Professional Documents

Culture Documents

29 05 2022 12849797

29 05 2022 12849797

Uploaded by

K KARTHIK0 ratings0% found this document useful (0 votes)

15 views62 pagesdfgfdsg

Original Title

29_05_2022_12849797

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdfgfdsg

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views62 pages29 05 2022 12849797

29 05 2022 12849797

Uploaded by

K KARTHIKdfgfdsg

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 62

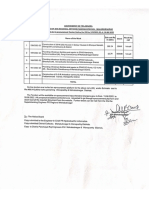

National Rural Infrastructure Development Agency

Ministry of Rural Development, Government of India

sea QB Version 2021.0- Part I

Format for information to QM for Inspection of Ongoing/Gompleted Bridge Work

IL

Wv.

VL

Vu

vill.

IX,

Xi.

XIIL

PART I: Work Information (Zo be filled-up by PIU)

GENERAL:

Work: (checkYany one box)

Date of inspection:

‘Name of quality monitor (QM):

State: FE Lantaanrr

] District:

lin-Progress [Completed |

(6- 03-202 2

NQM || Code|

£.D ash av athaor| oon eal

MAH ARopHAMH Block: | DE VARKADNA.

Name of bridge &

Location

[Conti Rua tor of Hin Live U DRdm, of

ROAD EROM Hacong PALLY TO DEVA RUAPRE Chee ios ly

Package number.

Saye BLBOL|

Sanctioned length of the bridge.

Deviation in length of the bridge (Ifany).:

Reasons for deviation (if any):

S4.3ep Mm

oe

se

Estimated cost (as cleared by GOI)

Technical sanction cost:

Awarded cost:

Expenditure: (if work is ongoing) a. Expenditure done:

b. Bills pending:

Total expenditure = (atb)

Completion cost: (if work is completed)

Rs2Sb2%6 (naman ~ 62-6.

CaNT 830 Nakh

Rs. >56226laxnWS Lakh

Rs.

\abo4y Lakh

Rs. _ Lakh

Rs. a Lakh

Rs, Lakh

Rs. Lakh

XIV. Date of award of work: (date/month/ year)

XV. Date of start of work:(date/ month/ year)

XVI. Stipulated date of completion:(date/ month/year) | 6

XVIL

Actual date of completion: (date/ month/

year)(in case of completed work)

2 Let zy

galli~n [foi

e\ |[as

2. PHYSICAL PROGRESS: (Ongoing/Completed)

Construction programme and Physical progress (Strike off whichever not applicable)

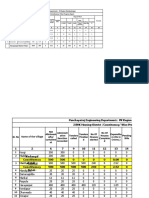

item of work | Units | Quantity [Quantity | Completed Fill in start and completion dates | Delay in

lis perDPR| executed | percentage months

cotitem | Progress | Start — [Completion

status Date Date

® OTe @ ® © ® ®, ®

: Due tla) Pelt ly

}) Layout [Cum | yisel Soup F4-99/ [Actual alia [Sto hoe,

F Due’ Zolle | yo] ler]

nao Com _| $3510 | Yee 68) | Actual sleba —

F Due’ ols 22] sofiitea

WD Substrctowe [Cw |A13| Cwm 2|y ort [Aout [istslan. | —

msmevsmenre be dice = a Soltth auth

D =

prawn wars [| egea] —~ | — Pt —}eelue{eslaka

Ivy Te] Bes Due [38/8 hx | Bolwhe

vi) Approaches elo nee? oe Be. eae sell

“Mandatory boards! | Due Beh] te forked

Signage ete. PN) Ss] we | Actual

3. PARTICULARS OF THE BRIDGE:

3.1 Type ofthe bridge (according to HPL) Submersible \ANon-submersible|

{according to Material) RCC Steel

Composite Pre-Stress

3.2 Type of foundation Open { Raft

Pile Well

3.3 Length of bridge 543u al

3.4. Number of spans and spans length S Ves Of-[0 Ab Mts

35

3.6

37

3.8

39

3.10

3.1

3.12

3.13

3.14

3.15

3.16

3.17

Width of the bridge eae m

Footpaths provided Yes No

If provided, width of footpath am

Formation Level (F.L.) OS. 2uy_™

Highest Flood Level (HFLYOrdinary Flood Level (OFL) [| go. em m m

Bed level (Lowest) tL BRoso m

Catchment area tL tq km?

Linear waterway at HFL, S430 m

Design discharge *{Gip-t3 _cumeo

Design velocity “ol ms

Foundation levels (a) Piers : [PI m| [P2 m| [3 m

Pa m | [Ps m| [Ps ™

p7 | Pg m| [Po m

(b) Abutments :[Al m | {a2 7]

(©) Returns [RI m | [R2 m

Foundation Strata

Safe Bearing Capacity (SBC) tons/m

River protection works provided or not (PV ves No

if provided :

Rigid boulder apron

Type of Substructure

@ Piers ~ Solid ciroular Hollow circular

Mf Wall type pier

Any other type:

7 pe oaeniee Gravity type Spill through

Box type Counter fort ype

Any other type:

© Returns

3.19 Type of bearings:

3.20. Test report of bearings available or not

3.21 Type of superstructure

3.22. Type of expansion joints

3.23. Type of wearing coat

3.24 Type of drainage spouts

Box type Counter fort

Tied returns Cantilever type

Any other type

Elastomeric Pot PIFE,

Rooker & Rofigr fh

‘Any ther type:

Yes No

wt RCC

Solid slab ‘T Beam slab

Voided slab Box girder

Any other type

Steel

Plate girder Truss frame

Arch bridges Cable stayed

Suspension Bailey bridges

B Copper plate

Bituminous Strip seal

Modular Finger type

Any other type:

RCC

Bituminous

per IRC SP

042

As per Design

3.25 Design loading

3.26 Whether approaches are in cutting or in filling

3.27 Type of pitching in approaches

3.28 Whether bench marks and alignment are established

near the bridge site (give locations and RLs)

3.29. Type of Railings

4. QUALITY CONTROL:

1. Locati6n of Field Laboratory

I, Geo-tagged photograph of laboratory uploaded on: (date/ monty year):[ 2.4 | tx | rert

IIL. Reason for delay in establishment of field laboratory (ifso):

Single lane IRC Class “AA” loading or

double lane IRC class “A” loading which

ever produces severe stresses,

IRC class “B” loading

[Sfigle lane IRC class “70R” loading or

double lane IRC class “A” loading which

ever produces severe stresses

Any other type:

Cutting. Filling

Partly cutting and filling

joulder pitching! Conerete block

Yes No

HPAL: oem

Location: (re Nv RL! 10) 2es m

THATS

Location: Cee ay RL: [o% gym

Location: RL: m

°C as per Pipe

standard pitching

Steel il

Any other type:

rile:

IV. Details of contractor, executing the work:

‘Name of contractor PAN number Mobile number E-mail ID.

K. Muratrpg x keooy [Ranpretyrd I SQ292 oF 8

V. Details of contractor's engineer available at sit

: (Responsible for maintaining quality control register part-1

Duration of posting at site

SI. | Name of contractor’ i i

a5 cngincer at seat S| Identity number | Mobile number coo i

[Le | Hea Wve | AS 8149oG02_| york, | pawns

VI. Details of head of PIU supervising the work:

SI.

‘Duration of posting at site

Head of PIU i

20. | (Executive Engineer) Employee number | Mobile number From To

| OM. Netever Pett YOUR | | YS4SS5 69 lea\og lay | proses) |

g

Vu.

Deiails of assistant engineer supervising the work and maintaining quali

ty control register Part-If:

‘Name of assistant

Duration of posting at site

_ engineer Employee number | Mobile number fan ne

LS RewakAistwr |i sags [yy uss ¢ [ey Jouks | premap

VII. Details of the junior engineer supervising the work:

| SE] Name of junior aEtieaey ,_ | Duration of posting at site

engineer Emplayessuinbe ere

INLoti ye 1 Fevnpleyo Vile? From To.

T |b, Satepowric hay [166847 sy | IAL 38 4a, Heath | prow:

IX. List of equipment available in field lab:

— NSH Srahesed —

‘Available equipment that are in wo

ay

ble equipment that are wot in working

condition (2)

Ma

wat

X. List of equipment not available in field lab:

— BL -

XI. Reasons put forth by PIU for non-availability of equipment in field lab:

— wit-

XII. Details of calibrations of equipment done:

XIIL. Equipment, documents and drawings ready to be made available to QM before or during the inspection:

DER) Rarcument COM) Design Mi, Veet Dp of-

Mederihg

DETAILS OF MIX DESIGNG):

Sl. Mix Desi, Average Details of Institute’ Details of Mix

No. en Mix laboratory where mix | Design approving

Design design was done PMGSY Authority

Strength

i. | Cement Concrete M20 JOP Noten, a)

De fo Mhal yd Sorviies Pt Hal

ii, | Cement Concrete M25 ee, ae v

DHSS a] SoAriee BT

iti, | Cement Concrete M30 ae nee es Rett Tearing:

34-6504 QIN] ens

iv. | Cement Conerete M35 oe :

v. Cement Concrete M40 — 7

vie Wet Mix Macadam (WMM)

Dense Bituminous Macadam |

— eae pase

viii. | Semi Dense Bituminous Concrete

ix. | Bituminous Conerete

6 EARLIER INSPECTIONS BY NQM, SQM or SENIOR DEPARTMENTAL

OFFICERS (SEs & CEs) AND ACTION TAKEN STATEMENT:

(Please indicate chronologically name and designation of the officer who had inspected the work).

Date [Name and Designation) Stage of work at the time ‘Major observations Action taken by PIU

of | of inspecting officer of inspection with date

visit_|(QM/SQMI/CE/SE)

@) 2) 3) 4) (3)

aes — oe ee oe

Signature of the Head of PIU.

Name and Designation of the Head of PIU .M.

National Rural Infrastructure Development Agency

Ministry of Rural Development, Government of India

Format QB Version 2021.0- Part II

a

Report Fdoaibrite bebe (NQM)/State Quality Monitor <2

(To be filled-up by OM)

1. GENERAL DETAILS:

L Date of inspection: 16-03-2022.

