Professional Documents

Culture Documents

Certified Reference Material BCR - 109: Certificate of Analysis

Uploaded by

Jose GarciaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Certified Reference Material BCR - 109: Certificate of Analysis

Uploaded by

Jose GarciaCopyright:

Available Formats

EUROPEAN COMMISSION

JOINT RESEARCH CENTRE

Institute for Reference Materials and Measurements

CERTIFIED REFERENCE MATERIAL

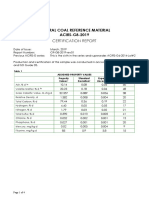

BCR® – 109

CERTIFICATE OF ANALYSIS

ZINC ORE CONCENTRATE

Mass Fraction based on dry mass Number of

Certified value 1)

Uncertainty 2) accepted sets

[g/kg] [g/kg] of data p

Hg 0.00096 0.00012 9

Pb 7.38 0.03 11

Mg 0.20 0.01 11

Fe 145.1 0.6 12

Cd 4.61 0.09 12

Cu 9.46 0.08 13

F 0.081 0.004 8

1) The certified value is the unweighted mean value of the means of p accepted sets of data, each set being

obtained in a different laboratory and/or with a different method of determination. The certified value is traceable

to the International System of Units (SI).

2) The certified uncertainty is based on the half-width of the 95 % confidence interval of the mean as defined in 1).

This certificate is valid for one year after purchase.

Sales date:

The minimum amount of sample to be used is 1 g.

DESCRIPTION OF THE SAMPLE

The zinc ore concentrate sample consists of homogeneous powder with a grain size smaller than

250 µm. Each unit contains around 200 g.

NOTE

This material has been certified by BCR (Community Bureau of Reference, the former reference

materials programme of the European Commission). The certificate has been revised under the

responsibility of IRMM.

Brussels, May 1982

Revised: May 2007

Signed:

Prof. Dr. Hendrik Emons

Unit for Reference Materials

EC-JRC-IRMM

Retieseweg 111

2440 Geel, Belgium

Page 1 of 2

ANALYTICAL METHOD USED FOR CERTIFICATION

Cold vapor atomic absorption spectrometry (CV-AAS)

Electrogravimetry

Flame atomic absorption spectrometry (FAAS)

Gravimetry

Ion selective electrodes

Polarography

Spectrophotometry

Titrimetry

X-ray fluorescence spectrometry (XRF)

PARTICIPANTS

AG des Altemberg für Bergbau und Zinkhüttenbetrieb, Essen (DE)

Bundesanstalt für Materialprüfung, Berlin (DE)

Duisburger Kupferhütte, Duisburg (DE)

Institute for Industrial Research and Standards, Dublin (IE)

European Commission, Joint Research Centre, CETIS, Ispra (IT)

European Commission, Joint Research Centre, Chemistry Division, Ispra (IT)

Métallurgie Hoboken Overpelt, Hoboken (BE)

Minemet Récherche, Trappes (FR)

Preussag AG Metall, Goslar (DE)

Rhur-Zink GmbH, Datteln (DE)

Ridsdale & Co. Ltd., Middlesbrough (GB)

Société de la Vieille Montagne S.A., Angleur (BE)

Universität Frankfurt/M, Frankfurt (DE)

SAFETY INFORMATION

The usual laboratory safety precautions apply.

INSTRUCTIONS FOR USE

Before use the sample contained in the bottle must be homogenised. Extreme care should be taken to

avoid any sample contamination.

The sample size required for the analysis should be obtained from the whole sample through the coning

and quartering procedure. For this purpose the entire content of the bottle should be spread on a sheet of

paper, cardboard or glass to form a 5 mm thick layer. By means of a spatula the amount for the analysis

as well as two 20 g fractions should be taken along the crossing diagonals.

The two 20 g fractions should be placed in weighing bottles, weighed to ± 0.1 mg, dried at 105 °C for 2

hours, cooled to room temperature in a desiccator and weighed. The drying at 105 °C should be repeated

for periods of 1 hour until constant mass is achieved. The moisture content thus determined should be

taken into account in order to calculate the content of the sought element(s) on a dry basis.

