Professional Documents

Culture Documents

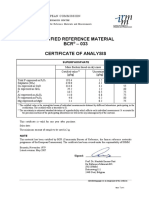

Statement of Measurement: Poultry Feed - Proximates and Elements

Uploaded by

eduardo hernandezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Statement of Measurement: Poultry Feed - Proximates and Elements

Uploaded by

eduardo hernandezCopyright:

Available Formats

Statement of

measurement 4005

Poultry feed – proximates and elements

Reference Material LGC7173

Assessed Values

Number of Assessed value1 Uncertainty2

Constituent Weight3 (g) k value4

laboratories (g/100 g) (g/100 g)

Moisture 9 10.70 0.36 5 2.26

Nitrogen 9 2.559 0.062 0.25 2.14

Oil 8 4.95 0.23 2.5 2.31

Ash 9 7.224 0.091 5 2.18

Crude Fibre 7 3.75 0.38 1 2.11

Number of Assessed value1 Uncertainty2

Constituent Weight3 (g) k value4

laboratories (mg/kg) (mg/kg)

Calcium 10 17800 1200 0.5 2.12

Copper 9 14.0 4.0 0.5 2.12

Iron 9 148 27 0.5 2.09

Magnesium 8 2037 81 0.5 2.09

Manganese 10 90 13 0.5 2.09

Phosphorus 9 6590 370 0.5 2.20

Potassium 9 7480 310 0.5 2.16

Sodium 9 1180 130 0.5 2.09

Zinc 10 78 15 0.5 2.10

Notes:

1. These values have been assigned using data derived from a variety of methods – see page 3.

2. The uncertainty quoted is the half-width of the expanded uncertainty interval calculated using a coverage factor

(k), providing a level of confidence of approximately 95 %.

3. Weight of sample taken for homogeneity assessment.

4. Coverage factor (k).

Date of Issue: January 2020

Signed:

Gill Holcombe (Mrs)

for the Government Chemist

Material number: LGC7173

Batch number: 004

Page 1 of 5

Indicative Values

The following figures have not been assessed but are provided for information purposes and should

be regarded as indicative values only.

Constituent Content (g/100 g)

Starch 41

Chloride 0.23

Material Production

A sample of poultry feed, purchased from a commercial animal feed manufacturer, was ground to

pass a 1 mm sieve, thoroughly mixed and vacuum-sealed in sachets as 50 g portions.

Homogeneity

The homogeneity of the packaged material was assessed by the analysis of a representative

number of units for each constituent of interest. A value was calculated for the between unit

variation for each constituent and an uncertainty was estimated for each constituent due to any

possible non-homogeneity.

Characterisation

The material was characterised by means of an inter-laboratory exercise organised by LGC.

Laboratories were asked to determine Moisture, Crude Protein (expressed as Nitrogen), Oil

(according to procedure ‘B’), Ash, Crude Fibre and Starch according to ‘EEC methods of analysis

for the official control of feedingstuffs’ as incorporated into UK law in ‘The Feeding Stuffs (Sampling

and Analysis) Regulations 2009’. Analytical methods were not specific by LGC for the remaining

analytes. Details of the analytical methods used for the characterisation of this material are

contained in the following pages.

The assessed values are based on the mean of the individual laboratory means, after elimination of

outlying results. The standard deviation of the mean of the laboratory means was used to calculate

the uncertainty arising from the inter-laboratory characterisation exercise. The combined expanded

uncertainty for each assessed value (quoted in the tables on page 1) was calculated by combining

the inter-laboratory characterisation uncertainty with an uncertainty value calculated from the

homogeneity assessment, and expanding using an appropriate coverage factor to obtain a 95 %

confidence interval.

Stability

Previous experience suggests that this material is stable over the anticipated lifetime, however

LGC7173 Batch 004 will be subjected to routine stability testing under LGC’s ‘reference material

stability testing’ program. Purchasers will be informed of any changes that affect the assessed

values.

Material number: LGC7173

Batch number: 004

Page 2 of 5

Summary of Analytical Techniques Used by Laboratories in the

Characterisation Study (Accepted Data Only)

The techniques used for the characterisation of this material are shown below.

Element ICP-OES ICP-MS AAS Other techniques

Calcium 5 4 1 0

Copper 4 4 1 0

Magnesium 5 2 1 0

Phosphorus 5 3 0 1 (Photometric molybdovanadate method)

Potassium 5 3 0 1 (AES)

Sodium 5 3 0 1 (AES)

Iron 5 2 2 0

Manganese 5 4 1 0

Zinc 5 4 1 0

Constituent Techniques used

Moisture Five laboratories determined moisture according to ‘The Feeding Stuffs (Sampling and

Analysis) Regulations 2009. Other laboratories used variations on this procedure

involving heating for longer or shorter periods of time. All used a temperature of

102 – 103 °C.

Nitrogen Three laboratories analysed nitrogen according to ‘The Feeding Stuffs (Sampling and

Analysis) Regulations 2009. Six laboratories made reference to the Dumas method.

Oil Five laboratories analysed oil according to ‘The Feeding Stuffs (Sampling and Analysis)

Regulations 2009. One laboratory used ICC Standard which included an acid digestion

and two laboratories used a Werner Schmidt method.

Ash Two laboratories analysed ash according to ‘The Feeding Stuffs (Sampling and Analysis)

Regulations 2009. Other laboratories used variations on this procedure, including ashing

of the sample at temperatures between 500 °C and 550 °C and for longer periods of time

than the regulation method.

Crude Fibre Four laboratories analysed crude fibre according to ‘The Feeding Stuffs (Sampling and

Analysis) Regulations 2009. The other three laboratories used the following procedures:

Ankom method, Fibre Cap extraction and Fibre bag.

Starch Two laboratories analysed starch according to ‘The Feeding Stuffs (Sampling and

Analysis) Regulations 2009. One laboratory used enzymic hydrolysis of the starch to

glucose and then a glucose determination by the glucose oxidase method with a

spectrophotometric end determination.

Where laboratories used statutory methods, results were consistent with the values reported on

page 1 of this statement.

Material number: LGC7173

Batch number: 004

Page 3 of 5

Intended Use

This material is intended for use in the development, validation or quality control of analytical

methods for the determination of proximates and elements in animal feeding stuffs. The material

may also be applicable to other similar matrices where more clearly matched reference materials

are not available.

Storage Conditions

The reference material should be stored in the unopened sachet at (5 ± 4) °C. Once opened, the

material should be stored in a closed container at (5 ± 4) °C and used within 3 days.

Shelf Life

If stored under the recommended conditions, the assessed values of the material will remain valid

for 12 months from the date of shipment (please refer to page 5 for date of shipment).

Instructions for Use

The sachet should be brought to room temperature (20 ± 5) °C before opening and then the entire

contents transferred immediately to an airtight jar. Stir the powder well before removing a sub-

sample. To minimise any change in moisture content, the lid should be replaced as soon as

possible after removing a sub-sample. The jar may be stored at (5 ± 4) °C for up to 3 days if the

material is to be used again, but should be brought to room temperature (20 ± 5) °C before taking a

sub-sample.

The minimum sample size is dependent upon the analyte and is determined by the weight of the

sample taken for homogeneity assessment (quoted in the tables on page 1).

Metrological Traceability

The assessed values are considered to be traceable to the SI through the physical and chemical

standards used by the participants in the inter-laboratory study.

Participants in the Inter-laboratory Exercise

The number of participants results used in the calculation of the assessed values is given in the

tables on page 1. The following participants took part in the inter-laboratory exercise:

Alliance Technical Laboratories Ltd (UK)

Ashwood UK Ltd (UK)

DM Scientific Ltd (UK)

Edinburgh Scientific Services (UK)

Industrial Technology Institute (Sri Lanka)

Lancashire County Scientific Services (UK)

Premier Analytical Services (UK)

Sciantec Analytical Services (UK)

The State Laboratory (Ireland)

Trouw Nutrition GB Analytical Services (UK)

Worcestershire Scientific Services (UK)

Material number: LGC7173

Batch number: 004

Page 4 of 5

Unit Number Date of Shipment

Legal notice

The values quoted in this document are the best estimate of the true values within the stated

uncertainties and based on the techniques described herein. No warranty or representation, express

or implied, is made that the use of the product or any information, material, apparatus, method or

process which is the subject of or referred to in this document does not infringe any third party rights.

