Professional Documents

Culture Documents

Catalogue Tong The Van UNIK

Catalogue Tong The Van UNIK

Uploaded by

Trọng Trương Ngọc0 ratings0% found this document useful (0 votes)

24 views24 pagesOriginal Title

Catalogue Tong the Van UNIK

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views24 pagesCatalogue Tong The Van UNIK

Catalogue Tong The Van UNIK

Uploaded by

Trọng Trương NgọcCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 24

BRASS VALVE

Fig: UKV - 1021R

BRASS GATE VALVE

125psi saturated steam to 178°C or 350°F

250psi non-shock cold water, oil or gas

Feature

© Pressure Rating: PN 16, Option: PN 20/ PN 25

© Working Temperature: t < 120°C

Working Medium: Water, Oil, Gas & Steam

©Non-ring stem.

© Screwed-in bonnet.

© Comply with BS5154

© Connected ends comply to: BS21.0 (BSPT), BSPF, NPT (ANSI BI.20.1)

Parts & Material

1 Body Brass CW617N

2 Disc Brass CW617N

3 Stem Brass CW617N

4 NUT Stee!

5 Hand Wheel Cast Iron

6 O-Ring Rubber

7 Packing PTFE

8 Gasket PTFE

9 Markings ‘Aluminum

7 -

f a

Z if a 1.1/4" 55.0 945 29 60

Ai : lea |e | SERCO ED 72

i s Za 64.0 131045 80

Contact: 715 Shuei Yuan RD, Feng Yuan Dist, Taichung City 420, Taiwan _ Tel:(+886)425121678 * Fax:(+886)425290390

nc ek as

BRASS VALVE

Fig: UKV - 7011R

BRASS BALL VALVE

125psi saturated steam to 178°C or 350°F

250psi non-shock cold water, oil or gas

Feature

‘© Pressure Rating: PN 16, Option: PN 20/ PN 25

© Working Temperature: t < 120°C

© Working Medium: Water, Oil, Gas & Steam

© Blow-out proof stem.

. © Two piece body.

© Lever handle.

© Standard port.

© Comply with BS5154.

© Connected ends comply to: BS21.0 (BSPT).

Parts & Material

1 Body brass CWo17N

2 Cap brass CW617N

3 BallSeat —

4 BallDicc Brass (Chrom pated)

5 O-Ring Rubber

6 Stem Brass CWet7N

7 Lockut aa

CaS

2° NUT Brass CWet7N

Dimension

ww 47.0 106

x a = 47.0 96

yy 15 49 44.0 175 x

2490218

rr ee

32 76 62.0 532 ~-

40 8730785

| so 103s asta

11212502078

2 © 12813003686

100148 149.0 «4673

Contact: 715 Shuei Yuan RD, Feng Yuan Dist, Taichung City 420, Taiwan _ Tel:(+886)425 121678 * Fax:(+886)425290390

oc i tae

BRASS VALVE

Fig: UKV - 3011R

BRASS SWING CHECK VALVE

Feature

© Pressure Rating: PN 16, Option: PN 20/ PN 25

© Working Medium: Water, Oil, Gas & Steam

125psi saturated steam to 178°C or 350°F

250psi non-shock cold water, oil or gas

© Working Temperature: t < 120°C

© Comply with BS5154.

© Connected ends comply to: BS21.0 (BSPT), BSPF, NPT (ANSI BI.20.1)

Parts & Material

1

oaren

Body

Cap

Disc

Hinge

Hinge Pin

Hinge Nut

Brass CW617N

Brass CW617N

Brass CW617N

Brass CW617N

Stainless Stell 2Cr13

Brass CW617N

50 46 14 70

65 65 146 89

80 80 165 105

100 100 192125

Contact: 715 Shuei Yuan RD, Feng Yuan Dist, Taichung City 420, Taiwan _ Tel(+886)425121678 * Fax:(+886)425290390

eee aes

uni unik

hh

BRASS VALVE

Fig: UKV - 4021R

BRASS Y-TRAINER VALVE

125psi saturated steam to 178°C or 350°F

250psi non-shock cold water, oil or gas

Feature

© Pressure Rating: PN 16, Option: PN 20/ PN 25

© Working Medium: Water, Oil, Gas & Steam

© Working Temperature: t < 120°C

©.40 Microns Mesh Filter

© Comply with BS5154.