The two dried fractions combined with the remainder of the fraction taken for the analysis may be

combined and bottled and stored in a desiccator provided all sample contamination has been avoided.

STORAGE

The material must be kept in the tightly closed bottle at 18 °C; it may be damaged by moisture. However,

the European Commission cannot be held responsible for changes that happen during storage of the

material at the customer's premises, especially of opened samples.

LEGAL NOTICE

Neither IRMM, its subsidiaries, its contractors nor any person acting on their behalf,

(a) make any warranty or representation, express or implied that the use of any information, material,

apparatus, method or process disclosed in this document does not infringe any privately owned intellectual

property rights; or

(b) assume any liability with respect to, or for damages resulting from, the use of any information,

material, apparatus, method or process disclosed in this document save for loss or damage arising solely

and directly from the negligence of IRMM or any of its subsidiaries.

NOTE

A technical report on the production of BCR-109 is available on the internet (http://www.irmm.jrc.be). A

paper copy can be obtained from IRMM on request.

European Commission – Joint Research Centre

Institute for Reference Materials and Measurements (IRMM)

Retieseweg 111, 2440 Geel (Belgium)

Telephone: +32-(0)14-571.722 - Telefax: +32-(0)14-590.406

Page 2 of 2

You might also like

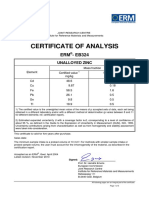

- Certificate of Analysis: ERM - EB324Document3 pagesCertificate of Analysis: ERM - EB324Sidneide Ferreira SantosNo ratings yet

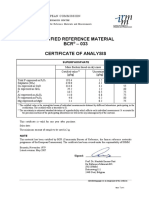

- Certified Reference Material BCR - 033 Certificate of AnalysisDocument3 pagesCertified Reference Material BCR - 033 Certificate of Analysisandri gerhanaNo ratings yet

- Certified Reference Material BCR - 033 Certificate of AnalysisDocument3 pagesCertified Reference Material BCR - 033 Certificate of Analysisandri gerhanaNo ratings yet

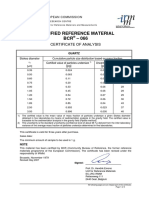

- Certified Reference Material BCR - 066: Certificate of AnalysisDocument3 pagesCertified Reference Material BCR - 066: Certificate of Analysisharry mahfuzanNo ratings yet

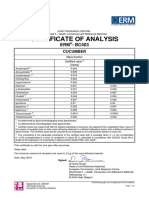

- Certificate of Analysis: ERM - BC403Document3 pagesCertificate of Analysis: ERM - BC403ana mariaNo ratings yet

- Certified Reference Material BCR - 074: Certificate of AnalysisDocument3 pagesCertified Reference Material BCR - 074: Certificate of AnalysisJose GarciaNo ratings yet

- Certified Reference Material BCR - 074: Certificate of AnalysisDocument3 pagesCertified Reference Material BCR - 074: Certificate of AnalysisJose GarciaNo ratings yet

- Certificate of Analysis: Reference SubstanceDocument6 pagesCertificate of Analysis: Reference SubstanceLucica BarbesNo ratings yet

- Statement of Measurement: Poultry Feed - Proximates and ElementsDocument5 pagesStatement of Measurement: Poultry Feed - Proximates and Elementseduardo hernandezNo ratings yet

- PM 2.5 Final - Report - RC - 121753 - Ermcz110Document68 pagesPM 2.5 Final - Report - RC - 121753 - Ermcz110Thanachai TengjirathanapaNo ratings yet

- SGS Analysis of South African CoalDocument2 pagesSGS Analysis of South African CoalAamirMalik71% (7)

- AMIS0332 CertificateDocument8 pagesAMIS0332 CertificatejemmacruzNo ratings yet

- IRMM-804 ReportDocument57 pagesIRMM-804 ReportGabriela RaicuNo ratings yet

- List of Imo Recognized Test LaboratoriesDocument18 pagesList of Imo Recognized Test LaboratoriesyulithNo ratings yet

- Complete Report Jrc84696Document136 pagesComplete Report Jrc84696mondal2010No ratings yet

