Professional Documents

Culture Documents

Rivets Lesson Plan

Uploaded by

sriram 18140 ratings0% found this document useful (0 votes)

33 views1 pageOriginal Title

63Rivets and riveting

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

33 views1 pageRivets Lesson Plan

Uploaded by

sriram 1814Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

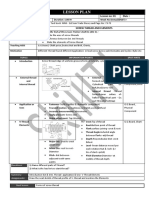

LESSON PLAN

Name:SRIRAM Lesson no:63 Date :

Trade:FITTER YEAR-1 Duration: 1.00 Hr Week No (Actual/DGET) =

Ref Book & Page No: Fitter Text book NIMI - ...... Sem Trade theory and Page No:

NAME OF TOPIC Rivets and riveting

OBJECTIVES At the End of this Lesson Trainee shall be able to :

• define rivets Rivets are used to join together two or more sheets of metal

• specify rivets permanently. In sheet metal work riveting is done where:

• name the materials from which

rivets are made

Teaching AIDS

Motivation brazing is not suitable,

the structure changes owing to welding heat,

the distartion due to welding cannot be easily removed etc.

TOPICS INFORMATION POINTS SPOT HINTS

Introduction Rivets Shape of head

There are various kinds of rivets as shown in Fig 1. Snap Diameter

head rivets, countersink rivets and thin bevelhead rivets are Length

widely used in sheet metal work.

Material:

Rivets are made of ductile materials like low carbon sheet

(mild steel), brass, copper, yellow brass, aluminium are

their alloys.

The length of the rivets ‘L” is indicated by the shank length.

Sketch/Parts/ Types and uses

Snap head

Construction

Pan head

Conical head

Countersunk

head

Bifurcated rivet

Specification Specification of rivets

Rivets are specified by their length, material, size and

shape of head.

Applications/ Rivets are cylindrical rods having heads of various

shapes.They are used for assembling the parts of a

Uses

workpiece together.

Questions: 1)what is rivet ?

2) Specification of rivets ?

Summery: Introduction- Parts- Specification- Applications/Uses

Assignments:

Next lesson:

Signatureof ATO:

You might also like

- Workshop ManualDocument96 pagesWorkshop ManualDatta YallapuNo ratings yet

- Lesson PlanDocument7 pagesLesson Planvinod petkar100% (3)

- How to Make a Dovetail FittingDocument1 pageHow to Make a Dovetail FittingAayush AgrawalNo ratings yet

- LESSON PLAN Fitter 1sem PDF - PDF - First Aid - DuctilityDocument1 pageLESSON PLAN Fitter 1sem PDF - PDF - First Aid - Ductilitymcstand318No ratings yet

- Lesson Plan: Manauyya Balacaa IvakasaDocument4 pagesLesson Plan: Manauyya Balacaa IvakasaBhojappa Ganamukhi100% (1)

- Fitter 1 Year Theory Breakup..Document6 pagesFitter 1 Year Theory Breakup..MAA TECHNICAL CLASS100% (2)

- LESSON PLAN Fitter 1semDocument15 pagesLESSON PLAN Fitter 1semsudhansu mohan nayak100% (8)

- Demonstration Plan ElectricianDocument2 pagesDemonstration Plan ElectricianE Learn ITI0% (1)

- LESSON PLAN Fitter 1sem PDFDocument15 pagesLESSON PLAN Fitter 1sem PDFsudhansu mohan nayak86% (7)

- Lesson Plan Fitter PDFDocument18 pagesLesson Plan Fitter PDFvikas89% (9)

- Fitter Lesson Plans - Lesson Plan - Education TheoryDocument7 pagesFitter Lesson Plans - Lesson Plan - Education TheoryvikasNo ratings yet

- Work Shop Practice OneDocument35 pagesWork Shop Practice OneberhaneNo ratings yet

- Drillingmachine1 151022133645 Lva1 App6891Document17 pagesDrillingmachine1 151022133645 Lva1 App6891Fatin Nadzira0% (1)

- CTS FitterDocument14 pagesCTS FitterSahitya SaxenaNo ratings yet

- Electrician Lesson Plans 1Document68 pagesElectrician Lesson Plans 1sandy kumarNo ratings yet

