Professional Documents

Culture Documents

Ultratech Cement Report

Ultratech Cement Report

Uploaded by

Abhishek NS - Technical0 ratings0% found this document useful (0 votes)

10 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views2 pagesUltratech Cement Report

Ultratech Cement Report

Uploaded by

Abhishek NS - TechnicalCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

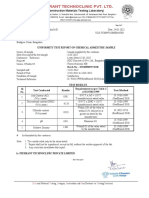

STEDRANT TECHNOCLINIC PVT. LTD.

(Construction Materials Testing Laboratory)

Lo #296, Govardhan Garde, 1 indi ren, Yelechenahal off Karalapure Moin Fo ve

Bangsar £60062 Ph; 080 26880348, Em labbi@etedant com CIN. UTA999KA701TPTCICDAT?

>

STPL GST No. 29AAYCS1231L120 www stedrant com Tos

fefsrcex me 05300

Ref. STPLICEMENTIBLR95/4/2022/1aR

Seb Order dated: 07.04.2022 ULR-TC659922 100004965

MisRDC Coneret(ina) Pvt. Li .

Bangalore

FINAL TEST REPORT ON PHYSICAL PROPERTIES OF CEMENT

‘Source of sample ‘Sample supplied bythe customer

Dat of recip ofthe sample suasaazt

Catone Referense Leer No BMRCL/02472-2RT-42022959277 Dae: 0604202

tn ronsar

Graeype# Sivore

Source? Gras

Pica Dang Consrcon of Underround Succ (Tinel & Sins)

Orttean Sb ts apo) ow Soha Teme oad Stone Noh Rap

(Gules 161 52 ht 210 298 ntng ed srs sed toc!

a hats Sins iy Taner Road, Venatepen, Aa Coleg an

egunrsin Rech neo Bangs Met fal Pes Fase?

Lecaion# Cope Pa Casting Yd

Ween 2

Peder tet 4.020221 02052022

Cano mle Satan

a | T ‘Requirements per]

Aa “Test Conducted Rests Test Method |S: 309 2018Clase 7

hb CONSISTENCY 26% | TS 4051 Pa 4-198

> That SETTING TNE | 145 Vines ;

3. FINAL SETTING TIME 20 Minas | 194091 (Par 39-1988 |

| COMPRESSIVE STRENGTH:

2) 4 th(eengeottivee eats) | -340MPa | Shat be es tan

| Hows |

1b) 168-£2h (average of tree resuts) | 45.0MPa | S481 (P2M6)- 1985 | Spay gor be less than

| Soxoe

©) omssnavenge otters) | S7OMPa Staab haa

> | FINENESS —SS~sS ~ Tsao pan T

S| pv tana perme meted) | 295m%G | 184031 Part 2) 1908

G 'SOUNDNESS

[° | wy rechaatie'smetod Lomn |

'SOUNDNESS. eee -

(by Auoeeeepansin mebod) | 0.088% :

7s fished y the estore

‘This rept aperidsthe eer ULRTCHSS22000207F Dud 190422

Note: 1. The results relate only tothe items tested.

2. Report shall not be reproduced except in full, without the written approval, ofthe i

3. Any correction invalidates this report.

for STEDRANT TECHNOCLINIC PVT. LTD.

Xo

obfestee

(Soil and Material Fstng, Designs, Restoration snd “on Desrwtve esi Serves

Corporate ofce Hyderabad Of Lab

‘Sua ide # 5 Model House Set Sawarag ‘Sed No FAIA Set No 1008 ashram Hyde abc S0078

Bangalore 560004000 76829992

‘Mob. °91 9000085780091 990009579031 8908875755 «91 9NN80SST90

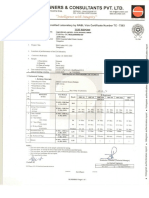

STEDRANT TECHNOCLINIC PVT. LTD.

(Construction Materials Testing Laboratory)

Lab; # 39/5, Govardhan Garden, JC industrial Ares, Yelechenahali, of. Kanakapura Main Road.

Bangalore - 560062, Ph: 080 26860348. E-mail: labbl¢@stedeant.corn CIN: U74999KA2017PTC100477

GST No. 29AAYCS12311120 www stedrant com

&>

STPL

oc: SreLRFescem 42

Ref: STPLICEMENT/BLR/95/4/2022/1/S

Job Order dated:07.04.2022

Peet

Date:20.04.2022

ULR-TC689922100004235F

M/s RDC Concrete (India) Pvt. Ltd.