Further, save to the extent: (a) prohibited by law; or (b) caused by a party's negligence; no party shall

be liable for the use made of the product, any information, material, apparatus, method or process

which is the subject of or referred to in this document. In no event shall the liability of any party

exceed whichever is the lower of: (i) the value of the product; or (ii) £500,000; and any liability for

loss of profit, loss of business or revenue, loss of anticipated savings, depletion of goodwill, any third-

party claims or any indirect or consequential loss or damage in connection herewith is expressly

excluded.

This material was produced by LGC in its role as the UK’s National Measurement Laboratory and

Designed Institute for Chemical and Bio-measurement.

This document may not be published except in full, unless permission for the publication of

an approved extract has been obtained in writing from LGC Limited. It does not of itself

impute to the subject of measurement any attributes beyond those shown by the data

contained herein.

Material number: LGC7173

Batch number: 004

Page 5 of 5

You might also like

- Metal Powders: A Global Survey of Production, Applications and MarketsFrom EverandMetal Powders: A Global Survey of Production, Applications and MarketsNo ratings yet

- Certificate of Measurement: Processed Meat - Proximates, Chloride, Hydroxyproline & MetalsDocument5 pagesCertificate of Measurement: Processed Meat - Proximates, Chloride, Hydroxyproline & Metalseduardo hernandezNo ratings yet

- Principles and Applications of Thermal AnalysisFrom EverandPrinciples and Applications of Thermal AnalysisPaul GabbottRating: 4 out of 5 stars4/5 (1)

- Bam m384b eDocument6 pagesBam m384b eterecuaNo ratings yet

- Acirs A-1 2016Document6 pagesAcirs A-1 2016Ahmad IbrahimNo ratings yet

- Certified Reference Material BCR - 074: Certificate of AnalysisDocument3 pagesCertified Reference Material BCR - 074: Certificate of AnalysisJose GarciaNo ratings yet

- Certified Reference Material BCR - 074: Certificate of AnalysisDocument3 pagesCertified Reference Material BCR - 074: Certificate of AnalysisJose GarciaNo ratings yet

- Complete Report Jrc84696Document136 pagesComplete Report Jrc84696mondal2010No ratings yet

- Inductively Coupled Plasma-Mass Spectrometry: Practices and TechniquesFrom EverandInductively Coupled Plasma-Mass Spectrometry: Practices and TechniquesNo ratings yet

- Certificate of Analysis: National Institute of Standards & TechnologyDocument13 pagesCertificate of Analysis: National Institute of Standards & TechnologyOrestes LenizNo ratings yet

- Analysis of Lithium Ore With Avio 550 Max Icp Oes 359050Document6 pagesAnalysis of Lithium Ore With Avio 550 Max Icp Oes 359050seninhentayNo ratings yet

- Annexure - 1 Fuel and Ash AnalysisDocument3 pagesAnnexure - 1 Fuel and Ash AnalysisashokNo ratings yet

- OREAS 999 CertificateDocument17 pagesOREAS 999 Certificatepatriciad08652986No ratings yet

- Production Technology: Processes, Materials and PlanningFrom EverandProduction Technology: Processes, Materials and PlanningRating: 5 out of 5 stars5/5 (1)

- IAL Chemistry Data Booklet Issue 3Document35 pagesIAL Chemistry Data Booklet Issue 3jeeshan sayed0% (1)

- Tabatana 2023 ReportDocument15 pagesTabatana 2023 ReportKudakwashe Pride ChirendaNo ratings yet

- Theory and application of Microbiological AssayFrom EverandTheory and application of Microbiological AssayRating: 2 out of 5 stars2/5 (1)

- OREAS 999 CertificateDocument17 pagesOREAS 999 Certificatepatriciad08652986No ratings yet

- Fishery Products: Quality, Safety and AuthenticityFrom EverandFishery Products: Quality, Safety and AuthenticityHartmut RehbeinNo ratings yet

- ACIRS G10 2022 CoA Rev01Document4 pagesACIRS G10 2022 CoA Rev01Kase Family (Kei&Ken)No ratings yet

- SJC 20180606 12Document7 pagesSJC 20180606 12elkey987654321No ratings yet

- OREAS 401 CertificateDocument7 pagesOREAS 401 Certificateflysch_ukNo ratings yet