IL. Name of Quality Monitor (QM) Nom || Code

(check/ relevant box and fill code) E.Das & ae ath Se SQM || Code}

I. State: Telangana | District: Block:

[Mahaboobuage” Devav kal ve

IV. Name of Bridge & Location: Gafni sep deve x a"

©

Devavk spas o kM

V. Package number: TSO4DENT BL Bot

‘VIL Physical status of work: { AS | Ongoing ‘Completed

(check/ anyone box)

VIL. Present status of work: (check boxes as applicable)

1

Layout Foundation Substructure

Suverstructure_| | Protection work _| ‘Approaches

Finishine stave

VIIL. Photographic or video-graphic records (optional) of all hidden items like reinforcements of foundations/ sub

structures/ super structures etc, are kept by PIU, till Defect liability period is over for bridge for any future

reference or not: (Check V any one box) | y | a ]

es

2, QUALITY ARRANGEMENTS-OBSERVATIONS (in case of ongoing works only):

(Geo-tagged photograph of the laboratory showing the available equipment’s fo be uploaded)

L

I.

Ti.

vu.

Whether field Inboratory established:(cheek V any one box)

Whether location of field laboratory is same as

indicated by PIU in format part-I: (check any one box)

Whether necessary equipment as indicated in part-I are actually

available: (check v any one box)

Whether equipment’s have been used: (check ¥ any one box)

Ifall necessary equipment is not available, whether you have

verified them with the list of deficient equipment’s provided

by PIU in format Part-I: (cheek any one box)

Calibration of equipment done or not: (check any one box)

‘Whether contractor’s engineer as per Part-I of this format, is

available at site: (check any one box)

If contractor's engineer as per Part-I of this report is not available,

whether you are satisfied with alternative arrangement made to

maintain QCR-I: (check/ any one box)

Whether lab technician and other staff is available for testing in the

laboratory: (check any one box)

Yes Partly No

“Yes No

ves | [-Partly No

Yes Partly No

Yes No

Yes No

‘Yes No

Yes Partly No

Yes No

Guiding note: Ifthe field laboratory Is not established, overall item grading shal

sub-items are graded partly or no, overall item grading shall be SRI.

Item Grading-2:

(Check any one box)

s sri] [ [vu

II be U. If anyone or more

If this item is graced SRIU, write clear reasons and suggestions for improvement, indicating important

deficient equipments

yetm

2,

essive sty best machen

a one ee tk OOo Ha

se

ood meter are pes x oil ble

Be proceed and

L

(a) Based on executed quantities, whether all mandatory

(b) Whether Quality control test register maintained as Ye

(©) Whether QC register part J] maintained and test results

Ce Acct ect

3. ATTENTION TO QUALITY (in case of ongoing works ont}. “the teat

Maintenance of Quality Control Test Registers:

Ye

tests conducted (check any one box) ia

Partly

Partly

per provisions: (check any one box)

‘Yes

monitored as per provisions: (check any one box)

Partly

No

0 022

a

* IL @: Adequacy of quality control tests, as per quality control test register:

Item of Work [ Quantity | Quantity [Name ofthe | Numberof | Namberof | Testing

asper | executed test tests required tests adequate

DPR (as per executed | actually | (Yes/No)

Cun quantity) conducted

a) Q) @) 4 6) 6) Mm

Foundation

tt .00| COTNPYeseit (

work Mas [426-75 425-00] PrPriie (5 6 Y

Substractuny

work 20 38.69) — pins oe _~ a

Superstructure

work PD) 2 4/390-48 — oa aa _

‘Approach Slab

and fixed N), . .

items Railing} 77-18 _ - oe

kerb, Crash

barrier etc.)

‘Approach

work

(b) If testing found inadequate, the reason for less testing: (Check v one or more box)

. Negligence

. Lack of equipment in lab NA =

: Lack of knowledge

: eee a

(©) __ Verification of test results: (C: conforming, N: non-conforming)

Quality control tests to be conducted by QM and the results to be matched with test results previously

recorded in Quality control test register, at the same component of the structure.

Ttem of ‘Name of Results of the ‘Test results as per | Results of the test] Whether the test

Work Test test Quality Control test | conducted | results recorded in

conducted by | register at the same {previously by QM| Quality control

QM at the location atdefined | test register and

component of | (Mention the Page no. location. as conducted by

Founda - the structure, of Register) cm QM are in

He‘on cm conformity?

(Yes/No)

@ @ ® @® 6) ©

Z Covep vest

Pee Foateny ‘stelngfi BET FA-%8 = x

Rag €

hetween % &PA 1 c | 75@4-78) oe ¥

Ba-Footin apiinat Cc | re (4-78) a ¥

Par Fosttng 7 c_| #7 @4-78) i y

[Pike Rho < 78 (H4-70)| 7 oat

oo

“OG

(a)

©

Whether non-conformities recorded in QCR-II by AE have been rectified and

recorded in Quality control test register again as conformities, after conducting

necessary tests: —NA—

(Check Vany one box) Yes No

In order to assess the quality of concrete in case of doubt, if any Non Destructive

Test (NDT) such as Rebound Hammer test, Ultra Sonic Pulse Velocity (UPV) et

‘has been conducted: (Check Vany one box)

Guiding note: If the QC registers are not maintained or verification of test results are not conforming,

overall item grading shall be U. Ifanyone or more sub-items are graded partly or no, overall item grading

shall be SRI.

Item Grading-3:

(Check any one box) : SRI a

Jf this item is graded SRI/U, write clear reasons and suggestions for improvement, are to be recorded:

‘'S

4, FOUNDATIO!

NA ne aloreney cowrp(etet

A) Ongoing (Work in progress)

1. Foundation Piers, Abutments and Returns progress as on date of inspection-in %

Abutment: [At %] [A2_%

Piers: ms) [_%] _%) (ee) fe

P6 % P7 % PS % Pg %

‘Returns: RL %o R2 %

Item of | concrete

Location’ | Grade of | Quality of material is adequate as per qu

control register

oe ‘Testing ] Grade

of | (SU)

work Cement | Coarse | Fine Steel | concrete

aggregate | ageregat cubes

by

NOM

Gfany)_

ay 2 3) Lie () 6) M (8)

Location’ | Grate | Fory?work | Reinforcement | Workability

Compaction | Curing | Gragg

Itemof | of | aqydlityand | checked by Of "| arrangement | arrangements | (git

work | concrete | gefangements | competent | Concrete

authority

a oy @ 4) © © @ @)

IL. Whether Cement and Steel tests (other than those provided by supplier), got conducted by

I.

independent laboratori

‘Whether flushing of bore before and after placement of reinforcement

uncased cast-insitu piles.

(Check V/any one box) Yes. No

it done in case of bored

——NA -

(Check /any one box) Yes No.

o

2 Fook 4 Me, 3-qo | [4:80] 5S HS. Ss

Po Pe RAM, § 14-00 | 23-50 s EE | EES 5

j 1

I. Whether Cement and Steel tests other than provided by supplier, got conducted by independent

laboratories:

(CheckVany one box) Yes No

Il. In order to assess the quality of concrete in case of doubt, if any, Non Destructive Test (NDT)

such as Rebound hammer test, Ultra Sonic Pulse Velocity (UPV) etc. has been conducted:

(Checkvany one box) Yes No

‘Guiding note: If quality of either material or workmanship is U, the overall item shall be graded as “U”.

Item Grading-4: S U

(check ¥ any one box)

(if this item is graded as U, clear reasons and suggestions for improvement are to be recorded),

tol

cc

p02

3

“ CaAcem

5. SUBSTRUCTURE ay

werk, é oe

ao veh

A) Ongoing (Work in progress) rot the ctene be vi lo ne.)

Location? | Grade of

Quality of material is adequate as per qualify | Testing | Grade

Item of | concrete control register of | G/U)

work ‘Cement Coarse Fine Steel] concrete

aggregate aggregate cubes

by

NQM.

(Gifany)

® 2 Q) Oy @) @ | o @

5{200%8

B/A00

Foutong Meo Ss s s Pee eee 3

Rat | Mes| 5 Ss s —|—| s

Location’ | Grade [ Form work | Reinforcement | Workability | Compaction | Curing | Guage

Item of of quality and | checked by or arrangement | arrangements | (yyy

work | concrete | arrangements | competent | Concrete

authority

a @) @) 4) | 6) © o (8)

: T

Foott he, M, Ste ete s s s s

Regt Ome 5 He Ss tS Ss |[s

I. Whether granular/ sandy filling behind the abutments and returns done properly:

{Checky/any one box) Yes. No

NA- work es on progues

IL. Whether marking with paint is done on bridge components with date of casting for concrete:

(Check\/any one box) ‘Yes No

Il Whether Cement and-SteeHtests other than provided by supplier, got conducted by

independent laboratories:

(Check/any one box) Yes No

Loe

a

aa?

sam

B) Completed work

Locatio | Grade | Compressiv | Testing | Surface | Size | Quality [ Weep | Riding | Grade

witem | of | estrength | of | acceptabil | & | assessment] holes | returns | (S/U)

of work | concret | of Concrete | concrete | ity and | Shape | by personal] Adequac

e | cubesas | cubes by | workman | as per | judgment | y (For

per Quality | NQM(if | ship | design abutment

Control | any) and

Test retur

Register

ay 2 QB) (4) (5) © . 8) (9) (10)

I. Whether Cement apd Steel tests other than provided by supplier, got conducted by

independent laboratories:

(CheckVany one box) Yes No

Il. In order to y&ess the quality of conerete in case of doubt, if any Non Destructive Test (NDT)

such as RoXound hammer test, Ultra Sonic Pulse Velocity (UPV) ete. has been conducted:

(Cheeky any one box) Yes ‘No

uiding note: If quality of either material or workmanship Is U, the overall item shall be graded as “U”.

Item Grading-5: 3 U

(check J any one box)

(Of this item is graded as U, clear reasons and suggestions for improvement are to be recorded)

Qh

eee

6. SUPERSTRUCTURE NA- To Acexe certo

@ RCC Superstructure

A) Ongoing (Work in progress)

Quali ofa Workansh :

S s ae BE a aE = =

18, a\e| ies |sbesel e2 4\,\2112

& os 2 Ele] 288. se ge Ao a ae a

2/52) 2 | 8| s| e528 22208 g ge) 2 | gs

3123) 8) <|2|ge85 e253 d es. £8| 6 | 22|2

2/2 |° | €) 2/232" eagiebag ée gel e

2 8 S/F i ges |SeeeP Ze J

ge [2 s 2

dQ) @ G1 4 1G) (8) (7) A8) (9) ao) | a) 12} | (13)

IL. Whether Cement/And Steel tests other than provided by supplier, got conducted by

independent labgratories:

(Cheeky any one box) Yes No

‘Guidjfg note: Tf quality of either material or workmanship is U, the overall fem shall be graded as “U"

Itgfn Grading-6 A:

feheck J any one box)

Of this item is graded as U, clear reasons and suggestions for improvement are to be recorded).

