Professional Documents

Culture Documents

Supply Chain Management of ZARA

Supply Chain Management of ZARA

Uploaded by

Nagaraj NavalgundCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Supply Chain Management of ZARA

Supply Chain Management of ZARA

Uploaded by

Nagaraj NavalgundCopyright:

Available Formats

ZARA Supply Chain

Management

Mona Singh 14868329

AUT UNIVERSITY | MEPM 2015

ZARA Supply Chain Management

Table of Contents

1. Introduction....................................................................................................2

2. Supply Chain Model........................................................................................3

2.1 Design and order administration................................................................4-6

2.2 Sourcing and Manufacturing.....................................................................6-9

2.2.1 Suppliers of Zara............................................................................9-11

2.3 Distribution................................................................................................11-13

2.4 Retailing.....................................................................................................14

2.5 Merchandising............................................................................................15

2.6 Store Operations.........................................................................................15

2.7 Contracts......................................................................................................15-16

3. Cultural Aspects.................................................................................................17

3.1 Cultural comparison between countries.......................................................18-20

3.2 Cultural challenges.......................................................................................21

3.3 Key policies for senior management and leadership....................................22

4. Unethical Risk Management in Supply Chain...................................................23

4.1 Supply Chain ethics......................................................................................23

4.2 Unethical activities in supply chain management.........................................23

4.3 Tools for unethical risk management in supply chain...................................24-26

5. References............................................................................................................27

Mona Singh (14868329) MEPM 2015 1

ZARA Supply Chain Management

1. Introduction

Supply chain is defined as the global network used to deliver products and services from raw

materials to end customers through an engineered flow of information, physical distribution

and cash. Supply Chain Management encompasses the planning and management of all the

activities involved in designing, sourcing and manufacturing, distribution, retailing and

logistics. It also includes coordination and collaboration with channel partners which can be

suppliers, intermediaries, third party service providers and customers (Ayers).

Zara is a Spanish clothing brand based in Arteixo, Glacia owned by a Spanish tycoon

Amancio Ortego Gaona. Zara is a flagship chain store of Inditex Group which is the world’s

largest apparel retailer. The business model of ZARA is characterized be a high degree of

vertical integration as compared to models developed by international competitors. The

vertical integrated business model include all the phases of fashion process: Design,

manufacture, logistics, distribution to its owned stores. The key to this model is ability to

deliver products to customer as per their desire in shortest span of time. Time is the main

factor that is been considered as compare to the production cost in ZARA. Vertical

integration shortens the turnaround times and achieves greater flexibility thereby reducing the

stock inventory to minimum and hence reducing the fashion risk to greatest possible extent.

The best feature of ZARA supply chain management is that it takes maximum five to six

weeks to deliver the product to the customers as compare to its competitors which deliver the

final product in five to six months (Garcia).

The total brand value of ZARA is $9.4 billion as of May 2015 and the revenue generated is

around $14.8 billion.

Mona Singh (14868329) MEPM 2015 2

ZARA Supply Chain Management

2. Supply chain Model

Zara has 2000 stores strategically located in 88 countries around the world. It becomes

challenging for such a firm to supply the orders as per the latest demand. Although Zara uses

its flexible business model in order to adapt to new changes as per the season and thereby

delivering the best output to the consumers as per their desires. Specific retail locations are

selected after an extensive market research to ensure that the target market segments by

ZARA is of sufficient size in that particular locality to render the store financially viable.

Moreover ZARA always tries to locate its stores in most up market with high traffic and

prestigious locations. These prime locations gives the opportunities to the customers to

browse the stores as and when they are going back from work.

The supply chain management of ZARA is divided into four categories as shown below:-

Information Flow

Design and order

Administration

Sourcing &

Manufacturing

Distribution

Retailing

Mona Singh (14868329) MEPM 2015 3

ZARA Supply Chain Management

Zara vertical supply chain

2.1 Design and Order Administration

Zara designs all its products. It has a “commercial team” which consists of designers, market

specialists, and buyers. All of them are involved in detailed designing of the products where

the designers are the key players. Almost 40,000 products are designed every year out of

which 10,000 are selected for production.

The teams work on both next season’s design and simultaneously updating the current

season’s design in order to maintain a competitive edge. There is dynamic atmosphere among

the designers and design inspiration is from global sources which includes catwalk,

magazines, trade fairs, discotheques etc. Zara creates two basic collection each year- one in

fall/winter, other in spring/summer season. The designers take around nine months before the

start of season to make initial sketches. After the sketches are done, the sketches are redrawn

using Computer Aided Design (CAD) and further adjustments are done in order to find the

better matching of weaves, textures and colours. Later, the fabric and other components are

finalised by the designers. Simultaneously the price of the product is determined at which it

will be sold in future. The samples are presented in front of sourcing and product

Mona Singh (14868329) MEPM 2015 4

ZARA Supply Chain Management

development unit for selection process. The sourcing unit identifies the production

requirement and decides whether the item will be insourced and outsourced.

Based on this, the sourcing unit allocates a timeline to ensure that initial collection arrives

before the start of selling season.

The process of adapting to the changing trends and differences across market is more

revolutionary in order to find the demand of customers. The demand of target customers who

are very young and fashion conscious city dwellers plays an important role. Thus frequent

conversations with store managers becomes important to capture the sales data in IT system.

Various other sources of information includes TV, internet, university campus, film industry,

and even Zara’s fashion conscious staff. Market specialist plays an important role in linking

the designers and stores. Several dozens of items are designed each day but only one third of

the items goes into production. Due to time constraint, very limited volumes of items are

prepared and presented in key stores to determine customer response. If the customer

response is unambiguously positive then those items are produced on large scale.

Market specialist are in constant contact with the store managers through phones discussing

the sales order, new lines and other matters. The store managers are equally in contact with

Market specialist and thereby rely heavily on these discussions before placing the final order.

Thus the failure rate is supposed to be 1% compared with an average of 10% in this sector.

