Professional Documents

Culture Documents

Solar Intelligent Braking and Automatic Tyre Inflation

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solar Intelligent Braking and Automatic Tyre Inflation

Copyright:

Available Formats

Volume 7, Issue 6, June – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Solar Intelligent Braking and Automatic Tyre

Inflation

Kemparajua, Sai Pavan M Ra, Kushal La, Naveen Kumar Ta, Rameshwar a

Department of Mechanical Engineering, New Horizon College of Engineering, Bangalore 560103, India

Abstract:- Modern cars have a lot of features and addition, the vehicle's speed is recorded. The microcontroller

electronic system which causes the driver in dangerous isutilised to control the vehicle's dialling back based on this

driving Situation. one of such system has the task to information. When certain criteria are met, the

measure and control the pressure of tyre that is automated microprocessor sends an electrical signal to the solenoid

tyredpressure system. This system will help to maintain valves, which opens the pneumatic chamber and causes the

the pressure in the tyre. The idea of building this dialling back operation. A scaled modelof a car was built, and

Automatic Braking & self-Tyre inflation" was at aimed at the model was put through its paces with the help of the Ansys

different aspects but at the Same time made sure it was assessment software.

even Budget friendly, the aspects that we Aimed is the tyre

its life. the impact of it on the fuel economy of vehicle and II. LITERATURE REVIEW

the safety of aspects. Is hold during Braking with ABS,

low Braking initial speed Cause the brake pressure in long Various investigations have been led on the impactsof

time. The why because there is a extending application tire filling strain on cornering soundness and vehicle

time of brake pressure & response time of solenoid valve. management. Sandoni and Ringforder (2006) proposed a

this paper will help to maintenance Vehicles handling programmed tire filling framework that would monitor

Characteristics. foreordained wheel pressures. The STI model by Szostak et

al. (1988) looks at the tire pressure sway on the tire/street

I. INTRODUCTION interface contact fixto the degree that tire depictions. This

change affects longitudinal and even tire versatility, and it

The importance of easing back components of ventures into the composite slip limit, taking level power,

commercial cars was, for the most part, given the highest longitudinal power, and moving second into thought. The

priority.in relation to concerns of prosperity and explicitly enchanted condition (Pacejka and Bakker, 1991) and SWIFT

security that changes with time The ill-advised reduction of tire (Schmeitz et al., 2005) models moreover consider strain,

these Vehicles has the potential to cause major disasters as well as varieties in longitudinal strength and squashing

because of their design. Stopping distances are a little longer coefficients. The up immovability is primarily influenced by

and the speeds are a little greater. Brakes have an energy tyre tension, leaves the contact fix largely which is determine

aftereffect. The quick reaction time the informationprovided by the tire verticalredirection. As tyre pressure drops, vertical

by the electronic control can be used for reducing the dialling soliditydrops and redirection increases, resulting in a larger

back distance by a significantamount introducing advanced contact patch. Käppler and Godthelp (1988) most likely

halting control action of the instrument the instrument has a looked at the impact of tyre stress on vehicle handling. The

sharp halting effect. A plethora of potential applications, open circle test looked at yaw gain, response time, and

particularly in the manufactured countries where ingenious understeer coefficient forvarious extension situations.

cars and astute drivers are being researched the street has

progressed to new heights. Thought. When the structure is To protect driver safety, the makers verified that tyre

fully integrated, with a variety of subsystems, such as a pressure variations that cause oversteer should be avoided.

modified balance controlsystem, a well-designed stifle, and Greater and faster controllinginformation sources, when the

auto-travel system, and so on will bring will result in a wise combined with lowered driver reaction time, may provoke

vehicle movement By the end of the day, the driverwill have vehicle fragility, as evidenced by the way drivers in closed

transformed into the traveller, with security being the most circle testing changed subsequent pressure assortments.

important concern, and theouting will have been smoothed Collier and Warchol (1980) studied corner stability in both

out in terms of duration, cost, adequacy, and suitability. The extended and tendency to use tyres with various filling

influenceof such a strategy and improvement will feed the pressures. Klyde et al. (2003) studied the effects of tyre

present society's desire for excellent drive as well as tocompel pressure on in- plane nosedeals and ground management.

development, particularly in spectacular sensors and Growing front tyre pressures over the rear wheels, as

actuators. expected, increased the tire's sidelong solidity, making it

moreresponsive while dealing with.

The proposed insightful mechatronic system

incorporates a pneumatic halting instrument that combines an

ultrasonic wavemaker placed on the model's forward portion

and emits ultrasonic waves forward in a predetermined

distance. The distancebetween the obstacle and the vehicle is

determined by the reflected wave (recognised beat). In

IJISRT22JUN882 www.ijisrt.com 108

Volume 7, Issue 6, June – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Automatic Pneumatic Guard component for halting. mechanical wave that travels through solid, liquid, or gaseous

N. Thepade et al., 2016. This journal depicts a planto materials. Depending on the technique of triggering, sound

reduce the impact on four-wheelers in emergency situations waves can travel through mediums at high speeds. Sound

where a collision is unavoidable. According to the magazine, waves with a high repeat frequency reflect off cut-off points

four-wheelers should install a long watchman to acclimate to and transmit precise resonation plans.

the collision shock. The pneumatic system, which receives

information from an electronic closenessassessment system, Ultrasonic ID is commonly utilised in modern

is used to widen the watchman.Vehicle Robustness Control applications to detect concealed tracks, discontinuities in

during emergency easing back down (Qing Chen et al., 2014) metals, composites, plastics, pottery manufacture, and water

The journal displays car tyres slipping during emergency level recognition. As a result, since ultrasonic sensors

dialing back and the requirement to applybrakes as in beats employ sound instead of light for discriminating proof, the

or a continually extending dialing back force, all other factors rules ofgenuine physics that show the multiplication of sound

being equal. waves through solid materials have been used.