- TP Job Information Sheets Aug - Jan - I PDFDocument365 pagesTP Job Information Sheets Aug - Jan - I PDFMohan kumar G100% (1)

- Calendar 2019 PDFDocument1 pageCalendar 2019 PDFmishrapriyanka360No ratings yet

- Format - Detail Progressive Record of The StudentDocument4 pagesFormat - Detail Progressive Record of The StudentAnita KumariNo ratings yet

- JJ104 Workshop Technology Chapter6 Milling MachineDocument27 pagesJJ104 Workshop Technology Chapter6 Milling MachineAh Tiang100% (3)

- Topic 1) Transistors: Marks 24: IntroductionDocument24 pagesTopic 1) Transistors: Marks 24: IntroductionSudershan Dolli100% (1)

- Job Marking RegisterDocument2 pagesJob Marking RegisterAnurag Patel100% (1)

- Machine Tools Hand Tools: Fitting ShopDocument12 pagesMachine Tools Hand Tools: Fitting ShopMadara uchihaNo ratings yet

- Fitter Trade Theory Balbir Singh PDF Download PDFDocument4 pagesFitter Trade Theory Balbir Singh PDF Download PDFsomnath sahu75% (4)

- Assignments Sub: Production Process IIDocument2 pagesAssignments Sub: Production Process IIShantanu Gaikwad100% (1)

- Presentation On Reforms in All India Trade Test (AITT) : Conducted Under The Aegis of NCVT On 11.10.2018Document28 pagesPresentation On Reforms in All India Trade Test (AITT) : Conducted Under The Aegis of NCVT On 11.10.2018Ravi TejaNo ratings yet

- MFT - II Lab ManualDocument33 pagesMFT - II Lab ManualMohan Prasad.M0% (1)

- Fitting Shop Operations Nazeef'sDocument6 pagesFitting Shop Operations Nazeef'sFaheem Fiaz ChohanNo ratings yet

- LatheDocument74 pagesLatheChandrakantha K100% (1)

- DFBN FilterDocument10 pagesDFBN FilterPutut SuprihartonoNo ratings yet

- MrJacksonMaths Unit 2 Higher November 2012Document23 pagesMrJacksonMaths Unit 2 Higher November 2012Russell Jackson100% (1)

- 0001 Syllabus For The Subject of "Training Methodology"Document20 pages0001 Syllabus For The Subject of "Training Methodology"Anonymous Rg4MaMg5F0No ratings yet

- Sheet Metal Shop GuideDocument37 pagesSheet Metal Shop Guideeafz111No ratings yet

- ADM Use of ComparativesDocument6 pagesADM Use of ComparativesCarlos RochaNo ratings yet

- Progress Report CardDocument4 pagesProgress Report CardChanna100% (1)

- Mel311 Part IIDocument165 pagesMel311 Part IIAarsh Vir GuptaNo ratings yet

- System of Limits, Fits, Tolerance and Gauging PDFDocument32 pagesSystem of Limits, Fits, Tolerance and Gauging PDFPraveen MohapatraNo ratings yet

- Hindi Notes 12th STDDocument14 pagesHindi Notes 12th STDSiddhart ManotharaNo ratings yet

- Workshop Report - Two Step FittingDocument2 pagesWorkshop Report - Two Step FittingShehryar AhmadNo ratings yet

- Iti PDFDocument419 pagesIti PDFhimanshu dutt100% (1)

- Introduction to Grinding Process Optimization Using Taguchi MethodsDocument27 pagesIntroduction to Grinding Process Optimization Using Taguchi Methodsranarani2013100% (1)

- Shaping Machine Operations GuideDocument25 pagesShaping Machine Operations Guidekatakamharish100% (1)

- Manufacturing Process - Screw ThreadsDocument13 pagesManufacturing Process - Screw Threadsradhiostrokes100% (1)

- Fitting ToolsDocument14 pagesFitting ToolsManoj Lohumi100% (2)

