Professional Documents

Culture Documents

PC-7320 (Polypoxy) - TDS

Uploaded by

edwin cCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PC-7320 (Polypoxy) - TDS

Uploaded by

edwin cCopyright:

Available Formats

Preliminary technical data sheet-

LOCTITE PC-7320

Product 3981

PRODUCT DESCRIPTION:

PERFORMANCE OF CURED MATERIAL

LOCTITE® Polypoxy PS is a solvent free elastomeric epoxy

(Cured at 25 C for 7 days, Tested @ 25 °C unless noted)

coating material, used to protect steel and concrete from Typical Value

chemical & mechanical attack. Epoxy is copolymerized with N/mm2

reactive flexible polysulfide based polymer that ensures long

lasting performance with high integrity and toughness. Fully Hardness, ASTM D-1706, SHORE D 50-60

cured coating provides better hardness & flexibility, superior Tensile Strength, ASTM D-412 >9

impact strength & minimize the brittle failure. This epoxy Adhesion on dry concrete, ASTM D 4541 2.5-4

coating has good water resistance features that provides (Concrete failure)

application area of water proofing and metal protection Adhesion on wet concrete, ASTM D 4541 1.5-2.5

(Concrete failure)

with service temperatures of -20 to 103 °C.

LOCTITE® Characteristics: Mixing:

Polysulfide modified

Chemistry 1. Thoroughly stir Part A (Resin) and Part B

epoxy

(Hardener) before mixing.

Appearance Light Grey

2. Material temperature should be between 18 °C to

Pot life @ 25ºC 45 min 27 °C.

% Solids 100 % 3. Mixing time should be 1-2 min.

Full cure @ 25ºC 7 days 4. As viscosity rises with time after mixing, it is

Shelf life 1 year recommended to mix only an amount that could be

Recommended DFT 10 mil applied within the application window (45 min).

TYPICAL PROPERTIES OF UNCURED MATERIAL Application Method:

Part A Range 1. Apply fully mixed material to the surface by roller or

Viscosity, Brookfield- 25 °C, (cP): 25000-35000 brush.

Density, gm/cc 1.45-1.55

2. 2nd coat to be applied at least after 4-6 hour of 1st

Part B coat.

Viscosity, Brookfield- 25 °C, (cP): 3000-5000 3. Cure the material for minimum of 7days at 25 °C for

Density, gm/cc 1.5-1.6 better chemical resistance and hardness.

4. Alternatively, LOCTITE® can be applied using

Mixed:

Viscosity, Brookfield- 25 °C, (cP): 8000-12000

airless spray gun. Henkel TCS group can provide

Mixed ratio (A: B) by weight 1:1 specific details of the equipment.

By Volume 1:1

TYPICAL CURING PERFORMANCE Caution:

(@ 25 °C unless noted)

Technical Tips for Working with Loctite@ Working

Curing Properties Typical Value time and cure depends on temperature and mass:

● The higher is the temperature, the faster the cure.

Working life 45 min

Tack free Time 250 µ DFT 240 min ● The larger the mass of material, the faster the cure.

Recommended Recoat Time 4- 6 hour

Foot traffic 48 hour

Chemical Exposure 7 days

NOT FOR PRODUCT SPECIFICATIONS

THE TECHNICAL DATA CONTAINEDHEREIN ARE INTENTED AS REFERENCE ONLY

PLEASE CONTACT HENKEL ADHESIVES TECHNOLOGIES TECHNICAL DEPARTNMENT FOR ASSISTANCE AND RECOMMENDATIONS ON SPECIFICATIONS FOR THIS PRODUCT

JEJURI, PUNE, INDIA 412 303 Ph +91 2115300000 FAX + 91 2115 253248

LOCTITE ® Flexi Corrosion Resistant Coating

Storage

Store product in the unopened container in a dry

location. Material removed from containers may be

contaminated during use. Do not return liquid to original

container. Storage information may be indicated on the

product container labeling. Optimal Storage: 18 °C to

25 °C. Storage below 10 °C or greater than 30 °C

can adversely affect product properties. Henkel

cannot assume responsibility for product which has

been contaminated or stored under conditions other

than those recommended. If additional information is

required, please contact your local Technical Service

Center or Customer Service Representative.