B) Completed work

= /8) 82, 82/2) = elel Jel 2 tls

Bch 33 eel easlele/#| 2) 2/2) 4 gl 2]¢

Be Ba selec) i) 2ig)a)3)a] ela) 2] EB) g|é

a | $a ea83| Be ajé ~“la/b] 2) ea] 2 alate

§ | £3 8228) $2) 3 é |e Bla E/E

2/2] bs |#2/3| 8 . fee

| 2) (3) TS) Try Tey 1 5) [oy Py Tray Ta) tay Tas) | 6) | a7) | a8),

|

l

I. Whether Cement and Steel tests

independent laboratories:

fher than provided by supplier, got conducted by

(Check/any one box) Yes No

‘of concrete in case of doubt, Non Destructive Test (NDT) such

lltra Sonic Pulse Velocity (UPV) etc. has been conducted if any:

IL. In order to assess the quali

(CheekVany one box) Yes No

Item GyAding-6 B: 7 U

(cheey/V any one box)

(Ufflis item is graded as U, clear reasons and suggestions for improvement are to be recorded.

tad

(ii) Stee! Superstructure NA- To Be execee

A) Ongoing (Work in progress)

Quality of Material Workmanship | »

g 3 milee ze

a\s g ja le [es 2 2

Ela|]2#|%/e |& |e 3 je Bett am re cca

€/2/¢6|2£/8.] €o/28 22 |225) kis | FR22

£/3|2| 2/83/42) 23 22 |3s2/ 822 | 2285

3/2] 2] a]2:)22]e2 32 |2ee) 225 2388

e#/S]e2)2/8") ge leq 23 |§ @er [22

3 2/3/8 |} 2 |28 Be | 2 25 a3

a 2 /¢e 5 oe 5 % z SE

“VF la [6 JS) 2 6 z oe

M1 O!]e@ 1 @/ o (©_| (1) (si (9) (10) a

yl

S

1. Presence of water spfay or moisture in the vicinity of bridge such as waterfall or marshy wet land?

(CheckVany one box) aa an

IL. Presence of dustrial units nearby, which emit corrosive fumes or discharge chemical effluents?

(Check/any one box) | Yes No

nce of salinity in the atmosphere? (CheckWany one box) Yes No

“Guiding note: If quality of either material or workamanship is Uy the overall Tem shall be graded as UO

Item Grading-6A: [s] u

(check Y any one box)

(f this item is graded as U, clear reasons and suggestions for improvement are to be recorded).

Agger

9

B) Completed Work

Welding Material

7 ® | a | Presence of Corrosion

S = § (Yes/No)

EFlsl2é |? If Yes, type of

% ] £ |_| 9 _| corrosion and specitie Any change in

B|/s|s3) 23 location Presence of | presence of load

= 4 es las Brittle Bueklin; classification

3) 2/33/23) 2. | Fracture (Yes/No)

g/o|selse| Ss EB] cvesNoy | We)

8 2 |2 | 2 £

2 ]a | g6 é

& [& | <

O/1@/)|@ | @ o) O | (8) @) (10)

= L.

L. Presence of water spray or yiSisture in the vicinity of bridge such as waterfall or marshy wet land?

(Check¥/any one box) (elves i

IL. Presence of industrig/units nearby, which emit corrosive fumes or

harge chemical effluents?

(Check/any one box) [ves No

t

yy in the atmosphere? _(Check//any one box) Yes No

Altem Grading-6B:

(check / any one box)

(if this item is graded as U, clear reasons and suggestions for improvement are to be recorded).

s U

: (li) Bailey Bridge Superstructure NIA — T Ae exected

A) Ongoing (Work in progress)

it ‘Quality of Material 3 Workmanship is

F ae Ba

¥ | 92. g2sl. ge

£ | 843 g |2e2/2 23

5 Boe § | eee|es Seas

5 pes eb /3o5| 8st] 58 §ag2

5 Baz BES |s25) 32°) 83 g Sas

a asa se |2e2\/Z28./ 8 g253

3 sea B23 | Peele oe | & So8e

€ ans Bee | Bae| age | we ge

3 aoe fs" |e°°) ges es gS

528 =8 £S9 /22 =

a | &e < patter gto tac z

@ <2 & 2

HDT @ ) a @) 6) o @

I. Any bolt and/or rakers and tie playés are missing or loose?(CheckVany one box)| Yes No.

TL. Any sway braces and/ ot trgom clamps are missing or loose? Yes No

(Cheek/any one box)

TIL. Presence of any crapking in the Bailey bridge? (Check/any one box) Yes No

IV. Presence of fy bends in bridge members? (CheekVany one box) Yes No

Gylding note: IF any of panel PIN Is missing or loose, the overall lem shall be graded as

fem Grading-6A: 3 U

(cheek J any one box)

(Of this item is graded as U, clear reasons and suggestions for improvement are to be recorded).

22

ee

B) Completed Work

Welding Material 5

#|a2-/2 2 Presence of Corrosion £25 é

2242/45 g (Yes! No) 332 aie

5 | 43a] & If'Yes, type of corrosion and | 3 2B a5

e | BE8| 5 25 specific location eae gz

2/32/22) 52 ge 83

= |28o/ 85] 35 5 34 ss

2)s?2/ 32) €2 | 2] ae] e| E42) 3&

g/age| Se] Se | BS | 35 | 48 & 2

3 | e388 | 8 8 ee | £2 | 22 3 5

& | 3 a §s | 68 |°8 g 2

e \8 £ z 5 2

Q@) Q) @G) a 6) ©. AD @) |

|

1

\ |

" |

WA |

J

I. Any bolt and or rakers and yi plates are missing or loose?(CheekVany one box) | | Yes No

TL. Any sway braces apf or transom clamps are missing or loose? Yes No

(Checkany one box)

TIL. Presenoyf any cracking in the Bailey bridge? (CheckVany one box) Yes No

Peésence of any bends in bridge members? (CheckVany one box) Yes No

Guiding note: If any of panel PIN is missing or loose, the overall item shall be graded as “U™

Item Grading-6B: I 7

(check Y any one box)

(if this item is graded as U, clear reasons and suggestions for improvement are to be recorded).

8

3

“7, Loap TestT— NA —

I. Results of Load Test attached or not (check any one box) Yes

No

Ifyes, comments required and copy of test results shall be enclosed.

Guiding note: If load test is not done or not satisfactory, overall item grading shall be U.

Item Grading-7; 4 7

(Check f any one box)

Jf this item is graded U, write clear reasons and suggestions for improvement:

NA-

s. Brarincs t4 To Az fexed — Wok es

A) Types of Bearing (Tick appropriate) |S n Prrawress at

Roller and Rocker Bearing A

Elastomeric Bearing Aave if

Pot cum PTFE Bearing

Spherical Bearing

‘Cylindrical Bearing

Any other type ~~

B) Conditi

mn of Bearings

(@) Metallie Bearings

crhog tre Have

i, General Condition- any rusting / ceasif of plates/ cleanliness or not 8

ii, Functioning ~any excessive m«

‘ment tilting/ jumping off guides

U

ifi,Greasingy oll bath requirego be redone or not $

iv, Cracks in supportingsfember- Abutment cap, Pier eap, Pedestal, if any 8

v. Effectiveness of

inchor bolts, whether in position and tight or not

vi Report anySther defect or observation found

292

» BAG

(b) Elastomeric Bearings

i, Report condition of pads ~ Oxidation, Creep, Flattening,

Bulging, Splitting, Displacement if any

fi, Report — Bearings are clean and free or not s

U

Report any other defect or observation found

(© Any type other than ‘a’ and ‘b’ above

Report - Any other defect or observation found

wh

IL. Whether test results of bearjygs are available or not:

(Check Vany one box) Yes

Guiding note: IF anygre of the sub-tems are graded as U, overall tem grading shall be U.

Item Grading8¢ a U

(check f any bne box)

(this teyyhs graded as U, clear reasons and suggestions for improvement are to be recorded)

gna

Jag -

SI

Py

9. EXPANSION JOINTS KA- Urovik 25 en oe

A) Types of Expansion joint (tick V’appropriate) fave!

Buried Expansion joint

[2

Filler Joint with Copper Plate

Asphaltic Plug J

‘Compression Seal Joint

Single Strip /Box Seal Joint

Reinforced Elastomeric Joint

‘Modular Strip /Box Seal joint

Finger Joint

Reinforced Coupled Elastomeric

B) Condition of Expansion joints

i, Isthere any crack in the wearing ed Yes No

ii, Whether existing gap is improgr Yes No

iii, Any hardening / crackje@ observed in bitumen filler ve ne

iv. Any splitting/ oyidation/ creep/ bulging observed in neoprene

Yes No

seating mayéial

v. Corrogfon/ damage to welds is visible Yes No

vi, hesence of debris in the joint [yes No

Report - any other defect or observation found ‘Yes No

Gui

ou

Item Grading-9: [

(check V any one box)

(this tem is graded as U, clear reasons and suggestions for improvement are to be recorded).

ing note: If any response of questions in sub item 9 B is“ Ves", the overall item shall be graded as

s] Le

2027

10, APPROACHES NA- Ta Ae exerted

wovk x o& pubstrncteve

fase

10.1 Embankment

Location | Suitability ofsoil | Compaction | Side slopes Shoulders Grade

(S/SRV/U)

a) @ QB) (4) (3) I ©

i

|

|

10.2 Sub Base (G.S.B.)

Location] Conforms] Material | Dry [% Comp] Thickness] Measured | Prescribed

(RD) to | Suitable | density | action las per DPR| Thickness | Thickness

Grading from kN/m? (in (in mm) | provided

(YIN) | plasticity mm) | “qyny

angle

a @ WN | 3) o 8) oy

10.3 Base Course (Non ae (WMM) and Bituminous Macadam (BM)

Location

Plasticity | Volume of | Compaction | Design | Thickness [Thickness

(RD) of Filler filler basedon | thickness | ofeach | adequate

material ‘material volumetric fas per DPR) layer of (S/U)

(S/U) | percent of |analysis/ sand | WBMi

coarse replacement | (mm) | WMM

| Aggregate method (mm)

| (Si)

a, ©)

@ QB) (4) (9) @ @)

Adee

v aeM

26

10.4 Wearing Course

NAR ook ta ak pubsipurctare

Location | Grading of | Laying Bitumen |Bitumen| Observed thickness ‘Surface

(D) | Coarse | Temper |content %, aslcontent % of layer un-evenness

AS ite att of R-]

Gaye | thew | POOR | Gee creasaned) S70 eu)

as per by

QcRI SNQM/SQM

a Q) @) @ © © Oo @)

10.5 Protection Work:

1 Whether sanctioned DPR has tJ

(check /any one box)

I Type of protection wo

provision of protection works: Yes No

{ (check boxes as applicable)

Retaining wall

Breast wall Parapet wall

rs

¢ other type of Protection work

Mm Qu

lity of Materials:

‘Locati

Structure Type

Type of Protection

(General quality of] Size and [Quality assessment

|(Retaining Wall/] work (RCC/CC/ material conforms} shape as | by personal

Breast Wall/ | Masonry/wire | to specifications |per design | judgement

Parapets) crate) (YesNo) | (Yes/No)

a Q) Q) @) () ©.