© Connected ends comply to: BS21.0 (BSPT), BSPF, NPT (ANSI BI.20.1)

Parts & Material

Body Brass CW617N

Cap Brass CW517N

Gasket PIFE

Soren Stainless Stel 304

Dimen: mm

LEE

0S ESO 9 10

1050 4410 10

2A 15 56 50 Ww 15

-zL 20 66 59 13 20

23 OT nm 16 2s

z 32 101 87 17 32

= i a 40 12 100 18 40

5012502020 50

6 15515626 6s

80 205 188 28 80

100 248235 30.100

Contact: 715 Shuei Yuan RD, Feng Yuan Dist, Taichung City 420, Taiwan _ Tel:(+886)425121678 * Fax:(+886)425290390_

ee ete)

BRASS VALVE

Fig: UKV - 6011

BRASS FOOT VALVE

250psi non-shock cold water, oil

Feature

‘© Pressure Rating: PN 16, Option: PN 20/ PN 25

© Working Medium: Water, Oil

Working Temperature: t < 110°C

© Connected ends comply to: BS21.0 (BSPT), BSPF, NPT (ANSI BI.20.1)

Parts & Material

1

oosen

Body Brass CW617N

Bonnet Brass CW617N

Disc. Brass CW617N

Stem Brass CW617N

Rubber Nitrile Rubber

Spring Stainless Stell Type304

Dimension mm

15 33.5

20 42.2

25 475

32 57.5

40 68.0

50 80.0

65 103.0

80 11S,

100 142.0

Contact: 715 Shuei Yuan RD, Feng Yuan Dist, Taichung City 420, Taiwan _ Tel:(+886)425121678 * Fax:(+886)425290390_

Pte rr tr sre

» 6 BRASS VALVE

: UKV - O1AV,

© Working Pressure And Temperature:

Working Pressure: PN 16

Working Temperature: -10 °Cto 70°C

(Working Medium:

Water

| Materials Specifications

Brass CW517N

© Valve Standard

Comply with BS EN 12165

Connected ends comply to: BS 24.0, Ansi BI.20.1

(Dimensions (mm)

qans | 34120 | 1°25 So)

143 | 147170,

116 | 116 ‘| 165

46 46 46 — &

60 60 60

INSTALLATION:

1

6.

7,

Select the desired mounting method

a, For nominal hydronic fluid air removal during system operation, or only when circulation is stopped, the air

vent may be mounted directly to the system piping or a fitting equipped with a threaded tap.

b. For maximum air removal performance, especially during hydronic system operation, install an Toraval

air removal trap, and mount the air vent to the corresponding air vent port.

Locate the air vent at a high point in the hydronic system piping where air is expected to accumulate.

Ensure there is sufficient room to operate the air vent manual shut-of

‘Screw the supplied service check valve or male/female adapter to the air vent (if applicable).

‘Always mount the air vent vertically to ensure proper float mechanism operation

Use pipe tape or compound on the mounting threads to ensure a liquid tight seal.

If desired, the manual shut-off cap of UKV-01AV model airvents may be removed and replaced by a fitting (not

supplied) to enable connection of a drain hose.

OPERATION:

1

During hydronic system filing or drai

vacuum break capacity.

For normal operation, close the manual shut-off cap and then open one full turn. Do not remove the cap or leave it

fully open, or water expulsion or mechanism fouling by debris may occur.

When automatic venting or vacuum break operation is not desired, close the manual shut-off cap,

1g, open the manual shut-off cap fully, to enable maximum

venting or

Contact: 715 Shuei Yuan RD, Feng Yuan Dist, Taichung City 420, Taiwan _ Tel:(+886)425121678 * Fax:(+886)425290390

rae

Pre

rhb a ke

BRONZE VALVE

Fig: UKV-1022

BRONZE GATE VALVE

150psi saturated steam to 185°C or 365°F

300psi non-shock cold water, oil or gas

Feature

©Non-rising Stem, Screwed-in Bonnet, Full port

© Comply with BS5154

© Connected ends comply to: BS21.0 (BSPT), BSPF, NPT (ANSI BI.20.1)

© Working Temperature: t < 120°C

© Working Medium: Water, Oil, Gas & Steam

Parts & Material

1 Body Cast Bronze

2 Bonnet Cast Bronze

3 Disc Cast Bronze

4 Stem Brass

5 Lock Nut Brass

6 Hand Wheel Cast Iron

7 Packing Nut Brass

8 Gland Packing PTFE (Teflon)

9 Gland Brass

Working Pressures psi Paci

Working pressure (Non shock) Test pressure 44" 3B" 412" 34" 1" HIN He 2 Bie 3" a"

