Professional Documents

Culture Documents

Effects of Organic Additives On Physical and Chemical Characteristics of Basic Aluminum Sulfate

Uploaded by

msaidsaidyoussefOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effects of Organic Additives On Physical and Chemical Characteristics of Basic Aluminum Sulfate

Uploaded by

msaidsaidyoussefCopyright:

Available Formats

Effects of Organic Additives on Physical And Chemical Characteristics of Basic Aluminum Sulfate

Effects of Organic Additives on Physical And Chemical Characteristics of Basic

Aluminum Sulfate

Cesar A. Contreras, Satoshi Sugita, Esthela Ramos and Leticia Torres

Copyright AD-TECH; licensee AZoM.com Pty Ltd.

This is an AZo Open Access Rewards System (AZo-OARS) article distributed under the terms of the AZo–OARS

http://www.azom.com/oars.asp which permits unrestricted use provided the original work is properly cited but is

limited to non-commercial distribution and reproduction.

AZojomo (ISSN 1833-122X) Volume 2 March 2006

DOI: 10.2240/azojomo0183

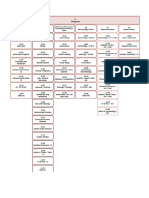

Topics Covered

Abstract

Keywords

Introduction

Experimental

Results and Discussion

Effects of Organic Additives on Chemical Composition of BAS

Effects of Organic Additives on Crystallinity and Chemical Structure of BAS

Effects of Organic Additives on Agglomeration Grade of BAS

Conclusions

Acknowledgements

References

Contact Details

Abstract

Basic aluminum sulfate can be prepared by homogeneous precipitation starting from

admixtures of ammonium aluminum sulfate and ammonium bisulfite solutions. Powder

agglomeration problems usually arise in wet precipitation processes mainly at high

concentration of precursors. Some organic additives have been used in order to modify the

physical and chemical properties of the final product during precipitation processes. In this

work, the effects of cationic, anionic and neutral organic additives on the physical and chemical

characteristics of basic aluminum sulfate (BAS) obtained by homogeneous precipitation were

investigated. Dodecylethyl-dimethyl-ammonium bromide (DEA) and chitosan were used as

cationic additives, whereas dodecyl lithium sulfate (DLS) was selected as anionic additive.

Furthermore, poly(vinyl alcohol) (PVA) and poly(ethylene glycol) (PEG) were used as neutral

additives. The products were characterized by Fourier transformed infrared spectroscopy

(FTIR), powder x-ray diffractometry (XRD), thermal analysis (TG and DTA) and scanning

electron microscopy (SEM). The chemical composition and crystallinity of the final product

were not modified by the presence of the studied additives in this reaction media. The basic

aluminum sulfates were amorphous, with chemical composition 2Al2O3·SO3·9 H2O. However,

the morphology and agglomeration state of the final product were modified by the nature of

the used additives. Anionic additive, DLS, produced irregular agglomerated particles. On the

other hand, neutral additives, PVA and PEG, provided particles with low agglomeration state.

The highest effect on dispersion was observed when cationic additives were used. Fine well-

dispersed particles of basic aluminum sulfate were obtained by addition of chitosan during the

precipitation process.

March 2006 | Volume 2 Page 1 of 10 DOI: 10.2240/azojomo0183

Cesar A. Contreras Satoshi Sugita Esthela Ramos and Leticia Torres

Keywords

Organic Additives, Agglomeration, Basic Aluminum Sulfate

March 2006 | Volume 2 Page 2 of 10 DOI: 10.2240/azojomo0183

Effects of Organic Additives on Physical And Chemical Characteristics of Basic Aluminum Sulfate

Introduction

Aluminas have been in use for many years as catalyst, adsorbents, desiccants, abrasives,

plastic fillers as well as fire retardants for many chemical process industries. Aluminas for

water adsorption, which are traditionally known as desiccants, were first introduced in 1932

[1]. Since long time ago, synthetic aluminas have been used in the chromatographic

purification of biological compounds. Recently aluminas have found widespread usage in

applications as diverse as municipal wastes treatment as well as in polymer and

pharmaceutical industries [2].

