Professional Documents

Culture Documents

Visqueen High Performance Damp Proof Membrane: Features and Benefits

Uploaded by

tashadzureenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Visqueen High Performance Damp Proof Membrane: Features and Benefits

Uploaded by

tashadzureenCopyright:

Available Formats

Technical support: +44 (0) 333 202 6800

Date Published: 17/11/2021

Visqueen High Performance Damp Proof Membrane

Features and benefits

BBA certified - third party accreditation

Robust - resistant to on site damage

Flexible - easy to detail and install on site

Supplied centre folded - reduces the risk of cracks in screed and limits creases

Dual jointing methods - lap joints can be taped or heat welded

Product description

Visqueen High Performance Damp Proof Membrane is a robust co-polymer thermoplastic membrane, 0.5mm thick, yellow in colour

and supplied 4m x 12.5m in a center folded roll.

Approvals and standards

Third party accreditation (BBA 94/3009)

CE Mark EN 13967:2017

Quality Management System ISO 9001:2015

Occupational Health and Safety System ISO 45001:2018

Environmental Management System ISO 14001:2015

Usage

Visqueen High Performance Damp Proof Membrane is suitable for use in ground floor constructions, positioned above or below

the structural floor, to protect buildings against moisture from the ground.

The product is not intended for use where there is a risk of hydrostatic pressure.

System components

VisqueenPro Double Sided Jointing Tape, 50mm x 10m

VisqueenPro Single Sided Tape, 75mm x 25m

Visqueen GR Lap Tape, 150mm x 10m

Visqueen Top Hat Units

Visqueen Preformed Units

VisqueenPro Detailing Strip, 300mm x 10m, 500mm x 10m

Visqueen TreadGUARD 300, 2m x 75m

Visqueen TreadGUARD 1500, 1m x 2m

Find your local stockist

1/4 Heanor Gate Road, Heanor, Derbyshire, DE75 7RG

+44 (0) 333 202 6800 I enquiries@visqueen.com I www.visqueen.com

Technical support: +44 (0) 333 202 6800

Date Published: 17/11/2021

Visqueen High Performance Damp Proof Membrane

Storage and handling

Visqueen High Performance Damp Proof Membrane should be stored horizontally, under cover in its original packaging.

Care should be taken when handling the product in line with current manual handling regulations.

Preparation

Visqueen High Performance Damp Proof Membrane should be installed on a smooth continuous surface e.g. grouted beam and

block floor, a compacted blinding layer e.g. 50mm thick sand blinding, or smooth concrete blinding. The substrate should be free

from irregularities such as voids or protrusions.

The membrane can be cut with a sharp retractable safety knife or robust scissors.

When installing the membrane in demanding site conditions, use Visqueen GR Lap Tape in place of Visqueen Pro Single Sided

Tape.

Installation

Visqueen High Performance Damp Proof Membrane should be loose laid on the substrate. The membrane should be clean and dry

at the time of jointing. It should be overlapped by at least 150mm, bonded with Visqueen Pro Double Sided Jointing Tape and

sealed with Visqueen Pro Single Sided Tape.

Airtight seals should be formed around all service entry points. Visqueen Preformed Top Hat Units should be used for sealing

service entry pipes. The base of the top hat and the upstand should be bonded using Visqueen Pro Double Sided Jointing Tape

and sealed with Visqueen Pro Single Sided Tape. The upstand should be secured with the supplied jubilee clip.

If the membrane is punctured or perforated a patch of the same material should be lapped at least 150mm beyond the limits of the

puncture and bonded with Visqueen Pro Double Sided Jointing Tape and sealed with Visqueen Pro Single Sided Tape.

Alternatively a patch can be formed using Visqueen Pro Detailing Strip and lapped at least 150mm beyond the extents of the

puncture.

Forming an effective barrier to damp may give rise to complex three-dimensional detailing where, it is recommended Visqueen

Preformed Units are used e.g. corners. Alternatively Visqueen Pro Detailing Strip can be used to seal awkward junctions.