Overall, the responsibility of the design team is to track customer preferences and use sales

information along with other factors for a detailed analysis of product life cycle. Based on

this analysis the orders are repeated and new designs are given to internal and external

suppliers. Thereby the design teams with market specialists bridge the merchandising and

back end production process (Kasra Ferdows).

Mona Singh (14868329) MEPM 2015 5

ZARA Supply Chain Management

2.2 Sourcing and Manufacturing

Zara manufacture approximately 50% of its product in its own store in Spain but uses

external suppliers for all its sewing operations. Zara sources fabrics, threads and other

components from external supplier with help of purchasing offices in Barcelona, Hong Kong

along with sourcing personal in headquarters located at Arteixo, Spain. About one half of the

purchased fabric is not dyed in order to provide latest season fashion with maximum

flexibility, thereby reducing the waste cost. Comditel, a 100% owned subsidiary of Inditex

deals with number of external suppliers of fabric and other components. Comditel deals with

dyeing, patterning and finishing undyed fabric.

Due to the vertical integration of Zara, it makes around 40% of its own fabric and purses rest

of the dyes from its own subsidiary. After cutting and dyeing, the items are stitched with help

of many local cooperatives. Since Zara manufactures around 60% of its own product, hence it

is more flexible in variety, amount and frequency of new style that are produced. Fifty

percent of the items that are sold by Zara are being manufactured in Spain, 28 % in Europe,

and 24% in Asia and rest of the world. Zara has a global distribution centre that functions as

mentioned below:

There is more risk involved in most fashionable item hence these type of items are produced

on small scale and if the customer response is positive then these items are reordered

depending upon the demand. The items that are price sensitive rather than time sensitive are

been outsources to Asia as the manufacturing cost in Europe is 15-20% higher as compare to

Asia. Zara has the ability to create rapid product turnover due to limited stock production and

controlled inventory. This creates opportunities in retail stores of Zara.

The quick response system of Zara is unique which consists of human resources and

Information technology. Zara focuses on ultimate customers and emphasizes on the use of

quick backward vertical integration rather than manufacturing efficiencies. It becomes crucial

for Zara to speed up the information flow from consumer desires to apparel designers. The

combination of vertical integration, technology-orchestrated coordination of suppliers, fined

tuned logistics and just in time manufacturing makes Zara so much competitive.

Mona Singh (14868329) MEPM 2015 6

ZARA Supply Chain Management

Inventory optimization helps the firm determine the exact requirement of items that needs to

be delivered twice a week and how much stock needs to kept to fulfil the requirement of

retail stores. The average time taken by Zara to implement an idea into a final product is

maximum 15 days as compare to other firms which takes four to five months. Zara is twelve

times faster than its competitors in delivering a product. Generally, there is a lead time of

about four to five weeks for new garments and two weeks to restock. In this period, Zara is

able to find the response of fashion items that are selling well and items that are to be

discontinued.

The procedure of design and procurement starts five to six months prior to the selling season

in order to find the requirement of approximately 65% of the fabric needs, rest depends on

the latest trends of market. Zara manufactures about 15-20% of the items before the season in

order to check the response of customers towards the newly designed items, it later

manufactures 50-60% at start of season and rest is manufactured in the season. The

manufacturing of the items is done is such a way that customer inputs are received at all

stages in order to determine the items produced are according to the expectations of the

fashion diva’s.

Mona Singh (14868329) MEPM 2015 7

ZARA Supply Chain Management

Zara always keeps the customers priority first and always delivers as per the below strategy:-

ZARA

SCM Focus Speed

Target Customers Young Women

Products Fashion conscious item

Manufacture System Small quantity batch production

Outsourcing Vertical Integration

(Design-Manufacture-Sales

R&D Strategy Trendy designs

Inventory Control Low inventory, short implementation

cycle

The production commitment of the company is different from other apparel industries. The

inventory of Zara is regulated and the items are been revealed on different stages as per

modified designs to maintain curiosity among the customers and not unlike other industries

where the designs are revealed in one stage and the same stock is repeated throughout the

season , thereby creating monotony among customers.

Mona Singh (14868329) MEPM 2015 8

ZARA Supply Chain Management

Product precommitment zara vs other industries

2.2.1 Suppliers of Zara

Supplier Product/Services Country

Sol System Trading L.L.C. Cloth Fabric Spain

ModaStock LLC Leather Spain

Mansana Adams International Ltd Belt Buckles Spain

Feelecco LTD Textile Stock London

Acacio Pacheco Unipessoal LDA Apparel Stock Portugal

Three Stars Group Co. Ltd. garment accessories Pakistan

YCC Zippers Zips China

Sunshine Garment Accessory Co.,Ltd lace, embroidery, beadwork China

Guangzhou Super U Shop Fitting Ltd display rack, gondola, garment display, China

shop design

Four Seasons Vina Ltd button, plastic button, polyester button, Vietnam

garment button, metal button, hook

eye, toggle,snap button, rivet, plating

button

Seaart Rhinestone Transfers Factory accessories, embroidery, laser cut, China

trimming

Jiangsu Hongdou Industrial Co., Ltd Sewing support China

Dongguan Fu Ngar Garment Co.Ltd foil transfer, crochet design China

Cu Tekstil San Ve Tic A.S. T-Shirt material Turkey

Teamlead Factory Sewing of fabrics China

D M Enterprises Apparel stock India

Moreenapparels Jacket, jeans material Bangladesh

Firma Handlowa Fur and woolen material Poland

Inter stock Cotton fabric Poland

Red Edge Concepts Ltd TA Kate's Weaving threads U.K

Clothing

Stock-Hurt Machinery Poland

Mona Singh (14868329) MEPM 2015 9

ZARA Supply Chain Management

Zustocks Flannel Romania

Dani&Mur Linen Israel

OUTEXX S.R.O. Cashmere blend Spain

Texport Acrylic fabric Bulgaria

Textil Brno Cheese Cloth Czech Republic

Matthias Bourdil Chiffon Spain

Sarl Eurostock International Corduroy France

Hugnkiss Georgette Vietnam

Ricoche Hemp, Shipping tote United Arab

Emirates

Stocklotsforsale.Com Mohair India

Mekki Polyester Moldova

M&G Textilvermarktung GmbH Silk, sequin, beaded design Germany

Atlantis Retail Co Ltd Cowhide, Lambskin,Faux, Patch Morocco

leather

Eurofashon Stock venise Israel

enjana sl velvet Spain

Inditex 50 % of Zara’s fabric Spain

Comditel Dyes, Colours, Sweing Spain

Since Zara has a very wide network across the world, hence delivery of raw materials

becomes crucial within the define timeperiod. In order to deliver the raw materials on time,

the transport logistics should be strong and reliable. Zara makes sure the order of raw

material is placed before start of season in order to avoid any last minute rush. Moreover,

