Professional Documents

Culture Documents

Machine Drawing Assembly Drawing

Machine Drawing Assembly Drawing

Uploaded by

ashok junapudi0 ratings0% found this document useful (0 votes)

11 views61 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views61 pagesMachine Drawing Assembly Drawing

Machine Drawing Assembly Drawing

Uploaded by

ashok junapudiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 61

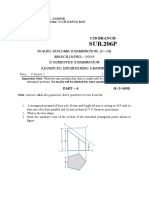

CHAPTER - 06 ASSEMBLY AND DETAILS DRAWING.

A] STEPS TO DRAW ASSEMBLY DRAWING FROM DETAILS DRAWING:-

1. Understand the purpose, principle of operation and field of application of the given machine.

This will hap in understanding the functional requirements of individual parts and their

location.

2. Examine thoroughly, the external and internal features of the individual parts.

3. Choose a proper scale for the assembly drawing.

4, Estimate the overall dimensions of the views of the assembly drawing and make the outline

blocks for each of the required view, leaving enough space between them, for indicating

dimensions and adding required notes.

5. Draw the axes of symmetry for all the views of the assembly drawing.

6. Begin with the view from the front, by drawing first, the main parts of the machine and then,

adding the rest of the parts, in the sequence of assembly.

7. Project the other required views from the view from the front complete views.

8. Mark the location and overall dimensions and add the part numbers on the drawing.

9. Prepare the parts list.

B] STEPS TO DRAW PART OR DETAILS DRAWING FROM ASSEMBLY

DRAWING:

1. Understand the assembly drawing thoroughly, by referring to the parts list and the different

orthographic views of the unit.

2. Study the functional aspect of the unit as a whole. This will enable to understand the

arrangement of the parts.

3. Visualize the size and shape of the individual components.

4. As far as possible, choose full scale for the drawing, Small parts and complicated shapes may,

require the use of enlarged scales so that their presentation will havea balanced appearance.

5, Select the minimum number of views required for describing each part completely. The view

from the front selected must provide maximum information of the part.

6. The under mentioned sequence may be fol lowed for preparing different views of each part :

(i) Draw the main centre lines and make outline blocks, using the overall dimensions of the

views.

(ii) Draw the main circles and arcs of the circles.

(iii) Draw the main outlines and add all the internal features.

(iv) Cross-hatch the sectional views.

(v) Draw the dimension lines and add dimensions and notes.

7. Check the dimensions of the mating parts.

8, Prepare the parts list.

1] PLUMMER BLOCK (PEDASTAL BEARING)

1] DETAILS OF PLUMMER BLOCK

2] ASSEMBLY OF CONNECTING ROD

Fig. 19.4 Petrol engine connecting rod

2] DETAILS OF CONNECTING ROD

Fig. 20.7 Detals of petrol engine connecting rod

3] ASSEMBLY OF LATHE TAIL-STOCK

BEEROOREE

Fig. 18.18A Lathe tail-stock

3] DETAILS OF LATHE TAIL-STOCK

BRRRCOSEEOIE

Fig. 18.18 Lathe tal-stock

4] ASSEMBLY OF GLAND &STUFFING BOX

4] DETAILS OF GLAND & STUFFING BOX

1 Body a [4

2 Gian Brass| 1

3 Bush Brass| 1

4 Stud ms | 2

5 Nut maiz | ms | 2

Fig. 18.1 Stuffing box

5JASSEMBLY OF SCREW) ACK

Fig. 18.51A Screw jack

5] DETAILS OF SCREW) ACK

so 328992

a

Gabel

nme wen

Fig. 18.51 Sorew jack

6] CROSS HEAD ASSEMBLY

Figure 1 The Crosshead assembly

Fig. 18.3A Crosshead

6] DETAILS OF CROSS HEAD

111 fesolk

doo cennal |

7] ASSEMBLY OF REVOLVING CENTRE

on

“LY

RSS

Fig. 18.20A Revolving centre

7] DETAILS OF REVOLVING CENTRE

Fig. 18.20 Revolving centre

8] ASSEMBLY OF MILLING MACHINE TAIL-STOCK

8] DETAILS OF MILLING MACHINE TAIL-STOCK

RZ

GY: ZZ

LPZZZIIIZDS

Fig. 18.19 Milling machine tail-stock

9] ASSEMBLY OF CRANE HOOK

ma.