Flexible trip control is the subject of research. (2016,

Chengwi.S, et al.) To reduce mishaps, the journal displays

splitting information across vehicles while they are travelling.

Area sensors and Bluetooth devicescould be used to facilitate

communication. When cars come very close to proximity

sensors, information on their speed and vehicle conditions

can be given to oneanother, resulting in a capable going with

a minor riskof tragedy.

Redirected drivers' brake reflexes to bystander forward

crash frames. (2017, Nils L.) This publication demonstrates

that a sound and visual reprimand with an extra heartbeat is

the most effective in obstructing effects and, as a result,

lowering setback chances.

If a redirected motorist does not detect a pedestrian, a

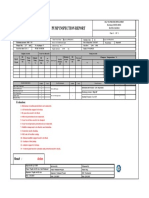

boom sounds nearby and red notification lights flash, Fig 1: Automated tire inflation control system with

reminding the driver to seek for the bystander and apply

powertrain control module data sharing

brakes.

IV. MAIN COMPONENTS

Ultrasonic sensor used to determine distance. (2016,

Koval.L, et al.) The journal illustrates dynamic and

standoffish ultrasonic noises, as well as the usage of Ultrasonic Sensor: - An ultrasonic sensor isa moving and

uninvolved ultrasonic for distance estimation. Theultrasonic differentiating device that detects the existence of an

sensor is shown to be extremely accurate. Unlike object and its range using high-repeat sound waves. As the

conventional closeness sensors, the ultrasonic sensor works articles travel between the transmitter and gatherer, these

well in windy and wet environments. structures either measure the resonation impression of

sound waves fromobjects or recognize the impedance of

III. WORKING PRINCIPLE the sound support point. In most cases, an ultrasonic

sensor employs a transducer that generates an electrical

By introducing enhanced control of halting system signal based on the received ultrasonic energy. In this

action, the electronic control's exceptionally quick response situation, thelevel opening point for a 75-meter distance

time can be employed to drastically shorten the dialling back between vehicles should be around 8 degrees. The vertical

distance. The control of a business vehicle's braking system hole is set at 1 degree and isstructured in such a way that

action is linked to more than just vehicle speed, but also to it does not exposeany weaknesses due to road conditions.

flat speed increments, yaw second control, and, on a very

basic level, reducing the risk of the vehicle rolling over. [4]

Such a perplexing duty confined to the control of relaxing

back, the instrument can't be set on the driver's restrictions

and must be completed independently of the driver.

Ultrasonic area guideline

Sound is a mechanical wave that travels through solid,

liquid, or gaseous materials. Sound waves can travel at high

speeds across various mediums, depending on the triggering

Fig 2: Sensor location

vehicle. Sound waves with a high repeat frequencyreflect off

cut-off points and send out clear resonation plans. Sound is a

IJISRT22JUN882 www.ijisrt.com 109

Volume 7, Issue 6, June – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Highlights: Test distance = undeniable level time × speed of undertakings. They may be little in size, but they are

sound (340M/S)/2, Working Voltage DC 5 V, Working incrediblystrong and energy efficient.

Current 15mA, Working Frequency 40Hz, Max Range 4m

Min Range 2cm, Measuring Angle 120degree.

Processor (ARDUINO UNO): The Arduino Uno is a

microcontroller board that is designed to work with the

Arduino platform. atmega328. It features 14 input/yield

robots. Six pins (six of which can be used for

PWM)yields), six main data streams, and a 16 MHz

processor a creative resonator, a USB connection, and a

Fig 5: Servomotor

power source an ICSP, jack.

Battery and Wheels: The tyre is employed to assist the

package in its centre, which is presenton the wheel, with

the goal of spreading the bodyweight evenly over

everything on the surface once the stack is applied on the

edge. The fundamental reason tyre turns on the move is

that the transmission of power from an engine through

chain allows the shaft in the centre, which is held by

bearing, to turn uninhibitedly all by itself.

Fig 3: Arduino Uno

Microcontroller (Motor driver)

Fig 6: Battery and Wheels

V. CASE STUDY - TIRE INFLATION

Tyre inflation has been corrected .A vehicle (150kw

engine, advance transmission, front wheel drive, rack and

pinion n power regulating) along P184/70 R13 tire and

numerical tested tostudy tyre filling repercussions for even

dealing with. The standard (configuration A) had m=1,370-

Fig 4: Motor Drive

kilogram, CG at (1.11m longitudinal from a front turn, 0.21m

above centre), explorer (configuration B) had m=1,623.5-

Determinations: Operating Voltage - 5V, Operating

kilogram, Centre of Gravity at (1.118 meter, 0.24 meter), and

Current-15ma, Counter cut-off - 5000rpm.

back with trunk load (configuration C) had m=1,643

kilogram, Centre of Gravity at (1.18 meter, 0.24 meter) (1.49

Servo Motor: The Need for a Servo Motor Downsizing, meter, 0.24 meter).

robotization, and high-quality parts by far most current

events Some fantastic cooling game plans, Fantastic tiny During a fourfold way change driving event (four 3.5-

motors and a high level of precision Metal roller that has meter equal turns of events, 90 kph target speed),records the

been machined. Servo motor is a type of motor that is used case number, tyre filling pressure, most notable controlling

to control alsoknown as a central motor, is a pioneer. a wheel point, most outrageous vehicle side-slip point, and most

component of a reworked controlframework Its The task noteworthy wheel slipfocuses. When standing out from the

at hand is to replacethe broken electrical sign. a daring obvious, thevehicle requires actually regulating work to

dislodging or a perfect speed yield on the motor shaft's stay conscious of the heading for the under-expanded tyre

yield Since its inception, ademonstration of a servo motor, (Cases 2-11) per stacking arrangements A [1]C.Case 1.

