Professional Documents

Culture Documents

3U-3UB - Iom1 (BOMBA)

Uploaded by

Paris AnabelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3U-3UB - Iom1 (BOMBA)

Uploaded by

Paris AnabelCopyright:

Available Formats

Models 3U / 3UB

End Suction Centrifugal

Operating Instructions, Installation & Maintenance Manual

EBARA Fluid Handling EBARA International Corporation

EBARA End Suction Centrifugal 3U / 3UB

Operating, Installation, and Maintenance

Contents

Section Page

Safety Specifications and Installation 3

3U / 3UB Selection Chart 5

3U / 3UB Specifications 6

3U / 3UB Type 1 Sectional View and Parts List 7

3U(B) 65 Type 3 Sectional View and Parts List 8

Installation Instructions 9

Maintenance and Service 10

3U / 3UB Assembly – 3HP - 15HP 11

3U / 3UB Assembly – 20HP - 30HP 12

Troubleshooting Checklist and Maintenance Information 13

WARNING

IMPORTANT SAFETY INSTRUCTIONS

Rules for Safe Installation and Operation

1. Read these rules and instructions carefully. Failure to follow them could cause serious bodily injury and/or property damage.

2. Check your local codes before installing. You must comply with their rules

3. For maximum safety, this product should be connected to a grounded circuit equipped with a ground fault interrupter device.

4. Before installing this product, have the electrical circuit checked by an electrician to make sure it is properly grounded.

5. Before installing or servicing your pump, BE CERTAIN pump power source is disconnected.

6. Make sure the line voltage and frequency of the electrical current supply agrees with the motor wiring. If motor is dual voltage

type, BE SURE it is wired correctly for your power supply.

7. Complete pump and piping system MUST be protected against below freezing temperature. Failure to do so could cause severe

damage and voids the Warranty.

8. Avoid system pressures that may exceed one and a half times the operating point selected from the pump performance curve.

9. Do not run your pump dry. If it is, there will be damage to the pump seal.

Installation

PACKAGE CONTENTS

1. Be sure all parts have been furnished and that nothing has been damaged in shipment.

2. The catalog lists all parts included with package. A packing list packed with pump, also lists contents.

3. OPEN PACKAGES AND MAKE THIS CHECK BEFORE GOING ON JOB.

PIPING – Pipes must line up and not be forced into position by unions. Piping should be independently supported near the

pump so that no strain will be placed on the pump casing. Where any noise is objectionable, pump should be insulated from

the piping with rubber connections. Always keep pipe size as large as possible and use a minimum of fittings to reduce

friction losses.

SUCTION PIPING – Suction pipe should be direct and as short as possible. It should be at least one size larger than suction

inlet tapping and should have a minimum of elbows and fittings (5 to 6 pipe diameters of straight pipe before inlet is recommended).

The piping should be laid out so that it slopes upward to pump without dips or high points so that air pockets are eliminated.

The highest point in the suction piping should be the pump inlet except where liquid flows to the pump inlet under pressure.

The suction pipe must be tight and free of air leaks or pump will not operate properly.

EBARA Fluid Handling

www.pumpsebara.com 3

(t) 803 327-5005 • (f) 803 327-5097 rev. 02/09

EBARA End Suction Centrifugal 3U / 3UB

Operating, Installation, and Maintenance

Rules for Safe Installation and Operation (continued)

DISCHARGE PIPING – Discharge piping should never be smaller than pump tapping and should preferably be one size

larger. A gate valve should always be installed in discharge line for throttling if capacity is not correct. To protect the pump

from water hammer and to prevent backflow, a check valve should be installed in the discharge line between the pump and

gate valve.

ELECTRICAL CONNECTIONS – Be sure motor wiring is connected for voltage being used. Unit should be connected to a

separate circuit. A fused disconnect switch or circuit breaker must be used in this circuit. Wire of sufficient size should be

used to keep voltage drop to a maximum of 5%.

Single phase motors have built-in overload protection. Flexible metallic conduit should be used to protect the motor leads.

PRIMING – The pump must be primed before starting. The pump casing and suction piping must be filled with water before

starting motor. When water is poured into pump to prime, remove all air before starting motor.

STARTING – When the pump is up to operating speed, open the discharge valve to obtain desired capacity or pressure.

WARNING! DO NOT ALLOW THE PUMP TO RUN WITH THE DISCHARGE VALVE TIGHTLY CLOSED. IF THE PUMP

RUNS FOR AN EXTENDED PERIOD OF TIME WITHOUT LIQUID BEING DISCHARGED, THE LIQUID IN THE PUMP

CASE CAN GET EXTREMELY HOT CAUSING SEVERE DAMAGE TO THE PUMP AND POSSIBLY CAUSE INJURY TO

PEOPLE.

ROTATION – All single phase motors are single rotation and leave factory with proper rotation. Three phase motors should

be checked to ensure proper rotation

FREEZING – Care should be taken to prevent the pump from freezing during cold weather. It may be necessary, when there

is any possibility of this, to drain the pump casing when not in operation. Drain by removing the pipe plug in the bottom of the

casing.

ROTARY SEAL – PRO STEEL pumps are fitted only with rotary seal. This seal is recommended for LIQUIDS free from abrasives.

