0% found this document useful (0 votes)

2K views20 pagesHigh-Strength Low-Alloy (HSLA) Steels For Cold Forming: Description

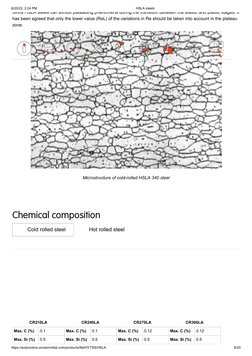

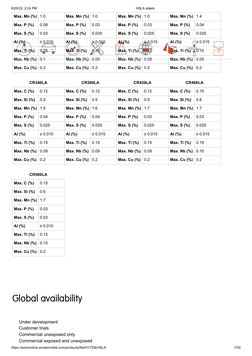

This document provides information about high-strength low-alloy (HSLA) steels for cold forming applications. It describes HSLA steels, their applications such as structural automotive components, and lists various grades and their mechanical properties.

Uploaded by

nandi_engineerCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

2K views20 pagesHigh-Strength Low-Alloy (HSLA) Steels For Cold Forming: Description

This document provides information about high-strength low-alloy (HSLA) steels for cold forming applications. It describes HSLA steels, their applications such as structural automotive components, and lists various grades and their mechanical properties.

Uploaded by

nandi_engineerCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd