Professional Documents

Culture Documents

Ezct S2 021210 108

Uploaded by

Selk CLOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ezct S2 021210 108

Uploaded by

Selk CLCopyright:

Available Formats

Thermal Printer

Simplify

A built-in 4.5-inch wide thermal printer can print the current transformer test

report and plot the excitation curves.

Test Record Header Information

The test record header information can include the company name, substation

name, circuit ID, manufacturer, CT serial number, operator’s name, and test record

comments. In addition to the test record header, a 20-character test description for

each test in the record can also be entered.

Internal Test Record Storage Capacity

The EZCT S2 can store up to 140 test records in Flash EEPROM. Each test record may

contain up to 10 excitation curves, current-ratio readings, and winding polarity read-

ings. Test records can be recalled and printed on the built-in thermal printer.

Internal Test Plan Storage Capacity

EZCT TM The EZCT S2 can store up to 128 CT test plans in Flash EEPROM. A test plan defines

the excitation test voltage and current selection, CT nameplate ratio, and CT wind-

ing terminal connection instructions for each test. Up to 10 test definitions can be

stored in each test plan. The use of a test plan greatly simplifies the CT testing

The EZCT S2 is Vanguard’s second-generation, microprocessor-based, current

process since it also provides instructions for making the proper CT cable connec-

transformer test set. The EZCT S2 can perform the current transformer (CT)

tions. Test plans can be created on the EZCT S2 itself or created on a PC and down-

excitation, CT current-ratio, and winding polarity tests automatically. The EZCT

loaded to the EZCT S2 via the unit’s built-in RS-232C or USB ports.

S2 automatically raises and lowers the excitation test voltage without any opera-

tor intervention. With up to 1500 Vac excitation test voltage available, the EZCT

S2 can easily perform excitation tests on very large CT’s.

Computer Interface

The EZCT S2 can be

used as a stand-alone

Excitation Test unit or can be computer-

The CT excitation test is performed using the ANSI/IEEE C57.13.1, IEC 60044-1 test

controlled via the built-in

method. The test voltage range for the CT excitation test (50 Vac, 250 Vac, 500 Vac,

RS-232C or USB inter-

or 1500 Vac) can be selected, and then the test voltage is raised and lowered auto- ®

faces. A Windows

matically by the EZCT S2. The test voltage and current data are collected and stored

XP/Vista-based Current

in the unit’s internal memory. Up to 10 CT excitation and current-ratio tests can be

Transformer Analysis

stored in one test record. IEEE-30, IEEE-45, ANSI/IEC 60044-1 (10/50) knee point

software application is

voltages are also calculated and printed on the test report. Once the test is com-

provided with each

pleted, test results can be printed and excitation curves can be plotted on the built-

EZCT S2. This software

in 4.5-inch wide thermal printer.

can be used to retrieve

test records from the

CT Ratio and Polarity Tests EZCT S2, create test

The EZCT S2 determines the CT current-ratio using the ANSI/IEEE C57.12.90 meas-

plans, download test

urement method. A test voltage is applied to the CT’s secondary terminals and the

plans to the EZCT S2,

induced voltage is measured through the CT’s H1 and H2 terminals. The CT current-

and can also be used to

ratio and polarity are displayed on the screen and stored in memory. The current-ratio

run CT tests from the

measuring range is from 0.8 to 5,000. The CT winding polarity is displayed as a

PC. Tabulated test

“+” sign (in-phase) or a “-” sign (out-of-phase) and is annotated with the phase

records can be export-

angle in degrees. ® ®

ed in Microsoft Excel

format.

User Interface and Display

The EZCT S2 features a back-lit LCD screen (4 lines by 20 characters) that is view-

able in both bright sunlight and low-light levels. A rugged, alpha-numeric, mem- EZCTTM S2

brane keypad is used to control the unit. Connections

Current-Transformer Test Set

the Tedious Procedure of Current-Transformer Testing with

Vanguard’s EZCTTM Series 2 Current Transformer Test Set

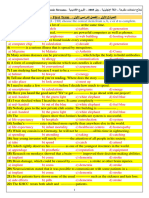

Connector for Connector for Back-lit LCD Screen Power Switch RS- 232C

X Terminals H Terminals (20 Characters by 4 lines) with Built-in Interface

Circuit Breaker

▼ PC Printer Output

▼ Thermal Printer Output

Ordering Information EZCT-S2™ Current Transformer Test Set

EZCT-S2™, Cable, Software Part No: EZCT-S2

EZCT-S2™ Shipping Case Part No: EZCT-S2 Shipping Case

4.5-inch Wide Rugged 16-Key Emergency Test Voltage USB

4.5-inch Printer Paper Part No: Paper TP4 Thermal Printer Membrane Keypad Stop Presence Indicator Interface

SPECIFICATIONS

TYPE Portable current transformer test set

PHYSICAL SPECIFICATIONS 16.8”W x 12.6”H x 12”D (42.7 cm x 32 cm x 26.9 cm); Weight: 48 lbs (21 kg)

INPUT POWER 100 – 120 Vac or 200 – 240 Vac (factory pre-set), 50 Hz/60 Hz

MEASUREMENT METHOD ANSI/IEEE C57.12.90, IEC 60044-1 and ANSI/IEEE C57.13.1

OUTPUT TEST VOLTAGES 0 – 50 Vac @ 10A max, 0 – 250 Vac @ 10A max

0 – 500 Vac @ 5A max, 0 – 1500 Vac @ 1.2A max

VOLTAGE READING RANGE 0 – 2,200 Vac; Accuracy: ±1.0% of reading, ±1 volt

CURRENT READING RANGE 0 – 10A; Accuracy: ±1.0% of reading, ±0.02A

CURRENT RATIO RANGE 0.8 – 999: 0.1%, 1000 – 1999: 0.3%, 2000 – 5000: 1%

PHASE ANGLE MEASUREMENT 0 - 360 degrees; Accuracy: ±1.0 degree

DISPLAY Back-lit LCD Screen (20 characters by 4 lines); viewable in bright sunlight and low-light levels

PRINTER Built-in 4.5-inch wide thermal printer

COMPUTER INTERFACES One RS-232C port (115k baud), one USB port

PC SOFTWARE Windows® XP/Vista-based CT Analysis software is included with purchase price

INTERNAL TEST RECORD STORAGE Stores 140 test records. Each test record may contain up to 10 sets of excitation, resistance and ratio data

INTERNAL TEST PLAN STORAGE Stores 128 test plans. Each test plan can store 10 excitation test voltage and current settings

SAFETY Designed to meet UL 61010A-1 and CAN/CSA C22.2 No. 1010.1-92 standards

ENVIRONMENT Operating: -10˚ to 50˚ C (15˚F to +122˚ F); Storage: -30˚ C to 70˚ C (-22˚F to +158˚ F)

HUMIDITY 90% RH @ 40˚C (104˚F) non-condensing

ALTITUDE 2,000m (6,562 ft) to full safety specifications

CABLES Two 20-foot X cable sets, One 35-foot H cable set, power cord, One cable-carrying duffel bag

WARRANTY One year on parts and labor

Note: The above specifications are valid at nominal voltage and ambient temperature of +25°C (+77°F). Specifications are subject to change without notice.

Vanguard Instruments Company

Reliability Through Instrumentation

RVFeb10

Vanguard Instruments Company, Inc.

Vanguard Instruments Co., (VIC), was founded in 1991.

Currently, our 28,000 square-foot facility houses Administration,

Design & Engineering, and Manufacturing operations. From its

inception, VIC’s vision was, and is to develop and manufacture

innovative test equipment for use in testing substation EHV circuit

breakers and other electrical apparatus.

The first VIC product was a computerized circuit-breaker analyz-

er, which was a resounding success. It became the forerunner of

an entire series of circuit-breaker test equipment. Since its begin-

ning, VIC’s product line has expanded to include microcomput-

er-based, precision micro-ohmmeters, single and three-phase

transformer winding turns-ratio testers, winding-resistance

meters, transformer tap-changing controllers, megaohm resist-

ance meters, and a variety of other electrical utility mainte-

nance support products.

VIC’s performance-oriented products are well suited for the util-

ity industry. They are rugged, reliable, accurate, user friendly, and

most are computer controlled. Computer control, with innovative

programming, provides many automated testing functions. VIC’s

instruments eliminate tedious and time-consuming operations,

while providing fast, complex, test-result calculations. Errors are

reduced and the need to memorize long sequences of procedur-

al steps is eliminated. Every VIC instrument is competitively

priced and is covered by a liberal warranty.

Vanguard products are available from:

Vanguard Instruments Company, Inc.

