Professional Documents

Culture Documents

v1 v2 Fiberglass Surfacing Veils

Uploaded by

victor japposanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

v1 v2 Fiberglass Surfacing Veils

Uploaded by

victor japposanCopyright:

Available Formats

TECHNICAL DATA SHEET SURFACING VEILS

Product Introduction cardboard inner tube with an inside diameter of 15cm (6"). The

300 meter rolls are wrapped in polyethylene film and packed in

Surfacing veils are used extensively in production of FRP cartons (1 roll per carton), which are then packed on pallets. For

products used in corrosive environments. Surfacing Veils are the 1500 meter rolls, it is one roll per pallet.

non-woven materials, composed of uniformly distributed glass

fiber strands. They are designed to add reinforcement at the Special package can be available according to customer’s

surface of a laminate and provide a smooth, resin-rich, durable requirements.

surface. The surface layer is an aesthetic enhancement and

corrosion resistant for finished parts, such as chemical tanks,

Storage

pipes and equipment, and the weather-ability of wind

generators and turbine blades. Our company provides two

Cartons containing the rolls of glass fiber veil should be stored

types of veils: E-glass veil (V1 series) and C-glass veil (V2). Both

vertically on a pallet. Stowing material must have smooth

of them are mainly applicable to hand lay-up process, Filament

surfaces without sharp edges.

winding process and others.

Carton should be handled with care and with the appropriate

Product Description equipment in order to prevent any damage. It is recommended

that the material is stored in a cool dry area in which the

Surfacing Veils are manufactured to meet ISO 9001 standards. temperature should not exceed 35°C (95°F) and the relative

They are composed of wet-laid, randomly dispersed E-glass or humidity should be kept below 75%. Material should remain in

C-glass fiber strands bonded with an appropriate resin. They its original packaging until immediately before use. It is advised

are characterized by uniform fiber dispersion, a smooth surface, that stock rotation of the material is exercised. If the above

soft hand-feeling, low binder content, unbreakable and long conditions are respected, the material should not undergo

lifetime property, fast resin impregnation and good mold significant changes when stored for extended periods of time.

obedience. E-glass veils have good insulation property, while C-

glass veils provide better corrosion resistant liner. Surfacing

Stacking

Veils are applicable to FRP molding processes such as hand lay-

up, Filament winding, vacuum injection and press molding, etc.

To ensure safety and avoid damage to the product, skids should

not be stacked more than two high. When stacking two pallets

Packaging high, care should be taken to correctly and smoothly place the

top pallet.

V1 and V2 Surfacing Veils are 50 inches in standard width, 300

meters or 1500 meters in length. They are wound on a

Customer Benefits

High mechanical strength during production of finished products

Absolute rot proof and resistant to all weather conditions

Good dimensional stability

Chemically inert and non-toxic

Allow a uniform impregnation and superior impact resistance

High wet-through and wet-out speed

Excellent chemical resistance

55 Valleywood Drive, Markham, ON L3R 5L9 Canada Technical Data Sheet

Tel: 905-475-2300 Fax: 905-475-2303 V1-V2 Fiberglass Surfacing Veils

sales@fiberglassfiberlink.com info@fiberglassfiberlink.com Last Update: 08/2020

www.fiberglassfiberlink.com Page 1 of 2

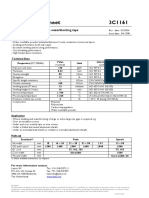

Product Data

Table 1: E-glass Veil

2

ID Filament Thickness (mils) Density (g/m ) Styrene % Binder % Moisture

Number Diameter Solubility Content Content

(Microns)

V1-030 9 11-13 30 ± 3 High ≤ 10 ≤ 0.5

V1-050 9 19-21 50 ± 4 High ≤ 10 ≤ 0.5

V1-090 16 31-33 90 ± 6 Medium ≤ 25 ≤ 1.0

ID Penetrating Tensile Length/Roll Compatible Compatible Process

Number time (two Strength (MD, (/feet) Resin

layers, second) N/5cm)