- IMO List of Recognized Test Laboratories October 2014 - tcm8-26040Document18 pagesIMO List of Recognized Test Laboratories October 2014 - tcm8-26040Kayhan AytuğNo ratings yet

- Ochnaflavone 4'-Methyl ether-COA-PRF21083044Document2 pagesOchnaflavone 4'-Methyl ether-COA-PRF21083044DhavalNo ratings yet

- Intelligent Temperature Transmitter STT25H: Int Ernat Ional Inst Rum Ent Users' A Ssociat IonsDocument53 pagesIntelligent Temperature Transmitter STT25H: Int Ernat Ional Inst Rum Ent Users' A Ssociat IonsKrishNo ratings yet

- ACIRS G10 2022 CoA Rev01Document4 pagesACIRS G10 2022 CoA Rev01Kase Family (Kei&Ken)No ratings yet

- AMIS0248 CertificateDocument8 pagesAMIS0248 CertificatesynedNo ratings yet

- Certified Reference Material BCR - 263R: Defatted Peanut MealDocument3 pagesCertified Reference Material BCR - 263R: Defatted Peanut MealMahmoud ElgamriNo ratings yet

- PD Cen TR 10362-2014Document24 pagesPD Cen TR 10362-2014MaiDuyNo ratings yet

- ReportDocument18 pagesReportAlsaadiNo ratings yet

- ACIRS-G9-2021 Certificate of Analysis: General Coal Reference MaterialDocument4 pagesACIRS-G9-2021 Certificate of Analysis: General Coal Reference MaterialShintya FebrizaNo ratings yet

- E-Cigarette Aerosol Analysis ReportDocument6 pagesE-Cigarette Aerosol Analysis ReportEdwinBerianzahNo ratings yet

- E-Cigarette Aerosol Analysis ReportDocument6 pagesE-Cigarette Aerosol Analysis ReportJayson VicencioNo ratings yet

- Certificate of Measurement: Processed Meat - Proximates, Chloride, Hydroxyproline & MetalsDocument5 pagesCertificate of Measurement: Processed Meat - Proximates, Chloride, Hydroxyproline & Metalseduardo hernandezNo ratings yet

- REFERENCE MATERIAL CERTIFICATE FOR MICONAZOLE NITRATEDocument2 pagesREFERENCE MATERIAL CERTIFICATE FOR MICONAZOLE NITRATEAGATHA RIA BUDIYANANo ratings yet

- Total Carbon and Total Organic Carbon Determination in SludgeDocument3 pagesTotal Carbon and Total Organic Carbon Determination in Sludgelaoying qdNo ratings yet

- Spectroscopy الشيت الثالثDocument14 pagesSpectroscopy الشيت الثالثMajdolen AhrkiNo ratings yet

- CGL 001Document5 pagesCGL 001Central Geology LaboratoryNo ratings yet

- Lana21075enc 002Document68 pagesLana21075enc 002VENKATESAN JNo ratings yet

- Cem I 52.5R EnciDocument7 pagesCem I 52.5R EnciRichard cooperNo ratings yet

- RoHS Compliant Polyethylene FoamDocument6 pagesRoHS Compliant Polyethylene FoamkingsleyNo ratings yet

- GAPM 2022 1529 MReportDocument1 pageGAPM 2022 1529 MReportLokeshTripathiNo ratings yet

- Lab Equipment for Water Content TestingDocument1 pageLab Equipment for Water Content TestingDilhara WickramaarachchiNo ratings yet

- Water in Bituminous Materials: Technical SpecificationsDocument1 pageWater in Bituminous Materials: Technical SpecificationsDilhara WickramaarachchiNo ratings yet

- D 4239 - 18e1 SulfurDocument8 pagesD 4239 - 18e1 Sulfurfatmachemist1No ratings yet

- Universiti Teknologi Mara Common TestDocument4 pagesUniversiti Teknologi Mara Common TestSyalmira LovetobelovedNo ratings yet

- Validation of Powder X-Ray DiffractionDocument16 pagesValidation of Powder X-Ray DiffractionKevin JosueNo ratings yet

- ERM-CC144 Report PDFDocument79 pagesERM-CC144 Report PDFAndres Julian Montoya EstradaNo ratings yet