Long periods of exposure to ultraviolet light will reduce the effectiveness of the membrane. The membrane should be covered by a

protective layer immediately after installation to prevent damage from following trades, ultraviolet light, etc. Care should be taken

to ensure that the membrane is not punctured, stretched or displaced when applying a screed or final floor covering. A minimum

thickness of 50mm screed is recommended.

When reinforced concrete is to be laid over the membrane the wire reinforcements and spacers must be prevented from

puncturing the membrane. Where there is potential for damage, the membrane should be covered with Visqueen TreadGuard

protection, screed, or other approved protection material before positioning the reinforcement.

In areas where high levels of settlement are anticipated, Visqueen Pre Applied Membrane should be considered.

Usable temperature range

It is recommended that Visqueen High Performance Damp Proof Membrane and all associated system components should not be

installed below 5°C.

Additional information

To assist build sequencing, Visqueen Zedex CPT DPC is available for damp protection through masonry wall constructions.

Visqueen Preformed Top Hat Units should be used at service pipe penetrations see HP-51.

To seal around steel columns use Visqueen Pro Detailing Strip see HP-52.

For additional detailing information, contact Visqueen Technical Services +44 (0) 333 202 6800.

The product is recyclable and categorised under LDPE recycling code 4. Visqueen is part of Berry bpi, the largest European

recycler of polyethylene. This product is recyclable and should be segregated on site in accordance with site management

procedures for plastic waste. We have 4 recycling sites in the UK where the plastic waste could be recycled and converted back

into a second life product. Please contact us to find out more.

The information in this datasheet was correct at the time of publication. It is the user’s responsibility to obtain the latest version of

the datasheet as it is updated on a regular basis. The information contained in the latest datasheet supersedes all previously

published editions.

2/4 Heanor Gate Road, Heanor, Derbyshire, DE75 7RG

+44 (0) 333 202 6800 I enquiries@visqueen.com I www.visqueen.com

Technical support: +44 (0) 333 202 6800

Date Published: 17/11/2021

Visqueen High Performance Damp Proof Membrane

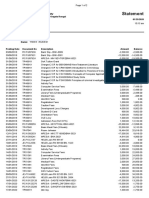

Property Test method Units Compliance criteria Value or Statement

Visible defects EN 1850 -2 - Pass/Fail Pass

Length EN 1848-2 m -10%/+10% 12.5

Width EN 1848-2 m -2.5%/+2.5% 4

Straightness EN 1848-2 - Pass/Fail Pass

Thickness EN 1849-2 mm -12%/+12% 0.5

Tensile elongation - MD EN 12311 % MLV 400

Tensile elongation - TD EN 12311 % MLV 400

Joint strength EN 12317-2 N MLV 200

Watertightness 2kPa EN 1928 - Pass/Fail Pass

Resistance to impact EN 12691 mm MLV 200

Durability (artificial ageing) EN 1296 and EN 1928 - Pass/Fail Pass

Durability chemical resistance EN 1847 - Pass/Fail Pass

Resistance to tearing (nail shank) CD EN 12310-1 N MDV 300

Resistance to tearing (nail shank) MD EN 12310-1 N MDV 300

Resistance to static loading EN 12730 kg MLV 20

Water vapour transmission - resistance EN 1931 MNs/g MDV 2100

Water vapour transmission - permeability EN 1931 g/m²/d MDV 0.08

Reaction to fire EN 13501-1 Class MDV F

Health and safety information

Refer to Visqueen High Performance Damp Proof Membrane material safety datasheet (MSDS).

3/4 Heanor Gate Road, Heanor, Derbyshire, DE75 7RG

+44 (0) 333 202 6800 I enquiries@visqueen.com I www.visqueen.com

Technical support: +44 (0) 333 202 6800

Date Published: 17/11/2021

Visqueen High Performance Damp Proof Membrane

About Visqueen

The Visqueen name has long been recognised as one of the leading manufacturers of high quality advanced membrane

technologies and design based solutions by specifiers, distributors, builders merchants and contractors throughout the UK and

Europe.