1520 S. Hellman Ave. • Ontario, California 91761 USA • P 909-923-9390 • F 909-923-9391

www.vanguard-instruments.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Apple Power Mac G5 Quad 2 5 Dual 2 0 2 3 GHZ Service Repair ManualDocument163 pagesApple Power Mac G5 Quad 2 5 Dual 2 0 2 3 GHZ Service Repair Manualpeteinnj91% (11)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Sample For Solution Manual Data Structures and Algorithms in C++ 2nd Edition by Goodrich & TamassiaDocument21 pagesSample For Solution Manual Data Structures and Algorithms in C++ 2nd Edition by Goodrich & Tamassiaomar burakNo ratings yet

- Arras Mexei Mas 4000Document5 pagesArras Mexei Mas 4000mohammed Khaled100% (1)

- Bare-Hand Live-Line Work Safety: BCM Series of Boom Current MonitorsDocument2 pagesBare-Hand Live-Line Work Safety: BCM Series of Boom Current MonitorsRogério Paião0% (1)

- Brochure Sat40a II Series - B S0sera 314 enDocument6 pagesBrochure Sat40a II Series - B S0sera 314 enSelk CLNo ratings yet

- Brochure CAT Advanced series-B-CATADV-112-ENDocument21 pagesBrochure CAT Advanced series-B-CATADV-112-ENSelk CLNo ratings yet

- Brochure Transducer Mounting Kit B TMKNS2 104 EN 1Document7 pagesBrochure Transducer Mounting Kit B TMKNS2 104 EN 1Selk CLNo ratings yet

- VLF-6022CM (F) : VLF Cable Testing For Cables Rated To 35kVDocument1 pageVLF-6022CM (F) : VLF Cable Testing For Cables Rated To 35kVSelk CLNo ratings yet

- Ezct S2: Digital Current-Transformer Tester User'S ManualDocument66 pagesEzct S2: Digital Current-Transformer Tester User'S ManualSelk CLNo ratings yet

- RMO-TD Series: Tap Changer Analyzer & Winding OhmmeterDocument6 pagesRMO-TD Series: Tap Changer Analyzer & Winding OhmmeterSelk CLNo ratings yet

- VLF 120 BrochureDocument1 pageVLF 120 BrochureSelk CLNo ratings yet

- Manual - CAT3x & CAT6x Advanced Series - Ver - M-CA6XAD-114-EN - Copyright A4Document83 pagesManual - CAT3x & CAT6x Advanced Series - Ver - M-CA6XAD-114-EN - Copyright A4Selk CLNo ratings yet

- Compact MIDAS micro 2883 for insulation testingDocument4 pagesCompact MIDAS micro 2883 for insulation testingSelk CLNo ratings yet

- PTS-100 PTS-100F: PTS Series - DC High Voltage Test Set and MegohmmeterDocument1 pagePTS-100 PTS-100F: PTS Series - DC High Voltage Test Set and MegohmmeterSelk CLNo ratings yet

- Quick Start Guide: EnglishDocument8 pagesQuick Start Guide: EnglishSelk CLNo ratings yet

- Compact MIDAS micro 2883 for insulation testingDocument4 pagesCompact MIDAS micro 2883 for insulation testingSelk CLNo ratings yet

- True Three-Phase Transformer Turns Ratio Tester TRT33A: Measurement of Phase ShiftDocument4 pagesTrue Three-Phase Transformer Turns Ratio Tester TRT33A: Measurement of Phase ShiftSelk CLNo ratings yet

- 5-kV Insulation Resistance Testers: BM11D and BM21Document2 pages5-kV Insulation Resistance Testers: BM11D and BM21Selk CLNo ratings yet

- 2010-Doble Case Studies - Lewand - Paper IM-01Document21 pages2010-Doble Case Studies - Lewand - Paper IM-01vzimak2355No ratings yet

- Stray GassingDocument9 pagesStray GassingSelk CLNo ratings yet

- ASTM G57-95A (2001) Standard Test Method For Field Measurement of Soil Resistivity Using The Wenner Four-Electrode MethodDocument5 pagesASTM G57-95A (2001) Standard Test Method For Field Measurement of Soil Resistivity Using The Wenner Four-Electrode Methodsebastián_lena_1No ratings yet

- A Guide To Sampling of Electrical Insulating Mineral OilsDocument11 pagesA Guide To Sampling of Electrical Insulating Mineral OilsSelk CLNo ratings yet

- Nypass: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument12 pagesNypass: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingSelk CLNo ratings yet

- E575R Series: Transformer Oil RegenerationDocument1 pageE575R Series: Transformer Oil RegenerationSelk CLNo ratings yet

- VLF 120 BrochureDocument1 pageVLF 120 BrochureSelk CLNo ratings yet

- VLF-6022CM (F) : VLF Cable Testing For Cables Rated To 35kVDocument1 pageVLF-6022CM (F) : VLF Cable Testing For Cables Rated To 35kVSelk CLNo ratings yet