V1-030 ≤ 10 ≥ 25 300/984 Polyester/Vinyl Hand lay-up/Filament winding/Spray-

1500/4921 ester/Epoxy up/Vacuum injection/Press molding/Dry-

winding/Centrifugal Casting

V1-050 ≤ 15 ≥ 40 300/984 Polyester/Vinyl Hand lay-up/Filament winding/Spray-

1500/4921 ester/Epoxy up/Vacuum injection/Press molding/Dry-

winding/Centrifugal Casting

V1-090 ≥ 400 300/984 Polyester/Vinyl Roofing

1500/4921 ester/Epoxy

Table 2: C-glass Veil

ID Weight per Area Unit % Moisture Content % Binder Content Tensile Strength MD

2

Number (g/m ) (N/50mm)

V2-030 30 ± 3 ≤ 0.2 6.0 ± 2.0 ≥ 20

V2-050 30 ± 3 ≤ 0.2 6.0 ± 2.0 ≥ 40

ID Filament Thickness (mils) Penetrating time Length (m/feet) Compatible Process

Number Diameter (µm) (two layers, second)

V2-030 13 10-12 10 300/984 Hand-lay up/Filament winding

1500/4921

V2-050 13 18-20 15 300/984 Hand-lay up/Filament winding

1500/4921

Disclaimer of Liability

This data is offered solely as a guide in the selection of a reinforcement. The information contained in this publication is based on actual

laboratory data and field test experience. We believe this information to be reliable, but do not guarantee its applicability to the user’s process or

assume any liability arising out of its use or performance. The user, by accepting the products described herein, agrees to be responsible for

thoroughly testing any application to determine its suitability before committing to production. It is important for the user to determine the

properties of its own commercial compounds when using this or any other reinforcement. Because of numerous factors affecting results, we

make no warranty of any kind, express or implied, including those of merchantability and fitness for a particular purpose. Statements in this data

sheet shall not be construed as representations of warranties or as inducements to infringe any patent or violate any law, safety code or insurance

regulation.

55 Valleywood Drive, Markham, ON L3R 5L9 Canada Technical Data Sheet

Tel: 905-475-2300 Fax: 905-475-2303 V1-V2 Fiberglass Surfacing Veils

sales@fiberglassfiberlink.com info@fiberglassfiberlink.com Last Update: 08/2020

www.fiberglassfiberlink.com Page 2 of 2

You might also like

- Heat Exchanger Calculations: Inside Heat Trasfer CoefficientDocument4 pagesHeat Exchanger Calculations: Inside Heat Trasfer CoefficientBimal DeyNo ratings yet

- Antoine CoefficientsDocument26 pagesAntoine CoefficientsAndikaSeptianSitanggangNo ratings yet

- Column Diameter and Hetp CheckDocument6 pagesColumn Diameter and Hetp Checkmayur1980100% (1)

- Astm A666 - StainlesssteelDocument8 pagesAstm A666 - StainlesssteelPeter MohabNo ratings yet

- Test Certificate: Chettinad Cement Corporation PVT LTDDocument1 pageTest Certificate: Chettinad Cement Corporation PVT LTDChander BauraNo ratings yet

- Fundamental PI Instruction ManualDocument18 pagesFundamental PI Instruction ManualAmin Hasan AminNo ratings yet

- Pack Column Hetp PDFDocument29 pagesPack Column Hetp PDFMayurShindeNo ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Finned Tube Heat ExchangerDocument6 pagesFinned Tube Heat ExchangerShailesh DeshmukhNo ratings yet

- Cu Xlpe LSZH TCWB or GSWB LSZH 0,6 1 KVDocument2 pagesCu Xlpe LSZH TCWB or GSWB LSZH 0,6 1 KVsrik11No ratings yet

- Residential Combustion Air Calcs Worksheet 3-5-12 - 201305151521424290Document1 pageResidential Combustion Air Calcs Worksheet 3-5-12 - 201305151521424290victor japposanNo ratings yet

- TDS Tuffpaulin PVC TarpDocument4 pagesTDS Tuffpaulin PVC TarpmukulsareenNo ratings yet

