Professional Documents

Culture Documents

TDS Conbextra at India3

Uploaded by

Abhishek NS - TechnicalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDS Conbextra at India3

Uploaded by

Abhishek NS - TechnicalCopyright:

Available Formats

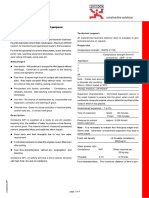

Conbextra AT

(Formerly Conbextra Spl.) constructive solutions

Non-shrink, free flow, extra high strength Technical Support

grout

Fosroc offers a comprehensive range of high performance, high

Uses quality concrete repair and construction products. In addition,

Fosroc offers technical support service to specifiers, end-users

Conbextra AT is used for heavy duty support beneath load bear- and contractors, as well as onsite technical assistance in loca-

ing units especially where high static and dynamic forces occur. tions all over the country.

Also as an efficient medium for transferring all operational loads

to the foundation. And for effective grouting of base plates Properties

and bolt pockets of Turbo Generators, Diesel Generating sets, Compressive strength (N/mm2)

Crane and Transporter Rails even with high wheel loadings, 1 day 3 days 7 days 28

Heavy Reciprocating Equipments, Compressors, Pump sets, days

Pulverising mills, Metal Shearing and Processing Machines, Flowable 40 60 70 80

Steel Rolling Mill Beds, Cement, Textile, Granite and Paper (W/P 0.16)

Plant machinery. Tensile strength At 28 days tensile strength

achieved is typically 3.5 N/mm2

Advantages

Young’s modulus 28 KN/mm2

Nonshrink : Will continue to occupy the filled space without Expansion character- Controlled expansion occurs in the

shrinkage. Ensures high level of contact with load bearing istics unset material to ensure that the

areas. Also helps complete filling without voids. No need grout, when cured, will continue

for external aids like rodding, poking, chaining etc. to occup its original volume within

the confines of the voids in which it

Increased strength: Can be used under heavy duty machines was placed (2% max).

and equipment with high operational and static loads Unrestrained expan- Upto 4%

Prepacked and factory controlled: Consistency and reliability sion

ensured. Site batching and blending variations eliminated. Time for expansion Expansion starts 20 minutes after

mixing and will be completed 150

Iron free : No chance of deterioration by uncontrolled rust minutes later.

expansion, corrosion and staining of grout. Presssure to restrain Approx. 0.004N/mm2

Chloride free : Does not cause corrosion of machine parts, plastic expansion

anchor bolts etc., in contact with grout Coefficient of Thermal 11 x 10-6 per oC

expansion

Standard Compliance Thermal conductivity 1W/moC

Conbextra AT conforms to ASTM C1107 (Standard Specification Fresh wet densit At flowable consistency 2200kg/m3

for Packaged Dry, Hydraulic-Cement Grout (Non-shrink). W/P ratio Recommended water poder ratio

for flowable consistency is 0.16.

Description Total quantity of water required for

25kg bag is 4 litres.

Conbextra AT is supplied as a ready-to-use dry powder, requir-

ing only the addition of water to produce a free flowing non- Flow characteristics The maximum distance of flow is

goverened by the gap width and

shrink grout. The material is a blend of specially processed the head of the grout. Typical data

cement, pregraded fillers and additives which impart : for flow design, assuming grout is

High early and final strengths due to very low water poured immediately after mixing, is

given in table below:

requirement

Max flow distance in mm

Controlled expansion to retain the original volume filled even

Grout consistency Gap 50 100 250

after setting width mm mm mm

Free flow characteristics without any segregation and (mm)

bleeding Flowable 30 200 1000 2000

Conbextra AT, on setting, will have a microcellular structure 40 500 1500 2500

with high frost, fire and oil resistance. 50 1000 2000 3000

Note : Cubes cast are kept under restraint before testing, to

simulate site conditions. Size of the cubes used 70.6mm x

70.6mm x 70.6mm tested at 270C.

Conbextra AT

N.B : This table is based on the following factors. Temperature

: 270C; Water saturated substrate; Minimum unrestricted flow

width : 300mm.

page 1 of 2

Conbextra AT

(Formerly Conbextra Spl.)

