo ratings yet

- Micron Optics sm130Document2 pagesMicron Optics sm130Vasu ManchesterNo ratings yet

- Moxa Imc 21 Series Datasheet v1.0Document4 pagesMoxa Imc 21 Series Datasheet v1.0AhmadBintangNegoroNo ratings yet

- Imc-21-S-Sc MoxaDocument4 pagesImc-21-S-Sc MoxaveragaNo ratings yet

- FS22DI. FiberSensingDocument3 pagesFS22DI. FiberSensingduberavilapNo ratings yet

- Glosario FTTHDocument34 pagesGlosario FTTHJOSE DANNY SIESQUEN CHAMBERGONo ratings yet

- 305 Extended Field Wiring Application NotesDocument8 pages305 Extended Field Wiring Application NotesSUBHASH CHNo ratings yet

- Patch Cord Singlemode Product Specifications (Comprehensive)Document8 pagesPatch Cord Singlemode Product Specifications (Comprehensive)parth mendirattaNo ratings yet

- Presentation 7sd52 enDocument17 pagesPresentation 7sd52 enJay KumarNo ratings yet

- Imc-21a-M-Sc Convertidor de MediosDocument4 pagesImc-21a-M-Sc Convertidor de MedioshayashiedNo ratings yet

- Moxa IMC 21A S SC DatasheetDocument4 pagesMoxa IMC 21A S SC Datasheetsyed sadiqNo ratings yet

- Quad OTDR Module: T-BERD®/MTS-2000, - 4000, - 5800 PlatformsDocument2 pagesQuad OTDR Module: T-BERD®/MTS-2000, - 4000, - 5800 Platformsesq psqNo ratings yet

- FFXLCLC42 Product Specifications (Comprehensive)Document8 pagesFFXLCLC42 Product Specifications (Comprehensive)h3ndr4.e04No ratings yet

- Aerospace Optical Sensors Handout WEB v2Document2 pagesAerospace Optical Sensors Handout WEB v2ggggggbNo ratings yet

- Optical Strain Gage - Os3155: Key Features DescriptionDocument2 pagesOptical Strain Gage - Os3155: Key Features DescriptionYi-jen ChanNo ratings yet

- UTP Cable Datasheet Nexans N100-605-O5Document3 pagesUTP Cable Datasheet Nexans N100-605-O5Ruddy Alfredo Cabrejos RamosNo ratings yet

- Calvin Youngman - Imes - IntegrityDocument4 pagesCalvin Youngman - Imes - IntegrityMateen AhmedNo ratings yet

- Optical Fiber Sensors for Suramadu Bridge MonitoringDocument81 pagesOptical Fiber Sensors for Suramadu Bridge MonitoringHeniNo ratings yet

- CM-P1 11604 EN SKF Vibration Sensors Catalog InstallationDocument8 pagesCM-P1 11604 EN SKF Vibration Sensors Catalog Installationambresh.09No ratings yet

- 1 1859218 6 Product SpecificationsDocument3 pages1 1859218 6 Product SpecificationsAlberto MartinezNo ratings yet

- 1542 22 GHZ 1310 NM Microwave DFB Laser: ApplicationsDocument4 pages1542 22 GHZ 1310 NM Microwave DFB Laser: ApplicationsParasaram SrinivasNo ratings yet

- Training Report: Fiber Optics and Power MeasurementsDocument14 pagesTraining Report: Fiber Optics and Power MeasurementsahmadramahyNo ratings yet

- Lecture 6. ComponentsDocument53 pagesLecture 6. ComponentsAmalia AzizahNo ratings yet

- Design of X-Band Micro Strip Line / Strip Line Filter: Y. Murali Mohan Babu, P.A.Harshavardhini, G.C.NarasimhuluDocument5 pagesDesign of X-Band Micro Strip Line / Strip Line Filter: Y. Murali Mohan Babu, P.A.Harshavardhini, G.C.NarasimhuluDr.P.A.Harsha VardhiniNo ratings yet