RAF 1:

9] DETAILS OF CRANE HOOK

SRS GRLE RSET

aenanaunan =|9

10] ASSEMBLY OF NON-RETURN VALVE

=

tH

ra RAS WF

‘Ss

Sy

=

SSS

SS

Ci

LAN

Ms

Ee

|

[

Saif

10] DETAILS OF NON-RETURN VALVE

S HOLES, M16 PCD150 4190

—e——_——ev

oats. 90 io ! "

| LIZA.

| 20 Kd

a “er “A 6 HOLES, DIA 18

N

Parts list

No. Name Matl_| Qty

1 | Body Brass! 1

2 | cover Brass] 1

3 |Valveseat Bronze] 1

4 | Valve Brass] 1

5 |studwihnut | Ms | 6

6 |setscew | ms | 1

Fig. 18.30 Non-retum valve (Light duty)

11] ASSEMBLY OF FEED CHECK VALVE

SNF

N

hae L\

SH

SY Wr,

Norbbe RY

Zs

Z

Fig. 18.34A Feed check valve

11] DETAILS OF FEED CHECK VALVE

Fg

e

Tame Mat [Oy

1 [Boar ays

2 | cover als

3 | seine ws | 1

4 | vane om | 4

5 | vie seat ow | 4

6 | clon om | 4

7 | Hana wheat a}

2 | sus ws | 6

9 | sus ws | 2

10 | ma ms | 6

1 [ne us | 3

PACKING

BODY/BONNET

CONNECTION

12] ASSEMBLY OF PRESSURE RELIEF VALVE

Fig. 18.35A Pressure relief valve

12]DETAILS OF PRESSURE RELIEF VALVE

13 41 10, ¥

4 : He i

Ne. Name: Mail [Qty

1 | Body ao [4

2 | Valve member ms | 1

3 | Adjusting serew ms [1

4 | Sealed adapter ws | 1

5 | Control sorew ws [1

2 | Adapter ws [1

7 | Control rod ws [4

8 | Control knob Exonte | 1

© | Washer Rubber | 2

10 | Seat Rubber | 2

11 | Spring :wiredia | Spring S| 1

mm :00 = 48

12 | Locknut mi ws [1

Fig. 18.35 Pressure relief valve

13] ASSEMBLY OF C-CLAMP

Fig. 18.48A C-clamp

13] DETAILS OF C-CLAMP

oe2e222

a

Raikes

El- ci to On

Fig. 18.48 C-camp

14] ASSEMBLY OF SQUARE TOOL POST

14] DETAILS OF SQUARE TOOL POST

iat [oy

— us]

% 2 |omeome | ve | 4

‘as 3 | sue we |

3 4 |Cameeana | us | 1

3 | Ree ts | 3

Es 5 les ae

5 | Sete :

peed B+ @ & [ona | us | 4

3 | Sey sow | 3

0 | auve ne |

15]ASSEMBLY OF DRILL JIG

Ea)

J

' “4!

=

Fig. 18.24A Drill jig

15] DETAILS OF DRILL J IG

SLOTTED CHEESE HEAD

SCREW Mi*50

_®

BGR RRROROE

Fig. 18.24 Drill jig

16] ASSEMBLY OF INDEXING DRILL JIG

Fig. 18.25A Indexing drill jig

16] DETAILS OF INDEXING DRILL J 1G

[Patna] tame Tas] Oy [partna | ams [as | Oe

| racer a{a | @ (ome ws tt

2 | sigpione ws] 1] 9 [Seq seat] &

3 | bocator ws | 1 | 10 | Societ head sca! MS | 5

4 [ode acing tec fms} 1 | it [manne as | 1

5 [Batch ansemey | Ms] 1 | 12 |oowatpm.aseas | aes | 2

6 | noun wes] 1 | 13 |Wonpece

1 |onteipuan — |ros} 1

Fig. 18.25 Indexing anil jig

17] ASSEMBLY OF LEVER SAFETY VALVE

Fig. 18.36A Lever safety valve

17] DETAILS OF LEVER SAFETY VALVE

eS a a CC

7 [ey att | 8 | taieer ust

2 | Va seat om 9 |rewrgue | us | 1

«| cowe a 4 |Facumen fs |

S |comrtas [oem] 2 | 2 | uno alt

8 | sonae us| 3 | 13. | Lewrpin ws]

1_| tora ws |i |_| suswinnanco| — | 6

18] ASSEMBLY OF SPRING LOADED RELIEF VALVE

Fig. 18.37A Spring loaded relief valve

18] DETAILS OF SPRING LOADED RELIEF VALVE

Prt it

[S.No] Name | Mat. [ Oy.