Application guidelines Yield

A few DOs and DON’Ts

One bag of Conbextra AT will yield 12.5 litres at flowable

DO’s consistency

Measure water precisely

Shelf life

Mix mechanically

6 months when stored under cold dry conditions in unopened

Use mixed grout within 30 minutes

bags.

Clean concrete and steel surfaces thoroughly before Precautions

grouting

Health & Safety instructions

Build a strong, carefully designed leakproof shuttering

Start curing when grout reaches ‘touch-hard’ state - within Conbextra AT is nontoxic, but alkaline in nature. Gloves should

4 - 6 hrs. be worn while handling this product. Splashes of grout on the

Cure properly for at least 7 days. skin or eyes should be washed off with clean running water. In

the event of prolonged irritation, seek medical advice.

DONT’S

Mix cement, sand, fibres, admixtures, etc., with Additional information

Conbextra AT

The Fosroc range of associated products includes Admixtures,

Mix water more than specified Floorings, Protective coatings, Repair and Protection systems,

Pour grout from two sides while grouting base plates. sealants and waterproofing compounds Adhesives & Mining.

Pour grout from a height Separate datasheets are available on these products.

Use vibrators in grout

Use damaged bags of Conbextra AT

Detailed application procedure will be supplied by Fosroc on

request.

Estimating

Packaging

Conbextra AT is supplied in 25 kg bags.

Important note :

Fosroc products are guaranteed against defective materials and manufacture and are sold

subject to its standard terms and conditions of sale, copies of which may be obtained on

request. Whilst Fosroc endeavours to ensure that any advice, recommendation, specification

or information it may give is accurate and correct, it cannot, because it has no direct or

continuous control over where or how its products are applied, accept any liability either

Fosroc Chemicals directly or indirectly arising from the use of its products whether or not in accordance with

any advice, specification, recommendation or information given by it.

(India) Pvt. Ltd.

Head Office telephone fax e-mail

Embassy Point, No. 150,

2nd Floor, Infantry Road, +91 80-42521900 +91 80-22281510 enquiry.india@fosroc.com

Bangalore 560 001,

Karnataka

Regional Offices

Chennai Mumbai Noida Kolkata

Hills Centre,Old No 5, MBC Park, 12th floor, Office No.12B, Unit No. 601, Highway Tower-II 304, Jodhpur Park

New No 9, 3rd Cross Street, ‘D’ Block, Near G Corp/Hyper City A-13/2, 6th Floor, Sector– 62 Kolkata 700 068

Jeth Nagar, Raja Annamalaipuram, Kasarwadawali, Ghodbunder Road, Gautam Buddha Nagar, Ph:+91 33-65343188

Chennai 600 028. Thane (West) 400 615 Noida 201 309, Uttar Pradesh Fax: 033-2499-0278

Ph: 9500064795 Ph: +91 22 6229 6800 Ph: +91 120 6121900

Fax: 0120-4270622

www.fosroc.com

page 2 of 2 INDIA/2022/0308/A

You might also like

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Conbextra ATDocument2 pagesConbextra ATLOPA THANDARNo ratings yet

- Conbextra AT and Conbextra BB80Document9 pagesConbextra AT and Conbextra BB80m.basim.technitalNo ratings yet

- Conbextra UHSDocument2 pagesConbextra UHSabhay_joshi20020% (1)

- Conbextra GP1 PDFDocument4 pagesConbextra GP1 PDFabhay_joshi2002No ratings yet

- TDS Conbextra GP1 India PDFDocument4 pagesTDS Conbextra GP1 India PDFvikash singh tomarNo ratings yet

- Conbextra HFDocument4 pagesConbextra HFm.elsanee.cubicNo ratings yet

- Conbextra UHS90: Non-Shrink Free Ow Ultra High Strength GroutDocument2 pagesConbextra UHS90: Non-Shrink Free Ow Ultra High Strength GroutVikas Singh ChandelNo ratings yet

- Fosroc Conbextra HF precision groutDocument4 pagesFosroc Conbextra HF precision groutThrtThrthNo ratings yet