- Component Cleanliness Analysis ReportDocument3 pagesComponent Cleanliness Analysis ReportbetelgueseNo ratings yet

- CR G8 2019 Rev1Document4 pagesCR G8 2019 Rev1Andhika Manggal Putra PNo ratings yet

- Sys Master - Pdfs - hc4 - h21 - 10538525327390 - COA - DRE C10569000 - ST WB CERT 4861948 1 1 1Document2 pagesSys Master - Pdfs - hc4 - h21 - 10538525327390 - COA - DRE C10569000 - ST WB CERT 4861948 1 1 1Fita Desti SenjaNo ratings yet

- Sapphire Fiber-Optic Temperature Sensor Based On B PDFDocument6 pagesSapphire Fiber-Optic Temperature Sensor Based On B PDFsayoneeNo ratings yet

- Co MSDSDocument26 pagesCo MSDSnaidu60606No ratings yet

- Brochure Elementrac ONH Hydrogen in Steel enDocument6 pagesBrochure Elementrac ONH Hydrogen in Steel enStancu BranNo ratings yet

- Determination of Metal Contents of Various Fibers 2015Document6 pagesDetermination of Metal Contents of Various Fibers 2015Mirha PazaljaNo ratings yet

- PU Conveyor Belt Test ReportDocument6 pagesPU Conveyor Belt Test ReportJim SmithNo ratings yet

- Hematite Ore AnalysisDocument7 pagesHematite Ore Analysisflysch_ukNo ratings yet

- Analysis of Residual Elements in Steel Pipe With The Thermo Scientific Niton XL3t 900 GOLDD SeriesDocument2 pagesAnalysis of Residual Elements in Steel Pipe With The Thermo Scientific Niton XL3t 900 GOLDD SeriesMarioNo ratings yet

- CSIR-NML Alloy Cast Iron CRMDocument2 pagesCSIR-NML Alloy Cast Iron CRMMetal deptNo ratings yet

- Et - Iso.14891.2012 Nitrogen With DumasDocument19 pagesEt - Iso.14891.2012 Nitrogen With DumasthellemoNo ratings yet

- Astm D4239 18 SulphurDocument8 pagesAstm D4239 18 SulphurMd Naseem Javed100% (3)

- SCRM No. 666/12 Ductile (Nodular) Iron: L Certificate of AnalysisDocument2 pagesSCRM No. 666/12 Ductile (Nodular) Iron: L Certificate of AnalysisPeterson SudlabNo ratings yet

- Lote SZBB222XVDocument2 pagesLote SZBB222XVCarlos RamirezNo ratings yet

- Topic 2 CHM421Document3 pagesTopic 2 CHM421Amirah NajihahNo ratings yet

- E-Cigarette Aerosol Analysis Report FindingsDocument6 pagesE-Cigarette Aerosol Analysis Report FindingsKarim MohsenNo ratings yet

- The Use of Electrochemical Scanning Tunnelling Microscopy (EC-STM) in Corrosion Analysis: Reference Material and Procedural GuidelinesFrom EverandThe Use of Electrochemical Scanning Tunnelling Microscopy (EC-STM) in Corrosion Analysis: Reference Material and Procedural GuidelinesNo ratings yet

- NDE Handbook: Non-Destructive Examination Methods for Condition MonitoringFrom EverandNDE Handbook: Non-Destructive Examination Methods for Condition MonitoringKnud G. BøvingRating: 4.5 out of 5 stars4.5/5 (4)

- XRFCore Scanner User ManualV2Document72 pagesXRFCore Scanner User ManualV2Jose GarciaNo ratings yet

- Biochemical Oxygen Demand (Bod) PDFDocument12 pagesBiochemical Oxygen Demand (Bod) PDFGilberto ContrerasNo ratings yet

- V2o5 Procedure EvrazDocument9 pagesV2o5 Procedure EvrazJose GarciaNo ratings yet

- Glass Beads by Borate Fusion - tcm50-54735Document60 pagesGlass Beads by Borate Fusion - tcm50-54735Hernán Alejandro Rosero VegaNo ratings yet

