Professional Documents

Culture Documents

WBM Mixing Procedure For STOPPIT

Uploaded by

ongcchemist gd chitra0 ratings0% found this document useful (0 votes)

6 views1 pageOriginal Title

WBM Mixing procedure for STOPPIT

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 pageWBM Mixing Procedure For STOPPIT

Uploaded by

ongcchemist gd chitraCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

MIXING PROCEDURE FOR STOPPIT LCM MATERIAL.

NOTE:

REFER THE DEAD VOLUME OF EACH RESERVE PIT AND CHOOSE THE PIT ACCORDINGLY

WHICH HAS LEAST DEAD VOLUME AND BETTER SUCTION FROM MUD PUMP.

MAKE SURE THE TANK IS CLEAN AND DOES NOT HAVE SETTLED LCM OR BARITE

REQUIREMENT: 100 BBL. STOPPIT LCM PILL.

IF PREPARING FRESH MUD, FILL THE RESERVE PIT WITH DRILL WATER. 80-85% OF

VOLUME TO BE PREPARED INITIALY. ( USE ACTIVE MUD IF SUFFICIENT VOLUME

AVAILABLE )

ADD VISCOSIFIER (BENTONITE /XC POLYMER SACKS) ALLOWING THE MUD TO REACH

VISCOSITY 70-80 SEC.

M.WT CAN BE MAINTAINED SIMILAR TO ACTIVE MUD WT OR (+/- 0.4 PPG approx.).

ADD 73 SACKS STOPPIT (40PPB).

MICA AND NUT SHELL ARE COMPATIBLE WITH STOPPIT AND IS RECOMMENDED TO BE

ADDED ALONG IF NEEDED.

TOP UP WITH REQUIRED VOLUME OF MUD FOR 100BBLS

REQUIREMENT: (15+15= 30BBL) OF HI – VIS PILL IN SLUG TANK.

PREPARE HI VIS WITH VISCOSITY NEAR 100 TO 120 SEC AND M.WT SAME AS ACTIVE

MUD W.T.

PUMING SEQUENCE:

NOTE: MUD PUMP STRAINER TO BE REMOVED.

15BBL HI VIS FROM SLUG TANK.

100BBL STOPPIT FROM RESERVE TANK.

15BBL HI VIS FROM SLUG TANK.

LINE UP ACTIVE TANK AND PUMP FOR DISPLACEMENT.

MONITOR FOR LOSSES DURING DISPLACEMENT.

HALLIBURTON 1

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Rig: GD Chitra 19.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1554M. Present OperationDocument7 pagesRig: GD Chitra 19.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1554M. Present Operationongcchemist gd chitraNo ratings yet

- Rig: GD Chitra 16.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1063M. Present OperationDocument7 pagesRig: GD Chitra 16.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1063M. Present Operationongcchemist gd chitraNo ratings yet

- Rig: GD Chitra 20.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1563M. Present OperationDocument7 pagesRig: GD Chitra 20.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1563M. Present Operationongcchemist gd chitraNo ratings yet

- Rig: GD Chitra 14.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 540M. Present OperationDocument7 pagesRig: GD Chitra 14.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 540M. Present Operationongcchemist gd chitraNo ratings yet

- Rig: GD Chitra 18.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1554M. Present OperationDocument7 pagesRig: GD Chitra 18.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1554M. Present Operationongcchemist gd chitraNo ratings yet

- Rig: GD Chitra 12.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 500M. Present OperationDocument7 pagesRig: GD Chitra 12.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 500M. Present Operationongcchemist gd chitraNo ratings yet

- Rig: GD Chitra 13.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 500M. Present OperationDocument7 pagesRig: GD Chitra 13.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 500M. Present Operationongcchemist gd chitraNo ratings yet

- Short DPR - GD Chitra - 07.06.2022Document7 pagesShort DPR - GD Chitra - 07.06.2022ongcchemist gd chitraNo ratings yet

- Rig: GD Chitra 09.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 500M. Present OperationDocument7 pagesRig: GD Chitra 09.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 500M. Present Operationongcchemist gd chitraNo ratings yet

- Rig: GD Chitra 17.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1208M. Present OperationDocument7 pagesRig: GD Chitra 17.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1208M. Present Operationongcchemist gd chitraNo ratings yet

- Rig: GD Chitra 15.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 711M. Present OperationDocument7 pagesRig: GD Chitra 15.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 711M. Present Operationongcchemist gd chitraNo ratings yet

- Rig: GD Chitra 06.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 500M. Present OperationDocument7 pagesRig: GD Chitra 06.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 500M. Present Operationongcchemist gd chitraNo ratings yet