IV. Workmanship of Retaining structures:

Location’ | Workmanship of Whether Have weep holes | Adequacy of

RD | retaining structures | honeycombinglany | been provided | weep holes

other defects are | (Yes/No) provided)

observed (Y/N) (YesNo)

o ® ® @ 6

V. Incase, Stone masonry is used in retaining ture:

>

2) Workmanship of stone masdnry is acceptable:

(ofleckVany one box) Yes No

») Bond stone has bpén provided in stone masonry: a a

(cheek / ary one bax)

‘Guiding note: If syb item 10.2, 10.3, 10.4 are graded as U, the overall item shall be U.

Item Grading/10: : mi 7

(check 7 anyfone box)

this it

h is graded SRI/U, write clear reasons and suggestions for improvement).

~al2

SQ

2s

Dae

11.BRIDGE FURNITURE AND MARKINGS:

11.1 Observations: Quality of Bridge Furniture and Markings : (Ongoing / Completed works)

() Main Information Board

Fixed: s SRI U

(il) Citizen Information Board s SRI U

Fixed :

Ttem Grading-11.1:

(Check¥ any one box) s |

srt | u

If this item is graded SRI/U, write clear reasons and suggestions for improvement:

,

“s

11.2 Observations: Quality of Bridge Furniture and Markings: WWA- Wovke cs on

“progress at prbctrctave faves,

(iii) Guard stones fixed on 7

approaches : § oe 7

(iv) Mandatory and caution KK SRI U

signage :

ct

Item Grading-11.2: “|

(Check / any one box) s SRI U

If this item is graded SRYC, write clear reasons and suggestions for improvement:

12. General Observations of QM, (including the observations made during

the interaction with PIU staff and Contractor/Consultant Engineers):

A. Observations about deficiency in project preparation: (Give detailed observations about

deficiencies in general and items which have been left but are required as per site conditions):

(cheskyA or I)

1. No deficiency in project preparation noticed during the interaction with PIU Staff and

Contractor/Consultant engineers:

Cy IL. Deficiencies Observed: (check one or multiple box)

Oo ‘Nomenclature of BOQ Items is not clearly stated such as what type of binder (VG

Grade/Emulsion) has to be used and the quantity of such items.

[EZ Number of spans are insufficient as per the site's hydrological condition,

[1 No provision of protective work in DPR but as per site conditions it is required.

oO Hydraulic Design & calculation for bridge design not provisioned in DPR.

[2 Guard stone/ Crash barrier/ Road studs on approches are required to be provisioned in

DPR.

[21 Deviation from proposed Alignment.

. Any other comment:

B. Whether the work has been completed/is in progress as per work programme or the delay has

occurred. If delay has occurred, whether the liquidated damages have been withhold or

recovered: (check V relevant box and fill details)

Completed In progress

‘Whether there was delay Work progress is

Yes No As per schedule Extension of last

date completion

Ityes, fill below details If extension of last date, fll below details

Period of delay (in montis) Period of extension (in months)

‘Amount is Withhold Recovered || Withhold amount refunded Yes No

‘Amount (in lakh) ‘Amount (in lakh)

Reason for delay/any other comment Amount of penalty on contractor

Reason for delay/any other comment :

od

C. Whether the work has been completed within the sanctioned cost, if not, what is the action

taken by the PIU (in ease of complete works): (check /relevant box and fill details)

Whether the work is completed within the sanctioned cost [] yeg

Ino, fill the below details WA — 1 Goan work

Sanctioned cost (in lakh)

No

Completion cost ( in lak

Reason for extra cost

Action taken by PIU

D. Observations about the action taken by the PIU on the observations of inspecting officers

including SQMs and NQMs. (clearly offer comments about the action taken on the

observations of Departmental Officers, State Quality Monitors and National Quality

Monitors).

Previous Previous QWs observtion ‘Action taken by PIU ‘Your observation about

u's PIU's action

Designation

aNQM)

SQM

DO

“thes & Che| fevet duspeetten of SQmy

a

E. Comments about difference in observations made by NQMs/SQMs in earlier inspections (the,

NOM/SOM shall study the earlier inspection reports of NQMs/SQMs, if any and offer his clear

‘comments about the differences in observations, if any). (check v relevant box and fill details)

Whether any difference found in previous observations of QMs [| ves ‘No

Ifyes, your comment on difference in observation

F. Other observations, if any:

es stve tanta amacks ng ,

topahcort op pero and Rape

anata woceved & Pocere

Qs

a

2

13, OVERALL GRADING OF BRIDGE WORK

Trem Htems Description ‘Awardable | Awarded

No. Grade Grade

1 | General Details

2 | Quality Arrangements “ssh | spi

3. | Attention to Quality SISRH S

4 | Foundation ( Stage 1) Sie- gs

5 | Sub-Structure (Stage I) Siu NA

6 | Super-structure ( Stage 111) Siu uA

7 | Load Test SAT RA

Bearing -

5 | Grading to be same as for condition of Bearing) su NA

‘A. Type of Bearing- Roller and Rocker Bearing, Elastomeric

Bearing, Pot cum PTFE Bearing, Spherical Bearing,

Cylindrical Bearing Any other Bearing)

B, Condition of bearing Siu NA

9 _| Expansion Joint a0 A

(Grading to be same as for condition of Expansion joints) N

‘Type of Expansion Joint- Buried Expansion joint, Filler

Joint with Copper Plate, Asphaltic Plug Joint,

Compression Seal Joint, Single Strip / Box Seal Joint, —_—_

Reinforced Elastomeric Joint, Modular Strip / Box Seal

Joint, Finger Joint, Reinforced Coupled Elastomeric Joint.

B. Condition of Expansion Joint Siu NA

10 | Approaches

(To be U, ifany of the sub items (ii, (iil), (iv) are SRI or U) ssrvu_ |)

(i) Embankment S/SRIU [

(ii) Sub Base (G.S.B) S/SRUU ( NA

iil) Base Course SSRVU

(Non Bituminous (WBM) and Bituminous(BM))

(iv) Wearing Course S/SRIU \

(¥) Protection Work ‘SSRI J

202"

2

Qm

11 | Bridge Furniture and Markings

(to be U, ifany of the sub items are U) au

@ Main information Board S/SRUU Ss

Gi) Citizen Information Board SRT Ss

(iii) Guard stone on approaches ‘S/SRUU WA

(iv) Mandatory and Caution signage S/SRIU NA

Overall Grading Sisrie SRI

Guiding notes for overall grading:

© Ifall work items are “S”, the overall quality of work shall be “S”

© Ifitemsatsl. nos. 4, 5, 6, 7 and 8 are “S” and other items are either “SRI” or “U”,

the overall quality of work shall be “SRI”

‘© Ifany item at sr. nos. 4, 5, 6, 7 and 8 are “U”, the overall quality of work shall be

“U”, invespective of the quality grading of other items,

Ah bn hf

LE Dasharethem

Signature of QM

Name of QM

Date

en

14, QUALITY GRADING OF ITEMS OF BRIDGE WORKS:

Ttem No. Ttem for observation ‘Awardable | Awarded

Grade Grade

item No. 1 General Details

Item No. 2 (Quality Control Arrangements -S/SRIU=T St

Item No. 3 ‘Attention to Quality S7SREU s

Item No. 4 Foundation SE Ss

tem No. 5 Sub structure 3/0 NA

Item No. 6 Super structure s7U NA

Trem No. 7 Load Test su NA

Tem No. 88 | Condition of Bearing s7U NA

tem No. 9 Expansion Joint 37U NA

Tem No. 10 | Approaches (Stage If and 111) S7SRI/U NA

Tem No. 11 | Bridge furniture & marking SRE Ss

Overall Grading -S/SRIAU SRI

Signature of QM

Name of QM

Date

38

Sogo enaeh 2

w

_4tKe l= ay pS

do yaaind uO 287° €0T SEL7TLEL |69°SETT €

do. yaajn> uO S87'€0T 7CS9T'GLET |69CG'EETT [7

quawaseg Jawojsues| UD 9T6°COT LvLs°0002 |évTc'0e6 |T

‘SeWaYy Wal apnyeq} apnysu0] ON'IS|

deseuqnqeyewi:3 eipeylenag:|epuew| | SUET 97957 SY=1509 154

TOSTEINIGPOSLON a8e}9ed I-yoqeg ‘IIFASD Wid *2UeID,

Jolsiq JeBeugnqeye |epueyy eapeyesenag U| eApeyxesenag Oo}

Ajjediemseg 4/Y-GOTU a3e}|!A eapexesenag JeaN aBplig J9A2] YBIH JO UOINAISUOD -2/40M ayy Jo aWeN

ASN Wal

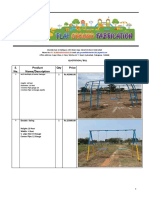

Quality Control Lab Equipments

| Name of the Work :CONSTRUCTION OF HIGH LEVEL BRIDGE ROAD FROM BASWAIPALLY TO

|DEVARKADRA AT 5/200 TO 5/400 KM OF DEVARKADRA MANDAL, MAHABUBNAGAR DISTRICT

Grant

= HeoH 2 (CHO SH

[PMGSY Il, Baten 1) DAE SE OUPECTE ON: LOA soap eiTacbO

+: RS:256,26 Lakhs (250+6.26)

‘Mandal: Devarakadra

District : Mahabubnagar

Qo

Lakhs

SINo List of Equipments No's.