- Icpms2 PDFDocument24 pagesIcpms2 PDFlabkpNo ratings yet

- Unknown Quantitative Analysis of Iron Using ICP OES and REDOX TitrationDocument7 pagesUnknown Quantitative Analysis of Iron Using ICP OES and REDOX TitrationSara Van HorneNo ratings yet

- Report Vol 2Document147 pagesReport Vol 2Inam ur RehmanNo ratings yet

- OREAS 620: Volcanic Hosted Massive Sulphide Zn-Pb-Cu-Ag-Au Ore Certified Reference MaterialDocument17 pagesOREAS 620: Volcanic Hosted Massive Sulphide Zn-Pb-Cu-Ag-Au Ore Certified Reference MaterialKEVINNo ratings yet

- OREAS 600b CertificateDocument22 pagesOREAS 600b CertificatesabisamoNo ratings yet

- Certified Reference Material BCR - 109: Certificate of AnalysisDocument2 pagesCertified Reference Material BCR - 109: Certificate of AnalysisJose GarciaNo ratings yet

- EAF Cost For Different Pellet MixesDocument17 pagesEAF Cost For Different Pellet Mixesnitish wagle100% (1)

- China Shandong Ruyi Sahiwal of Pakistan 2×660MW Coal-Fired Power Station Project 1 Boiler, Set To Start The Debugger StepsDocument32 pagesChina Shandong Ruyi Sahiwal of Pakistan 2×660MW Coal-Fired Power Station Project 1 Boiler, Set To Start The Debugger StepsJawad HussainNo ratings yet

- Certified Reference Material BCR - 033 Certificate of AnalysisDocument3 pagesCertified Reference Material BCR - 033 Certificate of Analysisandri gerhanaNo ratings yet

- Scci - Irr PT Bukit Asam - Maret 2021Document9 pagesScci - Irr PT Bukit Asam - Maret 2021wahyusetyawanNo ratings yet

- OREAS 501c CertificateDocument16 pagesOREAS 501c CertificatejemmacruzNo ratings yet

- AN3486r2-Compound FeedDocument6 pagesAN3486r2-Compound FeedJhonattanIsaacNo ratings yet

- OREAS 502c CertificateDocument17 pagesOREAS 502c CertificatesabisamoNo ratings yet

- Multielement Determination of Used and Unused Lubricating Oils and Base Oils by Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES)Document9 pagesMultielement Determination of Used and Unused Lubricating Oils and Base Oils by Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES)Luis Ernesto Marin JaimesNo ratings yet

- GCE Chemistry Data Booklet Issue 2Document35 pagesGCE Chemistry Data Booklet Issue 2purityplus89% (9)

- Blending Coal PDFDocument68 pagesBlending Coal PDFNur DiansyahNo ratings yet

- NIST 1643fDocument3 pagesNIST 1643fHumberto MachadoNo ratings yet

- Leaching Characteristics of Sulphide Mineralization From The Kay Tanda Prospect, PhilippinesDocument50 pagesLeaching Characteristics of Sulphide Mineralization From The Kay Tanda Prospect, PhilippinesahmedkhidryagoubNo ratings yet

- CRM 221, 3% Ni-Steel Certificate 17.03.22Document2 pagesCRM 221, 3% Ni-Steel Certificate 17.03.22Metal deptNo ratings yet

- Certified Reference Material BCR - 033 Certificate of AnalysisDocument3 pagesCertified Reference Material BCR - 033 Certificate of Analysisandri gerhanaNo ratings yet

- Direct Determination of Lime With EDTA Banerjee1976 - 2Document4 pagesDirect Determination of Lime With EDTA Banerjee1976 - 2Khalid JavedNo ratings yet

- Repeatability & ReproducibilityDocument23 pagesRepeatability & ReproducibilityYantiyanti IINo ratings yet

- Equipment:: (Feed 120000 Bbl/yr About 14000 M /yr)Document8 pagesEquipment:: (Feed 120000 Bbl/yr About 14000 M /yr)Mohamed Sayed AbdoNo ratings yet

- Certificate of Analysis: Canadian Certified Reference MaterialsDocument4 pagesCertificate of Analysis: Canadian Certified Reference MaterialsHAMDAOUI LAMJEDNo ratings yet