Zara has a very strong and flexible transport system that ensures timely delivery of raw

materials. Also, majority of the fabric suppliers are based in Europe and Spain, hence the

delivery of raw materials is speedy. The raw materials that have cost constraint and no money

constraint are usually delivered from across the world mainly HongKong and rest part of

Asia.

Suppliers across Zara Manufacturing

World unit Spain

Logistics Others suppliers in Inditex, Comidetel

Europe

Spain

Basic material flow

Mona Singh (14868329) MEPM 2015 10

ZARA Supply Chain Management

Detailed material flow(Group 2013)

2.3 Distribution

The distribution system of Zara is centralized giving it a copetitive advantage by miminizing

the lead time of the goods. Zara has a system which is about 600.000 square meter facility in

Spain and other smaller satellite centres in Argentina, Brazil, Mexico that consolidate the

entire shipment from Spain.

Distribution System

Mona Singh (14868329) MEPM 2015 11

ZARA Supply Chain Management

Zara has four main warehouses in Spain that receive shipments of finished clothes from

internal and external suppliers across Europe and different parts of world. These finished

items are then directed to Zara store in the world twice a week during regular periods and

twice during sale seasons. New models of items are incorporated with each delivery for

constant refreshing stock maintenance in stores. The products are inspected in order to check

if there are any defects in the stock that has to be delivered, after proper inspection the stock

is immediately shipped. There is a rule in Zara that the stock will not be kept on hold in

warehouses for longer period. As a result the items are shipped as soon as the stock arrives

from various suppliers after inspection. In order to increase the delivery speed, the shipments

are scheduled by time zones and the stock is shipped either through land or air. The retail

stores that are located closeby Spain recieves the stock through land transport. Rest the

shippment is done through air across the world for speedy delivery.

Basic logistic flow of Zara

Mona Singh (14868329) MEPM 2015 12

ZARA Supply Chain Management

Distribution centre of Zara Area

Galicia (Arteixo) 280.000 sq mt

Leon 40.000 sq mt

Madrid 160.000 sq mt

Zaragoza 125.000 sq mt

The software of logistic system is designed by the company’s own team, hence it reduces the

time between receiving the order at distribution center to the delivery of order in stores. On

an average it takes 24 hours to deliver the order within Europe and 48 hours for order

delivery in America or Asia. The distribution center moves around 2.5 million items per

week. Trucks serve closer locations like Europe and chartered cargo flights serve destinations

that are far from central distribution center.

Mona Singh (14868329) MEPM 2015 13

ZARA Supply Chain Management

2.4 Retailing

The aim of Zara is always to offer fresh newly designed style garments and acessories like

bags, jewelry, scarves, shoes at relatively low prices in order to draw attention of fashion

divas so that these customers become regular. Zara focuses on backward vertical integration

instead of manufacturing efficiencies to determine the next order of customers. As the

inventories are strictly control, hence Zara ensures that backward vertical integration is been

tracked carefully so that the following orders can be delivered on time with new designs and

latest fashion inventory. The merchandising and store operations help in achieving the goal

for the firm. The deadlines to order items are very strict and are been followed across the

world. If any store misses the deadline then it has to wait for the next upcoming deadline.

Orders have to be placed before 3 PM on Wednesday and 6 PM on Saturday in Spain and

southern part of Europe while in rest of the world orders needs to be placed by 3PM on

Tuesday and 6 PM on Friday. The orders are closely tracked through centralized IT system

that helps in maintaing the track record of incoming orders across the globe.

Mona Singh (14868329) MEPM 2015 14

ZARA Supply Chain Management

2.5 Merchandising

The merchandising policies of Zara’s product focus on high fashion content, changing

product lines and reasonable physical quality. Product lines are divided in three main

categories – Women’s wear, Men’s wear and children’s line. Women’s line is segmented in

three set of offerings price, fashion content and age targets. Since Zara has zero advertising

policy hence the expenses saved in zero advertising is utilised in international expansion of

the market making it more economical. This signifies Zara mainly relies on its store to project

the image of clothing. This is the reason why Zara acquires global prime locations acroos the

world. There are special departments in Zara that do an extensive reasearch in finding the

prime locations where Zara stores will be made.

2.6 Store Operations

Sale is not the end of process rather it’s restart as the store provide feedback to the design

teams about the trends. Store layouts are spaciously designed so that the customers can easily

explore the options available and share their feedbacks to the store manager. The store

manager constantly updates the design teams about the customer feedbacks and accordingly

the designers start working on the updated trends in order to prepare for the next assignment.

Customer feedback are of utmost importance to the store managers to find the exact

requirement of customers so that the next order sales increases by providing the exact item

that customer requires.

2.7 Contracts

A voluntary, deliberate and legally binding agreement between two or more companies is

called a contract. Contracts not only helps in building trust between two parties but also

influence decisions regarding Plan Procurement Management process. The assests that

influence the Plan procurement management process in the organisation are :-

Formal procurement, policies and guidelines.

Management system considered in developing procurement plan and selecting

contractual relationships that will be used among the company and suppliers.

Established mutli-tier supplier system of prequalified suppliers based on experience.