LOCATION OF UNIT – The pump should be installed as near to the liquid source as is practical so that the static suction

head (vertical distance from the center line of the pump to water level) is maximized, and so that a short, direct suction pipe

may be used. The capacity of a centrifugal pump is reduced when the unit is operated under a high suction lift. The piping

should be as free from turns and bends as possible, as elbows and fittings greatly increase friction loss. Place the unit so that

it is readily accessible for service and maintenance and on a solid foundation, which provides a rigid and vibration-free sup-

port. Protect the pump against flooding and excess moisture.

EBARA Fluid Handling

www.pumpsebara.com 4

(t) 803 327-5005 • (f) 803 327-5097 rev. 02/09

EBARA End Suction Centrifugal 3U / 3UB

Operating, Installation, and Maintenance

Model 3U / 3UB Selection chart Synchronous Speed 3450 RPM

3

M /MIN

0.1 0.2 0.3 0.4 0.5 0.6 0.8 1.0 1.5

Ft

100M

300

*40-200B-15HP 80

32-200-1-10HP 8

200 60

*40-200A- 9

32-200- 15HP

7½HP 7 6 50

150

TOTAL HEAD

32-160B-5HP 40

*50-160-1

40-160-1- 15HP

10HP 5

32-160A-5HP 50-160-

100 10HP 30

40-160-

7½HP

80 50-125-1

10HP

40-125B- 4

5HP 20

60

32-125-3HP 3

50 15

50-125

40-125A- 7½HP 2

40

5HP

1

10

30

20 30 40 50 60 80 100 150 200 300 400 600 700

CAPACITY IN GPM

*Three phase motor only

1. 3U65-125-7.5HP

2. 3U65-125-10HP

3. 3U65-160-10HP

4. 3U65-160-15HP*

5. 3U65-160-20HP*

6. 3U65-160-25HP*

7. 3U65-200-20HP*

8. 3U65-200-25HP*

9. 3U65-200-30HP*

EBARA Fluid Handling

www.pumpsebara.com 5

(t) 803 327-5005 • (f) 803 327-5097 rev. 02/09

EBARA End Suction Centrifugal 3U / 3UB

Operating, Installation, and Maintenance

Specifications

Standard Optional

Size

Suction 3U32 – 2'' ANSI Equivalent Companion Flange kit

(150 lb. ANSI R.F. equivalent) 3U40 – 21/2'' ANSI Equivalent 150 Lb. ANSI, Female NPT

3U50 – 21/2'' ANSI Equivalent

3UB65 – 3'' ANSI Equivalent

Discharge 3U32 – 11/4'' ANSI Equivalent

(150 lb. ANSI R.F. equivalent) 3U40 – 11/2'' ANSI Equivalent

3U50 – 2'' ANSI Equivalent

3UB65 – 21/2'' ANSI Equivalent

Range of HP 3U – 3 HP to 15 HP

3UB – 71/2 HP to 30 HP

Range of Performance

Capacity 13 to 750 GPM at 3450 RPM

Head 33 to 250 feet at 3450 RPM

Liquid handled

Type of liquid Clean water

Temperature 212°F (100°C) Max. 250°F (121°C) with optional

high temperature seal

Max. working pressure 230 PSI (15 Bar)

Materials 3U 3UB

Casing 304L Stainless Steel 304L Stainless Steel

Impeller (closed type) 304L Stainless Steel Bronze Stainless steel option for 3UB models

Shaft Sleeve 304L Stainless Steel 304L Stainless Steel

Bracket Cast iron Cast iron

Shaft Seal Mechanical Seal – Type 21

Seal Material Carbon/Ceramic/Viton Consult factory for additional

Carbon/Ceramic/Buna optional seal availability

Hot water – Carbon/Ni-Resist/Viton, 250°F (121°C) max.