Saturated Steam Cold water, Oil,Gas. Shell Seat 96 96 96 70 60 35 30 20 10 6 4 pds

150 300/400 (Opt) 450 80-28 28 2B 90 32 29 92 31 2B 25 2B kgs

4100p = 7.03kg)em"

Shell tested by hydro, saat tested by ait

Feature

© Working Temperature: t < 120°C

© Working Medium: Water, Oil, Gas & Steam

BRONZE VALVE

Fig: UKV-7021

UKV-7021B

BRONZE BALL VALVE

300psi saturated steam to 178°C or 350°F

© Blow-out proof Stem

© Two piece body

Lever handle

©PTFE seat and gland packing

© Comply with BS5154

© Connected ends comply to: BS21.0 (BSPT), BSPF, NPT (ANSI BI.20.1)

UKV-70218\Ful Type)

Eo)

Dimension

114" 49.0

3/8" 49.0

12 53.0

. 3a" 56.0

fi 68.0

1.1/8" 86.0

1.172" 96.0

2 108.0

2.112" 124.0

3 160.0

a 188.0

Working Pressures

‘Working pressure

Saturated Steam

300

1s00psi = 7.03kgtem*

Shall tested by hydro, seat tasted by a.

'15 Shuei Yuan RD, Feng Yuan Dist, Taichung City 420, Taiwan _ Tel:(+886)425121678 * Fax:(+886)425290390

Conta

42.0 106.2

42.0 106.2

42.0 106.2

50.0 106.2

50.0 106.2

62.0 141.2

62.0 141.2

650 141.2

80.0 171.5

100.0 201.0

127.0 201.0

(Non shock)

Cold water, Oil, Gas

600

Pauly

mm Parts & Material

54.0

54.0

56.0

63.0

76.0

86.0

96.0

120.0

171.0

Test pressure

Shell

900

eet ores cea

1 Body

2 Cap

3 Stem

4 Lever Handle

5 Packing

6 Lock Nut

7 Ball Disc

8 Ball Seat

Packing uxv-7021

4 aie" 12 wa

120 120 120 100 72

25 25 2 31 29

600psi non-shock cold water, oil or gas

Cast Bronze

Cast Bronze

Brass

Steel

PTFE (Teflon)

Brass

Brass (Chrom plated)

PTFE (Teflon)

14 ie 22a tae

36 30 20 10 6 4 pcs

29 31 31 30 32 33 kgs

psi Packing uxv-7oz18

14" ae 12" 3" 1" 14m tA 2 8

Seat 108 108 108

100 25 25 26

72 48 28 2 12 4 pes

31 28 25 29 31 23 kgs

BRONZE VALVE

Fig: UKV-3012

BRONZE SWING CHECK VALVE

4150psi saturated steam to 185°C or 365°F

300psi non-shock cold water, oll or gas

Feature

© Horizontal swing type

© Bronze (metal) disc

© Working Temperature: t < 120°C

© Working Medium: Water, Oil, Gas & Steam

© Comply with BS5154

© Connected ends comply to: BS21.0 (BSPT), BSPF, NPT (ANSI BI.20.1)

Cast Bronze

Cast Bronze

Cast Bronze

1i4"~2" Brass

2-4/2"~ 4" SUS 304

Brass

i mm

Ean

14" 38.0 (85.0

aie 390 55.0

138.0550 =

3” 45.0 63.0

fig 520 73.0

104620 81.0 u

1172" 670 82.0

2 790 108.0

212 86.0 137.0

97.0 148.0

4 113.0 180.0

Working Pressures psi Packing

Working pressure (Nonshock) Test pressure 14" aie" 1/2" 34" 1 MW MH 2 24a a

Saturated Steam Cold water, Oi, Gas Shell Seat 100 100 140 100 70 35 30 20 10 6 4 pcs