41 |IS Sieves Set with Lid pan Oneset

2 |Auto Levelling Instrument with staff and Stand Oneset ~~

3 Compressive strength testing machines ae avarlevole , One set

4 {Rebound Hammer To 0S ems tallest ‘One set

Agoregate Impacttest Apparatus - Alyt avian loble One set

6 |Flakiness and Elongation Guage 2Nos ~

7 [Electronic Weighing Machines 30 Kg, 10kg Each 1 No

8 [measurement tape , Rodemeter, Spirit Level Glass Jar 2eets

9 |Slump test Device 1No

Rapid Moisture Meter Clot axtarlable “No

11, [cube Moulds of 150 mm x 150mm eNO

12. [Proctor Density Apparatus 2nos

& pases

:

Ch

PNDN.2

|

" ENDN.2s |

4 {

ENDN-26

Ag

Moistire Content in Pine

Azgropae

Checking of Form Work

5) Strength of clamps and

of Form work

ii) Mortar tightness

Height of pancts _

iv) safe neces

the form work

Cube Strength Test of

Concrete

[Test

P Test 15

| Test 16 |

LT

Rebound Hammer Test

; RAdex Om Pood

Name ofthe Bad? Conmtanction of High feel

i + od g)roo +0 T]ae0 Meng

Peon Besurip 9 Peroswreddteee

peverwiedae CM), wet Disris

PackageNo; Tt Sogn pug ol

Date of Inspection : \ He \o3| af

Chainage :

Gonpsrenqin oy Pier 4 Cove Sheng on Ralf bakery

Footing Cadouys) Pee PX owe pa (ey Days)

Zp] rq] 25 30 | xe | x

23 wa] ay 2 BO] go

zy | ay zy BU] 2 Jog

: L

Ag Comp Gnunyeo = 2.9 650 ws fig Comp Seovegtin PIB omy

hae Creat upe Aa. (3-olmme AS pen Cho Type B= ZU lo Waa

Comp Seema oy, pier P3 CanP Sent © Ploy PU

Feoting Chaat i eating C4 deus)

ZH] ry Qe 2S as | ly

Mw ZY | 24 2% my fa

ZY U6 Vb 2 Ub ao

Avg, Corp Creag 2. US DOA moa > AVG Comp Gength 2254 Y

Ae pee ures “yf BRR) wave he pee ner Tyo -N 21480 mg

sot

AE Dercwuotey Ae

Rebound Hammer Test

Name of the S30: Gogteuatian, of HIgh hoe Baliga on Rood json aes

TY Derartiodey ot crop 19 ¢ yoo vng DUeAodsr(y), Horabubweru

Dilg >

Package No: TS o4 DE f1 BLBO

Date of inspection: 16 [oZ}r2

Chainage :

Comp Grenneptt on Rey

bekwen DA ord m- (14D)

2 | 2¢ 2%

re | se far ae

26 | zo | wz

Ng Comp Grong 2 2p ter el

45 pen desk type Be 23+ Shaw

2d

ae, Le

AE Demmetre,

MIX PROPORTION

OF

SONCRETE GRADE M10

{with using Cement OPC 53)

Name Of Work: Package No TSC4DEIIIBLB01- Construction of High level bridge on rosd from

Baswaipally to Devarkadra at /200 o 6/400 of Devarkacra Mandal Mehabubnagar distict,

To,

District Panchayat Raj Engineer

Plu Division Mahabubnagar Dist,

TOP WTC

‘TESTREPORT

Name & Address of the Customer:* ‘Tost Report No: TPL-ZZZ-HY!

The District Panchayat Ral Engineer,

PIU Division, Mahabubnagar Dist. Issue Date: 30/12/2021

Telangana,

to Devarkaca at 5/200 to 6/400 of Devarkadra Mandel Mahabubnayar district.

-21-1325-5

Name Of Work: Package No TSO4DEIIIGLEO1- Construction of High level bridge on road trom Baswaipally

Notes:

using OPC53 cement

‘Aggregates In ‘Aggregates Tn

MIX PROPOTIONS ‘SSD condition DRY condition .

[Cement 240 240 gin

[Om 1272 1268 kim

ISend 757 749 gir

{Water 144 182 gin

Density 2413 2409 kgim®

Free WIC ratio G80. 0.60, %

‘Summary Trial mlx resulte casted at laboratory

Paramator wo

‘slump. 80-100

‘Compressive Strength of trall mix cube

[specimen of 180 mmx150mmx150mm size

lcasted

T days

we 10.74

28 days

(Pa) 16.13

2} Sorteation for water absorption of tne aggregate & coarse agaregate to be applied at ste,

2)The mix proportions recommended above sheuld be tied in

‘Materials and finalized by observing the actual performance of the concrete mix

0 field using the proposed

3)The Stump shall be measured and the desage of admixture shal be adjusted on the basis of

‘concrete mixture, travel time and seasonal variations to achieve the required workable slump

For Topnotch

# Information provided by Customer.

[estresuts represent sarees proved io Topnoich by te sre which may

Important |@eresertaon oto eciua stlstutre Topnetcn dos nol esse tay sce

Notice [ttt of samp ifornaton proved by he can Th bly ef Topo

‘HR tang chargs uncor any cxcunstances. This repre cofidatal property a fe

{eserinatee, pbtahed or eproduced vittout prt wien approval

no[ BRAY

ines tone)

38 Not exceed t=

and mey not be|

‘TOP-NOTCH TESTING SERVICES PRIVATE LIMITED

1s adler Pte ua i Pees Car, a TPA Raja, Rend 5008

‘Repl Office: H.No.: 17-1-382/P/42, Press Colony, Sagar Road, Champapet, Hyderabad - 500 079.

‘Phone: 986 964 6280. 99466 86054 Fama nfo. topactcharvices@ pal om

Page tore

bare sonzeoet

louenr District Panchayat Raj Engineer PIL Division Mahabubnagerdiatrict

ca "ackage No TSO4DEIIBLBO'- Construction of High level bidge on rosd from Baswlpely to

Bovarkadra at 8/200 to 8400 of Devarkadra Mandal Mahabubnagar datict.

[A- STIPULATIONS FOR PROPOTIONING

8) Grade designaton() ‘] 10

2) Type of coment OPC 53 grade conforming to 1S 200

) Maximum nominal size of aggregate 400mm

8) Minimum cement content (kg) : 20 (As Portable § of 8 50)

8) Maximum water-cament rato + 060 (As Par be § ofS 450)

1) Worksbily 50225) alump(As par cause 7.1 1S 486:2000)

@) Exposure condition ws

1h) Mathod of concrete placing Dumping

1) Degree of supervision + Good

1) Type of apgrogate 1 Crushed angular aggrogate

1K) Maximum cement content (gi) 1 AsPeris 462000

[4-2 TESTOATAFOR MATERIALS

2) Comoat used

D) Specie gravity f cament

©) Specie gravy of:

1) Coaree aggrogato 288

2) Fine aggregato 258

4) Water absorpton

1) Cosrse aggregata(4omm)

2) Fi aggregato(M.cand)

©) Froejeurtace)moisture

41) Coarse aggragala

2) Fine aggregate

1) Sieve anayeie

4) Coarse aggregate

(OPO 59 grade conforming tos 269

345

930%

10%

Nifabsorbed moisture alco ni)

Nilabsorbod mature also ni)

isstew | APAYSIs of Coarse Aggragate

Jee) Fraction in passing

Tam

(aor "780

Honm 8:10

fare 7

[zen 3.08,

2) Fine aggregate 2) AloAggregate Grading

ISsieve| %

[Sizes mm} passing | #9) | is sieve A009

sizes |

an oT ‘an Sad |e

a a Table-i0

x 5 Gd 100 | TOO00_| 6

onm 17.50 4877 | 45076

enh |1.08 | — 66: 37 i

x 25 | 16 :

x

Fring sggragat confirming to gracing 2 lof Taba-a 1S 2892016

ING

f ‘sum

TARGET STRENGTH FOR MIX PROPOTIONING

Por 18 102822019 Target Mean Comprassve Strength fek= ok+1.65°S¢ or fek#X

[Fee Target 28 Days Target Mean Compressive Stength M-10 Grade Concretais 15.775 MPa

JA4 SELECTION OF WATER.CEMENT RATIO

‘As Por iS 458:2000 Maximum Water ComontRato 080%

JAS SELECTION OF WATER CONTENT

Fram Table 4 of1s 10262-2018;maximum water comtentfor AGmm aggragato 15 ite (for 25 to $0 mm sump range)

Be20c on sis, for pain coment concrete Uw water comantracuct 13.00 _perconthes been achived

Honce,he auived wala content= 143.55 thre

[4-8 CALCULATION OF CEMENT AND FLYASH CONTENT.

Cornent content = 240 git

From Tables 15 488:2000, minimum Cement

‘content or Mc” exposure conditon = m0 igi

Jcementious material centent . 0

Water content . 144

[ScWater-coment ato(watercementitous contant) = 0.80

Cement oR = 240

[A-7 PROPOTION OF VOLUME OF COARSE AGGREGATE AND FINE AGGREGATE CONTENT.

[rem Table 5 ofS 10282-2010 volume ef conre aggragate corresponding to 20mm size aggregaie and fine eggragate

or waer-coment rato of 0.50 «0.75

nthe present case watercoment rats 0.60:Therfore, volume of coarse aggregate is requir to be lneoased to

cszeate ihe fhe eggragate content.As te watercement rato is er by 0.08,ha propotion of volume of cere epgregale

neronsed by 0.010(a the rae of 40.01 for avery 4005 change ha watercament rai). Therefore corecte pepoton of

volume of coarse eggragae forthe water-coment alo of 0.8-0.860.