- HardnessDocument1 pageHardnessongcchemist gd chitraNo ratings yet

- Description Qty Available 3 1 1 3 1 1 2 1 2 1 1 3 3 1 1 1 1 1 1 3 5 8 1 1 1 1 5 1 1 1 2 1 1 1 1Document2 pagesDescription Qty Available 3 1 1 3 1 1 2 1 2 1 1 3 3 1 1 1 1 1 1 3 5 8 1 1 1 1 5 1 1 1 2 1 1 1 1ongcchemist gd chitraNo ratings yet

- Rig: GD Chitra 05.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 500M. Present OperationDocument7 pagesRig: GD Chitra 05.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 500M. Present Operationongcchemist gd chitraNo ratings yet

- Short DPR - GD - 08.06.2022Document7 pagesShort DPR - GD - 08.06.2022ongcchemist gd chitraNo ratings yet

- Rig: GD Chitra 03.06.2022 LAST CSG: 30"/198M Well Date Final TD: PHASE: 26" Phase TD: Drilled Depth: 500M. Present OperationDocument7 pagesRig: GD Chitra 03.06.2022 LAST CSG: 30"/198M Well Date Final TD: PHASE: 26" Phase TD: Drilled Depth: 500M. Present Operationongcchemist gd chitraNo ratings yet

- Rig: GD Chitra 01.06.2022 LAST CSG: 30"/198M Well Date Final TD: PHASE: 26" Phase TD: Drilled Depth: 500M. Present OperationDocument7 pagesRig: GD Chitra 01.06.2022 LAST CSG: 30"/198M Well Date Final TD: PHASE: 26" Phase TD: Drilled Depth: 500M. Present Operationongcchemist gd chitraNo ratings yet

- Rig: GD Chitra 02.06.2022 LAST CSG: 30"/198M Well Date Final TD: PHASE: 26" Phase TD: Drilled Depth: 500M. Present OperationDocument7 pagesRig: GD Chitra 02.06.2022 LAST CSG: 30"/198M Well Date Final TD: PHASE: 26" Phase TD: Drilled Depth: 500M. Present Operationongcchemist gd chitraNo ratings yet

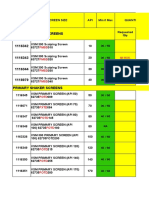

- Inventory Checked by John - Solids Control On dtd.20.06.2022 Ser - No Equipment QTY Location-1 Location-2 Sap Code Part NoDocument1 pageInventory Checked by John - Solids Control On dtd.20.06.2022 Ser - No Equipment QTY Location-1 Location-2 Sap Code Part Noongcchemist gd chitraNo ratings yet

- Synthetic-Based Mud Report No.10: Ongc 20-Feb-22Document4 pagesSynthetic-Based Mud Report No.10: Ongc 20-Feb-22ongcchemist gd chitraNo ratings yet

- Romantic Leh LadakhDocument7 pagesRomantic Leh Ladakhongcchemist gd chitraNo ratings yet

- Oil and Natural Gas Corporation Ltd. Evening Drilling Reports DTD: 30 MAY 2022-1800 HRS /GSSRDocument2 pagesOil and Natural Gas Corporation Ltd. Evening Drilling Reports DTD: 30 MAY 2022-1800 HRS /GSSRongcchemist gd chitraNo ratings yet

- Mud Log Book Jan 2022Document59 pagesMud Log Book Jan 2022ongcchemist gd chitraNo ratings yet

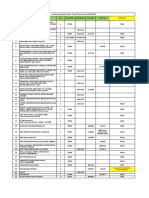

- Scalper Shaker Screens 1116342 1116343 1116344 1118070 Primary Shaker ScreensDocument4 pagesScalper Shaker Screens 1116342 1116343 1116344 1118070 Primary Shaker Screensongcchemist gd chitraNo ratings yet

- Sop For MBSDocument3 pagesSop For MBSongcchemist gd chitraNo ratings yet

- The Viscosity Is Measured With Two Different Instruments: The Marsh Funnel and The Fann ViscometerDocument3 pagesThe Viscosity Is Measured With Two Different Instruments: The Marsh Funnel and The Fann Viscometerongcchemist gd chitraNo ratings yet

- Hydraulics and Rheological Calculations: Following Datas Are Enterd in The Sheet To Get The ResultsDocument6 pagesHydraulics and Rheological Calculations: Following Datas Are Enterd in The Sheet To Get The Resultsongcchemist gd chitraNo ratings yet

- FGM Mud Log Book Jan 2022Document61 pagesFGM Mud Log Book Jan 2022ongcchemist gd chitraNo ratings yet

- Microbubble Chemicals Requirement SC#8YHDocument2 pagesMicrobubble Chemicals Requirement SC#8YHongcchemist gd chitraNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)