- Sikashield p24 s3mmDocument4 pagesSikashield p24 s3mmariefNo ratings yet

- VT 200Document2 pagesVT 200yusri jaafarNo ratings yet

- Water Swallable TapeDocument1 pageWater Swallable TapeSanthosh V RaajendiranNo ratings yet

- Sikabit Pro P 30 0peDocument3 pagesSikabit Pro P 30 0peSlamet Tri UsadhaNo ratings yet

- Sikabit® Pro P-40-0 Sand: Product Data SheetDocument3 pagesSikabit® Pro P-40-0 Sand: Product Data SheetBagastyo DaniNo ratings yet

- Scotch 2200,2210 DatasheetDocument2 pagesScotch 2200,2210 DatasheetJake AllenNo ratings yet

- Sikabit t-5270 PgsaDocument3 pagesSikabit t-5270 PgsaHassan AhmadNo ratings yet

- Datasheet - CoronaShield C - 215.51 - EN - GLDocument3 pagesDatasheet - CoronaShield C - 215.51 - EN - GLLECTORNo ratings yet

- Visqueen High Performance Damp Proof Membrane: Features and BenefitsDocument4 pagesVisqueen High Performance Damp Proof Membrane: Features and BenefitstashadzureenNo ratings yet

- E-CR Glass: Chopped Strand Mat (Emulsion) For UP, VE, EPDocument2 pagesE-CR Glass: Chopped Strand Mat (Emulsion) For UP, VE, EPAshit ShahNo ratings yet

- Datasheet - CoronaShield C - 215.55 - EN - GLDocument3 pagesDatasheet - CoronaShield C - 215.55 - EN - GLLECTORNo ratings yet

- CoronaShield® P 8001 SemiConductive Varnish Von RollDocument3 pagesCoronaShield® P 8001 SemiConductive Varnish Von Rollyeprem82No ratings yet

- Spectraplan SG: Product Data SheetDocument3 pagesSpectraplan SG: Product Data SheetydrasNo ratings yet

- Waterproofing - SikaBit - T-245 - MGMY-Product - Data - SheetDocument3 pagesWaterproofing - SikaBit - T-245 - MGMY-Product - Data - SheetCC Cost AdvisoryNo ratings yet

- VT-201 All Purpose Sealant: Low Modulus Acetoxy Silicone SealantDocument2 pagesVT-201 All Purpose Sealant: Low Modulus Acetoxy Silicone SealantENGINEER MONIRUJJAMANNo ratings yet

- Sikaflex - 11 FCDocument4 pagesSikaflex - 11 FCSahanNo ratings yet

- Tds - Woven Roving 600g TaishanDocument1 pageTds - Woven Roving 600g TaishanAbdullah SahlyNo ratings yet

- Sikaflex® PRO-3 WF: Product Data SheetDocument4 pagesSikaflex® PRO-3 WF: Product Data Sheetsugiarto budiNo ratings yet

- Tekadom Acrylic Sealant ProfiDocument2 pagesTekadom Acrylic Sealant ProfiEzeval GráficaNo ratings yet

- Sikabit 1.5mm Waterproofing MembraneDocument3 pagesSikabit 1.5mm Waterproofing MembraneGhayas Jawed0% (1)

- Sikacem®-711 Elastic: Provisional Product Data SheetDocument4 pagesSikacem®-711 Elastic: Provisional Product Data SheetDavid V. BaltazarNo ratings yet

- Vt-420 Vitalband: Bitumen Flashing TapeDocument1 pageVt-420 Vitalband: Bitumen Flashing Tapesakha abdussalamNo ratings yet

- Sikahyflex®-140 Construction: Product Data SheetDocument4 pagesSikahyflex®-140 Construction: Product Data SheetNicholas WashingtonNo ratings yet

- Tritosil W70-TDSDocument4 pagesTritosil W70-TDSRANo ratings yet

- Sika Multiseal: Self-Adhesive Bituminous Sealing TapeDocument2 pagesSika Multiseal: Self-Adhesive Bituminous Sealing TapeTitis W. PratiwiNo ratings yet

- 1 Component KiiltoDocument2 pages1 Component KiiltoMantas ButrimaviciusNo ratings yet

