Professional Documents

Culture Documents

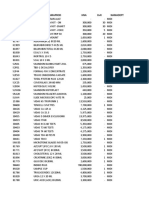

General Properties of Elastomers Summary Chart

Uploaded by

venkatraman0 ratings0% found this document useful (0 votes)

23 views1 pageOriginal Title

General Properties of Elastomers Summary Chart (1)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views1 pageGeneral Properties of Elastomers Summary Chart

Uploaded by

venkatramanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

®

Custom & Standard

Rubber Extrusions

300 Martinel Dr. | Kent, OH 44240 | Phone: (877) 302-0423 | Fax: (330) 673-3235 | www.elbex-us.com

GENERAL PROPERTIES OF ELASTOMERS SUMMARY CHART

The chart below provides general information for various common elastomeric compounds and very general features of the most common

elastomers. Rubber compounding is a broad field. Basic elastomers are mixed with a variety of chemicals and ingredients to obtain

desired physical properties. Many basic polymers are available that can yield compounds with unique physical properties.

Common Name Designation2 Composition2 General Properties1 General Chemical Resistance3

Resistant to: Attacked by:

Butyl IIR Isobutylene- Very good weathering resistance Animal and vegetable fats, Petroleum oils, fluids, and

isoprene oils, greases, oxygenated solvents; coal, tar, and

Excellent dielectric properties

solvents, alkalis, ozone, diester-based lubricants

Low permeability to air strong and oxidizing and solvents; aliphatic

Good flex properties chemicals, silicone fluids and aromatic

and greases, ammonia, hydrocarbons

Poor resistance to petroleum-based fluids phosphate ester type

hydraulic fluids

EPDM EPDM, EPM Ethylene- Excellent ozone, chemical, weather, UV, and Animal and vegetable oils, Mineral oils and solvents;

Propylene- aging resistance ozone, strong and oxidizing petroleum oils, fluids, or

Diene chemicals, alkalis, brake solvents; aliphatic and

Poor resistance to petroleum-based fluids

Modified fluids, phosphate ester type aromatic hydrocarbons

hydraulic fluids

Natural Rubber NR Isoprene, Excellent physical properties including abrasion Most moderate chemicals, Ozone, strong acids, fats,

natural and low temperature resistance wet or dry, organic acids, oils, fuels, solvents,

alcohols, ketones, petroleum derivatives,

Poor resistance to petroleum-based fluids

aldehydes hydraulic fluids, greases,

most hydrocarbons

Neoprene CR Chloroprene Good weathering resistance, resilience, and Moderate chemicals and Strong oxidizing acids,

abrasion strength acids, ozone, oils, fats, esters, ketones,

gasoline, greases, solvents, chlorinated, aromatic, and

Flame retarding

petroleum oils, animal and nitro hydrocarbons

Moderate resistance to petroleum-based fluids vegetable oils, refrigerants,

steam, carbon dioxide

Nitrile (Buna-N) NBR Nitrile- Excellent resistance to petroleum-based fluids Many hydrocarbons, fats, Ozone (except PVC

butadiene oils, gasoline, solvents, blends), ketones, esters,

Good physical properties such as resistance to

mineral and vegetable oils, aldehydes, chlorinated

tear, abrasion, and heat aging

fuels, greases, hydraulic and nitro hydrocarbons

fluids, chemicals

Polyisoprene IR Isoprene, Excellent resilience Most moderate chemicals, Ozone, strong acids, fats,

synthetic wet or dry, organic acids, oils, fuels, solvents,

Characteristics equal to, or similar to, those of

alcohols, ketones, petroleum derivatives,

natural rubber

aldehydes hydraulic fluids, greases,

Tensile strength is slightly lower than the tensile most hydrocarbons

strength of natural rubber

SBR SBR Styrene Good electrical insulation and resistance to Most moderate chemicals, Ozone, strong acids, fats,

Butadiene alcohol, oxygenated solvents, and mild acids wet or dry, organic acids, oils, fuels, greases, most

alcohols, ketones, hydrocarbons

Similar properties to natural rubber, but has

aldehydes

superior low-temp flexibility, heat aging

properties, and resistance to water, heat, and

abrasion

Abrasion resistance to petroleum-based fluids

Silicone Q, Si Polysiloxane Excellent high and low temperature properties Moderate or oxidizing Many solvents, oils,

chemicals, ozone, oxygen, concentrated acids and

Excellent vibration damping and maintains its

UV light, moisture, fungus, alkalines, fuels, dilute

dielectric strength

concentrated sodium sodium hydroxide,

Poor tensile, tear, and abrasion resistance hydroxide hydrocarbons, steam

Generally odorless and non-toxic

Good fatigue resistance, flex resistance, and

elongation

1 “Sheet Rubber Handbook – Gasket and Packing Materials” publication #IP-40 of the Rubber Manufacturers Association (RMA).