For further guidance on the Visqueen services shown below, please refer to the relevant section of the Visqueen website

(www.visqueen.com) or contact Visqueen Technical Services on +44 (0) 333 202 6800 or enquiries@visqueen.com

Complete Range, Complete Solution

Visqueen Technical Support

Visqueen combine an extensive product portfolio with industry leading levels of service and support which includes guidance over

the phone, bespoke CAD drawings to help with complex detailing, electronic NBS specifications and access to a dedicated team of

highly knowledgeable and experienced field based Technical Support Managers.

Visqueen Technical Support is available to all our customers including architects, specifiers, distributors, builders merchants,

contractors and end users. All of our technical team have been awarded the industry recognised qualification Certificated Surveyor

in Structural Waterproofing (CSSW).

Visqueen CPD Seminars

The Visqueen Continuing Professional Development (CPD) Seminars provide up-to-date information on changes within Building

Regulations/Building Standards and nationally recognised industry guidance affecting damp proofing, water vapour control,

hazardous ground gas protection and below ground structural waterproofing.

The one hour seminars have been produced for design specialists within the construction sector and are delivered by our team of

Technical Support Managers.

Visqueen PI designs and special projects

From initial design to the completed project, Visqueen are with you every step of the way. Whether it be hazardous ground gas

protection and/or below ground waterproofing protection employing barrier, structurally integral or drained systems, Visqueen can

offer professional indemnity (PI) insurance for bespoke Visqueen design solutions.

Visqueen Technical Support Managers work with all stakeholders to provide cost effective Visqueen solutions offering complete

peace of mind throughout the construction phase and beyond.

Visqueen Training Academy

Based at our manufacturing facility in Derbyshire, the Visqueen Training Academy is available to support Visqueen customers

throughout the UK by providing a wide range of both theory and practical skills related training.

Courses include one day product awareness training for our distributors and builders merchants to help them in their day-to-day

jobs, through to intensive three day courses giving detailed hands-on training in the practical skills required for safe and robust

product installation.

4/4 Heanor Gate Road, Heanor, Derbyshire, DE75 7RG

+44 (0) 333 202 6800 I enquiries@visqueen.com I www.visqueen.com

You might also like

- Proofex 12Document2 pagesProofex 12vinoth kumar SanthanamNo ratings yet

- TEST 1A BFC 32403 - Sem 2 20132014 ANWER SCHEMEDocument6 pagesTEST 1A BFC 32403 - Sem 2 20132014 ANWER SCHEMEtashadzureenNo ratings yet

- Visqueen Class B FR Vapour Check DatasheetDocument4 pagesVisqueen Class B FR Vapour Check DatasheettellpatryanNo ratings yet

- Visqueen Ultimate HC BLOK DatasheetDocument5 pagesVisqueen Ultimate HC BLOK Datasheetali aliNo ratings yet

- CE Mark To EN 13967Document5 pagesCE Mark To EN 13967Slinky BillNo ratings yet

- Damp Proof Membrane To PIFA Standard Datasheet 12-08-2011Document3 pagesDamp Proof Membrane To PIFA Standard Datasheet 12-08-2011Mrcoke SeieNo ratings yet

- v1 v2 Fiberglass Surfacing VeilsDocument2 pagesv1 v2 Fiberglass Surfacing Veilsvictor japposanNo ratings yet

- Sikaplan®-1652 Bonded VOC Gas Barrier: Product Data SheetDocument3 pagesSikaplan®-1652 Bonded VOC Gas Barrier: Product Data SheetKhin Sandi KoNo ratings yet

- Technische Information - COSMOFIN-FG R - ENDocument2 pagesTechnische Information - COSMOFIN-FG R - ENKat PNo ratings yet

- Sikashield p24 s3mmDocument4 pagesSikashield p24 s3mmariefNo ratings yet

- Damplas Damp Proof Membranes: CE Marked To EN 13967Document5 pagesDamplas Damp Proof Membranes: CE Marked To EN 13967Vikram MohanNo ratings yet