- Sikabit Pro P 30 0mgDocument3 pagesSikabit Pro P 30 0mgSlamet Tri UsadhaNo ratings yet

- Sikaflex-1a-Purform Es enDocument5 pagesSikaflex-1a-Purform Es enArturo Aguilar SantesNo ratings yet

- Revised MS For WaterproofingDocument9 pagesRevised MS For WaterproofingChamux skalNo ratings yet

- Sikasil 728 SLDocument5 pagesSikasil 728 SLJesusFloresRodriguezNo ratings yet

- Fisa Tehnica BitusealDocument3 pagesFisa Tehnica BitusealSavu CristianNo ratings yet

- Sikabit® Pro P-30-0 Sand: Product Data SheetDocument3 pagesSikabit® Pro P-30-0 Sand: Product Data SheetAkhbarPutraNo ratings yet

- SERIE 700 Subproceso Asociado:: Esp. de Cliente Sistema:ISO 9000Document8 pagesSERIE 700 Subproceso Asociado:: Esp. de Cliente Sistema:ISO 9000Eliezer BarrantesNo ratings yet

- HT Sika SealTape FDocument3 pagesHT Sika SealTape FJunior FlooNo ratings yet

- AquaArm SBS 3000X Ver 2 1 PDFDocument3 pagesAquaArm SBS 3000X Ver 2 1 PDFNovember RainNo ratings yet

- Sikaflex - 11 FC+Document5 pagesSikaflex - 11 FC+emmanuel nwankwoNo ratings yet

- VT-638FC MS Seam Sealant: Vital Technical Sdn. BHDDocument2 pagesVT-638FC MS Seam Sealant: Vital Technical Sdn. BHDal varezNo ratings yet

- Catalogue Băng Keo Alberta 80 FusionDocument2 pagesCatalogue Băng Keo Alberta 80 FusionHà Trần MạnhNo ratings yet

- Butyl Tapes, Mastic Tapes, Adhesives & SealantsDocument35 pagesButyl Tapes, Mastic Tapes, Adhesives & SealantsNikhil MathewNo ratings yet

- Sika Bituseal T-140 SGDocument3 pagesSika Bituseal T-140 SGjet toledoNo ratings yet

- Technical Data Sheet: Page 1 of 6 HCD-10307 (Rev. 2011-11-03 2:00 PM)Document6 pagesTechnical Data Sheet: Page 1 of 6 HCD-10307 (Rev. 2011-11-03 2:00 PM)Pedro NavarroNo ratings yet

- Sikahyflex 220 Window - Pds en PDFDocument4 pagesSikahyflex 220 Window - Pds en PDFKaya EmanuelNo ratings yet

- Mea Polybit Tds Polybit Bitustick R 3000 en MeaDocument2 pagesMea Polybit Tds Polybit Bitustick R 3000 en MeaMuhamed RiskhanNo ratings yet

- TL Engleski - SikaBit® PRO P-30-5 SandDocument3 pagesTL Engleski - SikaBit® PRO P-30-5 SandDejan MotikaNo ratings yet

- Sikaflex®-11 FC+: Product Data SheetDocument5 pagesSikaflex®-11 FC+: Product Data SheetYousef HalasehNo ratings yet

- Technical Data Sheet: Zwaluw Silicone UniversalDocument2 pagesTechnical Data Sheet: Zwaluw Silicone UniversalNatalia PocepneaNo ratings yet

- Sika SanisilDocument4 pagesSika SanisilA GlaumNo ratings yet

- Sika Bituseal T-130 SG PdsDocument4 pagesSika Bituseal T-130 SG Pdsmr_hendihalimNo ratings yet

- Sikahyflex 140 Construction - Pds enDocument4 pagesSikahyflex 140 Construction - Pds enPutra AfriadeNo ratings yet

- Sikaflex 140construction en ID 02 2023 1 1 PDFDocument4 pagesSikaflex 140construction en ID 02 2023 1 1 PDFcahyo hutomoNo ratings yet

- Pds Sikashield P55pert4mmDocument3 pagesPds Sikashield P55pert4mmĐức Thanh NguyễnNo ratings yet