- Uacc Om MM - DsDocument2 pagesUacc Om MM - DsLeonardo Dominguez GarciaNo ratings yet

- 4000mp Ds Fop TM AeDocument2 pages4000mp Ds Fop TM AeSebastianCaroAvantecNo ratings yet

- Aviat ODU600sp Used With CTR 8300 - 8540 (Rel - 2 - 4) Microwave Tech Spec (ETSI) - Aug 2017Document14 pagesAviat ODU600sp Used With CTR 8300 - 8540 (Rel - 2 - 4) Microwave Tech Spec (ETSI) - Aug 2017franz tercerosNo ratings yet

- 3300 5mm TransducerDocument15 pages3300 5mm TransducerTheerayootNo ratings yet

- Anritsu - Mt9085seriesDocument20 pagesAnritsu - Mt9085seriesFrancisco SeNo ratings yet

- MMIC Processing Techniques and Design ConsiderationsDocument23 pagesMMIC Processing Techniques and Design ConsiderationsVishal IyerNo ratings yet

- Imc-21 Series: Entry-Level Industrial 10/100baset (X) To 100basefx Media ConvertersDocument3 pagesImc-21 Series: Entry-Level Industrial 10/100baset (X) To 100basefx Media ConvertersDamjan BabicNo ratings yet

- Unit 5 - 18ECC302J - Seesion 1-4Document49 pagesUnit 5 - 18ECC302J - Seesion 1-4Harsha Vardhan ReddyNo ratings yet

- 012TEY-13188A2G - 12 Brins OM3 Armé en AcierDocument3 pages012TEY-13188A2G - 12 Brins OM3 Armé en Aciermic68hc11No ratings yet

- FMCI Series Ethernet Optical Fiber Media Converters: Product SpecificationDocument2 pagesFMCI Series Ethernet Optical Fiber Media Converters: Product SpecificationSakerhetsNo ratings yet

- 7sd 522 Presentation StudiesDocument17 pages7sd 522 Presentation Studiesjacob john100% (1)

- 1) To Establish A Digital Fiber Optical Link.: Pimpri Chinchwad College of EngineeringDocument5 pages1) To Establish A Digital Fiber Optical Link.: Pimpri Chinchwad College of EngineeringCat CheshireNo ratings yet

- Opt Hs TR Solution E1300Document8 pagesOpt Hs TR Solution E1300jualapasaja2015No ratings yet

- Premo-Flex Flat Flexible (FFC) Cable Jumpers: Features and AdvantagesDocument2 pagesPremo-Flex Flat Flexible (FFC) Cable Jumpers: Features and AdvantagesPhilip TadrousNo ratings yet

- FTV10D1/FRV10D1 Fiber Transmitter and Receiver: Product SpecificationDocument9 pagesFTV10D1/FRV10D1 Fiber Transmitter and Receiver: Product Specificationkenneth1195No ratings yet

- Metrix DPS Data Sheet Digital Proximity System Dps Doc 1087015Document10 pagesMetrix DPS Data Sheet Digital Proximity System Dps Doc 1087015abelNo ratings yet

- Understanding Fiber Optics Po Fop TM AeDocument1 pageUnderstanding Fiber Optics Po Fop TM AeAghna Tiyas MandalNo ratings yet

- DFX 250 Cable, Plenum: Features and BenefitsDocument3 pagesDFX 250 Cable, Plenum: Features and BenefitsRicardo RodriguesNo ratings yet

- TS Technical Specification For OPGW Fibre Optic CableDocument10 pagesTS Technical Specification For OPGW Fibre Optic CableabhishekNo ratings yet

- FTV10D1/FRV10D1 Fiber Transmitter and Receiver: Product SpecificationDocument2 pagesFTV10D1/FRV10D1 Fiber Transmitter and Receiver: Product SpecificationSakerhetsNo ratings yet