- Elotene 3000 X: Self-Adhesive Bituminous Membrane Self-Protected With A Cross-Laminated HDPE FilmDocument34 pagesElotene 3000 X: Self-Adhesive Bituminous Membrane Self-Protected With A Cross-Laminated HDPE FilmConstantin GubavuNo ratings yet

- TDS - Masterpren TGE-FDocument2 pagesTDS - Masterpren TGE-FAlexi ALfred H. TagoNo ratings yet

- Visqueen DPM Flyer PDFDocument4 pagesVisqueen DPM Flyer PDFAnonymous 3VAQ9SNxl7No ratings yet

- Carrier Membrane PDSDocument4 pagesCarrier Membrane PDSbassem kooliNo ratings yet

- Scotch 2200,2210 DatasheetDocument2 pagesScotch 2200,2210 DatasheetJake AllenNo ratings yet

- SikaProofA 08 en GB 06 2019 1 1Document5 pagesSikaProofA 08 en GB 06 2019 1 1slavisa05No ratings yet

- Visqueen Self Adhesive Damp Proof Membrane: Description Typical PropertiesDocument2 pagesVisqueen Self Adhesive Damp Proof Membrane: Description Typical PropertiesJNo ratings yet

- PDF Case Study-Trentons Wax-Tape 2 Anticorrosion WrapDocument2 pagesPDF Case Study-Trentons Wax-Tape 2 Anticorrosion Wrapparesh tadasNo ratings yet

- Sealfl Ex: Description Method of UseDocument4 pagesSealfl Ex: Description Method of UseramiNo ratings yet

- VCS ID Pikotek Gaslets Technical CanadaDocument3 pagesVCS ID Pikotek Gaslets Technical CanadaRajesh RadeNo ratings yet

- Pds Sikashield P55pert4mmDocument3 pagesPds Sikashield P55pert4mmĐức Thanh NguyễnNo ratings yet

- Datasheet - CoronaShield C - 215.51 - EN - GLDocument3 pagesDatasheet - CoronaShield C - 215.51 - EN - GLLECTORNo ratings yet

- Push-Fit System For Metal Plastic PipesDocument2 pagesPush-Fit System For Metal Plastic PipesRUDI YANTONo ratings yet

- 2179CE (G) Datasheet-2011v0 BackupDocument4 pages2179CE (G) Datasheet-2011v0 BackupHữu Khánh NguyễnNo ratings yet

- TDS Proofex Engage IndiaDocument4 pagesTDS Proofex Engage Indiabackupsanthosh21 dataNo ratings yet

- TDS - Masterpren HEDocument2 pagesTDS - Masterpren HEJaga NathNo ratings yet

- Client: Jacobs: Waterproofing System For BASEMENT - HIGH WATER TABLEDocument2 pagesClient: Jacobs: Waterproofing System For BASEMENT - HIGH WATER TABLEShakil AkhterNo ratings yet

- BituBOND Manual DigitalDocument19 pagesBituBOND Manual DigitalisuruNo ratings yet

- Antiradice PE PDFDocument4 pagesAntiradice PE PDFJM SubionNo ratings yet

- Donproof PT: Description Method of UseDocument4 pagesDonproof PT: Description Method of UseYousef HalasehNo ratings yet

- Sikabit 1.5mm Waterproofing MembraneDocument3 pagesSikabit 1.5mm Waterproofing MembraneGhayas Jawed0% (1)

- Wavin PE SWR Data Sheet LEDocument2 pagesWavin PE SWR Data Sheet LEvinayak abhaleNo ratings yet

- WPC120 PDFDocument2 pagesWPC120 PDFHamzaHashimNo ratings yet

- Datasheet - CoronaShield C - 215.55 - EN - GLDocument3 pagesDatasheet - CoronaShield C - 215.55 - EN - GLLECTORNo ratings yet

- TechnicalDataSheet Effisus2BondDS ENGDocument2 pagesTechnicalDataSheet Effisus2BondDS ENGPaula MoçoNo ratings yet

- Sikabit® Pro P-40-0 Sand: Product Data SheetDocument3 pagesSikabit® Pro P-40-0 Sand: Product Data SheetBagastyo DaniNo ratings yet