Note

The data contained herein are furnished for information

only and are believed to be reliable. Nevertheless,

Henkel Corporation cannot assume responsibility for

the results obtained by others over whose production

methods we have no control. Thus, it is the user's

responsibility to determine the suitability of this

developmental product for the user's purpose of any

production methods mentioned herein and to adopt

such precautions as may be advisable for the protection

of property and of persons against any hazards that

may be involved in the handling and use thereof. In light

of the foregoing, Henkel Corporation Specifically

Disclaims all warranties expressed or implied,

including warranties of merchantability or fitness

for a particular purpose, arising from sale or use of

Henkel Corporation’s products. Henkel Corporation

specifically disclaims any liability for consequential

or incidental damages of any kind including lost

profits. The discussion herein of various processes or

compositions, are to be interpreted as representation

that they are free from domination of patents owned by

others or as license under any Henkel Corporation

patents that may cover such processes or compositions.

NOT FOR PRODUCT SPECIFICATIONS

THE TECHNICAL DATA CONTAINEDHEREIN ARE INTENTED AS REFERENCE ONLY

PLEASE CONTACT HENKEL ADHESIVES TECHNOLOGIES TECHNICAL DEPARTNMENT FOR ASSISTANCE AND RECOMMENDATIONS ON SPECIFICATIONS FOR THIS PRODUCT

JEJURI , PUNE , INDIA 412 303 Ph +91 2115 300000, FAX + 91 2115 253248

You might also like

- The Twigan Cultural Centre Dispute: T I L M C C 2017Document59 pagesThe Twigan Cultural Centre Dispute: T I L M C C 2017Adimarta TeguhNo ratings yet

- Automatic Transmissions and Transaxles Halderman Automotive SeriesDocument314 pagesAutomatic Transmissions and Transaxles Halderman Automotive SeriesDavide Binelli100% (2)

- Software Review Testing - SRT Question and Answers - TrenovisionDocument46 pagesSoftware Review Testing - SRT Question and Answers - TrenovisionShadow Gaming50% (4)

- Injection: Solutions For Underground ConstructionDocument12 pagesInjection: Solutions For Underground ConstructionDevinder SokhiNo ratings yet

- Sikaproof Membrane: Safety Data SheetDocument6 pagesSikaproof Membrane: Safety Data SheetSamuel CastilloNo ratings yet

- POLYPOXY-NF Technical Data SheetDocument2 pagesPOLYPOXY-NF Technical Data SheetCommando crawlerNo ratings yet

- Iso 2503 1998 en FR PDFDocument8 pagesIso 2503 1998 en FR PDFInversiones thinkupNo ratings yet

- Tablas Cf574 - Sika Base AguaDocument13 pagesTablas Cf574 - Sika Base AguaDaniel PatronNo ratings yet

- Fosroc Chemical Breaker PDFDocument2 pagesFosroc Chemical Breaker PDFtalatzahoorNo ratings yet

- 10 - TDS - Emaco S22 NBDocument3 pages10 - TDS - Emaco S22 NBaahtagoNo ratings yet

- TDS Lokfix SFS India3Document4 pagesTDS Lokfix SFS India3R L RaoNo ratings yet

- CPVCDocument3 pagesCPVCannamalaicvNo ratings yet

- ISO 1512-1991 (Partial)Document9 pagesISO 1512-1991 (Partial)smupy_122-1No ratings yet

- IS 2185 Part1 2005Document1 pageIS 2185 Part1 2005stoneghoo2618No ratings yet

- Design No. XR736: BYBU - XR736 Fire-Resistance Ratings - ANSI/UL 1709 Design/System/Construction/Assembly Usage DisclaimerDocument2 pagesDesign No. XR736: BYBU - XR736 Fire-Resistance Ratings - ANSI/UL 1709 Design/System/Construction/Assembly Usage DisclaimeredoNo ratings yet