Direction of Rotation Clockwise when viewed from motor end

Motor

Type NEMA JM, TC, TSC Frame

Speed 60 Hz, 3450 RPM (2 poles) 4 pole – consult factory as noted

Bearing Ball Bearing

Single Phase TEFC – 3 HP

ODP – 3 HP to 10 HP

Three Phase TEFC – 3 HP to 30 HP Explosion proof – consult factory

ODP – 3 HP to 30 HP for availability

208-230/460V Washdown duty – consult factory

Motor Protection Overload protection must be provided for availability

Standard Accessories Suction and Discharge Flange Gasket

Motor support

EBARA Fluid Handling

www.pumpsebara.com 6

(t) 803 327-5005 • (f) 803 327-5097 rev. 02/09

EBARA End Suction Centrifugal 3U / 3UB

Operating, Installation, and Maintenance

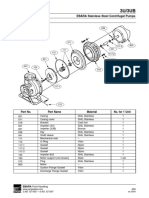

Sectional view – 3U / 3UB Type 1

039

011

117-3 800

111 041

115

021 129

135-1

001 125

018

117-2

117-1

212

Part No. Part Name Material No. for 1 Unit

001 Casing 304L Stainless 1

011 Casing cover 304L Stainless 1

018 Bracket Cast Iron 1

021 Impeller (3U) 304L Stainless 1

021 Impeller (3UB) Bronze 1

039 Key 304L Stainless 1

041 Shaft sleeve 304L Stainless 1

111 Mechanical seal – 1

115 O-Ring Viton 1

117-1 Gasket Nylon 1

117-2 Gasket Nylon 1

117-3 Gasket Nylon 1

125 Impeller Bolt 304L Stainless 1

160 Motor support (not shown) Steel 1 set

212 Plug 304L Stainless 1

800 Motor – 1

Suction Flange Gasket Viton 1

Discharge Flange Gasket Viton 1

EBARA Fluid Handling

www.pumpsebara.com 7

(t) 803 327-5005 • (f) 803 327-5097 rev. 02/09

EBARA End Suction Centrifugal 3U / 3UB

Operating, Installation, and Maintenance

Sectional view – Model 3U 65 Type 3

3U 65-160/20

3U 65-160/25

3U 65-200/20

3U 65-200/25

3U 65-200/30

Part No. Part Name Material No. for 1 Unit

001 Casing 304L Stainless 1

003 Motor bracket Cast iron 1

003A Adapter ring Cast iron 1

004 Casing cover 304L Stainless 1

006 Coupling Steel / Stainless steel 1

007 Impeller Bronze/optional Stainless Steel 1

011 Mechanical seal 1

012 Motor 1

025 Drain plug 304L Stainless 1

026 O-ring Viton 1

032 Key 304L Stainless 1

034 Impeller nut Stainless / Nylon 1

040 Flange Gasket EPDM 2

041 Flange Gasket EPDM 2

042 Motor support Steel 2

042A Casing support (65-160 25HP only) Steel 2

044 Coupling guard Stainless Steel 2

234 Lip seal 304L Stainless 1

EBARA Fluid Handling

www.pumpsebara.com 8

(t) 803 327-5005 • (f) 803 327-5097 rev. 02/09

EBARA End Suction Centrifugal 3U / 3UB

Operating, Installation, and Maintenance

3U / 3UB Installation Instructions

Mounting the Assembly

Do not operate the pump unless the assembly is securely and properly mounted.

Misalignment of the motor/pump assembly or not having the assembly reasonably level may cause pump vibration,

noisy operation, fluid leaks, or air leaks and air locks in the suction pipe.

1. Place the motor/pump assembly in its intended operating position.

2. Level the pump through the centerline of the motor/pump assembly suction port.

Initial Operation WARNING

Initialcertain

Make Operation

the motor is not connected to a power source until the motor is properly assembled and mounted.

Make certain

Serious the injury

personal motor oris damage

not connected

to the to a power source

motor/pump until the

assembly motor

could is ifproperly

occur the motorassembled andimproperly.

is activated mounted.

Serious personal injury or damage to the motor/pump assembly could occur if the motor is activated improperly.

Only certified electricians should make electrical connections.

Only certified electricians should make electrical connections.

1. Prime the pump by adding fluid to the volute case through the top plug.To properly prime the pump, venting

1. may

Prime

bethe pump by adding fluid to the volute case through the top plug.To properly prime the pump, venting

required.

may be required.

2. Check the nameplate on the motor to determine the correct wiring procedure for your intended power source

2. and

Check themotor

if the nameplate

is singleonorthe motor

three to determine

phase. the motor

Connect the correct

towiring procedure

a power source by forfollowing

your intended power

the wiring procedure

source

on and if the

the motor's motor is single or three phase. Connect the motor to a power source by following the wiring

nameplate.

procedure on the motor's nameplate.

Note:

a. Single phase motors are typically dual voltage. In some cases, three phase motors are tri-voltage. Check the

nameplate and follow the proper wiring procedure for the voltage you are using. Improperly wiring the motor

could result in damage to the motor.

b. Three phase motors require a control box. Install overload protection to help prevent motor damage.

c. Depending on the wiring, three phase motors may start in reverse. Interchange any two power leads to

change the starting direction and pump rotation.

• Always follow correct operating procedures.

• Always disconnect the motor/pump assembly from all power sources before servicing the pump or motor.

• Periodically check all power connections, bolts, screws, and the motor's mounting.

• Failure to properly follow assembly and operating instructions could result in damage to the pump and motor.

• Failure to properly install the impeller and impeller nut could result in damage to the pump and could cause

serious personal injury.

EBARA Fluid Handling

www.pumpsebara.com 9

(t) 803 327-5005 • (f) 803 327-5097 rev. 02/09

EBARA End Suction Centrifugal 3U / 3UB

Operating, Installation, and Maintenance

Maintenance

Service

Keep ventilation openings clear of extraneous objects which may hinder free flow of air thru motor. Motor bearings are lubricated

during manufacture. Additional lubrication is not required during their normal lifetime.

CAUTION

Draining

The pump and piping should always be protected against freezing temperatures. If there is any danger of freezing, the unit

should be drained. To drain the pump, remove the drain plug at the bottom of the volute, and remove the priming plug to

vent the pump. Drain all piping.

Disassembly Instructions

All pumping parts can be removed from case without disturbing the piping.

WARNING

POWER SUPPLY – Open the power supply switch contacts and remove fuses. Disconnect the electrical wiring from the motor.

VOLUTE CASE

(a) Drain pump case by removing drain plugs.

(b) Remove the bolts securing volute case to pump bracket.

(c) Pry volute case from casing cover with a screwdriver.

IMPELLER

(a) Hold the motor shaft with a screwdriver in the shaft end slot. Grasp and turn the impeller counterclockwise (as viewed

from pump end).

SEAL

(a) Remove the rotating part of the seal by pulling it off the shaft.

(b) The stationary seat can be pressed from the casing cover.

CHECK LIST FOR EXAMINATION OF PUMP PARTS

IMPELLER - Replace the impeller if any vane is broken, excessive erosion shows, or if labyrinth surfaces are worn. Impeller

cap screw, washer and lockwasher should be replaced if damaged.

MECHANICAL SEAL - Seal face, O-ring and sealing members should be free of burrs and dirt. Complete seal assembly

should be replaced if not in perfect condition.

SHAFT- Shaft sleeve surface under seal or packing must be clean, smooth and without any grooves. It should be replaced if

necessary.

VOLUTE AND SEAL/PACKING PLATE LABYRINTH SURFACES (Wear Rings)- If worn, replace the necessary part. If fur-

nished with pressed in wear rings, only the rings need be replaced.

GASKETS - Volute, suction pipe and discharge pipe gaskets should be checked for damage. Replace if necessary.

NOTE

If replacement parts are ordered, please furnish the following information to your EBARA distributor:

1. Reference Numbers

2. Description of Pump Part

3. EBARA Model Number and Serial Number on the Nameplate.

EBARA Fluid Handling

www.pumpsebara.com 10

(t) 803 327-5005 • (f) 803 327-5097 rev. 02/09

EBARA End Suction Centrifugal 3U / 3UB

Operating, Installation, and Maintenance

3U / 3UB Assembly Instructions

Position the pump on its end with the shaft up. The work surface should be level, capable of supporting the motor.

WARNING

Make certain the motor is not connected to a power source. Do not install or assemble the pump on a motor

connected to a power source. Serious injury could occur if the motor activates during pump assembly.

Assembling the Pump – Models 3HP - 15HP (see page 7 for sectional view)

1. Position a Nylon gasket (117-3) over the motor shaft.

2. Carefully press the rotating seal assembly onto the shaft sleeve (041). The smooth face of the

rotating ring must make good contact with the seal seat and the seal retainer must seal against the shaft sleeve.

Note: Seal faces should be wiped clean with non-oil based solvent or alcohol.

3. Using finger pressure only, insert the seal seat into the casing cover (011). Press the seal until it evenly

bottoms out in the seal cavity.

4. Position the cast iron motor bracket (018) over the shaft. Fasten the bracket to the motor, tightening bolts

using a cross-tightening pattern. (Tighten the bolts to the factory recommended torque specifications of 8 ft. lbs.)

Overtightening may cause stripping of threads.

5. Carefully position the casing cover (011) and seal over the shaft. Be careful not to damage the stationary

seal seat.

6. Slide the stainless steel shaft sleeve, with rotating assembly, over the motor shaft.

7. Position the O-ring (115) around the casing cover (011). Do not cut, nick, or damage the O-ring during the

installation.

8. Install the impeller shaft key (3/16" x 3/16" x 1 3/16").

9. Place the seal spring assembly over the rotating piece of the seal in position to receive the impeller.

10. Place a Nylon gasket (117-2) on top of spring retainer.

11. Firmly press the impeller (021) into position by aligning the slot over the shaft key. Press the impeller down

the shaft until it bottoms and seats squarely against the Teflon gasket (117-2) and shaft sleeve (041).

12. Place a Nylon gasket (117-1) over the impeller hub and into the impeller eye. Install the impeller bolt (125) to

secure the impeller to the shaft. Do not overtighten the shaft bolt. (Use a thread compound or cement to

secure the shaft bolt and prevent it from working loose.)

13. Tighten the impeller bolt. (Tighten the bolts to the factory recommended torque specifications of 11 ft. lbs.)

14. Install the pump volute (001) over the seal plate. Rotate the volute to align with the bolt holes and secure it

with the bolts, washers, and nuts. Cross-tighten the bolts to the factory recommended torque specifications

(8 ft. lbs.).

15. With a socket wrench, rotate impeller to check for alignment. If rubbing against casing, loosen bolts on

casing and retighten.

EBARA Fluid Handling

www.pumpsebara.com 11

(t) 803 327-5005 • (f) 803 327-5097 rev. 02/09

EBARA End Suction Centrifugal 3U / 3UB

Operating, Installation, and Maintenance

Assembling the Pump – Models 20HP - 30HP (see page 8 for sectional view)

1. Apply a coat of anti-seize lubricant to the inside of the coupling (005).

2. Insure that key is installed in motor shaft keyway, slide coupling (005) onto shaft. (Tip: To ease the installation

of the coupling tighten the set screw on the side of the coupling. Tightening this screw will cause the coupling

to open slightly allowing for easier installation. After the coupling is in place be sure to loosen the set screw

to release the pressure and allow the coupling to close down on the motor shaft.)

3. Secure the coupling to the motor shaft by tightening the socket head bolts in the side of the coupling. Torque

to 11ft. lbs.