the servo motor has shown to be quite important in a

variety of businesses. Servo motors have long been Because the vehicle need and requires bigger the wheel

associated with massive undertakings. They may be little slip focuses to create the sidelong power which is needed to

in size, butthey are incredibly strong and energyefficient. complete a given directionshift, the results consistently show

Its job is to convert the received electrical signal into a greater left [1] front (LF) and left-back (LR) wheel slip

precise speed yield orto dare to dislodge the yield on the focuses, Max (LF) and Max (LR). To orchestrate the

motor shaft. Since its introduction, the servo motor has indicated pathway, the higher wheel slip focuses necessitated

proven to be quite important in a varietyof companies. more visible directing wheel input focuses, Max (). Because

Servo motors have long been associated with massive of the vehicle's reduced directional taking care of capacities

IJISRT22JUN882 www.ijisrt.com 110

Volume 7, Issue 6, June – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

when supplied with under [1] expanded tyres, the optimum At the point when the front turn tire pressure drops,the

vehicle slip point, Max (), is likewise stretched. Case 1A, 2A, coordinating wheel input increments, fully intent on

and 7A, for example, are part of a conventional stacking with expanding the vehicle's obvious understeer in Fig. 7a for

consistent tyre filling rates of 100 present, 70%, and 40%, instance, the greatest organizing wheel point development at

respectively, and reflect the most extreme vehicle slide points t = 2.6s (first-way change) compares to front tires under-

of3.4°, 6.1°, and 15.8°. In Cases 3&8, the vehicle moving extended to 70 present Tdp; when wandered from the lengthy

execution with under-extended tyres at theLF/RF zones was situation, a 47.7 present augmentation was seen.

considered. Reduced tyre filling pressure extends the most Notwithstanding the way that the coordinating information

limit directing deal slip focuses. This could be attributed to had been extended, the vehicle'scourage had not been hurt on

the vehicle's understeer credits being increased due to the a central level since it had completed the excursion. When

lower front tyre cornering resilience due to underinflation. contrasted with the conventional model in Fig. 3c, the

Understeer was present but coordinated for RF/RR under [1] completely underinflated situation (all tires 70%) expanded

expanded tyres (Cases 5&10) due to the RR tyre under [1] the most outstanding vehicle slip point by 77.8persent (at

filling, which had an oversteer sway. Under [1] filling t=4.5 seconds). Comparable cases have been found pera

conditions, the front tire's Max () readings were consistently backload a line of activity in Figures 3b and 3d (Case C). The

greater than the rear tires for a comparable filling rate, mix of under-expanded tires and a vehicle CG moved to the

indicating oversteer sway. Under-expanded LR/RR situations back cause’s gigantic amplitudes in the oscillatory waveform.

(Cases 4&9) demonstrate significantly more oversteer sway

The, Case 9 depicts the vehicle besieging the target. Move For a vehicle voyaging anticlockwise (CCW) on a

with little regard for stacking. As the vehicle's mass increased 152.44m territory circuitous track (nom=0.851) at speeds

and the centre of gravity shifted, an oversteer influence going from 0-216 kph, the developments in understeer

happens while pivoting (Cases B&C). It brought about a propensity when it were investigated to corner with tire

decrease in the best-it was extended and wheeled toorganize pressure combinations. Each re- request followed the

the most absurd vehicle. place of inversion for example, think standard vehicle stacking methodology. Wheneverthe vehicle

about the vehicle in the back column. The most ludicrous is furnished with underinflated back tires, the understeer

coordination fight was found in Case 5C. 82.0° and 7.9° coefficient, Ku's, is reliably lower (see Fig. 4). Figure 4a

vehicle slip focus. shows the

Both elements vary from standard weight For back tires reached out to 70 present GDP in a 0.04-

circumstance (Case 5A), which were 85.11° an 55°, 0.62 sidelong g's reach, the understeer coefficient is negative,

separately. For the other under- expansion examples, Cases but for front tires it is extended to 70 present Tdp,

A&C hadcomparative plans. As found in Cases 7C and 10C, understeering coefficient is positive along the entire scope of

this oversteers influence joined with under-broadened back level g's. Figure 4b, Cornering with a high burden for each

tires brings about unfortunate vehicle taking care of and level improvement weight shift diminishes fearlessness. The

questionable vehicle course. The RR/LF tires were under- vehicle moves in a clockwise heading, making a weight

extended (Cases 6&11) from theclear strain to assess vehicle diversion to the right side. A totally under-extended back turn

adequate upgrades open with a tire filling framework. Cases tire on this side (expanding trouble) brings about the vehicle

5&10 recommend that the versatile front (back tire) tire being oversteered indeed.

pressure considering the administrative of the controlling

wheel exertion (vehicle slip point). The tyre back pressure

detects, and controls the diminished vehicle instability by

minimizing deviation from the ideal sides-lippoint, bringing

about superior vehicle taking care of. Identical plans were

found with nom=0.5 and an objective speed of 55 kph. Figure

7 shows the adjustment of vehicle lead (coordinated wheel,

vehicle sliping centres) the time for different tyre pressures

during the QLCmovement. In Figs. 7a and 7c, the standard

stacking (Case A) shows four inventive filling pressures (all

tires’ 100 percent, all tires 70percent, front tires 70 present,

and right tires 70percent).

IJISRT22JUN882 www.ijisrt.com 111

Volume 7, Issue 6, June – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Figure: 7(b)

Figure: 7(c)

Table 1: Quadruple Lane Change for nom = 0.85, 90 km/h

speed, 165.5 kPa nominal tyre pressure, * unsteadyscenario

Figure: 7(d)

Figure 7: For a quadruple lane change with (a, c) standard

(Case A) and (b, d) rear (Case C) loads, the steering wheel

and vehicle slip angles are shown Green (circle) indicates

that the tyres are fully inflated, purple (rectangle) indicates

that the tyres are 70% inflated, red (square) indicates that the

front tyres are 70% inflated, andblue (solid) indicates that

the right tyres are 70% inflated (all other tyres in

Figure: 7(a) configuration are at 100 percent Tdp tyre inflation unless

specified)

IJISRT22JUN882 www.ijisrt.com 112

Volume 7, Issue 6, June – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

VI. CONCLUSION 17.

[11]. "Ultrasonic Testing". testexndt. co.uk. 2016-08-04.

A mechatronic stopping mechanism is described inthis Retrieved 2016-08-04.

study, and it is designed and built so that while it is dynamic, [12]. „Distance Measurement with the Help of Ultrasonic

it can apply a break to any article identifiedby an ultrasonic Sensor‟ Sandeep Kumar Gupta, International Research

sensor. Keen slowing down is one of the great options for Journal of Engineering and Technology (IRJET) e-

stopping a moving body without jerky movement that may be ISSN: 2395-0056 Volume: 05 Issue: 03 | Mar-2018

used in a variety of car applications. The plan of canny brake [13]. Bakker, E., Nyborg, L., and Pacejka, H., “Tyre

applications is based on the sufficiency of Ultrasonic sensor Modelling for Vehicle Dynamics Studies”, SAE

and microcontroller (engine driver) and controlling the #870421, 1987.

vehicle's speed as needed to maintain a changed distance is [14]. CarSim, “Tire Models”, CarSim Version 7.01B, 2007.

revealed in our group's study. Our current study has taught us [15]. Collier, B., and Warchol, J., “Effect of Inflation Pressure

that the order of this clever structure is attainable and useful on Bias-Belted and Radial Tire Performance”, SAE

in the long run. We provide approaches and conclusions that #800087, 1980.

are only getting started and require a lot more research. While [16]. Grugett, B., Reineman, M., and Thompson, G., “The

the vehicle is turning, the sensor may give the false indication Effects of Tire Inflation Pressure on Passenger Car Fuel

of an obstruction. To overcome this, we will organize Consumption”, SAE #810069, 1981.

ourselves in such a way that this framework will turn off [17]. Iwazaki, K., and Tanaka, I., “Smart Algorithm for a Tire

when we are turning. This can be accomplished by installing Pneumatic Pressure Monitor Embedded in ABS

sensors on the wheel that are designed to estimate wheel Program”, SAE #980237, 1998.

rotation. This architecture is currently well-suited to planned [18]. Käppler, W., and Godthelp, H., “Effects of Tyre

transmission. However, by implementing certain Pressures on Vehicle Handling”, International Journal

enhancements, we will be able to use this on any compatible of VehicleDesign, vol. 9, no. 4/5, pp. 517-532, 1988.

vehicle. Similarly, for continuous action, creative and [19]. Klyde, D., Magdaleno, R., and Reinsberg, J., “Effects

thorough programming is essential. The use of an intelligent of Tire Pressure on Aircraft Ground Handling,” J.

halting mechanism for a fundamentally unique condition Guidance, Control & Dynamics, vol. 26, no. 4, pp. 558-

should be investigated. 564, 2003.

[20]. Lee, K., Yu, J., Choi, Y., Jung, H., and Ryu, K.,

REFERENCES “Development of Active Tire Pressure Control System

for Agricultural Tractor”, proc. ASABE conference, vol.

[1]. “Hardware Implementation of Intelligent Braking 9, pp. 5216-5227, Providence, RI, 2008.

System” Published By - S. N. Sidek and M. J. E. Salami, [21]. NHTSA - National Highway Traffic

Faculty of Engineering, International Islamic University Safety Administration, “Federal Motor Vehicle

Malaysia. Safety Standards, Tire Pressure

[2]. “Intelligent Mechatronic Braking System” Published [22]. Monitoring Systems; Controls and Displays”, NHTSA

By -.G.V. Sairam, B. Suresh, CH. Sai Hemanth, K. 2000-8572, 49 CFR Part 571, RIN 2127-AI33, 2000.

Krishna sai [23]. Osajda, M, “Highly Integrated Tire Pressure Monitoring

[3]. “IC Transaction on Control System Technology”, Solutions,” Advanced Microsystems

Lennon, W.K, and. Passino, K.MVOL.7, NO.2, 1999 for AutomotiveApplications 2004, J. Valldorf &

[4]. „Distance Measurement with the Help of Ultrasonic W. Gessner (editors), Springer-Verlag: Berlin, pp. 23-

Sensor‟ Sandeep Kumar Gupta, International Research 37, 2004.

Journal ofEngineering and Technology (IRJET) e- [24]. Pacejka, H., and Bakker, E., “The Magic Formula Tyre

ISSN: 2395-0056 Volume: 05 Issue: 03 | Mar-2018 Model”, proc. 1st Tyre Colloquium, Delft, October

[5]. “IDEA Program Transportation Research Board 1991.

National Research Council”, Dr. Stephen Amell May [25]. Sandoni, G., and Ringdorfer, M., “Electronic

31,1996 Regulation ofan Automated Car Tyres Pressure Control

[6]. “Automatic energy brake system: technical System”, proc. 4th IFAC Mechatronic Systems,

requirement, cost and benefits”, C Govar, I Knight, F Heidelberg, 2006.