- Ichikawa 2016Document22 pagesIchikawa 2016Jose GarciaNo ratings yet

- FDS Oni Green Edition enDocument8 pagesFDS Oni Green Edition enJose GarciaNo ratings yet

- NT Technical Report Nordtest Report TR 569Document52 pagesNT Technical Report Nordtest Report TR 569Fabianus Galih Ari WigunaNo ratings yet

- Determination of Copper in Unalloyed Copper by Gravimetry: Standard Test Method ForDocument4 pagesDetermination of Copper in Unalloyed Copper by Gravimetry: Standard Test Method ForROHITNo ratings yet

- Certified Reference Material BCR - 074: Certificate of AnalysisDocument3 pagesCertified Reference Material BCR - 074: Certificate of AnalysisJose GarciaNo ratings yet

- ALS Geochemistry Fee Schedule USDDocument52 pagesALS Geochemistry Fee Schedule USDcrononimeNo ratings yet

- Specs L-Menthyl LactateDocument1 pageSpecs L-Menthyl LactateJose GarciaNo ratings yet

- Certified Reference Material BCR - 110: Certificate of AnalysisDocument2 pagesCertified Reference Material BCR - 110: Certificate of AnalysisJose GarciaNo ratings yet

- International Journal of Mineral ProcessingDocument24 pagesInternational Journal of Mineral ProcessingJose GarciaNo ratings yet

- Kojima 1973Document20 pagesKojima 1973Jose GarciaNo ratings yet

- Certified Reference Material BCR - 074: Certificate of AnalysisDocument3 pagesCertified Reference Material BCR - 074: Certificate of AnalysisJose GarciaNo ratings yet

- Certified Reference Material BCR - 074: Certificate of AnalysisDocument3 pagesCertified Reference Material BCR - 074: Certificate of AnalysisJose GarciaNo ratings yet

- Kojima 1973Document20 pagesKojima 1973Jose GarciaNo ratings yet

- Flavoring Concentrate Price & Flavor List PDFDocument59 pagesFlavoring Concentrate Price & Flavor List PDFJose GarciaNo ratings yet

- E 1070 - 00 - RtewnzaDocument3 pagesE 1070 - 00 - RtewnzaJose GarciaNo ratings yet

- Seabirds As Indicators of Ocean Pollution: BackgroundDocument5 pagesSeabirds As Indicators of Ocean Pollution: BackgroundJose GarciaNo ratings yet

- Spark plug guide for Bosch, NGK, Denso, and Champion brandsDocument8 pagesSpark plug guide for Bosch, NGK, Denso, and Champion brandsJose GarciaNo ratings yet

- The ASME Measurement UncertaintyDocument8 pagesThe ASME Measurement UncertaintyKristof MCNo ratings yet

- mgpg11 - A Beginner's Guide To Uncertainty of Measurement by Stephanie BellDocument41 pagesmgpg11 - A Beginner's Guide To Uncertainty of Measurement by Stephanie Bellarylananyla100% (2)

- Minitab - Quality ControlDocument310 pagesMinitab - Quality ControlRajesh Sharma100% (4)

- 1312Document30 pages1312Jose GarciaNo ratings yet

- CHEMOMETRICS and STATISTICS Multivariate Classification Techniques-21-27Document7 pagesCHEMOMETRICS and STATISTICS Multivariate Classification Techniques-21-27Jose GarciaNo ratings yet

- Lab ACH Rates Standards & Guidelines PDFDocument15 pagesLab ACH Rates Standards & Guidelines PDFGopinath GopiNo ratings yet

- Fire Assay Determination of Gold in Copper Concentrates by GravimetryDocument4 pagesFire Assay Determination of Gold in Copper Concentrates by GravimetryJose GarciaNo ratings yet

- Ek Pardesi Mera Dil Le Gaya Lyrics English Translation - Lyrics GemDocument1 pageEk Pardesi Mera Dil Le Gaya Lyrics English Translation - Lyrics Gemmahsa.molaiepanahNo ratings yet

- Hydrocarbon: Understanding HydrocarbonsDocument9 pagesHydrocarbon: Understanding HydrocarbonsBari ArouaNo ratings yet