- A Presentation ON: Unit-IvDocument52 pagesA Presentation ON: Unit-IvVķ MãħëšħNo ratings yet

- Lesson 1Document7 pagesLesson 1api-273340865100% (1)

- Unit 1 - Manufacturing Process - WWW - Rgpvnotes.inDocument26 pagesUnit 1 - Manufacturing Process - WWW - Rgpvnotes.insuneel kumar rathoreNo ratings yet

- 9SurfaceRoughness Limits Fits and TolerancesDocument25 pages9SurfaceRoughness Limits Fits and Tolerancesharsha vardhanNo ratings yet

- Marking OutDocument2 pagesMarking OutOladimeji TaiwoNo ratings yet

- Interchangeability in MetrologyDocument5 pagesInterchangeability in Metrologyesakkiraj05100% (1)

- Surface Grinding ReportDocument3 pagesSurface Grinding ReportFiqri ProductionNo ratings yet

- Assignment of Class 9 Mathematics: AlgebraDocument5 pagesAssignment of Class 9 Mathematics: Algebraraja_tanuku100% (1)

- Assignment On ClutchDocument8 pagesAssignment On ClutchPankaj GillNo ratings yet

- Orthographic ProjectionDocument36 pagesOrthographic ProjectionDEEPANGaeNo ratings yet

- Fitting Workshop ReportDocument17 pagesFitting Workshop ReportAkshay kumarNo ratings yet

- First Angle ProjectionDocument20 pagesFirst Angle ProjectionFaqiroh Wajed100% (1)

- Title: Maintenance Electrical DOC. No: (ELE-P-01) : ControlledDocument6 pagesTitle: Maintenance Electrical DOC. No: (ELE-P-01) : ControlledTarek FawzyNo ratings yet

- Lesson Plan: Name:SRIRAMDocument1 pageLesson Plan: Name:SRIRAMsriram 1814No ratings yet

- Lesson Plan: Name:SRIRAMDocument1 pageLesson Plan: Name:SRIRAMsriram 1814No ratings yet

- Chapter 3 Coventional FastnersDocument37 pagesChapter 3 Coventional FastnersAtalelew ZeruNo ratings yet

- Beginner's Guide: Traditional RivetingDocument7 pagesBeginner's Guide: Traditional RivetingStephen NomuraNo ratings yet

- Arc Welding Safety PrecautionsDocument1 pageArc Welding Safety Precautionssriram 1814No ratings yet

- Lesson Plan: Name:SRIRAMDocument1 pageLesson Plan: Name:SRIRAMsriram 1814No ratings yet

- Lesson Plan: Name:SRIRAMDocument1 pageLesson Plan: Name:SRIRAMsriram 1814No ratings yet

- Lesson Plan: Name:SRIRAMDocument1 pageLesson Plan: Name:SRIRAMsriram 1814No ratings yet

- Lesson Plan: Welding SafetyDocument1 pageLesson Plan: Welding Safetysriram 1814No ratings yet

- Lesson Plan: Name:SRIRAMDocument1 pageLesson Plan: Name:SRIRAMsriram 1814No ratings yet

- Lesson Plan: Name:SRIRAMDocument1 pageLesson Plan: Name:SRIRAMsriram 1814No ratings yet

- Riveted Joint Lesson PlanDocument1 pageRiveted Joint Lesson Plansriram 1814No ratings yet

- 61process of Soft Soldering and Hard SolderingDocument1 page61process of Soft Soldering and Hard Solderingsriram 1814No ratings yet

- Lesson Plan: Name:SRIRAMDocument1 pageLesson Plan: Name:SRIRAMsriram 1814No ratings yet

- Fosroc Dekguard AC: Constructive SolutionsDocument4 pagesFosroc Dekguard AC: Constructive SolutionsVJ QatarNo ratings yet

- NBC Guidelines for Residential BuildingsDocument5 pagesNBC Guidelines for Residential BuildingsShreenidhi KullkarniNo ratings yet

- Frank Lloyd WrightDocument32 pagesFrank Lloyd WrightAhmad Monis AnsariNo ratings yet