1 | Vive boy Po [4

2 | Lave us|

3 | vane cu} 1

4 | Futremton | mas | 1

5 | Fucnmpn [us | 4

6 | stem ws | 1

7 a} 4

8 | tension spring | Hes | 1

8 | Tension chs}

torent | ws | 4

10 | Seve us | 3

Fig. 18.37 Spring loaded rete valve

19] ASSEMBLY OF AIR VALVE

oS save

cea ReOUCTION GEAR

CRANKSHAFT CAM OnIVE GEAR

oRANRSHART

19] DETAILS OF AIR VALVE

joe $egeggy|

ik

agsbete

Fig. 18.10 irvaive

20] ASSEMBLY OF BLOW OFF COCK

20] DETAILS OF BLOW OFF COCK

21] ASSEMBLY OF SELF CENTRING CHUCK

Face plate

i

5

| 1 §o88sa/E

waese a =|2

Fig. 18.26a Self centring chuck

21] DETAILS OF SELF CENTRING CHUCK

Fig. 18.26 Details of tf ceriring chuck

22] ASSEMBLY OF FOUR J AWCHUCK

22] DETAILS OF FOUR J AWCHUCK

Farts tit

[Sina] Naame mas [We

1 [oy alt

2 |e als

3 | Scr steel] 4

4 |Lecaie Steet] 4

8 |macnine screws ms | — | 8

Fig. 18.27 Details of four jaw chuck

23] ASSEMBLY OF GATE VALVE

23] DETAILS OF GATE VALVE

Eo

24] DETAILS OF STEAM ENGINE CROSSHEAD

STEAM ENGINE CROSSHEAD

160

a.

425

425

200 JF

100

925.2

‘ re)

i

opts

R23

al

Ay

i

i

BOREGIE

Teele

1

2 | Piston ros

= 3 | Gudgeon pin -

J 8 g 4 | Slide block

5 Cotter

24 ®

Fig. No. 1

24] ASSEMBLY OF STEAM ENGINE CROSSHEAD

25] DETAILS OF CRANE HOOK

fem wane Taran wore

aaa eee

tee 2 eee

3 | PULLEY FIN 2 <__1045-FORGING|

a

Seer | ead

6 [HOOK TRUNION 7 1045 |

5 eran — Tota

‘ 4 oe oa

> y ne 2 2s Her

_ 40 [COTTER PIN 2 [NOT *TLONG

PROB. 25 Crane hook.

Note: - Dimensions of assembly and details drawing are different.

141

26] DETAILS OF CLAPPER BLOCK

Fi

i

BRE ROOlE

er

26] ASSEMBLY OF CLAPPER BLOCK

aE [T | “4

S

ym A Ss

He

=

27] DETAILS OF MACHINE VICE

4HOLES.OAS we u

GERDA TS i Patt

i at] Oe

1 [Bose a]

5 2 | sowie jw als

en 3 | Sian boo a|s

4 | cooescen ws]

| 5 ws | 2

6 [osKscew sting | ws | &

7 |osKsows0ing | ws | 2

i pt oe a 8 |osKsaewsoing | ws | 2

3 | aster 2006 us| 1

to_[Nauzo us |

ss ® 0

27] ASSEMBLY OF MACHINE VICE

28] DETAILS OF PIPE VICE

fa

28] ASSEMBLY OF PIPE VICE

off! oo osBRolg

ewww wen === =(gl

29] ASSEMBLY OF SPEED REDUCER

30] DETAILS OF V-BELT DRIVE

30] ASSEMBLY OF V-BELT DRIVE

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MD r19 - Part - B PPT NewDocument42 pagesMD r19 - Part - B PPT Newashok junapudiNo ratings yet

- Machine Drawing Digital Material PPT ASHOKDocument76 pagesMachine Drawing Digital Material PPT ASHOKashok junapudiNo ratings yet

- MD R19 - PART - A WordDocument120 pagesMD R19 - PART - A Wordashok junapudiNo ratings yet

- BED Slip Test QP 2019Document5 pagesBED Slip Test QP 2019ashok junapudiNo ratings yet

- MD R19 - Part - ADocument116 pagesMD R19 - Part - Aashok junapudiNo ratings yet

- Sub.206p: C18-BranchDocument4 pagesSub.206p: C18-Branchashok junapudiNo ratings yet

- AED Slip Test I QP 2019Document3 pagesAED Slip Test I QP 2019ashok junapudiNo ratings yet

- Sub.206p: C18-BranchDocument5 pagesSub.206p: C18-Branchashok junapudiNo ratings yet

- Cadcam BitsDocument2 pagesCadcam Bitsashok junapudiNo ratings yet

- Mani Diploma 1st YearDocument2 pagesMani Diploma 1st Yearashok junapudiNo ratings yet

- Computer Aided Design CosDocument16 pagesComputer Aided Design Cosashok junapudiNo ratings yet

- Ansys ProblemsDocument9 pagesAnsys Problemsashok junapudiNo ratings yet

- Smithy & Forging ShopDocument24 pagesSmithy & Forging Shopashok junapudiNo ratings yet

- Mani Diploma 1st YearDocument3 pagesMani Diploma 1st Yearashok junapudiNo ratings yet

- Smithy & Forging ShopDocument24 pagesSmithy & Forging Shopashok junapudiNo ratings yet