150 300/400 (Opt.) 450, 80 27 2 32 30 32 23 24 23 26 19 21 kgs

1300p = 7-03kglem*

‘Shel tested by hydro, seat tested by ar

Contact: 715 Shuei Yuan RD, Feng Yuan Dist, Taichung City 420, Taiwan _ Tel:(+886)425121678 * Fax:(+886)425290390

ee ete

BRONZE VALVE

Fig: UKV-4031

unk

BRONZE Y-TYPE STRAINER

150psi saturated steam to 185°C or 365°F

300psi non-shock cold water, oil or gas

Feature

© Working Temperature: t < 120°C

© Working Medium: Water, Oil, Gas & Steam

© SS 304 Screen

Comply with BS5154

‘Connected ends comply to: BS21.0 (BSPT), BSPF, NPT (ANSI BI.20.1)

Parts & Material

1 Body Cast Bronze

| 2 Cap Cast Bronze

3 Stem SS 304

4 Gasket PTFE (Teflon)

5 Plug Cast Bronze

Dimension —_ mm

aI

12’ 58.0

si” 70.0

a 85.0

4.1/8" 105.0

1.472" 122.0

2 145.0

2.4/2" 184.0

3" 215.0

Working Pressures psi Packing sr.o02

Working pressure (Non shock) ‘Test pressure vet wa a Ne 2 ae

Saturated Steam Cold water, Oil, Gas__—_Shell 100 72 48 30 24 12 6 4 pos

150 300/400 (Opt.) 450

100psi = 7.03kg/em"

Shall tested by hyo

Contact: 715 Shuei Yuan RD, Feng Yuan Dist, Taichung City 420, Taiwan _ Tel:(+886)425121678 * Fax:(+886)425290390

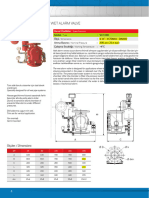

> o IRON VALVE

UNIK UNIK ae

00s (6S 5163)

NRS RESILENT SEAT GATE VALVE

Valve Standard

‘Comply with BS 5163 Type AAB, DINS352 or AWWA C515,

Working Pressure and Temperature

‘oVlrkng pressure Size SOmm 400 mm PN 16, PN 25

Size 4S0mm -600 mm: PN10

Temperate ram: 100 12° for EPDM

AOC 12 BC tor NBR.

Flange Type

‘9854506 PN10/16725, BSEN1092~ ae

PNIOIPNTBIPN2S, ANSI.1, een ae

{lase2s, ANSI B16 2, class25, Deseon ed

[8540 Table DIE, JIS 10K/16K. ol Bose

Operator Sean sears

‘Stem cap, handivhest cone Sonne

(gear operation, elect actuation = =

Dimension

g

!

i

:

;

> IRON VALVE

OS&Y RESILENT SEAT GATE VALVE

Valve Standard

Comp wih 885163

Pressure Temperature Ratings

Woning temperate: 20°C 19 110 EPOM

10°C to 80°C NBR

Flange Type

854504 PNTOV1625, BSEN 1092.2

PPNIOIPN6/PN26, ANSI 8.1,

{8510 Table DIE, JIS 10K/16K.

Operator

Hanae gear operator

Parts List

3 Gok — unber = EPOMINR Dimension cam

4 Gomet eset eves coor

5 O-Rrg ber EPOMNER. = mo I

6 Wane FC Conmers mat

7 O:Rrg ber EPOMINER am a2

Trust Foped ess cziz2 momo

Wiser Fogel ess CaIz2 mm mom

Vise Ling Rusher POM so 0 amar

Gace Paste Nye oer 08

Wisige —Outlowen— ENGUSSODT

omtac75 She Yuan RD Feng Yuan Dt, aehung Cy 2, avan Te +65)25 121678: Fax +885}425290350

IRON VALVE

Fig: UKV-9021 $5 Dise

» 6

UNIK UNIK

WAFER DOUBLE DOOR CHECK VALVE

PNi6ICiass125,

Working Pressure and Temperature

‘Werng pressure PR 6ICass125,

oTemparature rom 10°C to 120°C for EPDM seat.

Temperature rom -10'C to 62°C for NBR seat

‘Temporatre rom-10'G to 160°C for Viton seat

Flange Type

884504 pN10/10725, BSEN 1062-2 PNIOPNIGIPNZS, ANS BYE 1, Caes25,

fans) 8162 Clse250. 80 Tato DE ts TOT

SESSRSR Rake ee shy

IRON VALVE

Fig: UKV-3031 Disc: SS 304

UKV-3032 Disc: Bronze

WAFER SILENT CHECK VALVE

Specifications

® The Design is for liquid service and offers many obvious advantages

when compared with conventional swing check valve.