(Noten case the coarse aggregates not anguaronethen alse volume of coarse apgregala may be required to increases

Juin besed on experience.)

For Workaity tbe coarse apgrogate is reduced to & percent.

Theretcrevotume of coarse aggregate(Ca) = 0.62

[Volum of ne aggregats(Fa) content =1-cas 0.28,

The mic elewatione per unit volume of concrote shat be as fatews:

2) Volume of concrete = tet

») Volume of cament 7 Mase of Comant ‘ 1

gravy of carson aad

A240, 4

ss *

= 00765 m

©) Volume of water : Mass of water | 4

aang ear — —-

~ me 4

7 Too

= ats mt

4) Volume of an aggrogate = (edotyosey,

07701 mt

©) Mass of conrae aggragate(ca) = fx Volume of eax Specie gravity of ca x 1000

= 1272 igs

9) Mass of ne eggrepatata) = fxVolume offex Speate gravity offa x 1000

<5 kgs

JA‘ M-18 MIX PROPOTIONS. ‘Aggregates in $80 conaition ‘Aggragetes in Dry Condition

‘Cement - 240 Kgl? 1240 kgin?

40.0mm . 1272 kgim* 1268 kin?

Sand . 76 gi? 749 gin?

Water . 144 kgin? 182 kgim*

Density * 2443 kyl" 2408 kai

Free WIC rato . 060 % 0.80%

|Note: 1) Correction for water abecrpion of Fino Aggrogate & Coarse Aggragale fo be epplie a le.

2)The mix proportons racommended above shouldbe Wed Inthe fai utlng the proposed marials er finliced by

‘observing the actual performance ofthe concrate ml

‘3)The Slump shallbe measured and the dosage of admixture shal be adjusted on the base of conerelemisture, ave

‘and seanonal variation to achiave the required workable slimp based tal

For 701

TOP VW@TCH

TEST REPORT

Name & Addross of the Customer:# Test Report No: TPL-ZZZ-HYD-21-1325-58

‘The District Panchayat Ra] Engineer,

PIU Division Mahabubnagar Dist. Issue Date: 09/12/2024

Telargena,

Your Ref: Nil

Dated: Nil

[Namo oF Work: Package No TSO4DEINIBLBO1- Construction of High level bridge on road from

swalpaly to Devarkadva at 6/200 to 5/400 of Devarkadra Mandal Mahabubnagar citric,

‘Sample Particulars: # Date of Registration: 29/11/2021

Concrete trail mix cubas Dato of Commencement of Testing: 08/12/2021

(Grade : M10) Date of Completion of Testing: 09/12/2021

(Date of Casting: 02/12/2024)

Qiy: 01 Set (Each Set = 3 nos.) ‘Sample Condition at recelpt: Found satisfactory

Test Required: Compressive Strength.

Method of Testing: iS: 516:1989, I$ 456:2000,

Discipline/Group: MechanicalBulcing Materials

TEST RESULTS

COMPRESSIVE STRENGTH OF CONCRETE CUBE SAMPLES

compr,

sett. | cradet | Dsteof | Area | Datoor | aget | woignt | Load

oaategt | cont | tone | cm | "aa" | ah) Sena

M40 Joartareoe} 22600 |osriazoz1] 7 | a1zo | 2602 | 11.42

1 N10 [ozrtaiz021} 22600 josi22021] 7 | 030 | 2403 | 1068 | 10.74

M40 Joarrarzoat} 22600 josareozi] 7 | 6110 | 2344 | 1042

For TOPNOTS)

Wie resey |

“some gt ue cunwhna |

eu reqig pee AO OES TOSS yao on bY TONG ST STOTT]

Imporant|Soeaotsane any reson an estat anneraten pose oe cet Te sly Topoaa Sete eae he

tee try ae hes tens

Page tof

Regd Office: HLNo,:17-1-38/0/42, Press Colony, Sagar Rou, Coampepet, Hyderbed- 500079,

Phone: 9849646280, 93466 86054 al info pocstservices@pmall.com

TOP W@TCH

Name & Address of the Customer:#t

‘The District Panchayat Raj Enginer,

PIU Division, Mahabubnagar|

Telangana.

TESTREPORT

Tost Report No: TPL-ZZZ-HYD-21-1825-58 i

Issue Dato: 09/12/2024

Your Ref: Nil

Dated: Nit

Name Of Work: Package No TSCADEIIIBLBD1- Construction of High level bridge on road from

[Baswaipaly to Devarkadra at 5/200 to 1400 of Devarcadra Mandal Mehabutnager clstrct.

‘Sample Particulars: #

Conerate trail mix cubes

(Grace : M10)

(Date of Casting: 02/12/2021)

Qty: 01 Set (Each Set

os.)

‘Tost Required: Compressive Strength.

Mathod of Testing: IS: 516:1968, IS 458:2000.

to of Registration: 29/11/2021

Date of Commencement of Testing: 30/12/2021

Date of Completion of Testing: 30/12/2021

Sample Conditlon at receipt: Found satisfactory

Disciptine/Group: Mechanical/Bulding Materials

gor TRENC |

ae Trarage

ancl toa to. ‘Area | Datoof | Age! | Weight | Load Compr.

SetNo. | Grado" | casting | mm’ | testing | (days) | tka) | (cN) Strength 1

ata) |

M10 |02/12/2021) 22600 | 30/12/2021] 28 8.120 362.2 16.10

1 | mto Jozrziaoz1) 22600 | soriziacei] 28 | 0130 | s544 | 1675 | 16.19

M10 |02/42/2021| 22500 | 30/12/2021] 28 8,080 | 372.2 16.54

ForTOPI SING SERVES PYTLTO

ita Recéy |

*tonmton vent cau, unity anager |

ra EB pd TORS i oT AN ay oa Tea Ton ha a TS

"soit ii ane cence ate siti sane eae

[writen seproval Unconauired sacnsien willbe ducerced wt 7 : oe buasbaad

‘TOP-NOTCH TESTING SERVICES PRIVATE LIMITED

‘Lab Address: Pot No.16, Sochitta His, Peram Cheruvu, Near TSPA, Rajendranaat, Hyderabad -

Regt: HLNo; 11 MVPD, Pes Clay, Supa Ret, Caney, Hyde = 0 073.

sopacerheevicesial com

‘93466 6004 smal

= 00091,

Page tof

MIX PROPORTION

OF

CONCRETE GRADE M15

(with using Cement OP¢ 53)

Name Of Work: Packsge No TSO4DEIIIBLBO1- Construction of High level bridge is

Baswaipally to Devarkadra at 6/200 to 5/400 of Devarkacha Mandal, Mahabubnag;

To,

District Panchayat Raj Engineer

PIU Division, Mahabubnagar Dist.

fad from

lari.

TOP V@TCH

‘TEST REPORT

Tost Roport No: TPL-222-HYD-21-1326-4

Name & Addrass of the Customs

‘The District Panchayat Raj Engineer,

PIU Division, Mahabubnagar Dist. Issue Date: 30/12/2021

Telangana.

Name of Work: Package No TSO4DEIIIBLB01- Construction of High level bridge on roed from Baswaipally

to Deverkadra at 5/200 to 6/400 of Devarkedra Mandal Mahabubnagar dist

‘Summary of Mix proportion of M15 grade concrete:

using OPC53 cement

‘Agoregates in Aggregates in

MIX PROPOTIONS $80 condition DRY condition

[Cement 255 255 cgi]

[40.0mm, 328 327 kgien®

[20.0mm_ 304 302 kgin®

{40.0mm_ 594 588 egim®

[ORE 675 668 igi

Weter 152 163 igi

[Density 2995) 2384 gir

[Free wiG ratio 0.60 0.60, %

ul Tabs

Param mie

‘Slump 80-100

Compressive Strength of trall mix cube

lspacimen of 150 mmX150mmx150mm size

lcasted

T deve

a 1224

28 days

(MPa) basa

Notes:

41) Cartection for water absorption of ine aggre aggregate to be applied at si

aie mix poportans ecerencrded toone webu be ed whe eis ucee tne rocona

materials and finalized by cbserving the actual performance of the concrete mix

3)The Slump shall be measured and the dosage of admixture shall be acjusted on the basis of

‘onerete mixture, travel ime end seasonal variations to achieve the required workable slump

For Topnotch Testing Services Privafs Limite

Fest resuits represent sampes proved 9 Topnole by ha TaN WN Tay or May nel ba Tue

Important| resentation ofthe actual ete/tuetuo. Tepnoich does ac assume any esponsbly as othe

Notices. [euertely of sample internation provided by the cient The labiy of Topnoteh doesnot qiceed the

160! testing charges under any croumstances, This reports confidential property of tho clant ake may not bl

elsseminate, punished or reproduced wihout por wien approval,

‘TOP-NOTCH TESTING SERVICES PRIVATE LIMITED

ab Adress: Plot No.16, Soca Hil, Pezam Cheri, Neat SPA, Rajndrangar, Hyderabad - $00 091,

Regd Office: H.No.: 17-1-382/0/42, Press Colony, Sagar Road, Champapet, Hyderabad - 500 079,

‘Phone: 964 984 6200, $5466 8094 Email info.cpooetvercee@pmall om

TITS GRADE CONCRETE Mix FROPOTIONING WITH OFC CEMENT

TRTaT

are savas

euewr District Panchayat Ral Engineer PIL Dsl Mahabubnagar dat

ame crwork? _ :82h9ge No TSOADEMBLBCT- construction of Hghevel sen. on oad fom Batvapaly to

oe Devarhacra ot 200108409 ot Devaar NaraauMenburaar estes,

Jt srPUCATIONS FoR PROPOTIONNG

3) Grae ceagnaton) TeEtiity

5) Typocteament {8053 grate cntoming 8 260

2) Metrum nominate of pape : Some

3} Minor cron conto ana £280” apectbe setis 486)

©) Maxum waarsemon a 2 Oe0 faaper tm SetlS 438)

9) Woettty £0\eren emptor nse 7119 456:2000

@)Exreure orton oavete

8) Momedetcnerete taceg Domne

1) Banos sapere Cont

I Tyonctauyagnn Grahes agar arpa

inure ont in) : Aberisaeaond

Jn2 vest oATa FOR MATERIALS

2 Cemertveod + OPOSS mde contming ois 288

5) Sonos gravy of coment 1 is

3) Spach) ot

‘conse eppregae 20

2) Fie egos 23

8) War aston

1) Come agregate2mev2 in 2 agogassK roan

2} ra egoepsaseny i ite

©) Raaturtee}poture:

‘cone spgopae 1 Nllabeorbed mas ao ip

2) Few sggegste + Nilabeorbed motte ae

9 Sewarchue

5) Coane sesregate

ve]. *8hsb o Conse Agreana Wal tren Factores

Jszoenm|__Fabon peng am 2am [To]

Bima To [

[2G 47.50 39.15, 100.00} 756. 24.79 30.00 6265,

ona | er ber} or is [ove | ar 88 S078

even] —tae—| pte} ee aay—}-$e e

isenm_| es} —bee—| Fe seo} te

2) Fe eayeauin SAbaaeepaa Gag

Ta aa

$365 sonra] Poem paws parton i oe

ime | s

eee ee °° ee mae ae geen as

leven} [os eT i

Fzsemn| 7525 [75-100 ame —| on on 8o—| wees —Te estos tY

gern ekg0 | ee00— fam [a0] Torso tune | Ieee tet oe

eu [42s | ass0 orem | 108-[—1as—}-8ig | ef ee

[So faba —[-tor | —080—|- bap} ese ft |

9 [ere pr66; —} a0 toe

Fin ggregaecotring gradi aon a Tabloa18 932018

JAS TARGET STRENGTH FOR MIX PROPOTIONING

[As Per IS 10262:20% Target Mean Compressive Strength Fck= fke1.65°Sd or fekex

"Pe Target 28 Daye Target Mean Compressive Svergth M-18 Grade Concrete 20 775

JA SELECTION OF WATER.CEMENT RATIO.

‘AS Por iS 458:2000 Maximum Water Cement Ratio 0.60%

L

JA SELECTION OF WATER CONTENT

erm Tati 2 os 102822016 maximum nai contet to don agragela. 188k (Yor 26 060 mim sump range)

[Estos water content for 10omm slump 165+ 16638%) 178 ira

J88806 on tals for warkabity & cohassive mis, water content reducon of 18.00 percent nas bogn achived

ance the arived water contant = 162.16 — tre

[4-8 CALCULATION OF CEMENT CONTENT

CComnent content = 255 Kain?

From Table § 18 456:2000,stnimum Cement

Conant for"Mecaraie" exposure condiion = 250g?

|Cemenetous material content : 25

alr contant : 182

[Seater - coment rati(watericamentiious content) . 080

ICement (orc) .

255

Pram on THON OF VOLUME OF COARSE AGGREGATE AND FINE AGGREGATE CONTENT

done 8 102822019 vue of ears agpracaecrreaponing te 40mm se oeeee and fw aggregate

(Zone) or watercamont ratio of 0.60 = 0.71 t

PRET RCO TO ry

[The max caleuitons par unit volume of concrete shat bees olow: Page Sot

2) Volume ef eancrte, = im

D) Volume ef coment . Mags of coment : 4

pect oraviy oF coment 7005

2 1

a tO

2.0808 mi

©) Volume of water ass of water 4

; a Batic gravy of water .

2 ey ‘

7 "Toor

= 082 me

©) Volume of in aggregate = (@0oryo+0))

= 07809 me

©) Mass of coarse sggrogato(ca) = fxVolume ofa x Specie gravy of ca x 1000

= 133 ge

1) Mass offnw agaregatota) = fK\Volume ofa x Specie gravity of fax 1000

= ors gs

[A018 Mx PROPOTIONS. ‘Aggregates in $80 concition Agaregstos in Dry Condition

Comont . 256 gin? 258 kai?

4.0mm . 228 kgm? sar oe

200mm . 384 kgim® a2

400mm * 501 kgin? 158 kgf?

and : 675 kgin? 868 kgim*

water . 182 kgm? 163 kpin?

Density : 2395 kim? 2304 gin?

Free WIC ratio * 060 % ‘060%

Note: 1) Correction for watar absorption of Fine Aggregal & Coarse Aggregate tobe applied ot ste.

2yThe mi properonsrecemmended above shoul be tied inthe fed uing the proposed tala and fiatzed by

serving the actual perermance cf the conerate mix £

3)The Slump shal be measured and the dosage of amature shall be acjusted on th bas’ of concrete miaire vavel

fimo and senscnal variations o achieve the requires workable sump based tal.

For TOPNOTCH TESTING SERVICES

TOP V@TCH

TEST REPORT

Name & Address of the Customer:#t

‘The District Panchayat Raj Engineor,

PIU Division Mahabubnagar Dist.

Telangans.

‘Test Report No: TPL-ZZZ-HYD-21-1825-44,

Issue Date: 09/12/2021

Your Ref: Nil

Dated: Nil

Namo Of Work: Package No TSO4DEIIBLBO1- Construciion of High leva bridge on road from

ly to Devarkadra at 5°200 to 61400 of Davarkadra Mandal Manabubnagar district.

Sampte Particulars: #

Boswal

Coner

(Grade :

M16)

trail mix cubes

(Date of Casting: 02/12/2021)

Qty: 01 Set (Each Set = 3 nos.)

Test Required: Compressive Strongth.

Method of Tosting: IS: 516:1959, IS 456:2000,

Disciptine/Group: Mechanical/Buliding Materials

Date of Registration: 29/11/2021

Date of Commencement of Testing: 09/12/2021

Date of Completion of Testing: 09/12/2021

‘Sample Condition at receipt: Found eatisfactory

TEST RESULTS

PRESS! 17 ar MLE

1} paver | ave | patoot wight | oas | 2m | Come

SotNo, | rade’ | castingt | (mm*) | tating (ha) jen) | Spat | strnstn

ea)

mis oanarez1) z2aso0 loerzecet} 7 | e120 | zee | 1240

1 | mis foarzraces} 2200 Josrtzecet! 7 | aso | a7os | t202 | 1221

wis |oatarz0z1] 22600 |oertanoat 9.100 | 2746 | 1220

ForToruoren Tesi senveng eee

iPass

“runt ore uty ang i

trent peng OT SRW OR TH Svan el OE TRE

Imran [erase oy co gaan pvc ba a un Tp at eran rg

Note [espero cearemess,arptn sage on ete lb Sette pee ae a

[tin sonal Users an ha eae, i

‘TOP-NOTCH TESTING SERVICES PRIVATE LIMITED

Lab Adret: Pit No.16, Sait Fils, Peeram Cheruva, Near TSPA, Rajendcanaga, Hyderabad ~ 500 091.

‘Regd Office: H.No.:17-1-380/P/42, Pres Colony, Sapa

Phen: 994 984 6280, 93466 86004 Fal info.

Road, Campane, Hyderabad - 500 7.

Page tof

TOP V@TCH

TEST REPORT

Name & Address of the Customer# Test Raport No: TPL-ZZZ-HYD-21-1326-48

‘The District Panchayat Re] Engineer,

PIU Division Mahabubnagar Dist Iesue Date: 30/12/2024

Telangana,

‘Your Ref: Ni

Dated: Nil

‘Name Of Werk: Package No TSO4DEIIBLBOt- Consiructon of High level bridge on road fiom

Baswaipaly to Doverkacra at 8/200 to 6/400 of Davarkadra MencelMahabubnagar district

Sample Particulars: # Date of Registration: 29/11/2021

Concrete trall mix cubes Dato of Commencement of Testing: 30/12/2021

(Grado: M15) Date of Completion of Testing: 30/12/2021

(Date of Casting: 02/12/2021)

Qty: 01 Set Each Set = 3 nos.) ‘Sample Condition at receipt: Found satisfactory

Tost Required: Compressive Strength,

Method of Testing: IS: 518:1968, IS 458:2000,

Disclptine/Group: Mechanical/Bullding Materials

TEST RESULTS

ee STRENGT {ETE CUBE Sal

Wrorage

seine. | oraiat | 2atet, | ame | one or | ager | woigt | cana | come, | Reame

vase" | casting’ | mm’) | testing | (days) | tha) | (xn) "| Strength

(wa) | (ups)

mare joarereoet) 22600 |soaeoei] 28 | 8110 | 4882 | 2170

1 | M18 [o2staraces) 22600 |orta0e1| 28 | e140 | soos | 2180 | 2144

Nis Jozrtarzoa1) 22500 Jaonaeces| 26 | 8.0s0 | 4634 | 2062

For TOPNOTCH TESTING SERVI FLT

Page tof

= TESTING SERVICES PRIVATE LIMITED

rr et

‘Regd Office: H.No.; 17-1-382/P/42, Press Colony, Sagar Road, Champapet, Hyderabad - 500079.

2a ere

ce

i MIX PROPORTION

| OF

CONCRETE GRADE M25

{with using Cement OPC 53)

| Name Of Work: Package No TS04DEIiIBLB01- Construction of High level bridge on road from

Baswaipally to Devarkadra at 6/200 to 6/400 of Devarkadra Mandal, Mahabubnagar district.

To,

District Panchayat Raj Engineer

PIU Division, Mahabubnagar Dist,

TOP W@TCH

‘TEST REPORT

Name & Addross of the Customer

‘The District Panchayai Raj Engineer

PIU Division Mahabubnagar Dist Issue Da

Telangane,

}orr2/2021

‘Name Of Work: Package No TSO4DE

\© Devarkadra at 8/200 to 5/400 of Devarkadra Mandal Mahabubnagar ust.

using OPC53 cement

‘Test Report No: TPL-222-HYD-20-1325.2

L801. Construction of High level bridge on road from Baswalpaly

‘Aggregates in

MIX PROPOTIONS $8D condition

[Cement 360. 360 ign

20.0mm 575, 573, gin

[Orn 575 573 kgim®

[Sand 720 72 kgim®

water 162 172 gin?