Okoro, I Simmons, GCoupr, P Massle, And B Smith, [26]. Schmeitz, A., Besselink, I., Hoogh, J. de, and Nijmeijer,

PPR 227 VERSION 1.1 H., “Extending the Magic Formula and SWIFT Tyre

[7]. “Intelligent Control Of Commercial Vehicle Braking Models for Inflation Pressure Changes”, proc. VDI

System Function”, Aleksendric, Dragan, University of Tires-Chassis- Road Conference, Hannover, Germany,

Bal grade, Faculty of mechanical engineering, 2005.

Automotive Department, Serbia [27]. Szostak, H., Wade, A., and Rosenthal, T., "Analytical

[8]. www.sciencedirect.com/engg./automobile/brakingsyste Modeling of Driver Response in Crash Avoidance

m/microcontrollerbraking Maneuvering: Vol. 2", US Department of

[9]. SAE Brake handbook of brake, Transportation, Washington, DC, NHTSA DOT HS-

www.ijetae.com/publish/201352/, VOL.3, ISSUE 4, 807-207, 1988.

APRIL 2013, February 1997. [28]. Velupillai, S., and Guvenc, L., “Tire Pressure

[10]. "Label Sensor Types and Technologies, Clear Label Monitoring”, Control Systems, vol. 27, no. 6, pp. 22-25,

Sensor Choice". Labelsensors.com. Retrieved 2015-03- 2007.

IJISRT22JUN882 www.ijisrt.com 113

You might also like

- Mechanical Vibrations and Condition MonitoringFrom EverandMechanical Vibrations and Condition MonitoringRating: 5 out of 5 stars5/5 (1)

- Mechanical Systems and Signal Processing: N. Roveri, G. Pepe, A. CarcaterraDocument18 pagesMechanical Systems and Signal Processing: N. Roveri, G. Pepe, A. CarcaterraDebashis DashNo ratings yet

- Tyre InflatorDocument6 pagesTyre Inflatorprajith gowdaNo ratings yet

- Vehicle Dynamics ManuscriptDocument9 pagesVehicle Dynamics Manuscriptaditya bhandakkarNo ratings yet

- Vibration isolation clutch pre-damper idle rattleDocument18 pagesVibration isolation clutch pre-damper idle rattleTuna RefaioğluNo ratings yet

- Petrol Engine Fault Detection Using Mechanical Vibration AnalysisDocument10 pagesPetrol Engine Fault Detection Using Mechanical Vibration AnalysisEditor IjasreNo ratings yet

- Ijace9157 PDFDocument12 pagesIjace9157 PDFBipulBrahmaNo ratings yet

- Measurement and Analysis of Vehicle Comfort and Road Quality Using Quarter Car ModelDocument8 pagesMeasurement and Analysis of Vehicle Comfort and Road Quality Using Quarter Car ModelChethan GowdaNo ratings yet

- Dontu_2020_IOP_Conf._Ser.__Mater._Sci._Eng._997_012113Document19 pagesDontu_2020_IOP_Conf._Ser.__Mater._Sci._Eng._997_012113Rony TeguhNo ratings yet

- Chapter IiDocument12 pagesChapter IijoyNo ratings yet

- Optimal Braking and Estimation of Tyre Friction in Automotive Vehicles Using Sliding ModesDocument13 pagesOptimal Braking and Estimation of Tyre Friction in Automotive Vehicles Using Sliding ModesmvamsipNo ratings yet

- Intelligent Braking System Using Electromagnetic ActuatorsDocument5 pagesIntelligent Braking System Using Electromagnetic ActuatorsIJRASETPublicationsNo ratings yet

- SenthilnatDocument12 pagesSenthilnatm2010008No ratings yet

- Measurement 145 (2019) 631–639: Influence of camber angle on tire tread behavior by an on-board strain-based system for intelligent tiresDocument9 pagesMeasurement 145 (2019) 631–639: Influence of camber angle on tire tread behavior by an on-board strain-based system for intelligent tiresAmier AziziNo ratings yet

- Vehicle Steering Dynamic Calculation and SimulationDocument11 pagesVehicle Steering Dynamic Calculation and SimulationVaishnavi RoutNo ratings yet

- Design Evaluation of A Follower Cam With PDFDocument16 pagesDesign Evaluation of A Follower Cam With PDFMaria MeharNo ratings yet

- Fabrication of Intelligent Braking SystemDocument6 pagesFabrication of Intelligent Braking SystemVishal LabdeNo ratings yet

- Design and Analysis of Automated Pneumatic Door SystemDocument6 pagesDesign and Analysis of Automated Pneumatic Door SystemIJRASETPublicationsNo ratings yet

- Disc Brake Run-Out Detection SystemDocument7 pagesDisc Brake Run-Out Detection SystemIJRASETPublicationsNo ratings yet

- Design Evaluation of A Follower Cam With Variable Valve Lift MechanismDocument17 pagesDesign Evaluation of A Follower Cam With Variable Valve Lift MechanismMUHAMMAD UMAR KAMRANNo ratings yet

- Design and Fabrication of Tire Pressure Management SystemDocument29 pagesDesign and Fabrication of Tire Pressure Management SystemJayakumar ThangavelNo ratings yet

- Accident Protection System Using Electromagnetic Abs Braking SystemDocument26 pagesAccident Protection System Using Electromagnetic Abs Braking SystemCODING CHANNELNo ratings yet

- Housing Stiffness in Uence On Gearbox Dynamic Loading For Wind Turbine ApplicationsDocument10 pagesHousing Stiffness in Uence On Gearbox Dynamic Loading For Wind Turbine ApplicationsPietroNo ratings yet