© Complies with the requirements of EN 12334 (BS5153)

* Spring automatically closes disc at zero flow before flow reversal

occurs. This prevents surge and water hammer.

* Completely guided disc both top and bottom.

* Available with flanges BS 4504-PN16 or PN25, ANSI B16.1 Class 125.

Pressure Temperature Ratings

Working pressure ‘16bar/25bar

‘Shell:24bar/37.Sbar

(Dest reser Seal:17.6bar/27 Sbar

-20 to 110° EPDM

Working Temperature 0 1 Ao eR

' Suitable Media Water, Oi&Gas

S

Body Cast Fon ‘A126 Class B

Ductile Iron A536 65-45-12

Disc _Slailess Steel 304 A351 CFB

Bronze 862 C83600

Seat _Stainless Steel 304 A351 CFS.

Bronze 862 C83600

Seat Ring EPDM/NBR Commercial

Spring Stainless Steel 304. $30400

Clu) a avy 1.

D 108 127 150 167 213 (248 340 410 415 478

H 67 73 80 102 118 140 165 216 286 350

Contact: 715 Shuei Yuan RD, Feng Yuan Dist,

lung City 420, Taiwan _ Tel{+886)425121678 * Fax:(+886)425290390

Ree nent

ees ee cerca

IRON VALVE

Fig: UKV-4001 - PN 16

UKV-4002 - PN 25

Y-STRAINER

Working Pressure and Temperature

© Size 50 to 600, working pressure PN 16.

© Size 50 to 300, working pressure PN 25.

© Temperature from -10°C to 120°C.

Face to Face Dimension

©DIN 3202 F1 series,

Flange Type

©BS4504 PN10/16/25, BSEN 1092-2 PN

PN16/PN25

10/PN16/PN25,

ANSI B16.1, Class125, ANSI B16.2, Class250,

BS10 Table D/E, JIS 10K/16K.

Standard Screens

| 0120010

DN50 TO 80 4.5mm

DN100 TO 600] 3.0mm

Dimension

135 412"

5 = 165

80 310 186

100 350226

125 400-267

150 480 305

200 600 358

250 730495

300 850 530

350 980 740

400 1100 840,

33% 500 1250 968,

40% 600 © 1450S 1160

Materials Specification

a eee ee CSE

Bods Craze) Cast tron

Ductile Iron

| Cover [URV#007 Reese

RSET] ucte ron

Stainless Steel

Teflon/EPDM/Graphite

CSL] Cast iron

TSH Ductile tron

Contact: 715 Shuei Yuan RD, Feng Yuan Dist, Taichung

EN-JL 1040 ‘A126 Class B

EN-JS 1050 A536 65-45-12

EN-JL 1040 A126 Class B

EN-JS 1050 A536 65-45-12

BS970 304815 AISI 304

Commercial Commercial

EN-JL 1040 A126 Class B

EN-JS 1050 A536 65-45-12

City 420, Taiwan _ Tel:(+886)425121678 * Fax-(-+886)425290390

Seek keieey

d IRON VALVE

UN K Fig: UKV-6001

FOOT VALVE

PN16/Class125

Working Pressure and Temperature

Working pressure PN16/Class125.

Temperature from -10°C to 120°C for EPDM trim.

© Temperature from -10°C to 82°C for NBR trim.

Flange Type

©BS4504 PN10/16/25, BSEN 1092-2 PN10/PN16/PN25, ANSI B16.1, Class125,

ANSI B16.2, Class250, BS10 Table D/E, JIS 10K/16K.

D

Dimension mm WY +4

So B | ¢c | Dp |

50 100 160 94 165

65 120-205 = 120 185 <

80 140240142 200

100 170 «= 30017 220 Sars o

125 200 355 206 250 2

150 2302440237 285 4

200-288 «= 490290 340

250 354575330 405

300 410 «655360 460 5 '

Materials Specification

0

Cast Iron EN-JL 1040 ‘A126 Class B

[Cast iron EN-JL 1040 A126 Class B

ESS Gl Integral EN-JL 1040 A126 Class B

EPDM/NBR ‘Commercial ‘Commercial

Bronze EN1982.CC491K —_862.C83600

CON | Staines tec! 88970 420837 ASI 420

Stainless Stee! S970 304815 ANSI 304

Cast ron EN-JL 1040 A126 Class B

ESO | Stainess steo! BS970 304815 ASI 304

Contact: 715 Shuei Yuan RD, Feng Yuan Dist, Taichung City 420, Taiwan _ Tel:(+886)425121678 * Fax:(+886)425290390

a ea ea

RUBBER JOINT

». 6

UNIK UNIK FUER

DOUBLE SPHERE UNION TYPE

RUBBER EXPANSION JOINT

Working Pressure and Temperature

‘Working pressure 1,

‘Exposve Pressure 48 bar

{Vacuum Rating 400mm

Temparature rom -10'C to 120°C er EPOM.