2 ASTM C 1418-79

3 1979 Yearbook of the Los Angeles Rubber Group, Inc.

You might also like

- Comparision of GasketsDocument3 pagesComparision of Gasketsanwer_quadriNo ratings yet

- Rubber Properties ChartDocument1 pageRubber Properties Chartabhay guptaNo ratings yet

- Rubber Properties Chart PDFDocument1 pageRubber Properties Chart PDFArasarethina KumarNo ratings yet

- Rubber Properties Chart PDFDocument1 pageRubber Properties Chart PDFshalabh.g864177No ratings yet

- Rubber Properties Chart PDFDocument1 pageRubber Properties Chart PDFsefaNo ratings yet

- Chemical Resistance of Thermoplastics for Process ApplicationsDocument1 pageChemical Resistance of Thermoplastics for Process ApplicationsLisbeth Roos RoosNo ratings yet

- Rubber Elastomer Chemical Resistance Guide by TLARGI and WARCO BILTRITEDocument12 pagesRubber Elastomer Chemical Resistance Guide by TLARGI and WARCO BILTRITEpriyaprasad367792No ratings yet

- 18 Butterfly Valves A Disc BrayDocument10 pages18 Butterfly Valves A Disc BrayAli FananiNo ratings yet

- Rubber Material Selection Guide ACM or Polyacrylate Acrylic RubberDocument3 pagesRubber Material Selection Guide ACM or Polyacrylate Acrylic RubberHemanth KumarNo ratings yet

- Styrene Butadiene Rubber (SBR)Document1 pageStyrene Butadiene Rubber (SBR)NPNo ratings yet

- Rubber Material Selection Guide HNBR or Highly Saturated Nitrile Hydrogenated Acryonitrile ButadieneDocument3 pagesRubber Material Selection Guide HNBR or Highly Saturated Nitrile Hydrogenated Acryonitrile Butadienevivekanand bhartiNo ratings yet

- CarboxylatedNitrileRubber - XNBR PDFDocument3 pagesCarboxylatedNitrileRubber - XNBR PDFJitendra BhosaleNo ratings yet

- Silicone RubberDocument3 pagesSilicone RubberSh.nasirpurNo ratings yet

- J Flex Product Info - Nitrile Types Comparison ChartDocument2 pagesJ Flex Product Info - Nitrile Types Comparison ChartPeggy ITURBURU VILLACRESESNo ratings yet

- Winlex 4101 - Finjetchemical IndustriesDocument2 pagesWinlex 4101 - Finjetchemical IndustriescastasoftNo ratings yet

- CMchloropolyethyleneDocument3 pagesCMchloropolyethyleneCarlosNo ratings yet

- TDS Abitol E Hydroabietyl AlcoholDocument2 pagesTDS Abitol E Hydroabietyl AlcoholCaio OliveiraNo ratings yet

- ElastomerDocument2 pagesElastomerMiryam Gadola ClaudioNo ratings yet

- Laropal A 81 June 2014 R2 ICDocument3 pagesLaropal A 81 June 2014 R2 ICOswaldo Manuel Ramirez MarinNo ratings yet

- Laropal A81: Industrial CoatingsDocument3 pagesLaropal A81: Industrial CoatingsMOEEN KHAN ASLAM KHAN RISALDARNo ratings yet

- Bber Compounding TechnologyDocument94 pagesBber Compounding TechnologyArthi Selva100% (1)

- Spirit Soluble Rosin Modified Maleic ResinDocument1 pageSpirit Soluble Rosin Modified Maleic ResinMOHAMEDNo ratings yet