4. Fasten the adapter ring (003A) to the motor using a cross tightening pattern.

5. Fasten the motor bracket (003) to the adapter ring.

6. Apply a thin coat of non-petroleum based lubricant (i.e. dish soap) to the stationary seal seat in the casing

cover (004), using finger pressure only press the stationary seal into the seal seat. Wipe the seal face clean

with alcohol and a soft cloth.

7. Position the o-ring ( 026 ) around the casing cover.

8. Using hand pressure or a rubber mallet, press fit the casing cover ( 004 ) onto the motor bracket (003).

9. Apply a thin coat of non-petroleum based lubricant (i.e. dish soap) to the inside of the rubber boot on the

rotating seal. Slide the seal onto the coupling pushing it gently until it contacts the stationary seal that was

installed in step 6. Place the spring and spring retainer over the coupling and onto the rotating seal.

10. Place the stainless steel lip seal (234) onto the spring retainer insuring that the raised surface of the lip seal

seats into the spring retainer.

11. Install the impeller shaft key (032) into the coupling shaft.

12. Slide impeller (007) over the key and shaft.

13. Tighten the impeller nut (034) to secure the impeller in place. Tighten to 11 ft.lbs

14. Install Casing (001). Take care to align the bolt holes. Cross tighten the bolts to 8 ft. lbs.

15. With a socket wrench, rotate impeller to check for proper casing alignment. If rubbing against casing occurs

loosen casing bolts and retighten taking care to cross-tighten and use equal torque.

16. Install motor support (042) or casing support (042A) as required.

EBARA Fluid Handling

www.pumpsebara.com 12

(t) 803 327-5005 • (f) 803 327-5097 rev. 02/09

EBARA End Suction Centrifugal 3U / 3UB

Operating, Installation, and Maintenance

Troubleshooting

TROUBLE POSSIBLE CAUSE TROUBLESHOOTING

Pump does not run. Faulty connection of power supply circuit. Check power supply circuit.

Wrong wiring of control circuit. Correct control circuit.

Bound shaft Remove cause of obstruction.

Mechanical seal faces stuck together Release seal by turning shaft.

Faulty motor Repair or replace motor.

Damage to bearing Repair or replace any damaged bearing.

Pump does not pump water. Considerable voltage drop. Correct rotation direction.

Inadequate quantity. Rotation direction reversed. Re-prime the pump.

Lack of priming. Re-examine the plan.

High discharge head. Re-examine the plan.

Large piping loss. Clear foot valve suction.

Clogged foot valve. Check and repair suction piping.

Leakage from suction piping. Re-install as per our instructions.

Too high suction lift. Foot valve in ample immersion.

Low water level.

Overcurrent Considerable fluctuation of power supply Throttle flow rate at outlet.

voltage. Replace any damage bearing.

Considerable voltage drop.

Low head and overflow rate.

Damaged bearing.

Pump vibrates, excessive operating Beyond rated capacity. Reduce flow rate.

noise Cavitation. Consult distributor

Improper piping. Secure piping again.

Damaged bearing. Replace any damaged bearing.

Foreign matter clogging cooling fan. Remove foreign matter.

Pressurizing application. Too limited pressure switch setting. Replace pressure switch to wider range.

Pump starts and soon stops Check and repair leaks.

Pump does not stop Leakage in system. Reduce max pressure setting to the

Too high pressure setting. lower in pressure switch.

MAINTENANCE:

The pump does not require special maintenance.

The following rules must be observed for safe operation:

If the pump is not going to be used for a long period, the pump should be drained of water and flushed with clean water.

Where the pump is exposed to freezing temperatures, it should always be left drained when not in use.

*All specifications subject to change without notice.

EBARA Fluid Handling

www.pumpsebara.com 13

(t) 803 327-5005 • (f) 803 327-5097 rev. 02/09

Contact your dealer or supplier

for more information about other EBARA products

EBARA Fluid Handling

1651 Cedar Line Drive • Rock Hill, SC 29730

(t) 803 327 5005 • (f) 803 327 5097

www.pumpsebara.com

© 2005 EBARA International Corporation EFH 3U_3UB0209

You might also like

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- EVMU-EVMUG - Instruction and OperationDocument44 pagesEVMU-EVMUG - Instruction and OperationDavidThânNo ratings yet

- Berkeley Ownwes ManualDocument28 pagesBerkeley Ownwes ManualMoses Alvarado100% (1)

- Submersible Sewage Pump: Model DLU Model DLMUDocument16 pagesSubmersible Sewage Pump: Model DLU Model DLMUT Deus PrizfelixNo ratings yet

- Armstrong Installation43.80 VIL I&ODocument14 pagesArmstrong Installation43.80 VIL I&Osas999333No ratings yet

- Manual 606A-607Document36 pagesManual 606A-607Hoàng Nguyễn50% (2)

- Manual Rotámetro - 0.02 - 1.2 LPM Key InstrumentsDocument2 pagesManual Rotámetro - 0.02 - 1.2 LPM Key InstrumentsMax SdNo ratings yet

- Model DVSU Model DVSHU: Submersible Semi-Open Vortex Sewage PumpDocument12 pagesModel DVSU Model DVSHU: Submersible Semi-Open Vortex Sewage PumpVũ Đình QuangNo ratings yet