The legal contractual relationships aer classified in three categories :-

I. Fixed Price Contracts: In this category, the total price of a product is fixed. Fixed

price contracts includes financial incentives for achieving or exceeding project

objectives like delivery dates, exceptionally well designed product in limited

deadlines, or anything that can be quantified and measured. In case of any financial

Mona Singh (14868329) MEPM 2015 15

ZARA Supply Chain Management

damages the seller has to take full charge of the damages. Fixed price contracts are

further classified into three categories –

Firm fixed Price Contracts (FFP) : This type of contract is mainly possessed

by the buyer. In this contract the product cost is defined and will not change

until the scope of work changes. Any increase in the cost due to poor

performance is the responsibility of the seller. Under FFP contract, the buyer

should clearly specify the products that are to be procured or else increase in

cost will be the responsibility of buyer.

Fixed Price Incentive Fee Contracts (FPIF) : This price agreement gives

flexibility to the buyer and seller that allows performance deviation with

financial incentives. Financial incentives incorporates cost schedule . The final

contract price is determined after the delivery of product based on the

performance of seller.

Fixed Price with Ecoomic Price Adjustment Contracts (FP-EPA) : It’s a

fixed term contract with a special provision where contract price changes due

to changed conditionds, such as inflation, increase in cost of raw materials.

This contract is intended to both seller and buyer as it includes price changes

due to external factors which are beyond control.

II. Cost- reimbursable contracts: This category involves payments to the seller for all

the actual cost that have been incured while completing the work along with seller

profit. Cost – reimbursable contracts has three categories –

Cost Plus Fixed Fee Contracts (CPFF) : It is a fixed cost contract where the

seller gets the calculated cost for completed work. In this contract the fee does

not chnages until there is change in project scope.

Cost Plus Incentive Fee Contracts (CPIF) : In this contract the seller

recieves predetermined incentive fees based upon performance achievement.

If the final cost of the project is lesser or greater than the estimated project

cost then in that case the buyer and seller share costs based on pre-negotiated

cost sharing formula.

Cost Plus Award Fee Contracts (CPAF) : This cost is based on seller

performance and fee is determined by buyer based on the performance and is

generally not subject to appeals.

III. Time and Material Contracts: These contracts are mixture of cost – reimbursable

and fixed price contracts. Time and material contracts are used for staff augmentation,

experts acquistion, etc.

Mona Singh (14868329) MEPM 2015 16

ZARA Supply Chain Management

3. Cultural Aspects

The understanding of cultural aspects becomes crucial while doing business across the

globe. The cultural differences between the nations affects the business

communication which leads to failure of the company in that particular nation.

Sometimes the companies may loose business because of difference in understanding

the cultural requirements across the borders. The cultural classification system

designed by Geert Hofstede helps in understanding the dynamics of organisation

across national boundaries. The classification system consists of six dynamics:-

Power distance Index (PDI)

It expresses the degree to which less powerful members within an organisation

in a country expect and accept that power is distributed unequally.

Uncertainty Avoidance Index (UAI)

It expresses the degree to which members in a society feel uncomfortable with

uncertainty and ambiguity.

Masculinity versus Femininity (MAS)

It expresses the degree to which the gender roles in an organisation are distinct

and adhered to within a society

Individualism versus Collectivism (IDV)

Individualism is basically taking care of oneself and immediate families while

collectivism is a dimension where the individuals can expect their relatives or

particular group members taking care of them in exchange of loyalty.

Indulgence versus Restraint (IND)

A society that allows free gratification basic and natural human drives to enjoy

life and have fun. It restrains strict social norms that hinders the social life of

the society.

Mona Singh (14868329) MEPM 2015 17

ZARA Supply Chain Management

Long term orientation versus Short term Normative Orientation (LTO)

Society has to maintain links with its own past while dealing with present and

future challenges. In business terms the dimensions are referred as Normative

versus pragmatic (Hofstede).

3.1 Cultural comparison between countries

Zara originated from Spain which has a hierarchical society. The people in

Spain accepts hierarchical order where everyone has a space and nobody

S needs further justification. Spain has a collectivist dimension where people

work together towards achieving an objective. This helps Zara to work with

P many non-European countries who follow the same dimension. Excessive

competitiveness is not a part of Spain dimension and people work in harmony.

A Higher Management authorities consult their subordinates to know their

opinions and make a collective decision. Spain is a country of rules where

I there is rules for everything. This results to a lot of stress, thereby

confrontation is avoided that can cause further tension and stressful

N environment. Spain is a normative country where people like to live in the

moment. People like quick results without any delays. Spain is not an

indulgent country.

Comparison of cultural dimension between India and Spain

Mona Singh (14868329) MEPM 2015 18

ZARA Supply Chain Management

Zara stores in India needs to take into account different perspective while dealing with

I indian market. India scores high on power distance which clearly indicates ther is high

appreciation for hierarchy and top down structure in society and organisations in

N India. India is a society with both individual and collective dimension. In

Masculanity, India is male dominated society where major leadership roles related to

D power and success are been occupied by males in industry and females occupy roles

that are related to less strategic and related to quality of life. In India, people have

I medium low preference for uncertainity avoidance. India has a long term pragmatic

culture where long term plans are prefered and people always plan for future. India

A has a restraint dimension with high tendency to cynicism and pessimism.

Comparison of cultural dimension between Spain and New Zealand

Mona Singh (14868329) MEPM 2015 19

ZARA Supply Chain Management

Comparison of cultural dimension between Spain and US

Comparison of cultural dimension between Spain and New Zealand

Mona Singh (14868329) MEPM 2015 20

ZARA Supply Chain Management

3.2 Cultural challenges

Compatibility and potential issues arises among corporate due to differences in

national cultures. When companies decide an offshore outsourcing strategy, they have

to take into account the national cultures along with risk dimensions that can harm the

business in future. The detail study of these factors becomes crucial to achieve

successful output in other countries. The challenges faced by company while

outsourcing is mentioned as follows:-

Corporate culture differences: It includes client’s corporate culture and the

suppliers. It defines the operational policies, reward structures, control system,

corporate policies and employee evaluation system that exist among the

organisations.

National culture Differences: It plays a major role in determining the success

of business. An example of Zara where most of the clothes are designed

keeping European market in mind, hence the colours of clothes are subtle. But

in country like India, people prefer vibrant colours in clothing. Thus in such

cases Zara studies the national cultures that govern the country and bring

vibrant clothing designs in market to overcome such challenges.