- Fosroc Conbextra TS: Non Shrink Cementitious Aggregate Filled GroutDocument2 pagesFosroc Conbextra TS: Non Shrink Cementitious Aggregate Filled Grouthameed6101986No ratings yet

- High-strength heat resistant cement groutDocument4 pagesHigh-strength heat resistant cement groutSHAIK ASIMUDDINNo ratings yet

- Conbextra TSDocument2 pagesConbextra TSm.elsanee.cubicNo ratings yet

- Fosroc Conbextra HF PLUS High Strength GroutDocument4 pagesFosroc Conbextra HF PLUS High Strength GroutVincent JavateNo ratings yet

- High Strength Heat Resistant GroutDocument4 pagesHigh Strength Heat Resistant Groutabhay_joshi2002No ratings yet

- Fosroc Conbextra BB80: Constructive SolutionsDocument4 pagesFosroc Conbextra BB80: Constructive SolutionsVincent JavateNo ratings yet

- Conbextra PDocument4 pagesConbextra Pm.elsanee.cubicNo ratings yet

- Conbextra BB80Document4 pagesConbextra BB80m.elsanee.cubicNo ratings yet

- High Strength Epoxy Grout for Heavy LoadsDocument2 pagesHigh Strength Epoxy Grout for Heavy LoadsAcho SupraholicNo ratings yet

- 10 Conbextra EP10Document2 pages10 Conbextra EP10ahmad wildaanNo ratings yet

- Conbextra HF: Shrinkage Compensated Cementitious Precision GroutDocument4 pagesConbextra HF: Shrinkage Compensated Cementitious Precision GroutbinodNo ratings yet

- TDS-Conbextra-EP10-IndiaDocument3 pagesTDS-Conbextra-EP10-IndiaBabla SNo ratings yet

- Datasheet File Conbextra - HFDocument4 pagesDatasheet File Conbextra - HFandikaNo ratings yet

- Conbextra STDDocument2 pagesConbextra STDPritha DasNo ratings yet

- Conbextra AT: Non-Shrink, Free Flow, Extra High Strength GroutDocument2 pagesConbextra AT: Non-Shrink, Free Flow, Extra High Strength GroutVenkata Raju KalidindiNo ratings yet

- Markflow Grout 2 PDFDocument3 pagesMarkflow Grout 2 PDFBharat PaintsNo ratings yet

- Conbextra STDDocument2 pagesConbextra STDm.elsanee.cubicNo ratings yet

- Conbextra HESEDocument4 pagesConbextra HESEm.elsanee.cubicNo ratings yet

- (PDS) Conbextra STDDocument3 pages(PDS) Conbextra STDPritha DasNo ratings yet

- Sika - Sikagrout 215Document9 pagesSika - Sikagrout 215afnan hamimiNo ratings yet

- High strength epoxy grout for heavy duty applicationsDocument2 pagesHigh strength epoxy grout for heavy duty applicationszulfikarNo ratings yet

- CONBEXTRA-AT-2Document3 pagesCONBEXTRA-AT-2m.basim.technitalNo ratings yet

- High Strength Non-Shrink Micro Concrete GroutDocument4 pagesHigh Strength Non-Shrink Micro Concrete GroutilhamNo ratings yet

- Conbextra HF (Anchoring)Document66 pagesConbextra HF (Anchoring)LeogagNo ratings yet

- High Strength Non-Shrink Micro Concrete GroutDocument4 pagesHigh Strength Non-Shrink Micro Concrete GroutJoshua EkoNo ratings yet

- Conbextra HRDocument4 pagesConbextra HRAnonymous IwqK1NlNo ratings yet

- Conbextra atDocument4 pagesConbextra atsathishbe5No ratings yet

- Conbextra GP3 high performance groutDocument4 pagesConbextra GP3 high performance groutabhay_joshi2002No ratings yet

- Conbextra UW: Constructive SolutionsDocument4 pagesConbextra UW: Constructive SolutionstalatzahoorNo ratings yet