- Polymer & Material Selection Guide: Hardness Range Temperature Range Advantages in PerformanceDocument10 pagesPolymer & Material Selection Guide: Hardness Range Temperature Range Advantages in PerformanceAmmar ElSheikhNo ratings yet

- 1995, and To Video VC682 Part 1 For DetailsDocument5 pages1995, and To Video VC682 Part 1 For Detailsapi-3701567No ratings yet

- Linde WAO TechnologyDocument30 pagesLinde WAO Technologyrzlisk01No ratings yet

- On CoatingsDocument13 pagesOn Coatingshemant sonarNo ratings yet

- Nur Amalina Izzati 513Document2 pagesNur Amalina Izzati 513Nur Amalina Izzati ZakieNo ratings yet

- Light liquid paraffin product data sheetDocument1 pageLight liquid paraffin product data sheetAshraf KhanNo ratings yet

- There Are Three Main Groups of Resin:: Polyester ResinsDocument1 pageThere Are Three Main Groups of Resin:: Polyester ResinsmukeshNo ratings yet

- Semkim SMK 4444 TDSDocument1 pageSemkim SMK 4444 TDSDuman AbbasovNo ratings yet

- Resins: Singh Plasticisers & Resins (I) Pvt. LTDDocument26 pagesResins: Singh Plasticisers & Resins (I) Pvt. LTDmadumaxNo ratings yet

- Chemical Resistance of Rubbers (AIP)Document7 pagesChemical Resistance of Rubbers (AIP)윤병택No ratings yet

- MERCADO DE TINTAS: PRODUTOS QUÍMICOS PARA A INDÚSTRIA DE TINTASDocument2 pagesMERCADO DE TINTAS: PRODUTOS QUÍMICOS PARA A INDÚSTRIA DE TINTASLeandro Marques PitolNo ratings yet

- Huber's Alumina Trihydrate (ATH) A Versatile Pigment For Coatings, Inks, Adhesives, Caulks and Sealants ApplicationsDocument5 pagesHuber's Alumina Trihydrate (ATH) A Versatile Pigment For Coatings, Inks, Adhesives, Caulks and Sealants ApplicationsdewanibipinNo ratings yet

- Elastomers OverviewDocument2 pagesElastomers OverviewJobita JMNo ratings yet

- Ring Design Chapter016Document1 pageRing Design Chapter016ismail güleçNo ratings yet

- Uranox™ EE4 X-50 - DSM PDFDocument2 pagesUranox™ EE4 X-50 - DSM PDFمحمد مقلدNo ratings yet

- Coating Literature StudiesDocument54 pagesCoating Literature StudiesHose GamalielNo ratings yet

- Additives For Petroleum Products: Pham Thi Linh Xuan K4-Refining and PetrochemicalDocument15 pagesAdditives For Petroleum Products: Pham Thi Linh Xuan K4-Refining and PetrochemicalLinhXuânPhạmNo ratings yet

- Introduction to Waxes: Properties, Types & UsesDocument4 pagesIntroduction to Waxes: Properties, Types & Usesسلوى سلمان داود سلمانNo ratings yet

- LubricationDocument132 pagesLubricationHARI100% (2)

- Chemical Resistance GuideDocument9 pagesChemical Resistance GuideenthaiNo ratings yet

- Lube Base StockDocument60 pagesLube Base StockKrishnamoorthy VijayalakshmiNo ratings yet

- My - Transfo - 2014 - Ergon-Efecto de La Refinacion en El Stray GassingDocument29 pagesMy - Transfo - 2014 - Ergon-Efecto de La Refinacion en El Stray GassingalumnopitagorasNo ratings yet

- Indonesia's Growing Paint and Coatings MarketDocument14 pagesIndonesia's Growing Paint and Coatings MarketDzikri Khoirul UmamNo ratings yet

- Brochure Chelating Agents 2006Document16 pagesBrochure Chelating Agents 2006Oscar ChupayoNo ratings yet

- PigmentsDocument7 pagesPigmentsAbdul MujeebNo ratings yet

- Silicones For Coatings & InksDocument34 pagesSilicones For Coatings & Inksnano100% (1)

- Styrene Butadiene RubberDocument27 pagesStyrene Butadiene RubberabdulqadirNo ratings yet

- Technical data sheet for acrylic modified alkyd resin SERKYD DC29X60ACDocument1 pageTechnical data sheet for acrylic modified alkyd resin SERKYD DC29X60ACI Love MusicNo ratings yet