- Models: CDU CDX 2cdu 2Cdx: Instruction and Operation ManualDocument19 pagesModels: CDU CDX 2cdu 2Cdx: Instruction and Operation ManualHoàng Điệp NguyễnNo ratings yet

- 2400 Series IORPMDocument24 pages2400 Series IORPMab5951No ratings yet

- Owners ManualDocument20 pagesOwners ManualJavier AffifNo ratings yet

- Multistage Vertical Inline Pumps PM1, PM3, PM5 Series: Specifications Information and Repair Parts ManualDocument12 pagesMultistage Vertical Inline Pumps PM1, PM3, PM5 Series: Specifications Information and Repair Parts ManualAnibal QuezadaNo ratings yet

- 2300 Series ManualDocument24 pages2300 Series ManualJuprayNo ratings yet

- SHURflo 8000seriesDocument8 pagesSHURflo 8000seriesab5951No ratings yet

- Rotametro KeyDocument2 pagesRotametro Keydocumentos.envirotestNo ratings yet

- Blackmer Maintenance ScheduleDocument16 pagesBlackmer Maintenance ScheduleAbrar HussainNo ratings yet

- Installation AND Operation Manual: PremierDocument23 pagesInstallation AND Operation Manual: Premieralejandro jimenezNo ratings yet

- Owners Manual: Frame Mounted Centrifugal PumpDocument32 pagesOwners Manual: Frame Mounted Centrifugal Pumprhusseinpos4765No ratings yet

- 325 Lanzhou 3NB1300C Instruction Manual PDFDocument21 pages325 Lanzhou 3NB1300C Instruction Manual PDFOilGasManNo ratings yet

- G Series Industrial and Chemical Owners ManualDocument20 pagesG Series Industrial and Chemical Owners ManualbayuNo ratings yet

- Blackmer Power Pumps: Models: Xl2B, Xl3B, Xl4CDocument12 pagesBlackmer Power Pumps: Models: Xl2B, Xl3B, Xl4CKhoh Kai ShengNo ratings yet

- Manual M100T Series 50 60Document18 pagesManual M100T Series 50 60Samir KhanNo ratings yet

- Manual Bomba SumergibleDocument18 pagesManual Bomba SumergibleDavic LimachiNo ratings yet

- WEBTROL SP Series Self-Priming Centrifugal PumpDocument8 pagesWEBTROL SP Series Self-Priming Centrifugal PumpSilvan ZupancNo ratings yet

- WWH-IW-003 - A - Mounting and OperatingDocument24 pagesWWH-IW-003 - A - Mounting and OperatingKevin CavanaughNo ratings yet

- Operating Book For Mud Pump 2Document57 pagesOperating Book For Mud Pump 2Kaleem Ullah100% (3)

- Seven Inch Borewell Submersible Pump Sets: Instruction & Operating ManualDocument38 pagesSeven Inch Borewell Submersible Pump Sets: Instruction & Operating ManualUNITY LEARN100% (1)

- 3530 Pump Installation ManualDocument7 pages3530 Pump Installation ManualAnonymous 7xHNgoKE6eNo ratings yet

- Two Stage Water Ring Vacuum PumpDocument24 pagesTwo Stage Water Ring Vacuum PumpHassan FarazNo ratings yet

- Operating and Maintenance Manual LPG: M-285 Rev. G P.D. Oscillating Piston Flowmeter 1 4D-MD LP GasDocument20 pagesOperating and Maintenance Manual LPG: M-285 Rev. G P.D. Oscillating Piston Flowmeter 1 4D-MD LP GasCarlos RondonNo ratings yet

- Install, Operate and Maintain Sam Turbo Pump GuideDocument25 pagesInstall, Operate and Maintain Sam Turbo Pump GuidePradyumna Keshari NahakNo ratings yet

- Uploads Productz Technical Specs Tech Tech FFB PDFDocument4 pagesUploads Productz Technical Specs Tech Tech FFB PDFDenata Machmud SugandhiNo ratings yet

- Uploads Products Technical Specs TECH Tech FFBDocument4 pagesUploads Products Technical Specs TECH Tech FFBMuthu KumarNo ratings yet

- D-040 Rev 004 E150 Pump ELASTECDocument13 pagesD-040 Rev 004 E150 Pump ELASTECalvaro yepes oviedoNo ratings yet

- Super Polecat EvaporatorDocument39 pagesSuper Polecat Evaporatormezarafael6No ratings yet

- 7.06 EC 10M SINGLE BOP manDocument20 pages7.06 EC 10M SINGLE BOP manRafael BolivarNo ratings yet

- Sl-Series Installation Instructions: Important! Refer To Local Code Requirements Before Wiring MachinesDocument19 pagesSl-Series Installation Instructions: Important! Refer To Local Code Requirements Before Wiring MachinesEdwilson ReisNo ratings yet

- HS-3,4,6,7 (R) Ec-Series Installation: Important! Refer To Local Code Requirements Before Wiring MachinesDocument53 pagesHS-3,4,6,7 (R) Ec-Series Installation: Important! Refer To Local Code Requirements Before Wiring MachinesEdwilson ReisNo ratings yet

- Two Stage Water Ring Vacuum Pump PDFDocument24 pagesTwo Stage Water Ring Vacuum Pump PDFvallamreddyNo ratings yet