Alumina chemicals have been applied to treat industrial and municipal waters [3]. On the

other hand, aluminum sulfate is useful as a coagulant for removal of various metals, particles

and undesirable organic compounds from industrial waste water. Alumina trihydroxide

(gibbsite) and monohydrate (pseudoboehmites) also have been accepted as flocculants in

drinking-water. Transition forms of aluminas have been used as adsorbents for removal of

undesirable contaminants in both municipal and industrial waters.

As a result of more stringent conservation requirements large alumina adsorption processes

have been developed for water treatment. Successful new environmental applications of

alumina adsorbents include the removal of phosphate, mercaptan, arsenic, fluoride and

colloidal silica compounds in ground and drinking water [4].

The most important source of aluminum hydroxides is the Bauxite refining plant. More than

94% world alumina production is accounted for by the Bayer process for Bauxite refining. The

alumina product from the Bayer process is usually 99.5% pure with soda (Na2O) as the mayor

impurity [5]. Therefore, when a pure alumina product is required, it must be obtained by

another chemical process that uses pure aluminum salts as a raw material.

The interest to find alternative routes for the preparation of ceramic powders that avoid the

inconveniences of the traditional techniques has been growing. For this reason, the

development of new synthetic routes is required that allow to obtain ceramic powders with

specific properties, such as small particle size, spherical in shape, narrow particle size

distribution, absence of agglomerates and high chemical purity.

One of the most interesting recent developments in the preparation of aluminum hydroxide

and alumina has been the introduction of BAS as monosized alumina precursors with uniform

and controllable morphology. Matijevic [6] originally produced particles that contained an

appreciable amount of sulfate but this contaminant could be exchanged for hydroxide species,

in much the same manner as the one described by Gordon et al. [7], converting the BAS to

hydrous aluminum oxide.

Other researchers have also used basic aluminum salts as high purity alumina precursors.

Cornilsen and Reed studied amorphous basic aluminum succinate and BAS as potential

precursors [8]. Whereas Sacks et al. [9] and Blendell et al. [10] used spherical BAS as the

specific starting material for conversion to alumina.

The BAS studied by the above mentioned researchers, were obtained by homogeneous

precipitation of BAS in aqueous medium. In this case, agglomeration problems of the BAS

particles generally arise, especially when the precipitation process is performed at high

concentrations of aluminum salt. Therefore, under this condition it is difficult to obtain

monosized and non-agglomerated particles.

The use of low aluminum concentration solutions in the precipitation process allows the

preparation of non-agglomerated BAS particles. However, at these low alumina concentrations

the amount of product obtained is too low, from a practical point of view.

In one alternative process to prevent agglomeration, organic compounds are added to the

precipitation medium. Generally, the preparation of mono-dispersed alumina hydroxide by sol-

gel process was achieved, using high alumina concentration and hydroxyl-propylcellulose as a

steric agent to prevent agglomeration.

In this work, the effects of cationic, anionic and neutral organic additives on the physical and

March 2006 | Volume 2 Page 3 of 10 DOI: 10.2240/azojomo0183

Cesar A. Contreras Satoshi Sugita Esthela Ramos and Leticia Torres

chemical characteristics of BAS obtained by homogeneous precipitation were investigated.

DEA and chitosan were used as cationic additives, whereas DLS was selected as anionic

additive. Furthermore, PVA and PEG were used as neutral additives. The products were

characterized by XRD, TA (DTA and TG), FTIR and SEM.