Communication barriers: It is again a major issue while outsourcing abroad.

Extra time is required to educate interpreters on issues. Hence it’s also advised

to have written email communications to avoid confusion and conflicts in

future.

Weather: It plays a major role in manufacturing process of the organisation.

Countries like New Zealand and Australia experiences winters in June and

July while summers in December and January. If this is compared with other

parts of the world, then weather experienced in other parts of the world is vice

versa. Hence Zara has to manufacture the products as per the weather

requirements of the country.

Gender: In countries like India where major leadership and powerful roles are

dominated by males and females look after the less strategic roles. In such

scenarios the organisation has to study the masculinity of the country and then

accordingly perform supply chain management functions for an effective

outcome.

Clothing size: Zara designs slim fit clothes where the size choices are limited.

In countries like US, the limited size becomes an issue hence the company has

to change the few manufacturing processes as per the needs and requirements

of the country. More size availability is required in order to increase the sales

output.

Mona Singh (14868329) MEPM 2015 21

ZARA Supply Chain Management

3.3 Key policies for senior management and Leadership

I. Financial and Accounting Policies: It provides guidelines about where the capital is

coming from, how the capital will be used and how recurring needs will be met.

Accounting policies deals with questions related to inventories, expenses and cost.

These policies can make a huge difference in success and failure of the organisation.

Capital: Long term versus short term capital to finance business activities.

Lease or Buy: Policy related to lease certain classes of assets will change the

nature of need for funds over time and nature of balance sheet.

Investment Risk: Financial policies are designed while evaluating the

proposal for investment in certain project. It measures the financial risk

involved in the project before investing.

Use of Assets: Specific policies target current assets and cash flows that are

needed for inventories.

II. Marketing Policies: It uses the competitive tactics in marketing mixture. Specifically

how will price promote, distribute, quality of product.

Products and Market

Distribution and Promotion

Price

III. Product Operations Management Policies: It includes issues like can business be

handled with present facilities and number of shifts, firm’s inventory safety level,

level of productivity and costs etc.

Capacity and utilisation

Location of facilities

Processes

Equipment and maintenance

Sourcing

IV. Research and development Policies: It emphasizes on product and process

improvements, technology that should be pursue, management of transit from one

technology to another, focus on commercial development etc.

Products and processes

Basic and Applied Research

Offensive or defensive strategies

Allocating R&D Resources

V. Personnel, Legal and Public Relations policies: It includes standards and methods

used for promotion, recruitment through advertising or personal contact, adequate

work force, types of specialists required, payment policies, legal policies etc.

Personnel

Legal Issues

Mona Singh (14868329) MEPM 2015 22

ZARA Supply Chain Management

VI. Integrating Policies: It ensures there is internal consistency in policies developed for

line and staff. It is related to assessment of strength and weakness as they are related

to development of competitive advantage.

4. Risk Management in Supply Chain

Management of risks that are imposed by unethical practices in Supply Chain.

A system of moral principle where human actions or proposals are judged right or

wrong is defined as ethic.

Code of ethics is a document that represents values, how professionals are supposed

to approach problems.

4.1 Supply Chain ethics

Management of supply chain without any unethical activities is termed as ethical

supply chain. The ethics of supply chain are subdivided into four categories:-

Relationship Orientation

Channel Orientation

Completion Orientation

Environmental Orientation

4.2 Unethical activities in Supply Chain Management

In order to minimize the unethical practices in supply chain, it becomes crucial to

identify cause of problem. Unethical issues that arise in the supply chain are listed

below:-

Procurement

Using obscure contract terms to gain advantage over other party.

Following specifications that favour particular supplier.

Exaggerating a problem to gain concessions.

Bias Attitude

Allowing only certain suppliers to bid.

Giving preference to suppliers.

Offering gifts

Allowing suppliers to bid after closing date.

Unethical Behaviour

Bribery

Misleading the other party purposefully.

Asking other party information about the competitors.

Mona Singh (14868329) MEPM 2015 23

ZARA Supply Chain Management

Unethical business Strategies

Use of backdoor selling techniques.

Over committing resources or production schedules.

Increasing prices when there is shortage of product supply.

4.3 Tools for Unethical Risk Management in Supply Chain

The ISM standards are used to identify the ethical practices that govern the supply

chain management of the organisation. The professionals involved in supply chain

must abide by these code of ethics in order to avoid unethical behaviour towards the

organisation. The ISM standards are as follows:-

Impropriety

Prevents the intent of unethical conduct in relationship, communication and

actions. Guidelines to implement impropriety

Maintenance of business professionalism in all communication that

includes social media.

Identify situations that can have negative impact on business

relationships.

Discuss potential impropriety with management and take

appropriate action.

Avoid actions that could lead to impropriety in organisation.

Avoid discussing personal matters.

Conflict of Interest

Ensures that personal business and other activities do not conflict with lawful

interests of your employer. Guidelines to avoid and manage conflicts:-

Potential Conflicts: Discuss the conflicts of interest with management

and reassign responsibilities.

Guidance on Conflicts: Notify the person under whose guidance the

responsibilities were allocated.

Conflict of Interest Statement: The employer must review conflict of

interest with its employees to ensure the conflicts are resolved before it

becomes a major issue.

Inside Information: The inside information should not be used for

personal gains.

Outside Information: Never use your position as an employee to

detriment your employer or its reputation.

Secondary Business/ Employment: Do not harm the interests of your

employer by engaging yourself in secondary business.

Mona Singh (14868329) MEPM 2015 24

ZARA Supply Chain Management

Influence

Any behaviour or action that influence supply chain management decisions

should be avoided. Guidelines to avoid matter of influence

Strictly follow employer policies in supply chain management

professionalism.

Avoid in gift giving activities that influence business decisions of

supply chain.

Avoid situations where relationships can have negative impact on

business decisions.

The negative impact of political matters in internal and external forces

of organisation can be mitigated by adopting organisational policies

based on ethical principles and standards.

Follow organisation media policies.

Responsibilities to the Employer

Reasonable care and granted authority should be used while delivering value

to the employer. Guides used for satisfying responsibilities to employer

The authority granted by employer should be well understood.