- Fault Diagnosis of Automobile Gearbox Using Artificial Neural NetworkDocument8 pagesFault Diagnosis of Automobile Gearbox Using Artificial Neural NetworkGovindraj ChittapurNo ratings yet

- File ServeDocument7 pagesFile ServeRanjodh SinghNo ratings yet

- EHB For Autonomous VehicleDocument8 pagesEHB For Autonomous VehicleMurali Krishnan SelvarajaNo ratings yet

- Automatic Braking System Using Ultrasonic WaveDocument7 pagesAutomatic Braking System Using Ultrasonic WaveIJRASETPublicationsNo ratings yet

- Collision Avoidance System Design Using Embedded SystemsDocument16 pagesCollision Avoidance System Design Using Embedded SystemsSiva SubramanianNo ratings yet

- 25 JST-4097-2022Document14 pages25 JST-4097-2022adwinraj29No ratings yet

- Advancement in Suspension System: - A ReviewDocument6 pagesAdvancement in Suspension System: - A ReviewdbpublicationsNo ratings yet

- Shivaramu H T Numaan Naveed Ahmed Devdarsh C Ajay and Santhosh Kumar T CDocument8 pagesShivaramu H T Numaan Naveed Ahmed Devdarsh C Ajay and Santhosh Kumar T CHemanth C KNo ratings yet

- Investigation of Light Vehicle Stability On Overtaking Heavy Vehicle Using CFDDocument6 pagesInvestigation of Light Vehicle Stability On Overtaking Heavy Vehicle Using CFDIJRASETPublicationsNo ratings yet

- J Measurement 2017 04 011Document9 pagesJ Measurement 2017 04 011Rushikesh SadavarteNo ratings yet

- Vehicle Controllability Assessment Using Detailed Multibody Vehicle SimulationsDocument8 pagesVehicle Controllability Assessment Using Detailed Multibody Vehicle SimulationsХасан ПаштовNo ratings yet

- Automotive Sensors: Past, Present and Future: Home Search Collections Journals About Contact Us My IopscienceDocument7 pagesAutomotive Sensors: Past, Present and Future: Home Search Collections Journals About Contact Us My IopscienceanilmendruNo ratings yet

- Engineering Applications of Artificial Intelligence: T. Heyns, J.P. de Villiers, P.S. HeynsDocument9 pagesEngineering Applications of Artificial Intelligence: T. Heyns, J.P. de Villiers, P.S. HeynsDavid Esteban Meneses RendicNo ratings yet

- Design and Development of Automatic Pneumatic Bumper SystemDocument6 pagesDesign and Development of Automatic Pneumatic Bumper SystemSahaya robin singh MNo ratings yet

- Design & Development of Electro-Magnetic Braking SystemDocument33 pagesDesign & Development of Electro-Magnetic Braking SystemAkshay bypNo ratings yet

- Design and Fabrication of Automated Sand Filter and Waste Separator MachineDocument6 pagesDesign and Fabrication of Automated Sand Filter and Waste Separator MachineIJRASETPublicationsNo ratings yet

- In-Situ Torque Measurements in Hybrid Electric Vehicle PowertrainsDocument15 pagesIn-Situ Torque Measurements in Hybrid Electric Vehicle PowertrainspranjaljecNo ratings yet

- Test Rig MethodologyDocument12 pagesTest Rig MethodologyKannanKingmakerNo ratings yet

- Estimating tire stiffness to classify road surfacesDocument12 pagesEstimating tire stiffness to classify road surfacessherif aboelnourNo ratings yet

- Design and Analysis of Automated Braking System UsingDocument20 pagesDesign and Analysis of Automated Braking System Usingrenuka mulaNo ratings yet

- Brake Roughness - Disc Brake Torque Variation, Rotor Distortion and Vehicle ResponseDocument15 pagesBrake Roughness - Disc Brake Torque Variation, Rotor Distortion and Vehicle Responsedebisi14140100% (1)

- Design and Modification of Commercial Vehicle Braking System For Reducing Noise and GrabbingDocument7 pagesDesign and Modification of Commercial Vehicle Braking System For Reducing Noise and GrabbingdeepakNo ratings yet

- Applsci 14 01036 v3Document24 pagesApplsci 14 01036 v3Airton Stocco de AlmeidaNo ratings yet

- D R V G P V: RAG Eduction Using Ortex Enerator ONA Assenger EhicleDocument6 pagesD R V G P V: RAG Eduction Using Ortex Enerator ONA Assenger EhicleMbudNo ratings yet

- Wes 6 367 2021Document10 pagesWes 6 367 202122143141No ratings yet

- Complex system health management using condition monitoring and test dataDocument15 pagesComplex system health management using condition monitoring and test dataচারুলতা নীর সেনNo ratings yet

- Dynamic-investigation-and-experimental-validation-of-a-gear-transmission-system-with-damping-particlesDocument22 pagesDynamic-investigation-and-experimental-validation-of-a-gear-transmission-system-with-damping-particlesluuthuanNo ratings yet

- Measuring vibrations affecting power transmission sealsDocument9 pagesMeasuring vibrations affecting power transmission sealsAlejandro Santos MonterrubioNo ratings yet

- A Comprehensive Study On Technologies of Tyre Monitoring Systems and Possible Energy SolutionsDocument41 pagesA Comprehensive Study On Technologies of Tyre Monitoring Systems and Possible Energy SolutionsDildeep PallipadNo ratings yet

- Automatic Braking System Research PaperDocument5 pagesAutomatic Braking System Research Paperlzpyreqhf100% (1)

- Automated Pneumatic Bumper For Vehicle SafetyDocument7 pagesAutomated Pneumatic Bumper For Vehicle SafetyJAYAPRABHAKARAN N NNo ratings yet