- Duraflex DSDocument2 pagesDuraflex DSFeyiNo ratings yet

- Conbextra EP10Document2 pagesConbextra EP10m.elsanee.cubicNo ratings yet

- Fosroc non-shrink cement grout for bridgesDocument3 pagesFosroc non-shrink cement grout for bridgesGigih M. PrayogoNo ratings yet

- Conbextra GP: High-strength cement groutDocument4 pagesConbextra GP: High-strength cement groutsizmaruNo ratings yet

- Fosroc Conbextra EP10: Constructive SolutionsDocument2 pagesFosroc Conbextra EP10: Constructive SolutionsVincent JavateNo ratings yet

- Conbextra BB80Document3 pagesConbextra BB80talatzahoorNo ratings yet

- Sikagrout 215 PDFDocument2 pagesSikagrout 215 PDFMaki Salim HussainNo ratings yet

- TDS CONBEXTRA EP300 Saudi ArabiaDocument3 pagesTDS CONBEXTRA EP300 Saudi ArabiaShaikhRizwanNo ratings yet

- Non-shrink precision groutDocument4 pagesNon-shrink precision groutEngr.Mohammed KhaledNo ratings yet

- Conbextra BB80Document3 pagesConbextra BB80Angelo Carlo MalabananNo ratings yet

- Conbextra EP10: High Strength, Epoxy Resin GroutDocument3 pagesConbextra EP10: High Strength, Epoxy Resin GroutR.ThangarajNo ratings yet

- Fosroc Conbextra P: Constructive SolutionsDocument4 pagesFosroc Conbextra P: Constructive SolutionsVincent JavateNo ratings yet

- Conbextra EP10 : High Strength, Epoxy Resin GroutDocument1 pageConbextra EP10 : High Strength, Epoxy Resin GroutminedataNo ratings yet

- Conbextra HF - High Strength Shrinkage Compensated GroutDocument4 pagesConbextra HF - High Strength Shrinkage Compensated Groutabhay_joshi2002No ratings yet

- Conbextra TSDocument2 pagesConbextra TSAngelo Carlo MalabananNo ratings yet

- (PDS) Conbextra GPDocument4 pages(PDS) Conbextra GPSheena GardnerNo ratings yet

- Conbextra EP75 PDFDocument4 pagesConbextra EP75 PDFsaroat moongwattanaNo ratings yet

- TDS Conbextra GP3 IndiaDocument4 pagesTDS Conbextra GP3 IndiaashishroshanNo ratings yet

- Low Exotherm Epoxy Grout for Heavy LoadsDocument4 pagesLow Exotherm Epoxy Grout for Heavy Loadsabhay_joshi2002No ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

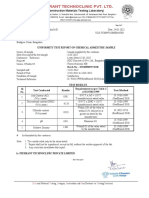

- Stedrant Technoclinic Pvt. LTD.: (Construction Materials Testing Laboratory)Document1 pageStedrant Technoclinic Pvt. LTD.: (Construction Materials Testing Laboratory)Abhishek NS - TechnicalNo ratings yet

- GgbsDocument2 pagesGgbsAbhishek NS - TechnicalNo ratings yet

- Fosroc 1Document1 pageFosroc 1Abhishek NS - TechnicalNo ratings yet

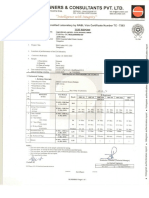

- Bucket Concrete RDC Concrete Po 00033Document1 pageBucket Concrete RDC Concrete Po 00033Abhishek NS - TechnicalNo ratings yet

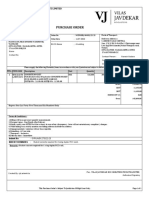

- Ftffi Fat A CH A Far 3ten: Finng, Qtry44Ii08Document2 pagesFtffi Fat A CH A Far 3ten: Finng, Qtry44Ii08Abhishek NS - TechnicalNo ratings yet

- Sfa-5 07Document10 pagesSfa-5 07lemuel bacsaNo ratings yet

- Recommended Erection Instructions For Steel FramesDocument32 pagesRecommended Erection Instructions For Steel FramesYel DGNo ratings yet