Avoid activities that compromise the interests of employer.

Ensure the working arrangements deliver value to the employer.

The employer should be notified about unethical activities.

Avoid unauthorized use of name of employer.

Supplier and customer relationships

Positive customer and supplier relationships should be promoted. Guidelines

to maintain positive relationships

Unreasonable demands should be avoided.

Prompt and fair resolution must be encouraged.

Communication must be prompt, open and direct.

Establish process for customers and suppliers where unethical

activities can be reported to the employer.

Social Responsibility and Sustainability

Best social responsibility and sustainability practices must be encouraged in

organisation. Guidelines includes

Anticorruption

Diversity and inclusiveness among workforce and supply base

Protection and preservation of natural environment

Ethics in business conduct

Financial transparency and integrity

Health and Safety

Human Rights

Global citizenship

Mona Singh (14868329) MEPM 2015 25

ZARA Supply Chain Management

Confidential and Proprietary Information

Protect confidential and proprietary information of the organisation. This

includes information regarding bids, production cost, designs and drawings,

Wages, contract etc. Guidelines recommended

Use confidential information for its intended purpose.

Mark and identify confidential and proprietary information.

Protect the information given to you.

Accept no confidential and proprietary information which is not

relevant to you.

Use nondisclosure agreements.

Reciprocity

Avoid improper reciprocal agreements.

Recommended guidelines

Understand suppliers that are also customer.

Apply and obtain ethical, legal guidance if reciprocity arises.

Recognise reciprocal relationships which can be illegal in some

countries.

Applicable laws, regulations and trade agreements

Know and obey the letter of intent in laws, regulations and trade agreement in

supply chain. It includes agency laws, trade regulations, environmental laws,

financial laws, employment laws, health and safety laws etc. Recommended

guidelines

Seek training in legal aspects of supply chain management.

Understand and follow laws, regulations and trade agreement.

Understand and apply government laws.

Seek legal counsel when conflict arises.

Professional Competence

Develop skills, expand knowledge and conduct business that demonstrate

competence and promote supply chain management profession.

Recommended guidelines

Adopt and promote ethical standards

Support and participate in ethical trainings.

Mentor and teach those who want to learn.

Active involvement in supply chain management

Earn and maintain Certified Professional in Supply Management

(CPSM) and other professional certificates.

(Derry 2014)

Mona Singh (14868329) MEPM 2015 26

ZARA Supply Chain Management

References

Ayers, J. B. Retail Supply Chain Management

Derry, T. (2014). "Principle and Standards of Ethical Supply Management Conduct with guidelines."

Garcia, J. M. C. "Zara and Benetton: Comparison of two business models."

Group, I. (2013). "Transparency is the fundamental principle that inspires inditex in its relations with

its stakeholders."

Hofstede, G. "Dimensions of National Culture."

Kasra Ferdows, M. L., Jose A.D. Machuca "Zara."

Business Policy and Strategy Management by William F.Glueck & Lawerence R. Jauch

Mona Singh (14868329) MEPM 2015 27

You might also like

- Nykaa DetailedDocument34 pagesNykaa Detailedsahil malhotra67% (9)

- Zara Operation ManagementDocument9 pagesZara Operation Managementmuhammadali_02233% (3)

- ZARA: IT For Fashion Case AnalysisDocument3 pagesZARA: IT For Fashion Case AnalysisAshutosh Singh89% (9)

- Operations Management in Automotive Industries: From Industrial Strategies to Production Resources Management, Through the Industrialization Process and Supply Chain to Pursue Value CreationFrom EverandOperations Management in Automotive Industries: From Industrial Strategies to Production Resources Management, Through the Industrialization Process and Supply Chain to Pursue Value CreationNo ratings yet

- Zara Supply Chain ManagementDocument5 pagesZara Supply Chain ManagementNithesh PawarNo ratings yet

- Zara Business Strategy - Zara Critically Evaluate, 2010 To 2014 - 2:1 Grade Derby UniDocument17 pagesZara Business Strategy - Zara Critically Evaluate, 2010 To 2014 - 2:1 Grade Derby Uni100134260100% (4)

- Information System For Managers Js1vSqxdnrDocument4 pagesInformation System For Managers Js1vSqxdnrManish Kumar0% (1)

- MangoDocument6 pagesMangoVarun Mehrotra50% (2)

- ZARA Case AnalysisDocument6 pagesZARA Case Analysispradeept_43No ratings yet

- Zara Market AnalysisDocument30 pagesZara Market Analysisdedjana lopaNo ratings yet

- ZaraDocument22 pagesZaraErich Cirstea67% (3)

- ZaraDocument26 pagesZaraAmritanshu Mehra100% (1)

- SainsburyDocument12 pagesSainsburyJuan Pablo MedinaNo ratings yet

- Zara Case StudyDocument14 pagesZara Case Studydavid100% (2)

- Zara Is by Far The LargestDocument12 pagesZara Is by Far The LargestMohit PandeyNo ratings yet

- Case AnalysisDocument7 pagesCase AnalysisRadhika ChhabraNo ratings yet

- Satyam Computer ScamDocument14 pagesSatyam Computer ScamRadhika ChhabraNo ratings yet

- Zarra Supply Chain Management ProjectDocument16 pagesZarra Supply Chain Management ProjectSaif KhanNo ratings yet

- Zara'S Operations Stategy, A Critique of A Business CaseDocument11 pagesZara'S Operations Stategy, A Critique of A Business CaseSilvia TjangNo ratings yet

- Individual Report of Zara Clothing CompanyDocument8 pagesIndividual Report of Zara Clothing CompanySinem DüdenNo ratings yet

- ZARA PresentationDocument17 pagesZARA PresentationMuhammad NaveedNo ratings yet

- ZARA Case StdyDocument12 pagesZARA Case Stdynanasha87100% (1)

- Zara Case StudyDocument14 pagesZara Case StudyGunjan Vishal Tyagi100% (4)

- ZaraDocument14 pagesZaraMax Tan50% (2)