- AkzoNobel MEA PIS Tcm53-24552Document1 pageAkzoNobel MEA PIS Tcm53-24552Desi Apriyanti RahayuNo ratings yet

- Driers and Metallic Soaps 2Document5 pagesDriers and Metallic Soaps 2Juan David NavarroNo ratings yet

- Permatex Industrial Strength Cleaner & Degreaser TDS 1 GallonDocument1 pagePermatex Industrial Strength Cleaner & Degreaser TDS 1 GallonAsadNo ratings yet

- Transforming Future Trends Into Innovations:: Siemens Alternative Insulating Liquid TransformersDocument2 pagesTransforming Future Trends Into Innovations:: Siemens Alternative Insulating Liquid TransformersbinodeNo ratings yet

- TDS A2203 70MVDocument1 pageTDS A2203 70MVDao Duy HoNo ratings yet

- Erional FRN Fixative and Reserving Agent: Technical Data SheetDocument5 pagesErional FRN Fixative and Reserving Agent: Technical Data SheetTrinhTruong100% (2)

- E211Document2 pagesE211JeanCarlo Vargas BarrantesNo ratings yet

- Carbothane 8815Document2 pagesCarbothane 8815Roberto LeonNo ratings yet

- Oxidative Stability of Malaysian Palm Oil and Its Blends Boey Peng Lim +, Teh Guat Bee, and Junji TERAODocument5 pagesOxidative Stability of Malaysian Palm Oil and Its Blends Boey Peng Lim +, Teh Guat Bee, and Junji TERAOOrea ThreeNo ratings yet

- Closed Cell Tds InterflexDocument1 pageClosed Cell Tds InterflexvenkatramanNo ratings yet

- Operational Excellence Infographics 1678592755Document19 pagesOperational Excellence Infographics 1678592755venkatramanNo ratings yet

- 3m Double Coated Tape GPT 020 and GPT 020f Brochure - PDF&FN 3M GPT 020F Double Coated Tape Brochure R3Document4 pages3m Double Coated Tape GPT 020 and GPT 020f Brochure - PDF&FN 3M GPT 020F Double Coated Tape Brochure R3venkatramanNo ratings yet

- Shore A Shore D Shore 00 Material Durometer ScaleDocument1 pageShore A Shore D Shore 00 Material Durometer ScalevenkatramanNo ratings yet

- MSDS VHBDocument7 pagesMSDS VHBvenkatramanNo ratings yet

- Mylar® El21 Product Description: 21/05/20, 4:54 PM DatasheetDocument3 pagesMylar® El21 Product Description: 21/05/20, 4:54 PM DatasheetvenkatramanNo ratings yet

- International Standard: Rubber-Tolerances For ProductsDocument6 pagesInternational Standard: Rubber-Tolerances For ProductsvenkatramanNo ratings yet

- Classification of ASTM Flexible Cellular MaterialsDocument1 pageClassification of ASTM Flexible Cellular MaterialsvenkatramanNo ratings yet

- GST Update: GST On Merchant Trade TransactionsDocument5 pagesGST Update: GST On Merchant Trade TransactionsvenkatramanNo ratings yet

- SPECTRO NABL Certificate TC-5492Document1 pageSPECTRO NABL Certificate TC-5492venkatramanNo ratings yet

- POLYETHYLENE (PE) - Grades & ApplicationsDocument2 pagesPOLYETHYLENE (PE) - Grades & ApplicationsRizwanSaifiNo ratings yet

- Biology WS AnswersDocument17 pagesBiology WS AnswersKazeNo ratings yet

- Extract Ethanol Effect of Robusta Coffe Antihyperlipidemia Towards TAG Level On Male Wistar Rat Induced With High Fat DietsDocument31 pagesExtract Ethanol Effect of Robusta Coffe Antihyperlipidemia Towards TAG Level On Male Wistar Rat Induced With High Fat DietsPbkkel 15No ratings yet

- Organic Chemistry CurrentDocument48 pagesOrganic Chemistry CurrentBierzo JomarNo ratings yet

- Exam Organic Chemistry I WhittenDocument19 pagesExam Organic Chemistry I WhittenDaniel Baylosis Asong60% (5)

