Professional Documents

Culture Documents

S6700E ESC Speed Controller Manual

S6700E ESC Speed Controller Manual

Uploaded by

German E.0 ratings0% found this document useful (0 votes)

346 views3 pagesS6700E

Original Title

S6700E-ESC-speed-controller-manual (1)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentS6700E

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

346 views3 pagesS6700E ESC Speed Controller Manual

S6700E ESC Speed Controller Manual

Uploaded by

German E.S6700E

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

POWER

SEGMA POWER PRODUCTS

SPECIFICATION

PRODUCTS

1, Introduction

‘The $6700E Speed Control Unit is an all-electronic device designed to control

‘engine speed with fast and precise response to transient load changes. Based on

‘a closed loop control, the basic characteristics of this units to reach rated speed

‘and power as well as reducing smoke exhaust through adjustment of firing fuel

‘and speed-rate. The S6700E Speed Control Unit provides a series of protection

‘once the power supply is reversely connected, transient overvoltage or actuator

fault happens, or speed input breaks.

il, Technical Paramet

rs

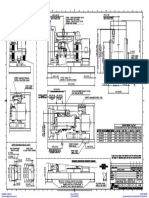

Ill, The S6700E Speed Control Unit Wiring/Outline

° SPEEDCONTROLER

‘ =F =

ae rm

| +S IB

3s

Ss sieaw eat Etnperatorerange —40~80%

Relative humidity 95%

‘Supply 2avDc

Input power Actuator current range | 2.5-10A (continuous)

Speed sensor signal 1-20

ee eee mooiae

prescient Frequency fluctuation 0.25%

Steady speed droop 0-3% (variable) f=

Temperature drift £4% (maximum)

IV, Adjustments

Before'starting engine: Check the wiring and remove connection 1 and connection

2. Measure the resistance value of the actuator. Then, use connection 1 and

Connection 2to touch positive and negative electrode of the battery jar. If applied, the

actuator will energize to maximum fuel position with a sound of Pa, and return to

‘minimum fuel position with another sound of Pa, when power is off. Atlast, check fuel

ump racks to insure they can move smoothly.

The FIRING adjustment: The FIRING adjustment sets the amount of firing supply. It

approximately points to mid position before turning on the power. Rotate the FIRING

‘adjustment clockwise to increase firing {uel supply and counterclockwise to decrease

it, Connect7 and 8, and rotate the FIRING clockwise to the end before turning on the

power. After adjustment ofthe unit, rotate the FIRING adjustment from clockwise

‘maximum to counterclockwise minimum, Start the engine. At the same time, rotate

the FIRING adjustment to a position where engine is just able to start. Then, start the

unitand adjust repeatedly until minimal smoke exhaust,

‘The SPEED RAMPING Adjustment: The SPEED RAMPING adjustment sets time

length of adjustment from engine's starting speed to rated speed. It originally points.

to mid position. Rotate the SPEED RAMPING adjustment clockwise to prolong the

time length, and counterclockwise to shorten it, Rotate the SPEED RAMPING.

anticlockwise to the end before turning on the power. Start the engine after adjusting

the unit. Atthe same time, adjust the SPEED RAMPING to minimal smoke exhaust

under the condition of smoothly starting

‘The SPEED adjustment: The SPEED adjustment sets rated speed of the engine. Itis

originally set as 1500 rpm. Rotate the SPEED adjustment clockwise to increase the

speed and anticlockwise to decrease the speed

‘The STABILITY adjustment: It originally points to mid position, Rotate the

STABILITY adjustment clockwise until instability develops after starting the engine

and adjusting the SPEED. Gradually move the adjustment counterclockwise un!

stability returns. And then rotate the GAIN 5-10 degree counterclockwise to insure

the stability (under any loading condition).

‘The GAIN adjustment: It originally points to mid position. Once the engine is at

‘operating speed, rotate the GAIN adjustment clockwise until instability develops.

Gradually move the adjustment counterclockwise untit stability returns. Move the

adjustment 5-10 degree counterclockwise to insure stable performance. (under any

loading condition)

‘The IDLE adjustment: The IDLE adjustment decides the idle speed. Itis originally

set within the range of required idle speed. The idle speed set point is increased by

clockwise rotation of the IDLE adjustment and decreased by counterclockwise

rotation, after 7 has been connected with13.A switch can be placed here to insure

engine's idle speed and rated speed.