- Zara PPT - Group9Document16 pagesZara PPT - Group9Snehashis KhanNo ratings yet

- Zara-Supply Chain ManagementDocument6 pagesZara-Supply Chain ManagementAnkit Saha100% (1)

- Zara CaseDocument17 pagesZara CaseHamza Burhan MujaddidiNo ratings yet

- Supply Chain ManagementDocument5 pagesSupply Chain ManagementJshDelaCruzNo ratings yet

- Business Fundamentals ProjectDocument6 pagesBusiness Fundamentals ProjectMarian ZamfirescuNo ratings yet

- IntroductionDocument4 pagesIntroductionLidia JanNo ratings yet

- August 20, 2010: Supply Chain Management of ZaraDocument11 pagesAugust 20, 2010: Supply Chain Management of ZaraHosna Mobarak Farhan100% (1)

- Zara Sonja VadjenoDocument2 pagesZara Sonja VadjenomadicmNo ratings yet

- Zara Case Discussion ResultsDocument9 pagesZara Case Discussion ResultsArifur RahmanNo ratings yet

- Zara SCMDocument8 pagesZara SCMAnurag MosanNo ratings yet

- Zara CaseDocument2 pagesZara CaseE100% (1)

- Operations Management AzharDocument6 pagesOperations Management Azharpuneet_mishra3159No ratings yet

- Zara Case Analysis Operations Management MBM1110Document8 pagesZara Case Analysis Operations Management MBM1110MacMehta100% (1)

- OM Assignment 3Document5 pagesOM Assignment 3Rabeea UmairNo ratings yet

- ZaraDocument12 pagesZaraTamrika TyagiNo ratings yet

- Capstone Project Sriparna Neogi 11551 ZaraDocument14 pagesCapstone Project Sriparna Neogi 11551 ZaraSri NeogiNo ratings yet

- Executive SummaryDocument4 pagesExecutive SummaryKarishma BaggaNo ratings yet

- Inditex StrategyDocument14 pagesInditex Strategyminunair2024No ratings yet

- ZARA Group Quiz - FinDocument16 pagesZARA Group Quiz - FinFenny PuspitaNo ratings yet

- Case Zara CH 2 Management OperationDocument2 pagesCase Zara CH 2 Management OperationFika AprianiNo ratings yet

- Business 2 Business Management: Assignment 1 Value Chain AnalysisDocument5 pagesBusiness 2 Business Management: Assignment 1 Value Chain AnalysisShane MathewNo ratings yet

- Zara Caso1Document11 pagesZara Caso1BillyBonillaPauloNo ratings yet

- Competitive Analysis For ZARA and HDocument9 pagesCompetitive Analysis For ZARA and HOlicik@67% (6)

- Rapidfire Fulfillment-Zara: A Case StudyDocument6 pagesRapidfire Fulfillment-Zara: A Case Studyekta agarwalNo ratings yet

- Zara. Abdullah Al Sakib Yo YoDocument11 pagesZara. Abdullah Al Sakib Yo YoAbdullah Al SakibNo ratings yet

- Operations and Project Management Fast-Fashion Zara by Noof Malallah Al AjmiDocument14 pagesOperations and Project Management Fast-Fashion Zara by Noof Malallah Al AjmiMANUEL JESUS TUTACHA CUASIALPUDNo ratings yet

- Zara Supply ChainDocument3 pagesZara Supply ChainMochamad Eka PrasetyanNo ratings yet

- Agile Supply Chain Zara Case Study AnalysisDocument11 pagesAgile Supply Chain Zara Case Study Analysisr_vivekanand100% (1)

- Zara Case Study - Nishant 1133573 - Term 3, MBA 31Document7 pagesZara Case Study - Nishant 1133573 - Term 3, MBA 31nm_nishant100% (1)

- Agile Supply Chain: Zara's Case Study AnalysisDocument11 pagesAgile Supply Chain: Zara's Case Study AnalysisAshmi NeupaneNo ratings yet

- Agile Supply Chain Zara Case Study AnalysisDocument11 pagesAgile Supply Chain Zara Case Study AnalysisBasuki RachmatNo ratings yet

- Zara: Transforming The International Fashion Industry Through Innovative Supply ChainDocument4 pagesZara: Transforming The International Fashion Industry Through Innovative Supply Chaindubai9963No ratings yet

- 11 Shiv Shankar S 44306Document8 pages11 Shiv Shankar S 44306Shreyanshi AgarwalNo ratings yet

- Wal-Mart Stores, Inc., Global Retailer case study, the GUIDE editionFrom EverandWal-Mart Stores, Inc., Global Retailer case study, the GUIDE editionNo ratings yet

- How to Manage Fashion Business: A Comprehensive Guide for Fashion DesignersFrom EverandHow to Manage Fashion Business: A Comprehensive Guide for Fashion DesignersNo ratings yet

- Behavior Analytics in Retail: Measure, Monitor and Predict Employee and Customer Activities to Optimize Store Operations and Profitably, and Enhance the Shopping Experience.From EverandBehavior Analytics in Retail: Measure, Monitor and Predict Employee and Customer Activities to Optimize Store Operations and Profitably, and Enhance the Shopping Experience.No ratings yet

- The ChatGPT Print On Demand Millionaire Blueprint (GPT-4 2024 Edition): ChatGPT Millionaire Blueprint, #4From EverandThe ChatGPT Print On Demand Millionaire Blueprint (GPT-4 2024 Edition): ChatGPT Millionaire Blueprint, #4No ratings yet

- Fortune Institute of International Business SESSION (2018-20)Document10 pagesFortune Institute of International Business SESSION (2018-20)Radhika ChhabraNo ratings yet

- Boho Tribee: "Gracious and Unique Just Like You"Document7 pagesBoho Tribee: "Gracious and Unique Just Like You"Radhika ChhabraNo ratings yet

- Consumer Behaviour Presentation ON Diffusion of InnovationDocument34 pagesConsumer Behaviour Presentation ON Diffusion of InnovationRadhika ChhabraNo ratings yet