- Sikatherm® Foam 45 IN: Product Data SheetDocument4 pagesSikatherm® Foam 45 IN: Product Data SheetTarun KumarNo ratings yet

- PDFDocument22 pagesPDFasitdeyNo ratings yet

- Interthane 990 Test Data PDFDocument2 pagesInterthane 990 Test Data PDFImam Situmeang100% (2)

- Pure Epoxy Fx-E400: Technical Data SheetDocument7 pagesPure Epoxy Fx-E400: Technical Data SheetRana Ahmad Aamir100% (1)

- Aropol in 5334Document2 pagesAropol in 5334GautamNo ratings yet

- EN ISO 23278-2009 (Replace EN 1291) PDFDocument12 pagesEN ISO 23278-2009 (Replace EN 1291) PDFThe Normal HeartNo ratings yet

- Nitoflor SL1000: Flow Applied, 0.5 - 1.5mm Thick Epoxy Resin Based Floor Topping UsesDocument4 pagesNitoflor SL1000: Flow Applied, 0.5 - 1.5mm Thick Epoxy Resin Based Floor Topping UsestalatzahoorNo ratings yet

- BS 7079-C2 1989 Preparation of Steel SubstrDocument15 pagesBS 7079-C2 1989 Preparation of Steel SubstrTeymur RegenmaisterNo ratings yet

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 pagesDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraNo ratings yet

- Fenomastic Hygiene Emulsion SilkDocument4 pagesFenomastic Hygiene Emulsion Silkمحمد عزتNo ratings yet

- DC 781 Acetoxy SealantDocument3 pagesDC 781 Acetoxy SealantL.S.No ratings yet

- DS - 645 - Pro Anticarb HB Elastomeric CoatingDocument2 pagesDS - 645 - Pro Anticarb HB Elastomeric CoatingRay EngineeringNo ratings yet

- Etag 002 PT 2 PDFDocument13 pagesEtag 002 PT 2 PDFRui RibeiroNo ratings yet

- Sikaproof Membrane: Product Data SheetDocument2 pagesSikaproof Membrane: Product Data SheetKennethNo ratings yet

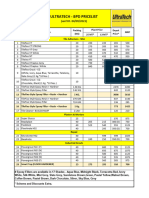

- DSR PuneDocument4 pagesDSR PunedigvijayjagatapNo ratings yet

- TDS - IPNet SystemDocument2 pagesTDS - IPNet SystemRadha KrishnanNo ratings yet

- QCDFSS-3.15.1 - Intumescent PaintsDocument2 pagesQCDFSS-3.15.1 - Intumescent PaintsAnoirNo ratings yet

- Coating As An Ideal Prevention For Corrosion in Manufacture and Infrastructure IndustryDocument43 pagesCoating As An Ideal Prevention For Corrosion in Manufacture and Infrastructure IndustryLarasanto Larasanto100% (1)

- TDS - Sonoshield ParkcoatDocument2 pagesTDS - Sonoshield ParkcoatVenkata RaoNo ratings yet

- Proceq Equotip 2 Operator ManualDocument35 pagesProceq Equotip 2 Operator ManualAzee TitouNo ratings yet

- K-Flex Insul-SheetDocument2 pagesK-Flex Insul-SheetJuan SantosNo ratings yet

- Isobond: SBR Bonding AdmixtureDocument3 pagesIsobond: SBR Bonding AdmixtureHussain MarzooqNo ratings yet

- Mil PRF 32440B - Amendment 1Document17 pagesMil PRF 32440B - Amendment 1eiearjun100% (1)

- Quality HandbookDocument8 pagesQuality HandbookGuillermo Guerrero VacasNo ratings yet

- TDS005-Grade 2 and ASTM A307 BoltingDocument2 pagesTDS005-Grade 2 and ASTM A307 BoltingKrish DoodnauthNo ratings yet

- Drymix Price List 04092023Document1 pageDrymix Price List 04092023Dhruv ChadderwalaNo ratings yet

- Technical Submittal: Product Name Nitoflor EPU100Document14 pagesTechnical Submittal: Product Name Nitoflor EPU100rayNo ratings yet