- Silirub Is: Revision: 01/01/2016 Page 1 of 2 Technical DataDocument2 pagesSilirub Is: Revision: 01/01/2016 Page 1 of 2 Technical DataGomathi SankarNo ratings yet

- Ottocoll® M 590: The Hybrid-Adhesive For Full-Surface BondingDocument3 pagesOttocoll® M 590: The Hybrid-Adhesive For Full-Surface BondingJoeNo ratings yet

- Build: Builders Silicone SealantsDocument3 pagesBuild: Builders Silicone SealantsAhmed KhameisNo ratings yet

- Sikaflex® PRO-3: Product Data SheetDocument4 pagesSikaflex® PRO-3: Product Data SheetArrow LazarusNo ratings yet

- Dr. Fixit Bathseal Range 169 1 PDFDocument3 pagesDr. Fixit Bathseal Range 169 1 PDF41464147No ratings yet

- 0-07-070-1e EMCO Restriction Plate Type IRB6 For Insertion Between Compact Flanges - 2Document2 pages0-07-070-1e EMCO Restriction Plate Type IRB6 For Insertion Between Compact Flanges - 2victor japposanNo ratings yet

- Biocorrosiondsteel: © 2018 Elsevier Inc. All Rights ReservedDocument15 pagesBiocorrosiondsteel: © 2018 Elsevier Inc. All Rights ReservedKArenNo ratings yet

- IJEIR 1657 Final - PdfmypaperDocument5 pagesIJEIR 1657 Final - PdfmypaperVaibhav BodeNo ratings yet

- The Poisoning of Nickel Hydrogenation Catalysts by Water Vapor' 'Document2 pagesThe Poisoning of Nickel Hydrogenation Catalysts by Water Vapor' 'victor japposanNo ratings yet

- Upgrading and Life Extension Technologies FOR Geothermal Steam TurbinesDocument6 pagesUpgrading and Life Extension Technologies FOR Geothermal Steam Turbinesvictor japposanNo ratings yet

- AlphaSEP Coalescers PDFDocument12 pagesAlphaSEP Coalescers PDFRajesh KrishnamoorthyNo ratings yet

- Woodward Gamme Tecjet 110 Technical Manual en 2017Document52 pagesWoodward Gamme Tecjet 110 Technical Manual en 2017Suresh kumar ChockalingamNo ratings yet

- MC Crometer White PaperDocument10 pagesMC Crometer White PaperdliyaxNo ratings yet

- Wika Selecting A Pressure Gauge Product Catalog PG 2 6 - 60Document6 pagesWika Selecting A Pressure Gauge Product Catalog PG 2 6 - 60Cobra BabaNo ratings yet

- FMCGs Retail Earn 66 of Gross Profits in Palm Oil Value ChainDocument14 pagesFMCGs Retail Earn 66 of Gross Profits in Palm Oil Value Chainvictor japposanNo ratings yet

- Vcbul 04493 enDocument16 pagesVcbul 04493 enAbhishekNo ratings yet

- Convection Heat Transfer From Tube Banks in Cross Ow: Analytical ApproachDocument8 pagesConvection Heat Transfer From Tube Banks in Cross Ow: Analytical ApproachGiancarlo CorsiNo ratings yet

- Flame Arrestor DatasheetDocument3 pagesFlame Arrestor Datasheetvictor japposanNo ratings yet

- "Kraft Recovery Boilers" by T. N. Adams, W. J. Frederic, T. M. Grace, M. Hupa, K. Iisa, A. K. Jones, H. TranDocument16 pages"Kraft Recovery Boilers" by T. N. Adams, W. J. Frederic, T. M. Grace, M. Hupa, K. Iisa, A. K. Jones, H. Tranvictor japposanNo ratings yet

- RegerterDocument2 pagesRegertervictor japposanNo ratings yet

- Book 3Document4 pagesBook 3victor japposanNo ratings yet

- BlendingDocument2 pagesBlendingvictor japposanNo ratings yet

- BlendingDocument2 pagesBlendingvictor japposanNo ratings yet

- S Loc 30071002Document3 pagesS Loc 30071002victor japposanNo ratings yet

- PKFAD Balance Sept 2019Document3 pagesPKFAD Balance Sept 2019victor japposanNo ratings yet