- Multivariate Analysis Homework QuestionsDocument2 pagesMultivariate Analysis Homework Questions歐怡君No ratings yet

- ElectricalDocument30 pagesElectricalketerNo ratings yet

- Starting A Business Candle Making 2009Document2 pagesStarting A Business Candle Making 2009Carlo Fabros Junio100% (4)

- $R6RN116Document20 pages$R6RN116chinmay gulhaneNo ratings yet

- English Extra Conversation Club International Women's DayDocument2 pagesEnglish Extra Conversation Club International Women's Dayevagloria11No ratings yet

- 3.1 C 4.5 Algorithm-19Document10 pages3.1 C 4.5 Algorithm-19nayan jainNo ratings yet

- Second Quarterly Examination Math 9Document2 pagesSecond Quarterly Examination Math 9Mark Kiven Martinez94% (16)

- AnhvancDocument108 pagesAnhvancvanchienha7766No ratings yet

- SHORT STORY Manhood by John Wain - Lindsay RossouwDocument17 pagesSHORT STORY Manhood by John Wain - Lindsay RossouwPrincess67% (3)

- Lesson Plan 2 Revised - Morgan LegrandDocument19 pagesLesson Plan 2 Revised - Morgan Legrandapi-540805523No ratings yet

- Service Parts List: 54-26-0005 2551-20 M12™ FUEL™ SURGE™ 1/4" Hex Hydraulic Driver K42ADocument2 pagesService Parts List: 54-26-0005 2551-20 M12™ FUEL™ SURGE™ 1/4" Hex Hydraulic Driver K42AAmjad AlQasrawi100% (1)

- Quality Improvement Reading Material1Document10 pagesQuality Improvement Reading Material1Paul Christopher PinedaNo ratings yet

- Complete Guide To E-Commerce TechnologyDocument420 pagesComplete Guide To E-Commerce Technologypilatus100% (4)

- ??????? ?? ??????Document29 pages??????? ?? ??????Aysha ShahabNo ratings yet

- Useful Relations in Quantum Field TheoryDocument30 pagesUseful Relations in Quantum Field TheoryDanielGutierrez100% (1)

- Indonesia Banks Bank Mandiri Trading Buy on Strong 9M21 EarningsDocument8 pagesIndonesia Banks Bank Mandiri Trading Buy on Strong 9M21 EarningsdkdehackerNo ratings yet

- Types of Speech StylesDocument31 pagesTypes of Speech StylesRomnick BistayanNo ratings yet

- Variables in Language Teaching - The Role of The TeacherDocument34 pagesVariables in Language Teaching - The Role of The TeacherFatin AqilahNo ratings yet

- Barelwiyah, Barelvi Chapter 1 (Part 2 of 5)Document31 pagesBarelwiyah, Barelvi Chapter 1 (Part 2 of 5)Dawah ChannelNo ratings yet

- Staining TechniquesDocument31 pagesStaining TechniquesKhadija JaraNo ratings yet

- Tirfor: Lifting and Pulling Machines With Unlimited Wire RopeDocument26 pagesTirfor: Lifting and Pulling Machines With Unlimited Wire RopeGreg ArabazNo ratings yet

- Omobonike 1Document13 pagesOmobonike 1ODHIAMBO DENNISNo ratings yet

- K230F Equipment ManualsDocument166 pagesK230F Equipment ManualsHui ChenNo ratings yet

- CURRICULUM AUDIT: GRADE 7 MATHEMATICSDocument5 pagesCURRICULUM AUDIT: GRADE 7 MATHEMATICSjohnalcuinNo ratings yet

- Translation of Japanese Onomatopoeia Into Swedish (With Focus On Lexicalization)Document20 pagesTranslation of Japanese Onomatopoeia Into Swedish (With Focus On Lexicalization)Aldandy OckadeyaNo ratings yet

- Understanding 2006 PSAT-NMSQT ScoresDocument8 pagesUnderstanding 2006 PSAT-NMSQT ScorestacobeoNo ratings yet

- AIOUDocument2 pagesAIOUHoorabwaseemNo ratings yet

- PropensityModels PDFDocument4 pagesPropensityModels PDFSarbarup BanerjeeNo ratings yet