- Fault Size Estimation Using Vibration Signatures in A Wi 2016 Procedia EnginDocument7 pagesFault Size Estimation Using Vibration Signatures in A Wi 2016 Procedia EnginAhmed El-ShafeiNo ratings yet

- An Investigation On Gearbox Fault Detection Using Vibration Analysis Techniques: A ReviewDocument17 pagesAn Investigation On Gearbox Fault Detection Using Vibration Analysis Techniques: A ReviewMarthandeNo ratings yet

- Automatic Pneumatic Bumper SystemDocument4 pagesAutomatic Pneumatic Bumper Systemsgcreator 8189No ratings yet

- Experimental Work On Automatic Pneumatic BumperDocument8 pagesExperimental Work On Automatic Pneumatic BumperSahaya robin singh MNo ratings yet

- Final Paper IJLTETDocument7 pagesFinal Paper IJLTETaditendra1No ratings yet

- Advancing Healthcare Predictions: Harnessing Machine Learning for Accurate Health Index PrognosisDocument8 pagesAdvancing Healthcare Predictions: Harnessing Machine Learning for Accurate Health Index PrognosisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Investigating Factors Influencing Employee Absenteeism: A Case Study of Secondary Schools in MuscatDocument16 pagesInvestigating Factors Influencing Employee Absenteeism: A Case Study of Secondary Schools in MuscatInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Exploring the Molecular Docking Interactions between the Polyherbal Formulation Ibadhychooranam and Human Aldose Reductase Enzyme as a Novel Approach for Investigating its Potential Efficacy in Management of CataractDocument7 pagesExploring the Molecular Docking Interactions between the Polyherbal Formulation Ibadhychooranam and Human Aldose Reductase Enzyme as a Novel Approach for Investigating its Potential Efficacy in Management of CataractInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- An Analysis on Mental Health Issues among IndividualsDocument6 pagesAn Analysis on Mental Health Issues among IndividualsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Relationship between Teacher Reflective Practice and Students Engagement in the Public Elementary SchoolDocument31 pagesThe Relationship between Teacher Reflective Practice and Students Engagement in the Public Elementary SchoolInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Making of Object Recognition Eyeglasses for the Visually Impaired using Image AIDocument6 pagesThe Making of Object Recognition Eyeglasses for the Visually Impaired using Image AIInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Terracing as an Old-Style Scheme of Soil Water Preservation in Djingliya-Mandara Mountains- CameroonDocument14 pagesTerracing as an Old-Style Scheme of Soil Water Preservation in Djingliya-Mandara Mountains- CameroonInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Dense Wavelength Division Multiplexing (DWDM) in IT Networks: A Leap Beyond Synchronous Digital Hierarchy (SDH)Document2 pagesDense Wavelength Division Multiplexing (DWDM) in IT Networks: A Leap Beyond Synchronous Digital Hierarchy (SDH)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Harnessing Open Innovation for Translating Global Languages into Indian LanuagesDocument7 pagesHarnessing Open Innovation for Translating Global Languages into Indian LanuagesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Utilization of Date Palm (Phoenix dactylifera) Leaf Fiber as a Main Component in Making an Improvised Water FilterDocument11 pagesThe Utilization of Date Palm (Phoenix dactylifera) Leaf Fiber as a Main Component in Making an Improvised Water FilterInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Formulation and Evaluation of Poly Herbal Body ScrubDocument6 pagesFormulation and Evaluation of Poly Herbal Body ScrubInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Diabetic Retinopathy Stage Detection Using CNN and Inception V3Document9 pagesDiabetic Retinopathy Stage Detection Using CNN and Inception V3International Journal of Innovative Science and Research TechnologyNo ratings yet

- Auto Encoder Driven Hybrid Pipelines for Image Deblurring using NAFNETDocument6 pagesAuto Encoder Driven Hybrid Pipelines for Image Deblurring using NAFNETInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Impact of Digital Marketing Dimensions on Customer SatisfactionDocument6 pagesThe Impact of Digital Marketing Dimensions on Customer SatisfactionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Electro-Optics Properties of Intact Cocoa Beans based on Near Infrared TechnologyDocument7 pagesElectro-Optics Properties of Intact Cocoa Beans based on Near Infrared TechnologyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Survey of the Plastic Waste used in Paving BlocksDocument4 pagesA Survey of the Plastic Waste used in Paving BlocksInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Automatic Power Factor ControllerDocument4 pagesAutomatic Power Factor ControllerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Comparatively Design and Analyze Elevated Rectangular Water Reservoir with and without Bracing for Different Stagging HeightDocument4 pagesComparatively Design and Analyze Elevated Rectangular Water Reservoir with and without Bracing for Different Stagging HeightInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Cyberbullying: Legal and Ethical Implications, Challenges and Opportunities for Policy DevelopmentDocument7 pagesCyberbullying: Legal and Ethical Implications, Challenges and Opportunities for Policy DevelopmentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Explorning the Role of Machine Learning in Enhancing Cloud SecurityDocument5 pagesExplorning the Role of Machine Learning in Enhancing Cloud SecurityInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design, Development and Evaluation of Methi-Shikakai Herbal ShampooDocument8 pagesDesign, Development and Evaluation of Methi-Shikakai Herbal ShampooInternational Journal of Innovative Science and Research Technology100% (3)

- Review of Biomechanics in Footwear Design and Development: An Exploration of Key Concepts and InnovationsDocument5 pagesReview of Biomechanics in Footwear Design and Development: An Exploration of Key Concepts and InnovationsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Navigating Digitalization: AHP Insights for SMEs' Strategic TransformationDocument11 pagesNavigating Digitalization: AHP Insights for SMEs' Strategic TransformationInternational Journal of Innovative Science and Research Technology100% (1)