- AOC 99.10 Lead, CadmiumDocument3 pagesAOC 99.10 Lead, CadmiumJuan Felipe Romero RojasNo ratings yet

- Astm D 5185 02 Icp PDFDocument7 pagesAstm D 5185 02 Icp PDFReyzza AndiaNo ratings yet

- En Assets ANE4 18328 Analysis of Major and Minor Elements in Cement Pressed Powders Tcm50-55501Document2 pagesEn Assets ANE4 18328 Analysis of Major and Minor Elements in Cement Pressed Powders Tcm50-55501JGGNo ratings yet

- ACIRS-G9-2021 Certificate of Analysis: General Coal Reference MaterialDocument4 pagesACIRS-G9-2021 Certificate of Analysis: General Coal Reference MaterialShintya FebrizaNo ratings yet

- Alternative Fuels For Cement Industry: A ReviewDocument5 pagesAlternative Fuels For Cement Industry: A ReviewAnonymous Ja3jvaXNo ratings yet

- AMIS0248 CertificateDocument8 pagesAMIS0248 CertificatesynedNo ratings yet

- Science Learning Center, November 2001 Written by Bette Kreuz Produced by Ruth Dusenbery, Assisted by Pranjal PatelDocument36 pagesScience Learning Center, November 2001 Written by Bette Kreuz Produced by Ruth Dusenbery, Assisted by Pranjal PatelvirparaNo ratings yet

- Egypt BUEDocument21 pagesEgypt BUEMohamed HussienNo ratings yet

- Practical 01 (Emergency and Laboratory Safety)Document28 pagesPractical 01 (Emergency and Laboratory Safety)Mr. GoogleNo ratings yet

- Labumat 2 Um Sw2.1 Eng v1.2 User ManualDocument60 pagesLabumat 2 Um Sw2.1 Eng v1.2 User ManualCARLOS50% (2)

- 7 Golden Safety Rules For Working in HV LaboratoryDocument4 pages7 Golden Safety Rules For Working in HV LaboratoryPierre Enrique Carrasco FuentesNo ratings yet

- Brochure (Dti)Document2 pagesBrochure (Dti)Harizal HamidNo ratings yet

- Higher Education PDFDocument10 pagesHigher Education PDFBachir lejlifaNo ratings yet

- PSM Compliance ChecklistDocument18 pagesPSM Compliance ChecklistSachin SikkaNo ratings yet

- A Briefing and Design Guide, Laboratories - W. HainDocument160 pagesA Briefing and Design Guide, Laboratories - W. HainlocyoriaslettNo ratings yet

- PMLS 1 Topic 8.0 TransDocument6 pagesPMLS 1 Topic 8.0 TranslalaNo ratings yet

- 2010 - 05 - 2912 - 22 - 06BS-400 Operation Manual (v12.0)Document413 pages2010 - 05 - 2912 - 22 - 06BS-400 Operation Manual (v12.0)RemNo ratings yet

- EM-III Lab DEE C20 Front Pages AC MachineDocument13 pagesEM-III Lab DEE C20 Front Pages AC MachineHarimadhavareddy YenireddyNo ratings yet

- Biotechnology (Fast Track) - Centennial CollegeDocument7 pagesBiotechnology (Fast Track) - Centennial Collegeashoo chaudaryNo ratings yet

- Lab Risk AssessmentDocument8 pagesLab Risk Assessmentaqilah haronNo ratings yet

- Gen Lab Tech ND HNDDocument107 pagesGen Lab Tech ND HNDFavour OjukwuNo ratings yet

- R.E.A.G.E.N.T. Final PDFDocument5 pagesR.E.A.G.E.N.T. Final PDFEsteban TamayoNo ratings yet

- ASTM E691 18 Realización de Un Estudio InterlaboratorioDocument22 pagesASTM E691 18 Realización de Un Estudio InterlaboratorioDoina MarquezNo ratings yet

- WSD Drawing PDFDocument28 pagesWSD Drawing PDFyiuloi997023No ratings yet

- Quality ControlDocument30 pagesQuality ControlkhanNo ratings yet

- Internal Audit Checklist QACDocument9 pagesInternal Audit Checklist QACdhir.ankur100% (1)