[Densi 2391 2389 kgim®

Free WIC ratio as 0.45,

summary Telal mix

Paramotor| M25

‘Slump 80-100

Compressive Strength of trail mix cube

[Specimen of 160 mmX150mmx150mm size

leasted

7 days

Tar 2120

28 days

(MPa) a

Notes:

2) Ferection for water absorption of fine aggregate & coarse aggreg;

2i7he mx Proportions recommended above shoul be tned nts fed usm ine ‘proposed

‘paterials and finalized by observing the actual performance of the concrete ni

ate to be applied at site,

cyihe Slump shall be measured and tne dosage of admklue sal be adjusted onthe basis of

) Typectoament £ OPC89 grade conteming to 18 280

©) Maximum nominal size of aggregate 200mm

8) Minimum cement content (gine) 350 (As Portable of 5 456)

©) Maximum vatarcoment rats £050 (As Par table Sef i8 486),

1) Workabity 100(e26mm) slump(As por cause 7.118 456:2000)

9) Exposure canation 2 Moderate

1) Mattie oF concrete pacing Dumping

1) Degree ot supervision 1 Good

D Type ot aggregate ‘Grushed angular aggregate

) Maximum cement content gi + As Paris 496-2000"

JA TEST DATA FOR MATERIALS

a) Coment used OPC 89 grade conforming to 8 289

©) Specie gravy f coment 1 ous

©) Specie graviy of

4) Coarse aggrgate 26

2, Fie eggegat : 26

©) Water bsorpton

1) Goats aggregate(2ommi2.smm) £ oeiiodon

2) Fine aggregataMsena) 10K

©) Frossuracoymeste:

1 Coates aggregate Niteosotoad motu aso ni)

2)Fine epgregate ‘Nxsbeotbe melee see a)

0 Stove anaio

1) Coats sgaregete

arava of Cove torent Fracons

{S500 | soargate Factor a

sizes mm met TO — | Combined

ena ok a

Bn Ita 15 [yaa “358 | “20 Ha

Hommage [sos] tz—[~asas—| a9]

ie 75mm 10.16“ 908 | 270 “gre

z36nn | —oco—}“Fas—| 009 —053 [$38

2) Fo agaragata 3) Avn-aggregate Grading

ssiee] «| S38 Reaarae

passing | (Tables) s sieve Aven ‘avin. | tse per

La si Acorns 18

oo a maa | —Saae oH) ses 2018

Temi 88 00 [eto] 30 se a8 Tapb-10

P23emm—| “Pass |—Te00

sen [ser Eom [oars (rene Tea] oat a

eboy ar fers — Ge "540 — oso —| arog See}

[-2000-} feoou [08 [too] ae}

[ota eis

[tno o9 [524

Fos agree oni fo grading zo of Tatin STeSa0

[4:3 TARGET STRENGTH FOR MIX PROPOTIONING.

Jas Per ts 1¢262:2018 Target Mean Compressive Strangth fk «fc, €8"Sd oF ek

[The Target 28 Daye Target Maan Compressive Strength M-26 Grace Coneeiels 31.10 MPA

[4-4 SELECTION OF WATER-CEMENT RATIO.

‘4s PerS 456-2000 Maximum Walar ComentRato 060%

SELECTION OF WATER CONTENT

From Table 2 of 10262-2019 maximum wal content for 40mm aggragete : 16 te for 25 fo $0 mm sump range)

[Esuratod water content for 100mm slump(185+16530%) Hate

[Besed on val for workability & cohessve mix, water content reduction of, 10.00 percent has bean achived

Honco.the arrived water contont= 161.87 _Rre

‘CALCULATION OF CEMENT CONTENT

Goment content = 360 git

From Table 51S 456:2000, Minimum Cement

conlentfor"Moderale' exposure condlion = = 800 _gint

|cemenstous material contont : 380

lWeter content . 102

[sc.Water- cement rato(watercerrentiious conton) == 048,

loement oP} = 380

[A-7 PROPOTION OF VOLUME OF COARSE AGGREGATE AND FINE AGGREGATE CONTENT

[From Tabi Sof tS 10262-2019 volume of coarse apgragate corresponding to 20mm ze aggregate and fine aggragate

zone i) for water-cement rato of0.50 = 0.80,

in to prosert caso watr-coment rat i 0.00:Thoreforevolume of coarse aggregate is requfed tobe Increased to

|secrease tha fre aggregate contents he waler-comert rao i lower by 0.05 tha propoten of velume of coaree aggro

[sincreated by 0.010(at tho rate of-+0.01 for avery £008 change inwale-cament rato). Therefore,corectedpropoton of

[sours of coarse aggregate forthe water-cament rato of 0.450620,

|Ncte-in case the coaree aggregate le not anguiaronethen alto volume of coaree aggregate may be required to increaved

stab based on experience)

|For workabty of concrete, coarse eggregate can be reduced upto 3 percant

‘bsarving the actual performance of the coneele mix,

RRS

[The mic calculators per unt vate ot concceta shale a8 flows: Page sod

3) Volume ofconelo tne

um of amen mn 1

©) Value efcoment : uncoenet —_g

©) Volune of ater a : 4

Tr

~ y i

7 Tao

= ota mt

4) Valune cain aggregate = (oor)

= one a

©) Mave ofcoarse agerensl(cs) =f Volume of x Sect graviy of a 1000

= 1150 ge

1) Mass ofa aggregate) = txvoume of fax Specie gravy ofa x 1000

= m0 kgs

J4-0m.26 mx PROPOTIONS ‘Aggregates in 880 condtion Agaregatas n ry Conlon

‘Cement : 30 kgin* 2380 kon!

200m : 75 kg? 673 kan!

100mm : 78 kgin? 873 kgm?

Send : 720 Kain? 712 kon!

Water : 162 kgm? 172 kgin?

Density : 2301 kgim? 2360 gle?

FreeWic ratio : 08 cas

JNote: 1) Correction or water absorption of Fine Aggregate & Coarse Aggragate tobe apple at al

_2yThe mix proportions recommended above should be ted le eld using te proposed materiale and fazed by

‘3)The Slump ahell be moasured and the cosege of atintture shal be adjusted on th basis of concrete mitre rave

‘ue and seasonal variations to acheve he required workable alump based Val.

For TOPNOTCH TESTING SERVI

TOP W@TCH

TEST REP

Name & Address of the Customer? Test Report No: TPL-Z22-HYD.21-1926.28

‘The District Panchayat Raj Engineer,

IU Division Mahabubnagar Dist Issue Dato: 09/12/2021

Telangana,

Your Ref: Ni

Dated: Nil

Daven oi package No TSO4DENBLEOT- Consucion o High vel ridge on cad tom Bashapaly es

Devarkadra at 6/200 to 8/400 of Devarkacre Mandal Mahaoubnagar dst,

‘Sample Particulars: # Date of Registration: 20/11/2021

‘Concrete trail mix cubes Date of Commencement of Testing: 30/12/2021

(Grade : M25) of Completion of Testing: 30/12/2021

(Dato of Casting: 02/12/2021)

Qty: 01 Set (Each Set = 3 nos.) ‘Sample Condition at receipt: Found satisfactory

‘Tost Required: Compressive Strength,

Mothod of Testing: 18: 516:1959, 1S 468:2000,

Discipline/Group: Mechanical/Building Materials

COMERESAIVE sTRENTHOF CONSRETE CUBE SAMPLES

rerage

Compr.

Datoot | area | vatvot | aget | worgnt | toed Compr.

to. |r .

Seno. | Grade! | ccetingt | cmt) | toca (eam | a) | cen | SES | strong

(Pay

M25 fozzi2cz1) 22500 |sorerzo21 28 8.190 | 660.2 29.34

1 ‘M25 | 02/2/2021) 22500 | 30/2/2021] 28 8140 | 6466 28.74 28.85

‘M25 joanarezi| 22500 |aanaeeri} 23 | 9250 | e403 | zeae

oh tans een SoG FORT BT

ln rot anne ay pint ses eset tonne ies iene tg

feta anna Gren ra aril ray eh wey abe ctesnne poten chester en

seri renamed nme be deen tebe

Important

tie

Page tof

‘TOP-NOTCH TESTING SERVICES PRIVATE LIMITED

{ab Aes: Pt N16, Ss Hs Perm Chenin, Ne TSP, Raeosge,Hydenta 501,

‘Regd Office: H.No.: 17-1-382/P42, Peas Coloy, Sagar Road, Champepet, Hyderabad

Phone: 964 984 6280, 93466 86004 Ema nfo opntcuervicee@ gmail.com

Name & Addi

TOP W®TCH

TEST REPORT

of the Customers#

‘Tho District Panchayat Raj Engineer,

PIU Division, Mahabubnagar Dist.

Telangana,

‘Test Roport No: TPL-ZZZ-HYD-21-1325-20,

Isaue Date: 09/12/2021

Your Ref: Ni

Dated: Ni

[Name Of Work: Package No TS04DEIIIBLBO1- Construction of High level bridge on road rom Saswalpely to

Devarkadra at 67200 to 5/400 of Devarkadra Mandal Mahabubnagar district

‘Sample Particulara: #

Concrete trall mix cubes

(Grade : M25)

(Date of Casting: 02/12/2021)

Qty: 01 Set (Each Set = 3 nos.)

‘Tast Required: Compressive Strength.

Mothod of Tosting: IS: 516:1959, IS 466:2000.

Discipline/Group: Mechanical/Building Materials

Date of Registration: 29/11/2024

Date of Commencement of Testing: 09/12/2021

Date of Complation of Testing: 09/12/2021

‘Sample Condition at receipt: Found satisfactory

Mr (GRE

se eee s Soman | Neraee

ate 2 | datoot Weight | Load | Compr.

sot rang

No! Grads | cosungt | dm) | texting | ceaye) | eo) | cay | Sapp" | strong

qua,

mos |cartzm021) 22600 loarraaces| 7 | ateo | arse | 21.18

+ | mas joararez1) 22600 |osrtaoai} 7 | e270 | 4702 | 2090 | 2119

mas |ozraeoe1| 22800 Jooamcrs] 7 | azz0 | sass | 21.48

For TOPNOTCH TESTING SERVICES EVT LT

Pui Rey

snipe cae: Guaty tamer!

ep Ty SAN SAT al ST,

imporan [testes ymapoian a nanayo cape ome pad du Suny oth one ane

a eee eee enna eee

‘TOP-NOTCH TESTING SERVICES PRIVATE LIMITED

[Lab Adee: Plot No.16, Sueita Hills, Peeram Cheruvu, Neat TSPA, Ralendranagar, Hyderabad - 500 091,

‘Regd Office: H.No.: 171-382/PI42, reas Colony, Sagar Road, Champapet, Hyderabad - 500 079.

‘Phone: 984 964 6280, $2466 86004 Email: ito Jopnotcvervices@gmal com

C

Page tof

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)