Experimental

The organic additives used in this study were reagent-grade products obtained from Sigma-

Aldrich. The BAS was obtained by the following procedure. The aluminum bisulfite solution

was prepared by dissolving previously precipitated basic aluminum sulfate with sulfur dioxide

in aqueous media. The organic polymers described above were added to the aluminum

bisulfite solution. This solution is added drop by drop to previously heated water with vigorous

agitation. After the total quantity of the solution was added, the solution was stirred for 15

minutes in order to complete the precipitation. The obtained BAS precipitates were separated

by filtration, washed with hot water and dried at 75°C for 24 hours. The solids were

characterized by X-ray diffractometry (XRD) (Model D-500, Siemens, Germany) using Ni-

filtered CuKα radiation. Infrared analysis was performed using KBr pellets and the samples

were run on a Fourier transform infrared (FTIR) spectrometer (Model 1600 series FTIR, Perkin

Elmer, Norwalk, Connecticut, USA). Differential thermal analysis (DTA) and thermal

gravimetric analysis (TGA) of the samples were obtained by heating 20 mg of sample up to

1300°C, at a rate of 10°C/min, in air (Model SDT 2960, TA instruments, New Castle,

Delaware). The morphology of the particles was determined by scanning electron microscopy

(SEM) (Model jsm-35C Jeol, Tokyo, Japan).

Results and Discussion

Effects of Organic Additives on Chemical Composition of BAS

Chemical composition of BAS obtained by homogeneous precipitation in presence of organic

additives was determined by thermogravimetric analysis. Typical TG curve of BAS is shown in

Figure 1. Table 1 summarized the results of thermal analysis.

In TG curve of Figure 1, the mass loss occurred below 800°C corresponds to the loss of water.

On the other hand, the loss weight between 800 – 1280°C can be attributed to the sulfur

trioxide. So, considering the weight losses of the samples, the amount of water, sulfate and

aluminum oxide can be calculated. The chemical formula of BAS with different additives can

be estimated by this method and the values varied in the range of (1.9-2.3)Al2O3 SO3 (8.4-

11)H2O. On the other hand, the chemical formula of BAS prepared without organic additives

was 2Al2O3 SO3 9H2O. Thus, we can conclude that the organic polymers used here have not

effect on the chemical composition of the precipitated BAS.

Figure 1. Typical TG and DTA curves for BAS with additive.

March 2006 | Volume 2 Page 4 of 10 DOI: 10.2240/azojomo0183

Effects of Organic Additives on Physical And Chemical Characteristics of Basic Aluminum Sulfate

Effects of Organic Additives on Crystallinity and Chemical Structure of BAS

The XRD spectra of all BAS samples obtained with different additives show only amorphous

phase (data not shown).

The FTIR spectra corresponding to a typical BAS precipitated in presence of additives

correspond to a hydrated basic aluminum sulfate. The FTIR spectrum in Figure 2 indicates that

the compound was a hydrate, because of the strong and broad absorption band in the region

from 3000 to 3700 cm-1 and the absorption band which peaks at 1655 cm-1 [11, 12].

Furthermore, the strong and broad band centered at 1135 cm-1 and the small shoulder at 998

cm-1 could been assigned to sulfate absorptions (ν3) and (ν1) respectively [11-13]. The strong

and broad absorption band centered at 613 cm-1 probably resulted from the combined

absorptions of sulfate (ν4), the Al-O stretching vibrations and the Al-OH wagging vibrational

mode of molecular water [11, 12]. Therefore this compound corresponded to a hydrated basic

aluminum sulfate, very similar to those obtained and studied by Matijevic [14] and Saks [15].

Figure 2. Typical IR spectrum of BAS obtained with additives.

It should be notice that the additives were not detected in any BAS samples by FTIR

spectroscopy. This is probably due to the small amount of additive adsorbed on the BAS

surface. Non-ionic macromolecules such as polyethylene oxide and polyvinyl alcohol are

linear, flexible molecules with no charge, which adsorb non-specifically on the surface of

oxides. Because the interaction with the surface takes place through hydrogen bonds between

polar functional groups of the polymer chain and the hydroxylated and protonated groups on

the surface, the adsorption density decreases with increasing pH, irrespective of the nature of

the oxide. Furthermore, the affinity of the polymer for the surface will be weaker when the

surface sites are more prone to salvation [16]. In this case, low adsorption of non-ionic

polymers on BAS surface is expected owing to the high solvation energy of aluminum ion

(4700 kJmol-1, 25°C) [17].