- 3M 2179CE Fiber Optical Closure: ApplicationsDocument4 pages3M 2179CE Fiber Optical Closure: ApplicationsHữu Khánh NguyễnNo ratings yet

- TDS Proofex Engage IndiaDocument4 pagesTDS Proofex Engage IndiaatrijoshiNo ratings yet

- Danosa - POLYDAN 50 - GP ELAST. VERT JARDINDocument5 pagesDanosa - POLYDAN 50 - GP ELAST. VERT JARDINAudrey SeninNo ratings yet

- Fisa Tehnica BitusealDocument3 pagesFisa Tehnica BitusealSavu CristianNo ratings yet

- 3170Document2 pages3170Mohammed Satti100% (1)

- Aquaproof Tape FlexDocument2 pagesAquaproof Tape Flexosama mohNo ratings yet

- Manual Tamaño 3 FlejeDocument48 pagesManual Tamaño 3 FlejeSonia Noval LlorianNo ratings yet

- Declaration of Performance Firestone Ultraply Tpo 1.8: No. Doptpo1.8-Etav03R-2016-09-01Document3 pagesDeclaration of Performance Firestone Ultraply Tpo 1.8: No. Doptpo1.8-Etav03R-2016-09-01Youl SilvaNo ratings yet

- Dekguard E2000 0608Document3 pagesDekguard E2000 0608Samar HusainNo ratings yet

- Raychem MWTM Medium Wall PDFDocument4 pagesRaychem MWTM Medium Wall PDFLeo TopacioNo ratings yet

- Sikaplan®-1651 Loose VOC Gas Barrier: Product Data SheetDocument3 pagesSikaplan®-1651 Loose VOC Gas Barrier: Product Data SheetKhin Sandi KoNo ratings yet

- Premier Coatings SeaShield Series 2000HDDocument6 pagesPremier Coatings SeaShield Series 2000HDfakmiloNo ratings yet

- TDS Proofex Engage Saudi ArabiaDocument5 pagesTDS Proofex Engage Saudi ArabiaMudassir AliNo ratings yet

- TDS - Bronco Pre HDPE Membrane (S)Document3 pagesTDS - Bronco Pre HDPE Membrane (S)Shreyansh UdaniNo ratings yet

- HT Sika SealTape FDocument3 pagesHT Sika SealTape FJunior FlooNo ratings yet

- Sika Bituseal T-130 SG PdsDocument4 pagesSika Bituseal T-130 SG Pdsmr_hendihalimNo ratings yet

- Index Fidia P - Mineral Roof Deck Plant Room Acciona W2E Kwinana 03-2019Document6 pagesIndex Fidia P - Mineral Roof Deck Plant Room Acciona W2E Kwinana 03-2019Biju_PottayilNo ratings yet

- Armourflex PVC - TDSDocument3 pagesArmourflex PVC - TDSPhạm Thanh PhươngNo ratings yet

- Visqueen PIFA Damp Proof Membranes: DescriptionDocument2 pagesVisqueen PIFA Damp Proof Membranes: DescriptionJNo ratings yet

- Sikaplan-Sgma 2.0 PB EngDocument5 pagesSikaplan-Sgma 2.0 PB EngstilpgNo ratings yet

- GP-05 TDS-Proofex-12-IndiaDocument2 pagesGP-05 TDS-Proofex-12-IndiaEddy NgNo ratings yet

- 02 - Retaining Wall Confined WaterproofingDocument6 pages02 - Retaining Wall Confined Waterproofingannayya.chandrashekar Civil EngineerNo ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- SikaGrout-215 2011-11 - 1 PDFDocument4 pagesSikaGrout-215 2011-11 - 1 PDFFaiz RahmatNo ratings yet

- Instruction: Answer All Question: Assignment 1 Analysis of Prestress and Bending Stress BFS 40303Document4 pagesInstruction: Answer All Question: Assignment 1 Analysis of Prestress and Bending Stress BFS 40303tashadzureenNo ratings yet