V, Installation and Wiring

'$6700E is rugged enough to be placed in a control cabinet of engine. water. mist

‘or condensation may come in contact with the governor, it should be mounted

vertically to allow the fluid to drain away form the unit. Radioactive heat and high

temperature should be avoided. Install particular shielding device in case of strong

electromagnet.

Notice: in order to insure security and prevent loss, another over-speed shutdown

device should be provided to cut off fuel in case of fault.

Terminal Bolow 6 met Above 6 meters

[Connect 1-2 to the actuator| 2.5mm? 4.0mm?

Connect 3-4 to the speed

sensor (The lowest

operation signal between

Band4isAC 2.5V)

20.75mm? or 21mm? with shielding mesh,

the end of the shielding mesh on the unit

should be connected to 4.

Connect 6-6 to the battery 2 2

euy 2.5mm: 4.0 mm’

na pote ine ‘speed In electromagnetic field, cable shield should be

ive aera et t The shielding mesh should be connectec

Connect 3 tothe placed, The shielding mest should be contested

once Cofino OLE)

VI, Fault judgment and treatment

“symptoms, Probable cause Treatments:

Alexian fel system Discharge bal

: olaton speed signals top| Gheok ne sensor and cables

Power atthe governors eck he power au

Enginecannotbestarted | Gorconnectareversey | raring” PP

Divingbarsare deadlocked | pointe and aust

in null-position.

‘The adjusting direction of

fuel-adjustment mechanism

‘and movement direction of

the actuator conflict, ortheir | Check, reinstall and adjust

null-positions are not

Consietant with each other.

Engine starts ata higher

speeo

The rated spoedie eat too high| Decrease tho rated speed

‘Thegovernor parameter increase the GAIN moderately

heck and reinstall Drip

moderato amount cf engine oil

clamping siagnationottne [onthe preand post bearings

Givgboe Delve ie Pantin

Sctintorand rack pens or rales.

the gaps tovtarbe moves smooth mihiout any

[amping stagnation, ican be

eed normaly

Unstable engine Engiooverioass | reduce netoed ofihe engine

rotation speed: a educa tte tome ot eds

The instalation gapof peed | Checkand reinstall

tensor too (avout o.omm).

I) high trequenoy oscitation of

fotatlon speed. (> 10Hz)

(Governor parameter jecrease the GRIN moderately

adjusted wrongly ) low frequency oscillation of

talon speed (—1Hz) *

Iincreate the GAIN moderately.

Power supply ofthe governor | ong nower supply and cables

breaks off

[Feedback signals ofthe speed| Check the sensor and

breaks off its cables

Engine shuts off Selting signals ofthe speed | Check the remote-control

‘unexpectedly breaks off adjustment and its cables

[Open-cireultor short-cweultor

ons aeuba arent Check the actuator and

cable happens: iis.cabi

Fuel supply of the engine | Add fuel and discharge air

stoes inthe pipes

‘Null-positions of the actuator

‘nd control rack conflict Check and reinstall

Engine willnbt shut off

Control rack is deadlocked ‘Check and reinstall

‘The governor maintains

asstate of constant frequency Reset

‘The steady droop of the

device can nat be adjusted

‘Check and readjust or clean

Controtrackis deadlocked | Gheck and readhust orc

Notice: 1.the maximum fuel adjustment of the governor should be adjusted when engine

stops.

2. S6700E contains over-speed protection, whichis sel according o the rated speed,

However, the staring value may be unsuitable fr different users and can not be changed by

users. In order to insure securly, once engine's over-speed operation or runaway occurs,

ower supply of the governar should be off immediataly.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mtu 18v2000 PartsDocument156 pagesMtu 18v2000 PartsGerman E.100% (1)

- PGDLS310Document5 pagesPGDLS310German E.No ratings yet

- MOTORTECH Manual SparkView 40kV 01.10.021 EN 2013 03 WEBDocument28 pagesMOTORTECH Manual SparkView 40kV 01.10.021 EN 2013 03 WEBGerman E.No ratings yet

- GAC ActuadorDocument7 pagesGAC ActuadorGerman E.No ratings yet

- AMPS15599 - AMPS Power Magazine 2020, Issue 3 04e WebDocument44 pagesAMPS15599 - AMPS Power Magazine 2020, Issue 3 04e WebGerman E.No ratings yet

- Volvo Generator 500 KW V500uc2 IIDocument1 pageVolvo Generator 500 KW V500uc2 IIGerman E.No ratings yet