Bangalore.

(CHEMICAL TEST REPORT ON CEMENT SAMPLE.

Source of sample for testing Sample supplied by the customer

Date of receipt of the test 28.03.2022

Customer's Reference Letter No. BMRCL/0247/P-2RT-04/2022/959/277 Dated 06.04.2022

UIN No. 1003627

Brand/Grade/Type # Ultratech’ 53 / OPC , Week No. 12

Project # Design and Construction of Underground structures (Tunnels & Stations)

‘of length 4.591 km (approx.) from South of Tannery road station to North

Ramp (Ch. 16822.521 m to Ch. 21413.298 m) including Allied works and 4 No’s

of UG Metro stations viz, Tannery road, Venkateshpura, Arabic college and

‘Nagawara in Reach-6 line of Bangalore Metro Rail Project, Phase-2.

Station # Captive Plant, Casting Yard

Contractor # M/s. ITD Cementation India Limited, Bangalore

Period of Test 07.04.2022 to 18.04.2022

Condition of sample Satisfactory

Test Method 1S 4032 ~ 1985 (Reaffirmed 2019) - Amendment No.2 (March 2010)

_ TEST RESULTS

Requirement as per IS 269:2015,

UNe feeecessocel Results Clause 6.1 (Tabled) for OPC 53 Grade

[17 Loss on Ignition (% by mass) 3.26 Maximum 4.0 %

| 2 “Insoluble Residue (% by mass) | 446 Maximum 5.0%

Ratio of % of Lime to % of Silica, Alumina and

Iron Oxide, when calculated by the formula:

3 | Ca0-0.7 SOs 0.88 Not greater than 1.02

—— ‘And not less than 0.80

2.8xSiO;+1.2AI20,+0.65xFe20)

4 Ratio of % of Alumina to Iron oxide 1.16 Minimum 0.66

5 Total Suiphur Content calculated as sulphuric Bea Maximum 3.50 %

° anhydride ($03) (% | 2:93

6 | Magnesia (MgO), (%aby n 161 Maximum 6.0 %

7 Tri caleium aluminate (CsA), (% by mass) 6.09 | Not Specified

8 Chi (Coby mass) oon Maximum 0.10 %

Alkali Content (% by mass) In the case of reactive aggregates, the use of

9 i) Alkaties as Na,O 0.37 ‘cement with alkali content below 0.6

ii) Alkalies as K:0 0.34 percent expressed as sodium oxide (NaO+

_ iii) Total alkalies as Na:O equivalent 0.59 0.658K:0) is recommended

10. Tricalcium Silicate (CsS) (% by mass) 42.58 Not specified

# As furnished by the customer

Note: 1. The results relate only to the items tested.

2. Report shall not be reproduced, except in full, without the written approval of the lab,

3._ Any correction invalidates this report.

eee

(Goil and Materiab Testing! Desig, Restration and Non Destructive Testing Services)

Corporate office

“Sunvak Pride” #95, Model House Steet, Basavanagud

Bangalore - $60 004. Ph 080 26629992

Hyderabad Off / Lab

‘Shed No. F3/A, Street No. 10.1DA. Nacharam Hyderabad 500076.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Stedrant Technoclinic Pvt. LTD.: (Construction Materials Testing Laboratory)Document1 pageStedrant Technoclinic Pvt. LTD.: (Construction Materials Testing Laboratory)Abhishek NS - TechnicalNo ratings yet

- GgbsDocument2 pagesGgbsAbhishek NS - TechnicalNo ratings yet

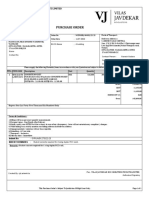

- Bucket Concrete RDC Concrete Po 00033Document1 pageBucket Concrete RDC Concrete Po 00033Abhishek NS - TechnicalNo ratings yet

- TDS Conbextra at India3Document2 pagesTDS Conbextra at India3Abhishek NS - TechnicalNo ratings yet

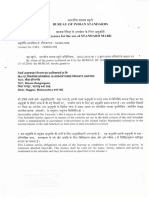

- Ftffi Fat A CH A Far 3ten: Finng, Qtry44Ii08Document2 pagesFtffi Fat A CH A Far 3ten: Finng, Qtry44Ii08Abhishek NS - TechnicalNo ratings yet