- Digital Proximity System (DPS) : The DPS Consists of Three Elements: A Probe, Extension Cable, and Driver or TransmitterDocument11 pagesDigital Proximity System (DPS) : The DPS Consists of Three Elements: A Probe, Extension Cable, and Driver or TransmitterDiego Alejandro Bermudez NuñezNo ratings yet

- E14F10P78 Product SpecificationsDocument3 pagesE14F10P78 Product SpecificationsAnonymous cDWQYsjd9No ratings yet

- Product SpecificationsDocument3 pagesProduct SpecificationsKhaled AlomariNo ratings yet

- Electrical Measurement and TestingDocument12 pagesElectrical Measurement and TestingMYres PengsonNo ratings yet

- Moxa Imc 21 Series Datasheet v1.3Document3 pagesMoxa Imc 21 Series Datasheet v1.3EdwinNo ratings yet

- Piezo Copolymer Coaxial Cable: SpecificationsDocument4 pagesPiezo Copolymer Coaxial Cable: SpecificationsArnas MAJUMDERNo ratings yet

- Cat. 6AF-UTP PDFDocument2 pagesCat. 6AF-UTP PDFGTest DrinkWaterNo ratings yet

- MV CONNEX Technical Data Surge Arrester Size 2 and DrawingDocument6 pagesMV CONNEX Technical Data Surge Arrester Size 2 and DrawingFelipe Mafioletti SchuartzNo ratings yet

- Medium Range (MR) OTDR Module: MTS/T-BERD PlatformsDocument6 pagesMedium Range (MR) OTDR Module: MTS/T-BERD PlatformsAlison ThomasNo ratings yet

- O F C-Details - Very GoodDocument230 pagesO F C-Details - Very GoodAyub MujtabaNo ratings yet

- AVIAT ODU 600 ETSI specs for CTR 8540 and 8300Document14 pagesAVIAT ODU 600 ETSI specs for CTR 8540 and 8300Sandra Milena ViracachaNo ratings yet

- 542 400 058 enDocument1 page542 400 058 enYi-jen ChanNo ratings yet

- March 2023 CFCC Manual V1.02Document34 pagesMarch 2023 CFCC Manual V1.02Yi-jen ChanNo ratings yet

- CFCC_SpecificationsDocument1 pageCFCC_SpecificationsYi-jen ChanNo ratings yet

- HYPERION Optical Sensing Instrument - Si255: Description Key FeaturesDocument2 pagesHYPERION Optical Sensing Instrument - Si255: Description Key FeaturesYi-jen ChanNo ratings yet

- HYPERION Optical Sensing Instrument - Si155: Description Key FeaturesDocument2 pagesHYPERION Optical Sensing Instrument - Si155: Description Key FeaturesYi-jen ChanNo ratings yet

- Optical Strain Gage - Os3155: Key Features DescriptionDocument2 pagesOptical Strain Gage - Os3155: Key Features DescriptionYi-jen ChanNo ratings yet

- Cns 10896Document23 pagesCns 10896Yi-jen ChanNo ratings yet

- C 989 - C 989M - 爐石Document7 pagesC 989 - C 989M - 爐石Yi-jen ChanNo ratings yet

- C 618 - 03 - Qzyxoa - PDFDocument3 pagesC 618 - 03 - Qzyxoa - PDFphaindikaNo ratings yet

- Reparatii DrujbaDocument279 pagesReparatii Drujbaest_nuNo ratings yet

- HCL - Acid Regeneration Plant: Tyasa I E VDocument107 pagesHCL - Acid Regeneration Plant: Tyasa I E Vjose santiago vazquezNo ratings yet

- 300MW Coal Power Plant in Davao Inaugurated PDFDocument5 pages300MW Coal Power Plant in Davao Inaugurated PDFAlan P. MangalimanNo ratings yet

- Info Iec62271-203 (Ed1.0) en DDocument11 pagesInfo Iec62271-203 (Ed1.0) en DdvamseeramNo ratings yet

- Installation, Operation, and Maintenance: Stealth™ Air-Cooled Chiller Model RTAEDocument80 pagesInstallation, Operation, and Maintenance: Stealth™ Air-Cooled Chiller Model RTAEghilesNo ratings yet