- Studying the Situation and Proposing Some Basic Solutions to Improve Psychological Harmony Between Managerial Staff and Students of Medical Universities in Hanoi AreaDocument5 pagesStudying the Situation and Proposing Some Basic Solutions to Improve Psychological Harmony Between Managerial Staff and Students of Medical Universities in Hanoi AreaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Formation of New Technology in Automated Highway System in Peripheral HighwayDocument6 pagesFormation of New Technology in Automated Highway System in Peripheral HighwayInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Review: Pink Eye Outbreak in IndiaDocument3 pagesA Review: Pink Eye Outbreak in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Hepatic Portovenous Gas in a Young MaleDocument2 pagesHepatic Portovenous Gas in a Young MaleInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Mobile Distractions among Adolescents: Impact on Learning in the Aftermath of COVID-19 in IndiaDocument2 pagesMobile Distractions among Adolescents: Impact on Learning in the Aftermath of COVID-19 in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Drug Dosage Control System Using Reinforcement LearningDocument8 pagesDrug Dosage Control System Using Reinforcement LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Effect of Time Variables as Predictors of Senior Secondary School Students' Mathematical Performance Department of Mathematics Education Freetown PolytechnicDocument7 pagesThe Effect of Time Variables as Predictors of Senior Secondary School Students' Mathematical Performance Department of Mathematics Education Freetown PolytechnicInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Root Cause Analysis For Employee TurnoverDocument77 pagesRoot Cause Analysis For Employee TurnoverRani Gujari100% (4)

- Linde Service Guide: LegendDocument2 pagesLinde Service Guide: LegendTrần Đức PhiNo ratings yet

- Section 7 - TransmissionsDocument692 pagesSection 7 - TransmissionsMTK2016No ratings yet

- GEP80SP1 (Single Phase)Document5 pagesGEP80SP1 (Single Phase)Jose PirulliNo ratings yet

- 8-11... Lobo Service ManualDocument41 pages8-11... Lobo Service ManualRusonegro100% (1)

- MDKBT BU Parts ManualDocument90 pagesMDKBT BU Parts ManualAhungNo ratings yet

- Operacion Terex TR100Document138 pagesOperacion Terex TR100Jose A. Basanta H.No ratings yet

- GD Bus Parts RequsitionDocument5 pagesGD Bus Parts RequsitionTavongasheMaddTMagwati100% (1)

- Man D2842 (630 - 730 Kva)Document4 pagesMan D2842 (630 - 730 Kva)eriscano169% (13)

- Pump Inspection Report: Page - 1 OF 1Document1 pagePump Inspection Report: Page - 1 OF 1hamadaNo ratings yet

- Brosur Genset Perkins 200 Kva SilentDocument2 pagesBrosur Genset Perkins 200 Kva Silentbagus saputraNo ratings yet

- Eni Product Range 2021Document1 pageEni Product Range 2021ranjanguptNo ratings yet

- Presentation TDDDocument7 pagesPresentation TDDEsau Jose PabloNo ratings yet

- Msa15 - Edc15Document4 pagesMsa15 - Edc15Giedrius Zasas80% (5)

- Reaccredited TSS Schools 2020-2021Document11 pagesReaccredited TSS Schools 2020-2021Hakim TaylorNo ratings yet

- 12 00 Me SPC 00019Document7 pages12 00 Me SPC 00019Erdal CanNo ratings yet

- Catalog Parts SD20 Transmision YanmarDocument16 pagesCatalog Parts SD20 Transmision YanmarDavid GalanNo ratings yet

- King KGD-951G GeneratorDocument4 pagesKing KGD-951G Generator2078oxfordNo ratings yet

- Carseat Recommendations For Children by Age SizeDocument2 pagesCarseat Recommendations For Children by Age SizeMNo ratings yet

- 3ha9 96Document50 pages3ha9 96Juan Arturo Ávila AguirreNo ratings yet

- 36 Wheels With TyresDocument27 pages36 Wheels With TyresaterrohotmailNo ratings yet

- Robotics Discover The Robotic Innovations of The Future - An Introductory Guide To Robotics by Klein Kevin.Document108 pagesRobotics Discover The Robotic Innovations of The Future - An Introductory Guide To Robotics by Klein Kevin.irteza_faruqiNo ratings yet

- Denso Common Rail Injectors 2010-12Document6 pagesDenso Common Rail Injectors 2010-12SergiyNo ratings yet

- SVM182 - Vantage 400 - Service ManualDocument166 pagesSVM182 - Vantage 400 - Service Manualmartin_jaitman100% (4)

- Kia MotorsDocument3 pagesKia MotorsShahid Iqbal100% (1)

- ClassificationDocument1 pageClassificationAlinaNo ratings yet

- Massey Ferguson 6490 TRACTOR (DYNA 6 TIER 3) Service Parts Catalogue Manual (Part Number 3906108)Document16 pagesMassey Ferguson 6490 TRACTOR (DYNA 6 TIER 3) Service Parts Catalogue Manual (Part Number 3906108)bvk2980022No ratings yet

- DD311 - 6114aesacDocument21 pagesDD311 - 6114aesacDionicio Palomino AguilarNo ratings yet

- 19-20 Lec 02 Traffic Engineering - Traffic Volume StudiesDocument41 pages19-20 Lec 02 Traffic Engineering - Traffic Volume StudiesDr Firas Asad100% (1)

- G240 (16 Speeds) CEI MERCEDES-4-307-231-242Document12 pagesG240 (16 Speeds) CEI MERCEDES-4-307-231-242عبدالغني القباطي100% (3)