Table 1: Results of thermal analysis (TG and DTA) of typical BAS with additive.

Temperature Weight Loss Thermal Effects Decomposition

(°C) (%) (°C) Stage

30-400 30.21 Endo (121 °C) - H2O

400-800 4.68 ---- - H2O (de OH)

800-1000 17.59 Endo (956 °C) - SO3

1000-1280 - 0.9 Exo (1259 °C) - SO3

On the other hand, polyelectrolytes and ionic surfactants absorb more strongly than neutral

molecules on charge surfaces, because the adsorption energy contains an electrostatic

contribution from sites of opposite charge on the polymer and on the oxide. The surfactant is

March 2006 | Volume 2 Page 5 of 10 DOI: 10.2240/azojomo0183

Cesar A. Contreras Satoshi Sugita Esthela Ramos and Leticia Torres

attached to the surface of the particle through electrostatic interaction between the polymer

charged head and opposite charged sites on the solid surface. In this case, the adsorption

density depends on the sign and number of surface charges [16]. Because BAS is positively

charged (+9.0 mV, Z-potential) at precipitation pH, it is expected that the negatively charged

additive DLS will adsorb more strongly on the positively charged BAS than the positively

charged additives DEA and chitosan.

Although DLS additive is not detected on the BAS sample by FTIR at used additive

concentration, when the added amount of DLS is higher than 4%, the precipitated BAS

becomes hydrophobic, i.e. the dodecylsulfate negative ion is adsorbed on the surface of BAS.

Effects of Organic Additives on Agglomeration Grade of BAS

The chemical nature of the organic polymers affects the morphology and agglomeration grade

of BAS. As shown in Figure 3, the precipitation of BAS with DLS produces agglomerates

consisting of fine particles (0.2 μm). Furthermore, irregular plate like particles (>1 μm) were

formed.

Figure 3. Scanning electron micrograph of BAS obtained with DLS.

As described above, this anionic polymer strongly interact with the positively charged BAS.

So, the molecules of DLS are attached to the surface of the solid through electrostatic

interaction between the negative head of polymers and charged sites on the solid of BAS. At

the same time, the hydrophobic tales of polymer escape contact with the water molecules by

adsorbing passively at the surface of the solution. This is the reason why plate like particles

were formed in the air-water interface. This type of additive is not adequate to obtain regular

shape particles.

Cationic additives, such as DEA and chitosan, produced the BAS with fine spherical particles (<

0.5 μm) and lower grade of agglomeration as shown Figure 4.

March 2006 | Volume 2 Page 6 of 10 DOI: 10.2240/azojomo0183

Effects of Organic Additives on Physical And Chemical Characteristics of Basic Aluminum Sulfate

(a)

(b)

Figure 4. Scanning electron micrographs of BAS obtained with additives (a) DEA and (b)

chitosan.

For comparison, the scanning micrograph of BAS obtained without additives is shown in the

Figure 5.

Generally, the precipitated BAS particles without additives are large agglomerates (>10 μm).

In the early stage of homogeneous precipitation, small particles of BAS are produced. Such

small particles are attracted between them with strong force, consequently this produces large

agglomerates. The presence of a cationic polymer, especially polyelectrolyte chitosan,

prevents formation of hard agglomerates or aggregates of BAS through electrosteric

mechanism. Owing to the fact that chitosan polymer has positive charge at the precipitation

pH of BAS, it is adequate to produce fine non-agglomerated particles of BAS.

March 2006 | Volume 2 Page 7 of 10 DOI: 10.2240/azojomo0183

Cesar A. Contreras Satoshi Sugita Esthela Ramos and Leticia Torres

Figure 5. Scanning electron micrograph of BAS obtained without additives.