- Sumo Pump: User and Maintenance ManualDocument31 pagesSumo Pump: User and Maintenance Manualcguillermosm100% (1)

- TEEL BRONZE ROTARY PUMP Manual & Parts ListDocument8 pagesTEEL BRONZE ROTARY PUMP Manual & Parts ListMoToBunnYNo ratings yet

- 2761 252 00Document8 pages2761 252 00joravicaNo ratings yet

- Psertx Phpb03u en - RevbDocument28 pagesPsertx Phpb03u en - RevbvjrNo ratings yet

- TITLE - Catalytic Converter Installation Requirements and RecommendationsDocument5 pagesTITLE - Catalytic Converter Installation Requirements and RecommendationsDmitryNo ratings yet

- m9143ws MPB Series Booster Pump DsDocument4 pagesm9143ws MPB Series Booster Pump DsJade AlexanderNo ratings yet

- O&m RnaaDocument20 pagesO&m RnaaГеннадий ПарфентьевNo ratings yet

- Anexo 1Document110 pagesAnexo 1rhusseinpos4765No ratings yet

- BT Series Owners Manual - CombinedDocument142 pagesBT Series Owners Manual - Combinedalejandro777_eNo ratings yet

- IFC6000 ManualDocument8 pagesIFC6000 ManualJohn Alexander Bonilla AngelNo ratings yet

- PUMPEX Service Instructions Sp20 80Document19 pagesPUMPEX Service Instructions Sp20 80Teodor BochevNo ratings yet

- Biodiesel Pump - 115V - 20 GPMDocument4 pagesBiodiesel Pump - 115V - 20 GPMOrganic MechanicNo ratings yet

- Install, Operate and Maintain SAM Turbo PumpDocument40 pagesInstall, Operate and Maintain SAM Turbo Pumpsanjayagrawal70-1No ratings yet

- Full Artesian2 Owners ManualDocument7 pagesFull Artesian2 Owners ManualbrandonjjarvisNo ratings yet

- 4 and 6 Submersible Manual 09-13 - WEBDocument24 pages4 and 6 Submersible Manual 09-13 - WEBnikosag86No ratings yet

- 300Q, 250T, 200T, 165T, 60T, 80T, 130T, 30T, 100T ManualDocument73 pages300Q, 250T, 200T, 165T, 60T, 80T, 130T, 30T, 100T ManualDonovan SookrajNo ratings yet

- Centro-Matic: Model 84050 (Series F ) Model 85460 (Series A ) Air Operated PumpDocument8 pagesCentro-Matic: Model 84050 (Series F ) Model 85460 (Series A ) Air Operated PumpSIDI ahmedou yahyaNo ratings yet

- OwnersManChemstar 1400N 1402N 1376N 1374NDocument36 pagesOwnersManChemstar 1400N 1402N 1376N 1374NvankarpNo ratings yet

- Compact Dehumidifier Fluted Flat Bed - FFB Series: Technical Data SheetDocument4 pagesCompact Dehumidifier Fluted Flat Bed - FFB Series: Technical Data SheetLê ĐạtNo ratings yet

- Copeland Condensing Unit Selection Guide For Commercial RefDocument151 pagesCopeland Condensing Unit Selection Guide For Commercial RefParis AnabelNo ratings yet

- SENTRON SiemensDocument50 pagesSENTRON SiemensParis AnabelNo ratings yet

- Viza Gate Globe Check ValveDocument32 pagesViza Gate Globe Check ValveariffstudioNo ratings yet

- P-SRF N: Process Sterile Air Filter ElementsDocument6 pagesP-SRF N: Process Sterile Air Filter ElementsParis AnabelNo ratings yet

- DIN 7500 D: Thread Forming Screws Steel, Case-HardenedDocument7 pagesDIN 7500 D: Thread Forming Screws Steel, Case-HardenedParis AnabelNo ratings yet

- Wilk IrsonDocument534 pagesWilk IrsonParis AnabelNo ratings yet

- 750-94 OM Manual ModelCBLE-400-800HP Dec09Document194 pages750-94 OM Manual ModelCBLE-400-800HP Dec09Elio Santana GonzenbachNo ratings yet

- Hora Main CatalogoDocument452 pagesHora Main CatalogoParis AnabelNo ratings yet

- Seccionador AbbDocument36 pagesSeccionador AbbParis AnabelNo ratings yet

- Grundfosliterature 2950863Document82 pagesGrundfosliterature 2950863Paris AnabelNo ratings yet

- Model 3U/3UB Exploded View 3U 3UB Type 1 EBARA Stainless Steel Centrifugal PumpsDocument2 pagesModel 3U/3UB Exploded View 3U 3UB Type 1 EBARA Stainless Steel Centrifugal PumpsPedro MercedesNo ratings yet

- Sitrans P DS III .PDDocument254 pagesSitrans P DS III .PDParis AnabelNo ratings yet

- Catlg GeneralDocument50 pagesCatlg GeneralParis AnabelNo ratings yet

- Closed-Coupled Pump Etabloc Installation-Operating ManualDocument60 pagesClosed-Coupled Pump Etabloc Installation-Operating ManualUdo IheanachoNo ratings yet