- Paula Yurkanis Bruice 4th Edition Table ofDocument7 pagesPaula Yurkanis Bruice 4th Edition Table ofGarvit Goyal100% (1)

- Afcona 4201Document1 pageAfcona 4201Mantas GrigonisNo ratings yet

- Alanine - The Essential, Non-Essential Amino Acid: © 2007 Dr. Mauro Di Pasquale MDDocument4 pagesAlanine - The Essential, Non-Essential Amino Acid: © 2007 Dr. Mauro Di Pasquale MDMarcelBorgesPinheiroNo ratings yet

- Daftar Obat IGD Dan Poli UmumDocument2 pagesDaftar Obat IGD Dan Poli UmumPku Aisyiyah JeparaNo ratings yet

- Carbs & Lipids Q Pages 1 - 8Document8 pagesCarbs & Lipids Q Pages 1 - 8Clover Haxor100% (1)

- CBSE Class-12 Chemistry Quick Revision Notes Chapter-11: Alcohols, Phenols and Ethers Structure of AlcoholsDocument8 pagesCBSE Class-12 Chemistry Quick Revision Notes Chapter-11: Alcohols, Phenols and Ethers Structure of AlcoholsSAKET TYAGINo ratings yet

- Antioxidant Activity of N-Hexane Extract of NutmegDocument7 pagesAntioxidant Activity of N-Hexane Extract of NutmegSavioNo ratings yet

- Enzymatic Synthesis of Amides 2015Document44 pagesEnzymatic Synthesis of Amides 2015bluedolphin7No ratings yet

- Org Chem II Guiding QuestionsDocument10 pagesOrg Chem II Guiding QuestionsMesfen MeleseNo ratings yet

- Carbohydrates Slide-2 PHARM-D, SALUDocument85 pagesCarbohydrates Slide-2 PHARM-D, SALUShahid AhmedNo ratings yet

- CH 05Document31 pagesCH 05nayan159No ratings yet

- Hult2007 Enzyme Promiscuity Mechanism and ApplicationsDocument8 pagesHult2007 Enzyme Promiscuity Mechanism and ApplicationsRoshiio Espinoza100% (1)

- Alkenes and Alkynes: Lesson 3Document21 pagesAlkenes and Alkynes: Lesson 3AlbaraaAliNo ratings yet

- Rencana Kebutuhan Obat & Alkes Bulan September 2022Document13 pagesRencana Kebutuhan Obat & Alkes Bulan September 2022Rini OktaNo ratings yet

- Medicinal PDFDocument52 pagesMedicinal PDFamr ahmedNo ratings yet

- DLL Grade 7 Video LessonDocument4 pagesDLL Grade 7 Video LessonJr CapanangNo ratings yet

- Phenylalanine and Tyrosine Metabolism (18 Oct)Document14 pagesPhenylalanine and Tyrosine Metabolism (18 Oct)api-19824406100% (6)

- LipidDocument31 pagesLipidصالح مقالحNo ratings yet

- Bahan2 Kosmetik Dan FungsinyaDocument16 pagesBahan2 Kosmetik Dan FungsinyaNuRhidayah Syarifuddin Wijaya'odeNo ratings yet

- Deep Frying Reactions: Chemical Changes in Oil During CookingDocument4 pagesDeep Frying Reactions: Chemical Changes in Oil During CookingAmit Kr GodaraNo ratings yet

- What are Lipids? The Building Blocks of Cell MembranesDocument4 pagesWhat are Lipids? The Building Blocks of Cell MembranesLanzBognotXDNo ratings yet

- UntitledDocument24 pagesUntitledDANo ratings yet

- Localhost - MySQL - SR - Food - Nutr - Def - phpMyAdmin 4.9.2Document3 pagesLocalhost - MySQL - SR - Food - Nutr - Def - phpMyAdmin 4.9.2kamikaza007No ratings yet

- Sem VII CBCS Question Bank Pharmacognosy and PhytochemistryDocument11 pagesSem VII CBCS Question Bank Pharmacognosy and Phytochemistryvaibhavi mali100% (1)

- Raws Price ListDocument2 pagesRaws Price ListVinicius100% (1)

- Stock UpdateDocument74 pagesStock UpdateElisabeth Intan Budi Pratiwi SNo ratings yet