On the other hand, neutral polymers, such as PVA and PEG, affect the agglomeration state of

the BAS in a lower grade than the ionic additives. This can be attributed to the weak

interaction force between the neutral polymers PVA and PEG with the positively charged

surface of BAS. In this case, the interaction of neutral additives with the surface takes place

through hydrogen bonds between the functional groups of the polymer and the hydroxylated

and protonated groups of the BAS surface [16]. According to the chemical compositions of

PVA and PEG, the first additive is expected to interact more strongly with the BAS surface than

the second one. PVA contains hydroxyl group, which can form hydrogen bonds with the

hydroxilated groups of the BAS surface, whereas PEG contains only ether group which is less

polar than hydroxyl. In Figure 6, the scanning electron micrographs of BAS obtained with

neutral additives can be seen. SEM micrograph of BAS obtained with PVA shows that this

additive exhibits higher effect on the agglomeration grade of the BAS particles, owing probably

to a steric effect.

(a)

March 2006 | Volume 2 Page 8 of 10 DOI: 10.2240/azojomo0183

Effects of Organic Additives on Physical And Chemical Characteristics of Basic Aluminum Sulfate

(b)

Figure 6. Scanning electron micrographs of BAS obtained with additives (a) PVA and (b)

PEG.

Conclusions

Chitosan is the best dispersant for BAS obtained by homogeneous precipitation. All additives

used here could modify the agglomeration grade without modifying the composition and

crystalline grade of BAS. The chemical compositions of BAS slightly vary in the range of (1.9-

2.3)Al2O3 SO3 (8.4-11)H2O. The crystalline nature of all BAS was amorphous. The adsorption

of all additives used here on the surface of BAS solid was not observed by IR spectroscopy.

Acknowledgements

The authors wish to express their gratitude to the Japanese government for supporting this

work through the 21st Century Center of Excellency (COE) Program of the Ministry of

Education, Culture, Sports, Science and Technology.

We thank Juan José Guzman A., Director of the Centro de Investigaciones en Química

Inorgánica for his permission to publish the paper. Juan Balderas P. and Diana Mendoza are

acknowledged gratefully for the technical assistance and instrumental data interpretations.

References

1. J. B. Barnit, “Adsorbent Materials and Method of Producing the same”, U. S. Patent No. 1 868 869 (26 July 1932).

2. H. L. Fleming and K. P. Woodboy, “Selective Adsorption Process”, in Alumina Chemicals Science and Technology

Handbook (Ed. L. D. Hart), The American Ceramic Society Inc., Westerville Ohio, (1990) pp. 251-61.

3. H. L. Fleming and K. P. Woodboy, “Water-Treatment Products and Process”, in Alumina Chemicals Science and

Technology Handbook (Ed. L. D. Hart), The American Ceramic Society Inc., Westerville Ohio, (1990) pp. 263-72.

4. Kreyenberg Heiner, “Method and apparatus for treatment of water polluted with phosphates, heavy metals, sulfur,

oil, or polymer residues as well as suspended substances, especially for treatment of water from dewatering of

sludges from natural water treatment, with recycling of the treated water to natural water”, German Patent No.

3631472 (24 March 1988).

5. C. Mishra, “Industrial Alumina Chemicals, Oxides and Hydroxides of Aluminum”, Alcoa Laboratories, Alcoa Center,

PA, (1987) pp. 36-40.

6. R. Brace and E. Matijevic, ”Aluminum Hydrous Oxide Sols.I. Sphericles of Narrow Size Distribution.” J. Inorg. Nucl.

Chem., 35 (1973) 3691-3705.

7. L. Gordon, M. L. Salutsky and H. H. Willard, “Precipitation from Homogeneous Solution”, John Wiley & Sons, Inc.,

New York, N. Y., (1959).

8. B. C. Cornilsen and J.S. Reed, “Homogeneous Precipitation of Basic Aluminum Salts as Precursors for Alumina,”

Ceramic Bulletin, 58 [12] (1979) 1199.

9. M. D. Sacks, T-Y. Tseng and S. Y. Lee. “Thermal Decomposition of Spherical Hydrated Basic Aluminum Sulfate,”

Ceramic Bulletin, 63 [2] (1984) 301-310.

10. J. E. Blendell, H. K. Bowen and R. L. Coble, “High Purity Alumina by Controlled Precipitation from Aluminum

Sulfate Solutions,” Ceramic Bulletin, 63 [6] (1984) 797-801.