- Final BFC 32403 Sem 1 2013 14 - SCHEMEDocument16 pagesFinal BFC 32403 Sem 1 2013 14 - SCHEMEtashadzureenNo ratings yet

- Sample Presentation ScriptDocument1 pageSample Presentation ScriptLouis LaiNo ratings yet

- Assignment SCM Sem II 2019 PDFDocument1 pageAssignment SCM Sem II 2019 PDFtashadzureenNo ratings yet

- Slump Cone Test Apparatus: Asia Leader Material Testing EquipmentDocument1 pageSlump Cone Test Apparatus: Asia Leader Material Testing EquipmenttashadzureenNo ratings yet

- Sika® Antisol® A: Product Data SheetDocument2 pagesSika® Antisol® A: Product Data SheettashadzureenNo ratings yet

- Plot Curve and ObcDocument3 pagesPlot Curve and ObctashadzureenNo ratings yet

- Cover LetterDocument1 pageCover LettertashadzureenNo ratings yet

- Test 1a BFC 32403 - Sem 2 20132014 Anwer SchemeDocument5 pagesTest 1a BFC 32403 - Sem 2 20132014 Anwer SchemetashadzureenNo ratings yet

- Final BFC 32403 Sem 1 2013 14 - SchemeDocument16 pagesFinal BFC 32403 Sem 1 2013 14 - SchemetashadzureenNo ratings yet

- Chapter 1 Part 1 - Introduction PDFDocument61 pagesChapter 1 Part 1 - Introduction PDFtashadzureenNo ratings yet

- Example Application Letter For Fresh Graduate Civil EngineerDocument1 pageExample Application Letter For Fresh Graduate Civil EngineertashadzureenNo ratings yet

- Example Application Letter For Fresh Graduate Civil EngineerDocument1 pageExample Application Letter For Fresh Graduate Civil EngineertashadzureenNo ratings yet

- Hirarc ProjectDocument2 pagesHirarc Projecttashadzureen100% (4)

- EarthwormDocument10 pagesEarthwormtashadzureenNo ratings yet

- Usage of Groundwater: 1. DomesticDocument3 pagesUsage of Groundwater: 1. DomestictashadzureenNo ratings yet

- Open Ended Lab Geotechnic (Constant Head Permeability Test)Document11 pagesOpen Ended Lab Geotechnic (Constant Head Permeability Test)tashadzureen0% (1)

- Intro and Obj HighwayDocument2 pagesIntro and Obj HighwaytashadzureenNo ratings yet

- Safety Science: SciencedirectDocument11 pagesSafety Science: SciencedirecttashadzureenNo ratings yet

- Open Ended Lab Geotechnic (Constant Head Permeability Test)Document11 pagesOpen Ended Lab Geotechnic (Constant Head Permeability Test)tashadzureen0% (1)

- Open Ended Lab Geotechnic (Constant Head Permeability Test)Document11 pagesOpen Ended Lab Geotechnic (Constant Head Permeability Test)tashadzureen0% (1)

- CompanyDocument7 pagesCompanylotchanNo ratings yet

- English: Quarter 2 - Module 1 Listening Strategies Based On Purpose, Familiarity With The Topic, and Levels of DifficultyDocument24 pagesEnglish: Quarter 2 - Module 1 Listening Strategies Based On Purpose, Familiarity With The Topic, and Levels of DifficultyMary Ysalina100% (3)

- CBSE Class 11 History Syllabus 2021-22Document12 pagesCBSE Class 11 History Syllabus 2021-22Muskan TiwariNo ratings yet

- Max-E2/841™ Family Nema Premium Efficiency: Type Aehh8B, Aehh8Bcf, Aeuh8BdcDocument1 pageMax-E2/841™ Family Nema Premium Efficiency: Type Aehh8B, Aehh8Bcf, Aeuh8BdcAnibal QuezadaNo ratings yet

- Shiksha Sopan April 09Document4 pagesShiksha Sopan April 09Amrendra NarayanNo ratings yet