- CPE2011 Student Forum 023-027Document5 pagesCPE2011 Student Forum 023-027anupam789No ratings yet

- VLF-12011CMF Manual Complete - 2k19Document40 pagesVLF-12011CMF Manual Complete - 2k19Selk CLNo ratings yet

- DDX 7000Document100 pagesDDX 7000lea_quilmes50% (2)

- Wa0015.Document23 pagesWa0015.slymanjaradatNo ratings yet

- Python Highway 2 Books in 1 The Fastest Way For Beginners To Learn Python Programming, Data Science and Machine Learning in 3 Days (Or Less) + Practical Exercises Included by Cox, AaronDocument174 pagesPython Highway 2 Books in 1 The Fastest Way For Beginners To Learn Python Programming, Data Science and Machine Learning in 3 Days (Or Less) + Practical Exercises Included by Cox, AaronAlberto FasceNo ratings yet

- SEO-Optimized Software Engineer ProfileDocument1 pageSEO-Optimized Software Engineer ProfileasahdhjkjNo ratings yet

- Text Chapter 2 Basic ObjectsDocument126 pagesText Chapter 2 Basic ObjectsLevinNo ratings yet

- MINDRAY ControlsDocument4 pagesMINDRAY ControlsAmr AshourNo ratings yet

- MY NEW LIFE MAIN WALKTHROUGH v. 1.7 FixedDocument54 pagesMY NEW LIFE MAIN WALKTHROUGH v. 1.7 FixedHenry CardozaNo ratings yet

- Control System and Solutions - Global Case Study Collection - JIV1901 PDFDocument11 pagesControl System and Solutions - Global Case Study Collection - JIV1901 PDFcodefinderNo ratings yet

- TSFC-12-2 Cloud Connected Fire Alarm PanelDocument2 pagesTSFC-12-2 Cloud Connected Fire Alarm PanelSwapnil SangodkarNo ratings yet

- Online Educational ResourcesDocument115 pagesOnline Educational ResourcesDr Johan @ Eddy LuaranNo ratings yet

- Analog Output Module: Catalog Number 1762-OF4Document24 pagesAnalog Output Module: Catalog Number 1762-OF4Juan Manuel De La CruzNo ratings yet

- Data Processor Cover LetterDocument5 pagesData Processor Cover Letterzys0vemap0m3100% (2)

- Essentials of Oracle Property ManagerDocument120 pagesEssentials of Oracle Property ManagerOsamaAzizNo ratings yet

- Sample Questions For Practical ExamDocument2 pagesSample Questions For Practical Examsamridhiverma0701No ratings yet

- Story Structure Analysis: The Matrix DeconstructedDocument15 pagesStory Structure Analysis: The Matrix DeconstructedAl DobkoNo ratings yet

- +FreeBSD Journal - 2014-01-03Document51 pages+FreeBSD Journal - 2014-01-03VyacheslavNo ratings yet

- CRR 718 Ben FTTHDocument66 pagesCRR 718 Ben FTTHanupkrajakNo ratings yet

- Cadangan Jawapan STPM 2013Document37 pagesCadangan Jawapan STPM 2013jennyhewmtNo ratings yet

- Python Function QuestionsDocument13 pagesPython Function QuestionsTooba MujeebNo ratings yet

- Primavera P6 Course SyllabusDocument10 pagesPrimavera P6 Course SyllabusHarsh PatelNo ratings yet

- Quality Standards and MetricsDocument2 pagesQuality Standards and MetricsAniqaNo ratings yet

- Visoka Škola Za Poslovnu Ekonomiju I Preduzetništvo: Seminarski RadDocument13 pagesVisoka Škola Za Poslovnu Ekonomiju I Preduzetništvo: Seminarski RadJelena StanicNo ratings yet

- PMP+Exam+Prep+ +Agile+ContentDocument578 pagesPMP+Exam+Prep+ +Agile+ContentOsny JeanNo ratings yet

- Tra Job AdvertDocument23 pagesTra Job AdvertDaniel EudesNo ratings yet

- 7 Role of Artificial Intelligence in Digital MarketingDocument7 pages7 Role of Artificial Intelligence in Digital Marketingdelel aimaNo ratings yet

- HT32F57331 41 42 52 Datasheetv140Document65 pagesHT32F57331 41 42 52 Datasheetv140John ThompsonNo ratings yet

- Service ManualDocument16 pagesService ManualAbiNo ratings yet

- Development of Finance Management System For Mwenge Catholic UniversityDocument55 pagesDevelopment of Finance Management System For Mwenge Catholic UniversityJames mollelNo ratings yet