- Denyo Euro Spec BrochureDocument16 pagesDenyo Euro Spec BrochureGerman E.No ratings yet

- Option h5 h7 h12 h13 Engine Communication Agc 4 4189341231 UkDocument118 pagesOption h5 h7 h12 h13 Engine Communication Agc 4 4189341231 UkGerman E.No ratings yet

- Field Terminal Outer Insulator Installation 37MT, 41MT and 42MTDocument1 pageField Terminal Outer Insulator Installation 37MT, 41MT and 42MTGerman E.No ratings yet

- MOTORTECH SalesFlyer Valve Cover Conversion Kit MAN E32 Series 01.65.008 EN 2019 07Document4 pagesMOTORTECH SalesFlyer Valve Cover Conversion Kit MAN E32 Series 01.65.008 EN 2019 07German E.No ratings yet

- Universal Spare Parts Instructions 37MT, 41MT 42MTDocument2 pagesUniversal Spare Parts Instructions 37MT, 41MT 42MTGerman E.No ratings yet

- MOTORTECH SalesFlyer SparkView 40kV 01.15.019 EN 2015 08Document2 pagesMOTORTECH SalesFlyer SparkView 40kV 01.15.019 EN 2015 08German E.No ratings yet

- MOTORTECH InstructionLeaflet Hall Effect Pickup 66.60.043 L 01.12.044 EN 2020 11Document2 pagesMOTORTECH InstructionLeaflet Hall Effect Pickup 66.60.043 L 01.12.044 EN 2020 11German E.No ratings yet

- Field Coil Assembly or Pole Shoe Package Replacement Instructions 37MT, 41MT 42MTDocument4 pagesField Coil Assembly or Pole Shoe Package Replacement Instructions 37MT, 41MT 42MTGerman E.No ratings yet

- Volvo Generator Silent V500uc2 IiDocument1 pageVolvo Generator Silent V500uc2 IiGerman E.No ratings yet

- Semi Solid Link Solenoid Replacement Instructions For 29MT, 38MT 39MT HD StartersDocument1 pageSemi Solid Link Solenoid Replacement Instructions For 29MT, 38MT 39MT HD StartersGerman E.No ratings yet

- Agc 150 Installation Instructions 4189341185 UkDocument30 pagesAgc 150 Installation Instructions 4189341185 UkGerman E.No ratings yet

- 1104D-E44T and 1104D-E44TA Industrial Engine Electrical SystemDocument2 pages1104D-E44T and 1104D-E44TA Industrial Engine Electrical SystemGerman E.100% (1)

- Agc 150 Engine Communication 4189341302 UkDocument178 pagesAgc 150 Engine Communication 4189341302 UkGerman E.100% (1)

- Apd631v 6Document4 pagesApd631v 6German E.No ratings yet

- Industrial Diesel Generator Set - 60 HZ: General Specifications KOHLER Premium QualityDocument7 pagesIndustrial Diesel Generator Set - 60 HZ: General Specifications KOHLER Premium QualityGerman E.No ratings yet

- More Performance Through Real-Time Monitoring: With The Digital Myplant Apm Solution From Innio JenbacherDocument7 pagesMore Performance Through Real-Time Monitoring: With The Digital Myplant Apm Solution From Innio JenbacherGerman E.No ratings yet

- Caterpillar C9 D300 GC SubmittalDocument42 pagesCaterpillar C9 D300 GC SubmittalGerman E.No ratings yet

- Package Performance: Standby: 60 HZDocument30 pagesPackage Performance: Standby: 60 HZGerman E.No ratings yet

- Operation and Maintenance Manual: 1204F-E44TA and 1204F-E44TTA Industrial EnginesDocument148 pagesOperation and Maintenance Manual: 1204F-E44TA and 1204F-E44TTA Industrial EnginesGerman E.No ratings yet

- Select Series: Standby GeneratorsDocument4 pagesSelect Series: Standby GeneratorsGerman E.No ratings yet

- Specifications Systems Operation Troubleshooting Testing and AdjustingDocument44 pagesSpecifications Systems Operation Troubleshooting Testing and AdjustingGerman E.100% (1)

- Gwta6Rp G Build Engines: Gamma SeriesDocument2 pagesGwta6Rp G Build Engines: Gamma SeriesGerman E.No ratings yet

- Perkins Data Sheet PCS100-150PDocument4 pagesPerkins Data Sheet PCS100-150PGerman E.No ratings yet