- IHS Markit - The Global Ultrasound MarketDocument2 pagesIHS Markit - The Global Ultrasound MarketwwtqfgtpNo ratings yet

- Schoolwide Plan Worksheet: School Name: Pioneer Elementary Principal Name: Brenda Lopresto School Planning TeamDocument10 pagesSchoolwide Plan Worksheet: School Name: Pioneer Elementary Principal Name: Brenda Lopresto School Planning TeamChauncey Mae TanNo ratings yet

- Introduction To Operations Research 11E Ise 11Th Ise Edition Frederick S Hillier Full ChapterDocument67 pagesIntroduction To Operations Research 11E Ise 11Th Ise Edition Frederick S Hillier Full Chapterrobin.mccomb793No ratings yet

- Sitronix ST7565RDocument72 pagesSitronix ST7565RStuart CouttsNo ratings yet

- Ex If Tool GuiDocument2 pagesEx If Tool Guipnb55No ratings yet

- Qualitative Study On Stress Among Nurses Working at Private Sector, in Suburban KolkataDocument9 pagesQualitative Study On Stress Among Nurses Working at Private Sector, in Suburban KolkataSandra RNo ratings yet

- M16a3 Upper SpecsDocument1 pageM16a3 Upper SpecsMosinNo ratings yet

- 4401 SyllabusDocument1 page4401 SyllabusTony LeungNo ratings yet

- Woldia University: The Role of Effective Communication in Resolving ConflictDocument17 pagesWoldia University: The Role of Effective Communication in Resolving ConflictMerry Hiyab100% (1)

- CitiBank ApplicationDocument15 pagesCitiBank ApplicationJordan P HunterNo ratings yet

- Job Evaluation & Grading - PPT Hrm2Document9 pagesJob Evaluation & Grading - PPT Hrm2Monica ReyesNo ratings yet

- Table of SpecificationDocument5 pagesTable of SpecificationEvangeline Delos Santos50% (2)

- Valtra A114 HitechDocument31 pagesValtra A114 Hitechhicev32274No ratings yet

- Four Gears ModelDocument13 pagesFour Gears ModelPratik PatilNo ratings yet

- Sport Obermeyer PaperDocument10 pagesSport Obermeyer PaperagarwalankurkNo ratings yet

- Inv - 2469306Document2 pagesInv - 2469306rajeshNo ratings yet

- Cablemaster RLC - ManualDocument8 pagesCablemaster RLC - ManualGlendinning Products, LLC.No ratings yet

- Getachew Final EditedDocument76 pagesGetachew Final EditedDesalegn DgaNo ratings yet

- TITLE: ONBOARDING-Make Better The Experience of New Hire Executive Summary Onboarding, Also Known As Organizational Socialization, Refers To TheDocument3 pagesTITLE: ONBOARDING-Make Better The Experience of New Hire Executive Summary Onboarding, Also Known As Organizational Socialization, Refers To ThePavel BawaNo ratings yet

- Development Operations: Presented by Ms. Caranay & Mr. EstradaDocument12 pagesDevelopment Operations: Presented by Ms. Caranay & Mr. Estradaangelo perezNo ratings yet

- CIRPs Ending in Resolution - 30sept 2022Document10 pagesCIRPs Ending in Resolution - 30sept 2022dip downNo ratings yet

- Crystal Report Viewer 1Document2 pagesCrystal Report Viewer 1David Lemayian SalatonNo ratings yet

- jOB aNALYSIS POWERPOINTDocument34 pagesjOB aNALYSIS POWERPOINTdushyant12288No ratings yet

- A Simple Guide To Energy Budgets: Number 167 WWW - Curriculum-Press - Co.ukDocument4 pagesA Simple Guide To Energy Budgets: Number 167 WWW - Curriculum-Press - Co.ukKamaria ThomasNo ratings yet

- Scheme and Syllabus FOR M. Tech. Degree Programme IN Civil Engineering With SpecializationDocument60 pagesScheme and Syllabus FOR M. Tech. Degree Programme IN Civil Engineering With SpecializationAdila AbdullakunjuNo ratings yet