- A1-80-3 External Painting and Coating - 1Document16 pagesA1-80-3 External Painting and Coating - 1ZYW100% (1)

- En 1436 2018-03 DINEN Road Marking Materials-TestmethodDocument33 pagesEn 1436 2018-03 DINEN Road Marking Materials-TestmethodTotal SolutionNo ratings yet

- TDS Nitocote EPU Saudi ArabiaDocument4 pagesTDS Nitocote EPU Saudi ArabiaShaikhRizwan100% (1)

- BS EB 934 - 6 - 2001 Corr 13534 Oct 01Document12 pagesBS EB 934 - 6 - 2001 Corr 13534 Oct 01Abu Muhammad iftikharNo ratings yet

- Epoxy ChalkingDocument2 pagesEpoxy Chalkingiran1362100% (1)

- Nitocote ET402: Constructive SolutionsDocument4 pagesNitocote ET402: Constructive SolutionsSinan A AzizNo ratings yet

- Technical Data Sheet: Stolevell Thinplast FinishDocument3 pagesTechnical Data Sheet: Stolevell Thinplast FinishAnthony Al Lakiss0% (1)

- C1582C1582M-Aditivos Inhibidores de CorrosionDocument10 pagesC1582C1582M-Aditivos Inhibidores de CorrosionAnthony López HuamanNo ratings yet

- Datasheet File - Conbextra GPDocument3 pagesDatasheet File - Conbextra GPmuraliNo ratings yet

- Astm C868-02 PDFDocument4 pagesAstm C868-02 PDFIan HsuNo ratings yet

- Astm D3282 93 - 260421Document6 pagesAstm D3282 93 - 260421Mark D VillanuevaNo ratings yet

- Astm D4385-10Document7 pagesAstm D4385-10roshniNo ratings yet

- 9975 2Document5 pages9975 2Senthil Kumar GanesanNo ratings yet

- Carbomastic 801 PDFDocument2 pagesCarbomastic 801 PDFkayNo ratings yet

- Product Profile For Concrete Repair ProductsDocument10 pagesProduct Profile For Concrete Repair ProductshemantrulzNo ratings yet

- GB5237.2-2017 英文Document16 pagesGB5237.2-2017 英文TheAnh TranNo ratings yet

- Data Sheet Proguard CN 200 A.SDocument3 pagesData Sheet Proguard CN 200 A.SAlexir Thatayaone NdovieNo ratings yet

- 0693 Bs2752 c50 50 Shore Specification Neoprene Chloroprene CR Rubber SheetDocument2 pages0693 Bs2752 c50 50 Shore Specification Neoprene Chloroprene CR Rubber SheetSerboNo ratings yet

- Luxathane 5000 Polyurethane High Gloss Finish: Technical DataDocument3 pagesLuxathane 5000 Polyurethane High Gloss Finish: Technical DataPV AnandNo ratings yet

- My T Bond Fast and Clear Epoxy TDSDocument2 pagesMy T Bond Fast and Clear Epoxy TDSChetan MahajanNo ratings yet

- GRP and Buildings: A Design Guide for Architects and EngineersFrom EverandGRP and Buildings: A Design Guide for Architects and EngineersNo ratings yet

- Msds Loctite 401 Idh 231472Document9 pagesMsds Loctite 401 Idh 231472edwin cNo ratings yet

- Teroson WX 178 HPDocument14 pagesTeroson WX 178 HPedwin cNo ratings yet

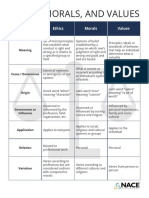

- Intro NACE EthicDocument1 pageIntro NACE Ethicedwin cNo ratings yet

- Credentialling ChecklistDocument2 pagesCredentialling Checklistedwin cNo ratings yet

- Owners Manual Comp Shock KTM 125 390 RC DukeDocument8 pagesOwners Manual Comp Shock KTM 125 390 RC Dukeedwin cNo ratings yet

- HP Board of School Education Dharamshala Syllabus: Subject: Computer Science Class: 9Document4 pagesHP Board of School Education Dharamshala Syllabus: Subject: Computer Science Class: 9Principal AveriNo ratings yet