11. R. A. Nyquist and R. O. Kagel, “Infrared Spectra of Inorganic Compounds”, Academic Press, New York (1971).

12. K. Nakamoto, “Infrared and Raman Spectra of Inorganic and Coordination Compounds”, Wiley, New York, (1978).

13. C. J. Serna, J. L. White and S. L. Hem, “Anion-Aluminum Hydroxide Interactions,” Soil Sci. Soc. Am. J., 41 (1977)

1009-1013.

14. R. Brace and E. Matijevic, “Aluminum Hydrous Oxide Sols-I,” J. Inorg. Nucl. Chem., 35 (1973) 3691-3705.

15. M. D. Sacks, T-Y. Tseng and S. Y. Lee. “Thermal Decomposition of Spherical Hydrated Basic Aluminum Sulfate,”

March 2006 | Volume 2 Page 9 of 10 DOI: 10.2240/azojomo0183

Cesar A. Contreras Satoshi Sugita Esthela Ramos and Leticia Torres

Ceramic Bulletin, 63 [2] (1984) 301-310.

16. J. P. Jolivet, M. Henry and J. Livage, “Metal Oxide Chemistry and Synthesis, from Solution to Solid State”, John

Wiley & Sons, LTD, England (2000) pp. 310-312.

17. L. T. Lee, P. Sumasundaran, “Adsorption of Polyacrylamide on Oxide Minerals”, Langmuir, 5 (1989) 854-860.

Contact Details

Cesar A. Contreras, Satoshi Sugita and Leticia Torres

Esthela Ramos

CIDEMAC, FCQ

CIQI Universidad Autonoma de Nuevo Leon

Universidad de Guanajuato Guerreo y Progreso s/n

Noria Alta s/n Monterrey N.L.

Col. Noria Alta, Guanajuato, Gto. Mexico. C.P. 64570

Mexico. C.P. 36050

E-mail: cesarcon@quijote.ugto.mx

This paper was also published in print form in “Advances in Technology of Materials and Materials Processing”, 8[1]

(2006) 35-40.

March 2006 | Volume 2 Page 10 of 10 DOI: 10.2240/azojomo0183

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Product Bulletin Nu-Calgon Product Bulletin: Product Name Evap Pow'rDocument2 pagesProduct Bulletin Nu-Calgon Product Bulletin: Product Name Evap Pow'rmsaidsaidyoussefNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- ArtyDocument3 pagesArtymsaidsaidyoussefNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Mab FfmuDocument4 pagesMab FfmumsaidsaidyoussefNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- IVD ClassificationDocument1 pageIVD ClassificationmsaidsaidyoussefNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Fermentas BuffersDocument2 pagesFermentas BuffersmsaidsaidyoussefNo ratings yet

- Effects of Adsorption To Aluminum Salt Adjuvants On The Structure and Stability of Model Protein AntigensDocument9 pagesEffects of Adsorption To Aluminum Salt Adjuvants On The Structure and Stability of Model Protein AntigensmsaidsaidyoussefNo ratings yet

- Thesis Final ETDver2Document185 pagesThesis Final ETDver2msaidsaidyoussefNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Adverse Effect of AdjuvantsDocument8 pagesAdverse Effect of AdjuvantsmsaidsaidyoussefNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Process: Aluminium Hydroxide Gel Powder (Ip Grade)Document2 pagesProcess: Aluminium Hydroxide Gel Powder (Ip Grade)msaidsaidyoussefNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- IFCC HbA1Document9 pagesIFCC HbA1msaidsaidyoussefNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Alpha Phase AluminaDocument266 pagesAlpha Phase AluminaböhmitNo ratings yet

- Metallurgy of AluminiumDocument9 pagesMetallurgy of Aluminiumhassan materialsNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Fluidisation TechnologyDocument16 pagesFluidisation TechnologyMostafa MehrjerdiNo ratings yet