- Composite Materials NotesDocument7 pagesComposite Materials NotesAnanya67% (3)

- Jis G3133-2009Document15 pagesJis G3133-2009Đình Sỹ TTPNo ratings yet

- V-Bank High Capacity Filter: Advantages ApplicationDocument2 pagesV-Bank High Capacity Filter: Advantages ApplicationDaryl Barrios LamedaNo ratings yet

- EagleBurgmann - Teflon Bellows Seal Y29 - ENDocument3 pagesEagleBurgmann - Teflon Bellows Seal Y29 - ENOmar SunasaraNo ratings yet

- Kukdo Epoxy R 46 Yd 013k55 TdsDocument1 pageKukdo Epoxy R 46 Yd 013k55 TdsRAZA MEHDINo ratings yet

- Acronal 4120 AdhesivesDocument2 pagesAcronal 4120 AdhesivesVenu KavetiNo ratings yet

- Flexitallic HPG - 2020Document8 pagesFlexitallic HPG - 2020jacquesstrappe06No ratings yet

- Kingspan 30 GSNDocument1 pageKingspan 30 GSNNoella AguiarNo ratings yet

- Henniker Plasma Surface Testing OverviewDocument7 pagesHenniker Plasma Surface Testing OverviewLenti TiborNo ratings yet

- Price List 22042013 National CablesDocument8 pagesPrice List 22042013 National CablesSukhirthan SenthilkumarNo ratings yet

- Accc/Tw London (780) : Data SheetDocument1 pageAccc/Tw London (780) : Data SheetkmiqdNo ratings yet

- 2024-O ASM Material Data SheetDocument2 pages2024-O ASM Material Data SheetAnonymous mq0U43UsPNo ratings yet

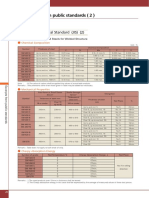

- STDs ListDocument5 pagesSTDs ListIlyas AhmedNo ratings yet

- 3M STOCK LIST - AKBAR TRADING-3M Electrical Materials Promotion - Mail@Document2 pages3M STOCK LIST - AKBAR TRADING-3M Electrical Materials Promotion - Mail@GIBUNo ratings yet

- Sika Sealtape FDocument3 pagesSika Sealtape FAbdulghani AsalaiNo ratings yet

- Science PPT q3Document66 pagesScience PPT q3Jezer Dzi ArimaNo ratings yet

- TD Istra-40 enDocument2 pagesTD Istra-40 enAsmir SofticNo ratings yet

- HelukabelDocument30 pagesHelukabelveezo_solutionsNo ratings yet

- Nordic Concrete Research: Publication No. 5Document6 pagesNordic Concrete Research: Publication No. 5Maurizio SiepiNo ratings yet

- Some Types of Glass-Ceramic Materials and Their ApplicationsDocument17 pagesSome Types of Glass-Ceramic Materials and Their ApplicationsGina BerríoNo ratings yet

- Sub075 - BlockTexxDocument8 pagesSub075 - BlockTexxLuthNo ratings yet

- Low Voltage Electrical Power Conductors and Cables-Rev05Document15 pagesLow Voltage Electrical Power Conductors and Cables-Rev05Mohamed HamedNo ratings yet

- BDS PPT Lecture 2Document59 pagesBDS PPT Lecture 2Stephen Bulay-ogNo ratings yet

- NYRYDocument5 pagesNYRYAhmad Arif SaktiNo ratings yet

- Plant Foundations - Tender BOQDocument19 pagesPlant Foundations - Tender BOQChrispen MachipisaNo ratings yet

- SVKM'S Nmims Mukesh Patel School Technology Management and Engineering Strength of Materials LabDocument5 pagesSVKM'S Nmims Mukesh Patel School Technology Management and Engineering Strength of Materials LabBender GamingNo ratings yet

- JFE STEEL JIS 3106 Grade Steel Chemical Composition, Ladle AnalysisDocument1 pageJFE STEEL JIS 3106 Grade Steel Chemical Composition, Ladle AnalysisIndra Nath MishraNo ratings yet