- BS-400 Service Manual (v1.3) PDFDocument369 pagesBS-400 Service Manual (v1.3) PDFVladimir BorjaNo ratings yet

- Lab Safety QuizDocument6 pagesLab Safety QuizlorenckleinNo ratings yet

- CM PF 201 Preliminary Inspection ReportDocument5 pagesCM PF 201 Preliminary Inspection ReportJagannath MajhiNo ratings yet

- Experiments in Transport Phenomena PDFDocument162 pagesExperiments in Transport Phenomena PDFRebeca Albino100% (1)

- CHEM 1701 - Lab 1 - Safety, Materials and Measurement: - /10 MarksDocument7 pagesCHEM 1701 - Lab 1 - Safety, Materials and Measurement: - /10 Marksapi-535210408No ratings yet

- 7697A Headspace Samplers Site Preparation ChecklistDocument7 pages7697A Headspace Samplers Site Preparation ChecklistnileshdhamorikarNo ratings yet

- Dental Laboratory Equipment TechnicianDocument48 pagesDental Laboratory Equipment TechnicianAllen SharonNo ratings yet

- Aidan Littman - Data Scientist PDFDocument1 pageAidan Littman - Data Scientist PDFAidan LittmanNo ratings yet

- Service Manual of CS-T180 CS-T240Plus Auto-Chemistry Analyzer REV.2021-08Document248 pagesService Manual of CS-T180 CS-T240Plus Auto-Chemistry Analyzer REV.2021-08Albeiro PiraquiveNo ratings yet

- 01.0-Industrial Chemicals Inc - ADocument11 pages01.0-Industrial Chemicals Inc - AUmairNo ratings yet

- ICH Quality Guidelines: An Implementation GuideFrom EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleNo ratings yet

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactFrom EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactRating: 5 out of 5 stars5/5 (5)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincFrom EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincRating: 3.5 out of 5 stars3.5/5 (137)

- AP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeFrom EverandAP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeRating: 5 out of 5 stars5/5 (1)

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsFrom EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsRating: 5 out of 5 stars5/5 (3)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactFrom EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactRating: 5 out of 5 stars5/5 (1)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeFrom EverandChemistry for Breakfast: The Amazing Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (14)

- It's Elemental: The Hidden Chemistry in EverythingFrom EverandIt's Elemental: The Hidden Chemistry in EverythingRating: 4 out of 5 stars4/5 (10)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeFrom EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeRating: 4 out of 5 stars4/5 (1)

- Taste: Surprising Stories and Science About Why Food Tastes GoodFrom EverandTaste: Surprising Stories and Science About Why Food Tastes GoodRating: 3 out of 5 stars3/5 (20)

- Guidelines for Defining Process Safety Competency RequirementsFrom EverandGuidelines for Defining Process Safety Competency RequirementsRating: 3 out of 5 stars3/5 (1)

- The Production of Volatile Oils and Perfumery Plants in the United StatesFrom EverandThe Production of Volatile Oils and Perfumery Plants in the United StatesNo ratings yet

- Formulating, Packaging, and Marketing of Natural Cosmetic ProductsFrom EverandFormulating, Packaging, and Marketing of Natural Cosmetic ProductsNo ratings yet

- AP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeFrom EverandAP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeNo ratings yet

- The Periodic Table: A Very Short IntroductionFrom EverandThe Periodic Table: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (3)

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideFrom EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideNo ratings yet

- Chemistry for Breakfast: The Amazing Science of Everyday LifeFrom EverandChemistry for Breakfast: The Amazing Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (90)

- Tribology: Friction and Wear of Engineering MaterialsFrom EverandTribology: Friction and Wear of Engineering MaterialsRating: 5 out of 5 stars5/5 (1)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolFrom EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNo ratings yet

- The Billion-Dollar Molecule: The Quest for the Perfect DrugFrom EverandThe Billion-Dollar Molecule: The Quest for the Perfect DrugRating: 5 out of 5 stars5/5 (2)

- Essential Chemistry for Formulators of Semisolid and Liquid DosagesFrom EverandEssential Chemistry for Formulators of Semisolid and Liquid DosagesRating: 5 out of 5 stars5/5 (2)