- Agricultural Mechanics Fundamentals and Applications 7th Edition Herren Solutions ManualDocument6 pagesAgricultural Mechanics Fundamentals and Applications 7th Edition Herren Solutions Manualquyenthamrww6100% (17)

- Paper Toys: BibleDocument8 pagesPaper Toys: BiblelourdesnevesNo ratings yet

- Encore BrochureDocument4 pagesEncore BrochureJagriti KashyapNo ratings yet

- Diamond Imperial Finish Plasters Application Tips en P838Document6 pagesDiamond Imperial Finish Plasters Application Tips en P838delzzzoneNo ratings yet

- 4 Home: A: VocabularyDocument5 pages4 Home: A: VocabularyKHue Nguyen100% (1)

- BOQ For Renovation of Bathrooms, Toilets & Sewage Line in A, B & C Block in Girls Hostel at MANITDocument6 pagesBOQ For Renovation of Bathrooms, Toilets & Sewage Line in A, B & C Block in Girls Hostel at MANITvivan enterprises pvt ltdNo ratings yet

- 2021 Worldwide Industrial Commercial Construction Schedule of Rates Yearbook SAMPLE 1Document14 pages2021 Worldwide Industrial Commercial Construction Schedule of Rates Yearbook SAMPLE 1Familia GonzalezNo ratings yet

- Barralastic Method StatementDocument2 pagesBarralastic Method StatementrajragavanNo ratings yet

- The Eye of KlothysDocument20 pagesThe Eye of KlothysChernabog100% (1)

- Hume PipesDocument3 pagesHume PipesSathish100% (1)

- We Salted Nannie - A True Southern Ghost Story - The BITTER SOUTHERNERDocument27 pagesWe Salted Nannie - A True Southern Ghost Story - The BITTER SOUTHERNERMiriam Berg, TeacherNo ratings yet

- Stonedust Used As Alternative For Sand in ConcreteDocument11 pagesStonedust Used As Alternative For Sand in ConcreteAbhijeeth NagarajNo ratings yet

- Re Cource Guide 2018Document44 pagesRe Cource Guide 2018Maria PopaNo ratings yet

- Building ConstructionDocument12 pagesBuilding ConstructionBipul PoudelNo ratings yet

- Čulig, Igor & Galetić, Matea - Star GatesDocument35 pagesČulig, Igor & Galetić, Matea - Star GatesIgor ČuligNo ratings yet

- Gold Series IOM Manual (Imperial) PDFDocument124 pagesGold Series IOM Manual (Imperial) PDFSARET respaldoNo ratings yet

- Comparison Between Manual Analysis and Software Analysis of A Shopping ComplexDocument5 pagesComparison Between Manual Analysis and Software Analysis of A Shopping Complexoluwaluyi danielNo ratings yet

- Chapter 29 - Fabrics FibresDocument20 pagesChapter 29 - Fabrics FibresAman KeltaNo ratings yet

- A M 06 Ironmongery July 09Document13 pagesA M 06 Ironmongery July 09suneethmohanNo ratings yet

- Retrofitting of Building Project ReportDocument144 pagesRetrofitting of Building Project ReportNisanth Thulasidas100% (1)

- Construction of Classrooms and Toilets Estimated Cost Rs. 190000Document2 pagesConstruction of Classrooms and Toilets Estimated Cost Rs. 190000K KARTHIKNo ratings yet

- Datasheet Cool 'N' Comfort V5Document4 pagesDatasheet Cool 'N' Comfort V5Dawn NguyenNo ratings yet

- Site Memo CHC - SM - 008Document2 pagesSite Memo CHC - SM - 008Park ParkNo ratings yet

- 01.STD DrawingDocument82 pages01.STD Drawingjplaza3074No ratings yet

- List of Tools Carpentry IiiDocument8 pagesList of Tools Carpentry IiiTESDA Regional Training Center- IloiloNo ratings yet

- Generator Na Vetar Deo 5Document33 pagesGenerator Na Vetar Deo 5SinišaNo ratings yet

- Cement and Concrete Research: DiscussionDocument4 pagesCement and Concrete Research: DiscussionArlen GutierrezNo ratings yet