- Siemens Hydrogen-Cooled Generators With Water-Cooled Stator WindingsDocument3 pagesSiemens Hydrogen-Cooled Generators With Water-Cooled Stator WindingsPradeep_VashistNo ratings yet

- CSIPL ProfileDocument11 pagesCSIPL ProfileSachin SachhNo ratings yet

- BFSK ReportDocument8 pagesBFSK ReportSneh Sagar RajputNo ratings yet

- Time Sheet - JulyDocument3 pagesTime Sheet - JulyraghuNo ratings yet

- Service Manual: Compact Disc ReceiverDocument44 pagesService Manual: Compact Disc ReceiverJorge Fernando de TivantaNo ratings yet

- أ. د / ﻴ اﺮﺑاﺮ ﺎﻄﻟا ،ةﺮﻜﺴ ﺔﻌﻣﺎﺟ ﺮﺋاﺰ ا - Brahimit@Live.Fr:Document23 pagesأ. د / ﻴ اﺮﺑاﺮ ﺎﻄﻟا ،ةﺮﻜﺴ ﺔﻌﻣﺎﺟ ﺮﺋاﺰ ا - Brahimit@Live.Fr:الاستادة بختةNo ratings yet

- JLL Chennai Residential Hotspots ReportDocument32 pagesJLL Chennai Residential Hotspots ReportGnaneswaranNo ratings yet

- EPRI Phosphat & Caustic Treatment GuidelinesDocument404 pagesEPRI Phosphat & Caustic Treatment Guidelinesrizal100% (7)

- Sizing of Capacitors Placed Ieee 735 PDFDocument9 pagesSizing of Capacitors Placed Ieee 735 PDFEnrique Anchundia GuerreroNo ratings yet

- 1.CEK LIST Syringe Pump PDFDocument1 page1.CEK LIST Syringe Pump PDFsri lestariNo ratings yet

- AIR32-AIR21 13102016 Rev ADocument8 pagesAIR32-AIR21 13102016 Rev ADENVALENZNo ratings yet

- ECA Task Force CCS GuidelineDocument54 pagesECA Task Force CCS Guidelineto van trung100% (3)

- Hull Speed & Slip FormulaDocument4 pagesHull Speed & Slip FormulaAlina BrescanNo ratings yet

- B2B Marketing Chapter on Managing InnovationDocument23 pagesB2B Marketing Chapter on Managing InnovationSaurabh JainNo ratings yet

- 0417 m15 QP 12, JDocument16 pages0417 m15 QP 12, JlsorourNo ratings yet

- Basics of Fire and Smoke Damper Installations - NFPADocument9 pagesBasics of Fire and Smoke Damper Installations - NFPAumerNo ratings yet

- Brittle Coating and Strain GaugeDocument29 pagesBrittle Coating and Strain GaugeAavash ShresthaNo ratings yet

- 22LS350S, 350T, 359S, 359T, 3500, 3510, 3590Document52 pages22LS350S, 350T, 359S, 359T, 3500, 3510, 3590Kiran VeesamNo ratings yet

- Latj 201190020Document4 pagesLatj 201190020Siddharth JhambNo ratings yet

- C++ Arrays - TutorialspointDocument3 pagesC++ Arrays - TutorialspointevilplueNo ratings yet

- CSP Mill PresentationDocument14 pagesCSP Mill PresentationGHANESH MAHANTANo ratings yet

- Asme Manual QuestionDocument4 pagesAsme Manual QuestionAjay SajeevNo ratings yet

- Modbus PVC To PowerFlex4MDocument4 pagesModbus PVC To PowerFlex4MEduardo Pinto VargasNo ratings yet

- Finisher SR3120 (D636) 111219Document54 pagesFinisher SR3120 (D636) 111219william lozadaNo ratings yet

- Solar AdvancedDocument48 pagesSolar AdvancedlakshmiramasubbuNo ratings yet