Professional Documents

Culture Documents

Raw Material Selection Guide Steel

Raw Material Selection Guide Steel

Uploaded by

Santosh KumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Raw Material Selection Guide Steel

Raw Material Selection Guide Steel

Uploaded by

Santosh KumarCopyright:

Available Formats

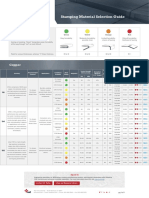

Stamping Material Selection Guide

Bend Rating Key:

Green Yellow Orange Red

ESI’s Bend Rating scale measures the formability of a Easy formability Moderate formability; Limited formability; Difficult formability;

material based on its ability to bend or form without possible strain chance of tearing likelihood of tearing

tearing or breaking. “Green” designates easier formability

all the way through “red” as most difficult.

Radii for various thicknesses, whereas “t”=times thickness. 0t to 3t 3t to 6t 6t to 9t 9t +

Steel

Yield Strength Density

Tensile Strength Elongation Minimum

Recommended Conditions Bend Hardness (lb/cu in) Corrosion

Summary Applications Magnetic? Minimum (KSI) Minimum (0.2% offset) Cost?

Finishes? Available Rating (Min-Max) Resistance

(% 2" Gauge) (lb/in³) (g/cm³)

KSI MPa KSI MPa

Carbon steels are steels that

have carbon as the main alloying

element. They contain about

1.2% of manganese and 0.4% of Zinc, Nickel,

silicon. There are other materi- Zinc-Nickel, Appliances, automo-

AISI 1006 Rockwell

C1006 als present in small quantities Mechanical biles, magnet core Yes 35 241 38% N/A N/A 0.2836 7.850 $$$$

Carbon Steel B30-B50

in these carbon steels, such as and Organic applications

copper, aluminum, molybdenum, finishes

nickel, and chromium. Features

of C1006 include ductility and

softness.

AISI 1008 #5 Rockwell

Yes 44 303 33% 25 172 0.2836 7.850 $$$$

Temper Soft B55 Max

AISI 1008 #4

Rockwell

Temper Skin Yes 48 331 24% 35 241 0.2836 7.850 $$$$

B65 Max

Zinc, Nickel, Virtually all indus- Pass

This most common carbon steel

Zinc-Nickel, tries. Brackets, Clips, AISI 1008 #3

C1008/ has excellent weldability, which Rockwell

Mechanical Plates, Washers, Temper 1/4 Yes 55 379 22% 42 290 0.2836 7.850 $$$$

C1010 includes brazeability, spot and B60-B75

and Organic Spacers Housings, Hard

fusion, butt, and projection.

finishes Weldments. AISI 1008 #2

Rockwell

Temper 1/2 Yes 65 448 20% 50 345 0.2836 7.850 $$$$

B70-B85

Hard

AISI 1008 #1

Rockwell

Temper Full Yes 80 552 16% 60 414 0.2836 7.850 $$$$

B84 Min

Hard

C1018, one of the most regular- Zinc, Nickel,

ly available grades around the Zinc-Nickel, Shafts, spindles, pins,

AISI 1018 Rockwell

C1018 world, is a free machining grade Mechanical rods, sprocket assem- Yes 64 441 15% 54 372 0.2836 7.850 $$$$

Carbon Steel B71 Min

that can be easily formed, ma- and Organic blies

chined, welded, and fabricated. finishes

Zinc, Nickel, AISI 1050 Rockwell

Yes 90 621 20% 58 400 0.2836 7.850 $$$$

C1050 is a medium carbon, Zinc-Nickel, Shafts, machinery Annealed B84 Max

C1050 medium tensile steel with solid Mechanical parts, bolts, pinions,

strength and toughness. and Organic gears AISI 1050 Rockwell

finishes

Yes 110 758 3% 100 689 0.2836 7.850 $$$$

Hardened C22-58

Zinc, Nickel, AISI 1074/1075 Rockwell

Blades, clips, brack- Yes 94 648 10% 62 427 0.2836 7.850 $$$$

C1074 steel is a carbon, non-al- Zinc-Nickel, Annealed B86 Max

C1074/ ets, brake discs,

loy steel made for primary form- Mechanical

C1075 clutches, springs,

ing into wrought products. and Organic AISI 1074/1075 Rockwell

washers, wear strips Yes N/A N/A N/A N/A N/A 0.2836 7.850 $$$$

finishes Hardened C25-64

C1095 is a basic form of carbon AISI 1095 Rockwell

steel and is frequently used in Zinc, Nickel, Yes 99 683 10% 76 524 0.2836 7.850 $$$$

Annealed B86 Max

the construction of knives. It Zinc-Nickel,

C1095 has a carbon content of .95%, Mechanical Springs, cutting tools

which hardens the material and and Organic

lessens the wear that a blade finishes AISI 1095 Rockwell

Yes N/A N/A N/A N/A N/A 0.2836 7.850 $$$$

will encounter over time. Hardened C30-66

HSLA Carbon

Rockwell

Steel ASTM Yes 58 400 22% 36 248 0.2836 7.850 $$$$

B68 Min

A36, Grade 36

HSLA Carbon

HSLA, or high-strength low-alloy Automotive, Bridge Steel ASTM Rockwell

Zinc, Nickel, Yes 58 400 20% 50 345 0.2836 7.850 $$$$

steel, is a type of carbon steel and similar construc- A572, Grade B75 Min

Zinc-Nickel,

with low amounts of alloying tion applications, oil 50

HSLA Mechanical

elements that are added to its and gas transmission HSLA Carbon

and Organic

chemical composition to primari- pipelines, storage Steel ASTM Rockwell

finishes Yes 70 483 18% 60 414 0.2836 7.850 $$$$

ly increase its strength. tanks A656, Grade B88 Min

60

HSLA Grade Rockwell

Yes 100 689 12% 80 552 0.2836 7.850 $$$$

80 B90 Min

About Us

Engineering Specialties Inc. (ESI) delivers custom manufacturing solutions, specializing in production metal stamping,

CNC machining and advanced assembly capabilities. For more information about ESI, visit www.esict.com.

Contact Us Today View our Resource Library

452 Twin Lakes Rd • North Branford, CT 06471

www.esict.com • Email: info@esict.com • Phone: 800-486-5546 • Fax: 800-486-2825 pg 1 of 1

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Raw Material Selection Guide CopperDocument1 pageRaw Material Selection Guide CopperSantosh KumarNo ratings yet

- Raw Material Selection Guide BrassDocument1 pageRaw Material Selection Guide BrassSantosh KumarNo ratings yet

- Raw Material Selection Guide Beryllium CopperDocument1 pageRaw Material Selection Guide Beryllium CopperSantosh KumarNo ratings yet

- Sheet Metal Cutting (Shearing)Document10 pagesSheet Metal Cutting (Shearing)Santosh KumarNo ratings yet