- Danfoss: New Light Commercial Scroll CompressorsDocument1 pageDanfoss: New Light Commercial Scroll Compressors12345laurNo ratings yet

- LIFTING PLAN2 of Materials and ContainerDocument9 pagesLIFTING PLAN2 of Materials and Containersubajit bhattacharjeeNo ratings yet

- Undergraduate Curriculum Vitae: PublicationsDocument1 pageUndergraduate Curriculum Vitae: PublicationsMuhammad Zaim EmbongNo ratings yet

- Class - 20200904 Restore - Recovery Using Keystore (My Practice)Document23 pagesClass - 20200904 Restore - Recovery Using Keystore (My Practice)RaihanNo ratings yet

- Liebert VFD Condenser - Model TCDV - Product Information Manual PDFDocument12 pagesLiebert VFD Condenser - Model TCDV - Product Information Manual PDFingfcontrerasNo ratings yet

- Case Studies of Steel Structure Failures PDFDocument6 pagesCase Studies of Steel Structure Failures PDFAvim Wira RagendaNo ratings yet

- Gujarat Technological University: Computer Engineering (Software Engineering) (02) Semester IDocument23 pagesGujarat Technological University: Computer Engineering (Software Engineering) (02) Semester IdivyaNo ratings yet

- Radio OperatorDocument2 pagesRadio OperatorJethro StanlyNo ratings yet

- Top 7 PMP Study Tips To Ace PMP Exam and Tackle PMP Exam QuestionsDocument13 pagesTop 7 PMP Study Tips To Ace PMP Exam and Tackle PMP Exam QuestionsBenchinoune AbderrahimNo ratings yet

- Foreign LiteratureDocument3 pagesForeign LiteratureAngeline HermosoNo ratings yet

- SM-T587P (Phonelumi Com)Document81 pagesSM-T587P (Phonelumi Com)Tomaso SulisNo ratings yet

- 2023 2024 Baldrige Excellence BuilderDocument24 pages2023 2024 Baldrige Excellence BuilderAlin Valentin Angheluta100% (1)

- HP LaserJet MFP M72625-M72630 Series Service Training - V0.94 - 20180206Document130 pagesHP LaserJet MFP M72625-M72630 Series Service Training - V0.94 - 20180206smrizalNo ratings yet

- (Notes) Financial Management FundamentalsDocument65 pages(Notes) Financial Management FundamentalsJoanna Danielle AngNo ratings yet

- Polycet Hallticket Revised ProformaDocument1 pagePolycet Hallticket Revised ProformaChinsdazz KumarNo ratings yet

- Raising FinanceDocument17 pagesRaising FinanceJephthah BansahNo ratings yet

- Chapter 4 - Partnership LiquidationDocument4 pagesChapter 4 - Partnership LiquidationMikaella BengcoNo ratings yet

- Project Report On Finance InvestmentsDocument106 pagesProject Report On Finance InvestmentsYalluraj HukkeriNo ratings yet

- Using Plant 3D in A State Plane Coordinate Project EnvironmentDocument12 pagesUsing Plant 3D in A State Plane Coordinate Project EnvironmentALBERTO ABSALON CRISTOBAL YACHASNo ratings yet

- Important Case Law & Legal GK 2020Document25 pagesImportant Case Law & Legal GK 2020kusu100% (1)

- Joint Accounts On Forex DepositsDocument2 pagesJoint Accounts On Forex DepositsdailydoseoflawNo ratings yet

- Uppercase Letter TracingDocument27 pagesUppercase Letter TracingElvis AungNo ratings yet

- 001-0001-12 Quality System ManualDocument12 pages001-0001-12 Quality System ManualPramod AthiyarathuNo ratings yet

- Chapter 1 The Accountancy ProfessionDocument7 pagesChapter 1 The Accountancy ProfessionJoshua Sapphire AmonNo ratings yet

- MODULE 1 Cafeteria by MJ RellonDocument24 pagesMODULE 1 Cafeteria by MJ RellonTricia Ann A. SodsodNo ratings yet