- Theories of Failure: Machine Design StructuralDocument3 pagesTheories of Failure: Machine Design Structuralamarkiran vinayakNo ratings yet

- AYC CHECKLIST PAINTING Rev.01Document3 pagesAYC CHECKLIST PAINTING Rev.01moytabura96No ratings yet

- Iron Carbon DiagramDocument43 pagesIron Carbon Diagramhrpatel_165No ratings yet

- Ship Constructions Lecture NotesDocument20 pagesShip Constructions Lecture Noteskyaw100% (1)

- Seeflex 040EDocument1 pageSeeflex 040EArstNo ratings yet

- Gypsum's role in cement and its uses in constructionDocument5 pagesGypsum's role in cement and its uses in constructionsalahromdhani89No ratings yet

- Design and crash analysis of a rollcage for Formula SAE race carDocument5 pagesDesign and crash analysis of a rollcage for Formula SAE race carVipulNo ratings yet

- Materials and Finishes in InteriorDocument10 pagesMaterials and Finishes in InteriorIvy FirmeNo ratings yet

- A Comparison Between The Old and New Indian Codes For Concrete Mix DesignDocument10 pagesA Comparison Between The Old and New Indian Codes For Concrete Mix DesigntheijesNo ratings yet

- Draw Management: Executive SummaryDocument13 pagesDraw Management: Executive SummaryJose HernandezNo ratings yet

- Bituminous Pavement Engineering: J. Murali Krishnan CE3015 2021Document40 pagesBituminous Pavement Engineering: J. Murali Krishnan CE3015 2021testerNo ratings yet

- Nano Coat Home: Technical Data SheetDocument2 pagesNano Coat Home: Technical Data Sheetcad camNo ratings yet

- Toilet Layout Details PDFDocument1 pageToilet Layout Details PDFVetrivel AjanNo ratings yet

- Is 12727 PDFDocument14 pagesIs 12727 PDFJanardhana ReddiNo ratings yet

- Imperium Presmat 03302017Document27 pagesImperium Presmat 03302017Leslie Anne De JesusNo ratings yet

- Resistance Seam WeldingDocument31 pagesResistance Seam Weldingaiman87_uitm100% (3)

- Steel StructuresDocument3 pagesSteel StructuresmariyaNo ratings yet

- Analysis Flange: Design ConditionsDocument35 pagesAnalysis Flange: Design ConditionsahmadNo ratings yet

- Bid SPECIFICATIONS & EstimationDocument53 pagesBid SPECIFICATIONS & EstimationVaibhav Kudtalkar100% (1)

- Case Against Balancing ValvesDocument4 pagesCase Against Balancing Valvesa_salehiNo ratings yet

- SPECIAL CONCRETES GUIDEDocument30 pagesSPECIAL CONCRETES GUIDECésar HuamánNo ratings yet

- API 577 EXAM QUESTION For 653 ExamsDocument27 pagesAPI 577 EXAM QUESTION For 653 ExamsEjaz AsgharNo ratings yet

- SXL Rudder Carrier Bearings IntroductionDocument4 pagesSXL Rudder Carrier Bearings IntroductionAndrea NaranjoNo ratings yet

- Standards For Old Bridges 1961-1965 Vol. 4 PDFDocument91 pagesStandards For Old Bridges 1961-1965 Vol. 4 PDFaapennsylvaniaNo ratings yet

- Fabrication Materials ListDocument6 pagesFabrication Materials ListcelonevesNo ratings yet

- TWI-2009-Improved Welding, Inspection and Integrity of Clad Pipeline Girth Welds First Progress Report PDFDocument60 pagesTWI-2009-Improved Welding, Inspection and Integrity of Clad Pipeline Girth Welds First Progress Report PDFRicardoSchayerSabinoNo ratings yet

- Chapter 4 - Radiation Heat Transfer PDFDocument52 pagesChapter 4 - Radiation Heat Transfer PDFSuraya Johari0% (1)

- Composite Propellant 2 PDFDocument9 pagesComposite Propellant 2 PDFAishwarya NNo ratings yet