Temperature rom 10 to 87° for NBR

Tomporature rom 10°C 10 10°C for Nooprene

Medium

End Thread Type

‘8821 OBST), BSPF, NPT(ANS! 120.1)

sinc teed’

a

ee

Dimension

nse) ares

2yaie) Bose 2

mir) amas

miu) me

war) 2m 8s

ar) 4 8S

maw) wo 2 5-6

Contac 718 Sue Yan RO, Feng Yuan Dist Tahun Cy 420, Tainan

RUBBER JOINT

Fig: UKV-9002R

SINGLE SPHERE RUBBER EXPANSION JOINT

PN16

Working Pressure

Size DN32 to DN300 Size DN350 to DN600

© Working pressure 16 bar ‘© Working pressure 10 bar

© Bursting pressure 48 bar © Bursting pressure 30 bar

© Vacuum Rating 750mmHg © Vacuum Rating 500mmHg

Working Temperature

© -10°C to 120°C for EPDM. —

© -10°C to 82°C for NBR.

©-10°C to 110°C for Neoprene.

Medium SS

© Air, Water, Oil, Acid, Alkali etc.

Flange Type

© BS4504 PN10/16/25, BSEN 1092-2 PN10/PN16/PN25, ANSI B16.1, Class125,

ANS! B16.2, Class250, BS10 Table D/E, JIS 10K/16K.

Materials Specification

EPDMINBR/Neoprene

Nylon Cord Fabric

Spring Steel Wire

Carbon Steel, Zinc Plated

Lateral Movement Angular Movernent

» ry PRESSURE GAUGE

UKV-PGO1 ukv-PG02

uKv-PG03

Genel ence Pressure Gauge ae high Process Industy Pressure Gauge are

‘qualy ty gauge service on applica suitable for covosion envvonment

‘lone not concave obs Preumat, and used with media that do not

Hycrautcs, Mocs, Meda and ost corrode the brass. Applications

Industaand corel pesto. Include hyraules. Reng, Process

engineering, Equipment, Marne,

Fev chemia te

nce exreonaes Aeoeteo ggese

pup Croan ae

georeiagi ‘gee

caw Recediar reer at

‘ora itntetost OE) a aa

‘penamon warns oases

scsi reranonunraions

Indust Service Presse Gauge ae

theultimate ncorosan estan and

eae duty The areused in cose

serie ward-nde where ruggedness

and reliably ae critica. Typeal

Spplesions clude Chemical and

nee

‘ge eager

al reo

Feuawo : Gre

Contac 715 Shs Yuan RD, Feng Yuan ist, achung Cy 20 Tavan Tel +8642512678" Fax +885425200380,

» 6 GLASS THERMOMETER

I

Fig: UKV - TGO1

APPLICATION

Glass Thermometer is suitable for temperature measurement in

various industrial plants such as oil refinery, sugar refinery and

rubber plant, chilled water system, etc.

TECHNICAL INFORMATION

CASING

Design : V-shape 150mm x 63mm

Material : Nylon fibre

Colour : Brass - cloured

POCKET

Material : Brass

Typr : Straight; Angle 90° backward

Length : 63mm; 100mm, 150mm

Diameter : 10mm

Connectinon : 1/2” BSPT

ined ELEMENT

Fluid : Alcohol

Colour : Blue

Working range: Maximum scale value

Accuracy : + 2.0% of full scale

SCALE RANGE

Division : Celsius (°C) + Fahrenheit (°F)

Range : -30~50°C;0~ 100°C; 0 ~ 120°C

0 ~ 150°C; 0 ~ 200°C

Contac: 715 shuel Yuan RO, Feng Yuan Dist Teich

ROTARY VANE WHEEL DRY - DIAL MAGNET - DRIVE

COLD WATER METER

Medidor de Agua, Registro seco, Transmision magnetca,

Tipo Volante, para agua tia

LXSG - 15E ~ 50E

~Feature:

\ Dry-dial, Magnetic drive, Resistance to exterior magnetinterference

~ Multijet

~ Selected high quality materials forsteady & reliable characteristic,

© Vacuum sealed register ensures the dial kept free from fog and keep the reading clear in a long term

service

© Measuring accuracy conform to ISO 4064 class B Standard

© Universal use. Easy forinterchange & maintenance

Caracteristicas:

| © Registro seco, Transmision magnetica, Resistente a la exterior interferencia magnetica

5 Chorro multiple

© Seleccion de material de alta calidad que dejia estable y segura lafuncion

© El registro sellado vacio puede evitar el problema de condensacion y puede mantener clara la lectura

durante largo tiempode trabajo

© Laprecision de medicion esta conforme ala norma ISO 4064 clase B

© Usouniversal. Facil mantenimiento y reparacion.

ovo =

This range of water meter is used to measure the total quantity of cbid potable water which

consumed in household ora resident unit, passing through the pipeline.

fr

Esta série de medidores de agua esta disenada para jawmt@€icion

pasada por laiuberia de agua potable en unaeasaoUindepa

Compliante With standard: |SO'4064|Class°B

Contorme a la norma :1SO 4064 Clase

Contact: 715 Shuei Yuan RDjFeng Yuan Dist, Taichung City 420, Taiwan _ Tel:(+886)425121678 * Fax:(+-886)425290390

MAIN TECHNICAL DATA

ESaeae

18 30 14

Especifiaciones tecnicas

15 B 3 . 120 0.0001 99999

20 B 5 25 200 50 16 0.0001 99999

25 B 7 35 280 70 19 0.0001 99999

32 B 12 60 480 120 25 0.0001 99999

40 B20 10 = 800 200 56 0.001 99999

50 B30 15 3000 450 70 0.001 99999

& INDICATING ERROR

{At low zone is 5% from minimum flow rate (qmin) to

transitional (qt) exclusive boundary

At high zone is #2% from transitional flow rate (qt) to

overload flow rate (qs)

& FLOW - ERROR CURVE

(Grafico de precision de caudal)

bestag

& ERROR MAXIMO PERMITIDO

De cau miro caudal do

transiion excido £5%

De caudal de rensicon a caudal

sobre carga ncido £2%

HEAD LOSS CURVE

(Gratico de perdida de carga)

POS stmt om som

oe

208

208

on

008

05

ons

ore

oor

°

DIMENSIONS AND WEIGHT (Dimension y peso)

15 160/250 99104 oy, 15/16

20 2001900 99S (106. a 178

25 220840 «104120 a" 2612.4

32 230/350 104120 ety, 2.8/2.7

40 250/870 «128185, G2 5.4/4.5

300 125 185 G2", 72

gD 270 Cola Reno ee Oneorec ome [aa

Working Condition:

Water temperature: < 40°C

Working pressure: 1, <1 0MPa

2,<1.6MPa

Made in TAIWAN Made in TAIWAN

We Material

Body: Cast ron

Option: Ductile Iron, Brass, Plastic

Coupling: Brass

Made in TAIWAN DECORA ZUT

HORIZONTAL WOLTMANN DETACHABLE MAGNET-DRIVE

DRY-DIAL WATER METER

Medidor de Agua, Horizontal y

Desmontabe, regis seco, Tipo Woltmann

LXLG - 50 ~ 500

Feature:

~ Dry-dial, magnetic drive

~ Vacuumisealed register ensures the dial kept free from fog and keep the reading clearin along term service

~ Selected high quality materials for steady & reliable characteristic

~ Measuring accuracy conform to ISO 4064 Class B Standard

~ Lowhead loss

~ Register for universal use within this range detachable, without removing the meter from the pipeline for a easy

maintenance and replacement

Caracteristicas:

~ Registro seco, transmision magnetica

~ Elregistro sellado vacio puede evitar el problema de condensacion

© Seleccion de material de alta calidad que deja estable y segura lafuncion

~ La precision de medicion esta conforme a la norma ISO 4064 clase B

~ Baja perdida de presion

~ Sinnecesidad de desmontar e! medidor de agua desde tuberia, sino solo abre la tuerca superior de flange

y saca el registro para la reparacion o reemplazo. Uso universal el registro. Facil mantenimiento y

reparacion

This range of water meter is used to measure the total quantity of cold water which consumed in

industrial enterprise & mining, passing through the pipeline.