- Atc2 U1 HidrometalurgiaDocument13 pagesAtc2 U1 HidrometalurgiaDANIEL EDUARDO CORTEZ GONZALEZNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Gland PlatesDocument102 pagesGland Platespaulo cesar hernandez mijangosNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Sequential Leaching For The Production of Alumina From A Nigerian ClayDocument7 pagesSequential Leaching For The Production of Alumina From A Nigerian ClayPuturrú De Fuá100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Alluminium ProductionDocument18 pagesAlluminium ProductionSovan NandyNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Dimas 2009 PDFDocument31 pagesDimas 2009 PDFlaurentiu_filipescuNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Ceramics I Lecture 0 Intro HS12 Lecture NoteDocument42 pagesCeramics I Lecture 0 Intro HS12 Lecture NoteXavier JonesNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 1 s2.0 S2238785419304600 MainDocument10 pages1 s2.0 S2238785419304600 Mainsketchup1990No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Extraction Metallurgy C B Perry 123sDocument123 pagesExtraction Metallurgy C B Perry 123smtanaydinNo ratings yet

- AMK Cradle-To-Gate LCA of Norðurál Primary Aluminium PDFDocument78 pagesAMK Cradle-To-Gate LCA of Norðurál Primary Aluminium PDFherrerapazNo ratings yet

- Opportunities and Challenges in CO2 UtilizationDocument23 pagesOpportunities and Challenges in CO2 UtilizationDaraNo ratings yet

- Park Et Al, 1997 - Production of Poly (Aluminum Chloride) and Sodium Silicate From ClayDocument5 pagesPark Et Al, 1997 - Production of Poly (Aluminum Chloride) and Sodium Silicate From ClayianphilanderNo ratings yet

- Kumpulan Soal Ver3 1Document27 pagesKumpulan Soal Ver3 1Yosia HutasoitNo ratings yet

- Availability of Bauxite Reserves: F. M. MeyerDocument12 pagesAvailability of Bauxite Reserves: F. M. MeyerJohn GiannakopoulosNo ratings yet

- Aluminium AssignmentDocument4 pagesAluminium AssignmentangellaNo ratings yet

- Metallurgical Processes ReviewDocument9 pagesMetallurgical Processes ReviewLeo Bayer PereiraNo ratings yet

- Ore Deposit Geology PDFDocument479 pagesOre Deposit Geology PDFcarlos ivan bahena100% (2)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Upgrading of Tayan'S Crude Bauxite Using Rotary Drum ScrubberDocument13 pagesUpgrading of Tayan'S Crude Bauxite Using Rotary Drum ScrubberEben EzerNo ratings yet

- Edwards 2010Document55 pagesEdwards 2010Devil faNo ratings yet

- Bauxite Technical NoteDocument4 pagesBauxite Technical NoteBiju Sebastian100% (1)

- Red Mud Treatment TechnologiesDocument28 pagesRed Mud Treatment Technologiesprakhar mishraNo ratings yet

- Unfired Brick Using Fly Ash and Red Mud Based On Geopolymer TechnologyDocument7 pagesUnfired Brick Using Fly Ash and Red Mud Based On Geopolymer TechnologyRajNo ratings yet

- Digestion and EvaporationDocument3 pagesDigestion and EvaporationsreenuNo ratings yet

- Potline ProcessDocument12 pagesPotline ProcesssssduduNo ratings yet

- The Bayer Process Was Invented and Patented in 1887 by Austrian Scientist Karl Josef BayerDocument3 pagesThe Bayer Process Was Invented and Patented in 1887 by Austrian Scientist Karl Josef Bayeracanis1016No ratings yet

- Bauxite Ore To Aluminum MetalDocument12 pagesBauxite Ore To Aluminum MetalmaamounejjehNo ratings yet

- Silva2020 Chapter BrazilianBauxiteResiduePhysicaDocument9 pagesSilva2020 Chapter BrazilianBauxiteResiduePhysicaRayaraNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hindalco Industries Limited, Belgaum: Our VisionDocument15 pagesHindalco Industries Limited, Belgaum: Our VisionMadan Jaiswal0% (1)