- Slaney Direct Ltd Control Valve CatalogueDocument15 pagesSlaney Direct Ltd Control Valve CatalogueParis AnabelNo ratings yet

- Bomba KSB Etablock y Etaline SYDocument4 pagesBomba KSB Etablock y Etaline SYParis AnabelNo ratings yet

- ZT 250 FaltanteDocument170 pagesZT 250 FaltanteParis AnabelNo ratings yet

- CHAPTER 9 - CompressedDocument42 pagesCHAPTER 9 - CompressedParis AnabelNo ratings yet

- M-33 Diesel Generator Engine ManualDocument847 pagesM-33 Diesel Generator Engine ManualJibu George Thomas100% (7)

- UPP Piping Installation GuideDocument16 pagesUPP Piping Installation GuidelowiyaunNo ratings yet

- Physics Past Paper Cape 2007-2011Document58 pagesPhysics Past Paper Cape 2007-2011Romon Deane90% (10)

- XG AC DC Annual Maint ScheduleDocument28 pagesXG AC DC Annual Maint ScheduleAnonymous YPx8ss48No ratings yet

- 175 140500Document2 pages175 140500Abu Anas M.SalaheldinNo ratings yet

- Ale75w Ale120wDocument26 pagesAle75w Ale120wThanh BarcaNo ratings yet

- EE 143 Microfabrication Technology Fall 2014: Prof. Clark T.-C. NguyenDocument9 pagesEE 143 Microfabrication Technology Fall 2014: Prof. Clark T.-C. NguyenstansilawNo ratings yet

- Electrocraft EAD BLDC CatalogDocument16 pagesElectrocraft EAD BLDC CatalogElectromateNo ratings yet

- 132kV Cable & FO Cable Layout in CUP S/SDocument16 pages132kV Cable & FO Cable Layout in CUP S/SSuprodip Das100% (1)

- Iran Deal Draft UNSC Resolution As Uploaded by Inner City PressDocument14 pagesIran Deal Draft UNSC Resolution As Uploaded by Inner City PressMatthew Russell LeeNo ratings yet

- Hydraulic SymbolsDocument1 pageHydraulic SymbolsHemil ChauhanNo ratings yet

- Engineering Chemistry Unit - 3 Surface ChemistryDocument9 pagesEngineering Chemistry Unit - 3 Surface ChemistryAnish Babu100% (1)

- Catalytic: Cracking Acetic Acid To AceticDocument6 pagesCatalytic: Cracking Acetic Acid To AceticPawan NagarNo ratings yet

- Service Manual Ve d12Document32 pagesService Manual Ve d12ramsi17100% (1)

- Sample GEO F3 TEST2 QDocument7 pagesSample GEO F3 TEST2 QBilly Lau0% (1)

- Installing Takegawa Hyper Cam (KLX110/DRZ110)Document1 pageInstalling Takegawa Hyper Cam (KLX110/DRZ110)MinibikeTechNo ratings yet

- Turnkey Epc Services: Your Path To A Prosperous ProjectDocument4 pagesTurnkey Epc Services: Your Path To A Prosperous Projectmarketingsunfix sunfixNo ratings yet

- Introduction to VAT exemptionsDocument102 pagesIntroduction to VAT exemptionsNatalie SerranoNo ratings yet

- Book of Wicca Spells PDFDocument20 pagesBook of Wicca Spells PDFfederica santovecchi100% (4)

- Bsbsus401 Implement and Monitor Environmentally Sustainable Work Practices AssessmentDocument62 pagesBsbsus401 Implement and Monitor Environmentally Sustainable Work Practices Assessmentfaraz83% (6)

- The Singapore EngineerDocument52 pagesThe Singapore EngineerGary GohNo ratings yet

- Gasification For Practical ApplicationsDocument352 pagesGasification For Practical ApplicationsOthmane DrissiNo ratings yet

- Method Statement - Underground Cable Laying Rev04Document26 pagesMethod Statement - Underground Cable Laying Rev04Ahamed UmarNo ratings yet

- Italian Submersible Pumps and Motors Manufacturer Since 1906Document286 pagesItalian Submersible Pumps and Motors Manufacturer Since 1906Diana NietoNo ratings yet

- English For Engineering PDFDocument259 pagesEnglish For Engineering PDFDan AndraNo ratings yet

- Design, Fabrication and Analysis of Fibonacci TurbineDocument5 pagesDesign, Fabrication and Analysis of Fibonacci TurbinearcaldartNo ratings yet

- Construction Drawing: Lac Long Company Limited Solar Rooftop Project 1073.4 KWPDocument21 pagesConstruction Drawing: Lac Long Company Limited Solar Rooftop Project 1073.4 KWPDat TranNo ratings yet

- Q4 LESSON 3 (Fire Hazards)Document15 pagesQ4 LESSON 3 (Fire Hazards)WhySoSerious?No ratings yet

- Aquapol Cosmic Dehydration by Wilhelm MohornDocument16 pagesAquapol Cosmic Dehydration by Wilhelm MohornJason Verbelli100% (3)

- Unit - 4 - Power Electronics and Energy Storage in Smart GridDocument50 pagesUnit - 4 - Power Electronics and Energy Storage in Smart GridsujithNo ratings yet