Esta série de medidorés de agua disenada para la medi¢lOn del con

pasada por la tuberiade agua potable en las indUstsié€y mina

ComplianceWith standard: \SO 4064 Class B

Conformea la norma :1SO 4064 Gla;

WW MAIN TECHNICAL DATA _Especifiaciones tecnicas

r

staring ae

Ea WW INDICATING ERROR

cH At low zone is +5% from minimum flow

gre

co

50 B80 15 «SOAS. 1500.01 9999989 rate (arm) to transitional flow rate (a)

65 B 50 25 5 075 170 0.01 9999999 exclusive DoUraaly,

Athigh zoneis-:2% from transitional flow

Go| Of Go | oy 6 | ae | ee | el Fee rate (qi) to overload flow rate (3)

100 B 120 60 12 1.8 400 0.01 9999999

125 B 200 100 20 3 800 0.01 9999999 * ERROR MAXIMO PERMITIDO

150 B 300 150 304.5 1200 0.01 9999999 De caudal minimo a caudal de transicion

200 B 500 250 50 7.5 2250 0.01 9999999 Cee

De caudal de transiion a caudal sobre

250 B 800 400 80 12 2500 0.01 9999999 .

carga incuide 425

300 B 1200 600 120 18 7000 0.01 9999999

Bi 300 80

4 ,

100 B 2000 1000 200 30 15000 0.01 9999999

A

500 3000 1500 AGO E120) 20000 0.01 9999999

8 300 45

W FLOW-ERROR CURVE We HEAD Loss CURVE

(Grafico de precision de caudal) (Grafico de perdida de carga)

2 APMC B oo! 5 160200 ps0 5 60400 satin)

& DIMENSIONS AND WEIGHT (Dimension y peso)

rege

ra

oN = +

42 - :

Se mK 4

80 225 200 265 200 160 15 .

100 250 220 275 220 180 19 |

125 250 245 285 245 240 22

WK Working Condition:

150 900 285 975 285 240 47 WeteWoprrahre:cadt

200 350 945 400 340 295 48 Working proccure:,0MPa

250 450 995 484 395 350 12x20 110 <1.6MPa

Eo eee NET] «yr Mitoral:

400 500 565 621 565 515 «16x24 180 Body! Cast ron

500 500 670 725 670 620 20xM24 330 \QpHn: Ductile Iron

DERE L OY} TEU) CURE) CCU)

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Alarm Vale Armas-1 - 1555493257Document10 pagesAlarm Vale Armas-1 - 1555493257Trọng Trương NgọcNo ratings yet

- 27, 28. Valfon - Vly-100 - Alarm Check ValveDocument2 pages27, 28. Valfon - Vly-100 - Alarm Check ValveTrọng Trương NgọcNo ratings yet

- Catalog SMS-227-Vi-rev210322 (New Version)Document6 pagesCatalog SMS-227-Vi-rev210322 (New Version)Trọng Trương NgọcNo ratings yet

- (Device) Electric Product Catalog en 202106Document68 pages(Device) Electric Product Catalog en 202106Trọng Trương NgọcNo ratings yet

- HC HQ uPVCDocument4 pagesHC HQ uPVCTrọng Trương NgọcNo ratings yet

- Catalogue Ống Gió Và Van Chống Cháy Vitduct Rev 3Document44 pagesCatalogue Ống Gió Và Van Chống Cháy Vitduct Rev 3Trọng Trương NgọcNo ratings yet

- (Susol Metasol ACB) Catalog en 202201Document144 pages(Susol Metasol ACB) Catalog en 202201Trọng Trương NgọcNo ratings yet

- Catalog PanasonicDocument43 pagesCatalog PanasonicTrọng Trương NgọcNo ratings yet

- Động Cơ Motorise Gắn Van Gió REGINDocument10 pagesĐộng Cơ Motorise Gắn Van Gió REGINTrọng Trương NgọcNo ratings yet

- 6 - 2019.03.20 PRIMAIRY - Catalog (Fixed Speed Series Cooling Only Type)Document26 pages6 - 2019.03.20 PRIMAIRY - Catalog (Fixed Speed Series Cooling Only Type)Trọng Trương NgọcNo ratings yet