- Business Problem Solving Assignment Work-1 Submitted By: Radhika Chhabra Roll - No.102Document5 pagesBusiness Problem Solving Assignment Work-1 Submitted By: Radhika Chhabra Roll - No.102Radhika ChhabraNo ratings yet

- Fortune Institute of International Business SESSION (2018-20)Document3 pagesFortune Institute of International Business SESSION (2018-20)Radhika ChhabraNo ratings yet

- Asian Paint Cost AnalysisDocument22 pagesAsian Paint Cost AnalysisRadhika ChhabraNo ratings yet

- Economics Assignment Team-9Document25 pagesEconomics Assignment Team-9Radhika ChhabraNo ratings yet

- Business Problem Solving: Practice QuestionDocument5 pagesBusiness Problem Solving: Practice QuestionRadhika ChhabraNo ratings yet

- PM-1 Radhika Chhabra - Roll No-65Document5 pagesPM-1 Radhika Chhabra - Roll No-65Radhika ChhabraNo ratings yet

- HRMS FileDocument17 pagesHRMS FileRadhika ChhabraNo ratings yet

- Final Report Chitrakshi Bhutani 135 PDFDocument66 pagesFinal Report Chitrakshi Bhutani 135 PDFRadhika ChhabraNo ratings yet

- (13377493 - Studia Commercialia Bratislavensia) The Economic Impact of Consumer Purchases in Fast Fashion Stores PDFDocument13 pages(13377493 - Studia Commercialia Bratislavensia) The Economic Impact of Consumer Purchases in Fast Fashion Stores PDFRadhika ChhabraNo ratings yet

- Vikram Rathore 178Document5 pagesVikram Rathore 178Radhika ChhabraNo ratings yet

- Radhika Chhabra 102Document6 pagesRadhika Chhabra 102Radhika ChhabraNo ratings yet

- FMCG Sales DistributionDocument8 pagesFMCG Sales DistributionRadhika ChhabraNo ratings yet

- Go To Market b2bDocument5 pagesGo To Market b2bRadhika ChhabraNo ratings yet

- Carlsbad Schedule and Attendee List 4Document21 pagesCarlsbad Schedule and Attendee List 4CREWNo ratings yet

- BA 128 2 Donor's TaxDocument5 pagesBA 128 2 Donor's TaxEyriel CoNo ratings yet

- Nutritional Status of Women and Children in North East IndiaDocument32 pagesNutritional Status of Women and Children in North East IndiaSandeepNo ratings yet

- Project On HSBCDocument11 pagesProject On HSBCShwetaMamaniaNo ratings yet

- MODUL 1 PELAKOR SEP 2020 - Dari Bu RatnaDocument47 pagesMODUL 1 PELAKOR SEP 2020 - Dari Bu Ratnapradana arif kurniawanNo ratings yet

- Daftar PustakaDocument6 pagesDaftar PustakaethachappunkNo ratings yet

- NTPC SipDocument18 pagesNTPC SipSaurabh ChaurasiaNo ratings yet

- SDG (Sustainable Development Goals)Document19 pagesSDG (Sustainable Development Goals)Galijang ShampangNo ratings yet

- Process CostingDocument15 pagesProcess CostingSanctaTiffanyNo ratings yet

- Tổng hợp kiến thứcDocument17 pagesTổng hợp kiến thức9zrwj8rbgdNo ratings yet

- Vita Student Partnerships PresentationDocument19 pagesVita Student Partnerships PresentationFryda Aguilar LeonNo ratings yet

- Restructuring (JLF Route)Document2 pagesRestructuring (JLF Route)lekshmyrajyNo ratings yet

- The Fatf & Pakistan: A Timeline: Usman W. Chohan, Mba, PHDDocument17 pagesThe Fatf & Pakistan: A Timeline: Usman W. Chohan, Mba, PHDAbdullah BhattiNo ratings yet

- On January 1 2015 Evers Company Purchased The Following Two: Unlock Answers Here Solutiondone - OnlineDocument1 pageOn January 1 2015 Evers Company Purchased The Following Two: Unlock Answers Here Solutiondone - OnlineAmit PandeyNo ratings yet

- Shangri-La Hotel 2018Document248 pagesShangri-La Hotel 2018Chantal HonNo ratings yet

- Integrated Report 2020Document196 pagesIntegrated Report 2020KarthikNo ratings yet

- Talent Attraction and RetentionDocument3 pagesTalent Attraction and RetentionВасилий БольшаковNo ratings yet

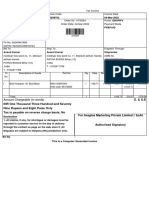

- Amount Chargeable (In Words)Document1 pageAmount Chargeable (In Words)Saurav Kumar SinghNo ratings yet

- Managerial AccountingDocument103 pagesManagerial AccountingKavya100% (2)

- Teaching Portfolio: Associate ProfessorDocument3 pagesTeaching Portfolio: Associate ProfessorSN SinghNo ratings yet

- Star River Electronic LTDDocument1 pageStar River Electronic LTDendiaoNo ratings yet

- Cash Ar Marketable Sec MNG TDocument30 pagesCash Ar Marketable Sec MNG TPee-Jay I. UlitaNo ratings yet

- Basic Features of Indian EconomyDocument18 pagesBasic Features of Indian EconomyPreeti KumariNo ratings yet

- Developing The Concept of Socially Responsible International Human Resource ManagementDocument14 pagesDeveloping The Concept of Socially Responsible International Human Resource ManagementUMAMA UZAIR MIRZANo ratings yet

- PAPANDREOU ANDREAS CV PDFDocument7 pagesPAPANDREOU ANDREAS CV PDFOlympia GrNo ratings yet

- Agricultural Scenario in Andhra PradeshDocument14 pagesAgricultural Scenario in Andhra PradeshDivyaNo ratings yet

- Investor Presentation June 2023Document31 pagesInvestor Presentation June 2023hegoyiw885No ratings yet

- Proforma Mahindra TeqoDocument1 pageProforma Mahindra Teqop m yadavNo ratings yet

- Yes Bank Case Study 3Document8 pagesYes Bank Case Study 3AbhishekNo ratings yet