Professional Documents

Culture Documents

United States Patent

Uploaded by

Barmak Cheraghi0 ratings0% found this document useful (0 votes)

32 views8 pagesOriginal Title

Us 4570341

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

32 views8 pagesUnited States Patent

Uploaded by

Barmak CheraghiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

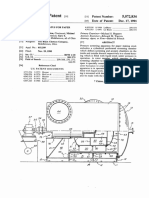

United States Patent (19) 11 Patent Number: 4,570,341

Konneker 45) Date of Patent: Feb. 18, 1986

(54) POCKETKNIFE WITH INTEGRAL RING 56) References Cited

FASTENER U.S. PATENT DOCUMENTS

900,339 10/1908 Woodruff ........................... 7/119 X

76 Inventor: Lloyd K. Konneker, 1810-A 2,896,290 7/1959 Salm et al. .......................... 7/118 X

Ashborough Rd., Marietta, Ga.

30067 FOREIGN PATENT DOCUMENTS

17031 of 1903 United Kingdom .................. 30/296

21 Appl. No.: 617,023

Primary Examiner-Douglas D. Watts

22 Filed: Jun. 4, 1984 Attorney, Agent, or Firm-Thomas & Kennedy

57 ABSTRACT

51) Int. Cl." ................................................ B26B 1/04 A pocketknife is formed with a latching mechanism that

52 U.S.C. .......................................... 30/161; 7/118; includes a catch and latch for releasibly holding a key

30/151; 30/155

58) Field of Search ................. 30/160, 161, 164, 159, ring.

30/151, 155-157; 7/118-120, 160; 145/61 R;

224/232, 233 4 Claims, 14 Drawing Figures

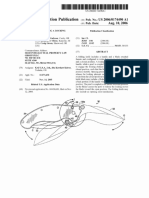

U.S. Patent Feb. 18, 1986 She of: 4,570,341

U.S. Patent Feb. 18, 1986 Sheet 2 of 4 4,570,341

U.S. Patent Feb. 18, 1986 Sheet 3 of 4 4.570,341

4,570,341 2

1.

In yet another form of the invention a foldable knife

POCKETKNIFE WITH INTEGRAL RING comprises a sheath that includes a pair of side plates

FASTENER spaced apart by a bar. A blade has a blade tang pivota

bly mounted to the sheath for movement between a

TECHNICAL FIELD sheathed position with a blade cutting edge located

This invention relates to knives of the type having a within the sheath and an unsheated position with the

blade that may be folded into a handle which are com

blade cutting edge located outside the sheath. The fold

monly referred to as pocketknives. able knife also includes latching means for releasibly

latching a key ring to the sheath.

BACKGROUND OF THE INVENTION 10

BRIEF DESCRIPTION OF THE DRAWING

Pocketknives have a blade mounted to a housing, FIG. 1 is an exploded view, in perspective, of a pock

which serves both as a sheath and as a handle, for pivot etknife embodying principles of the invention in one

able movement between sheathed and unsheathed posi form.

tions. They are well known in the art as exemplified by 15 FIG. 2 is a side elevational view of the pocketknife

those illustrated in U.S. Pat. Nos. 3,568,315, 4,148,140 illustrated in FIG. 1 shown with the knife blade in an

and 4,302,877. Such knives are well suited for general unsheathed position.

purpose, occasional use while carried on a person as in FIG. 3 is a side elevational view of the pocketknife

men's trouser pockets and in ladies' handbags since they illustrated in FIG. 1 shown with one side plate removed

may assume a compact configuration with their blade 20 to reveal internal structural features and with its latch

safely stowed. Keys constitute another personal article ing means shown in an unlatched position with a key

that are carried in a similar manner. Typically, they are ring being released thereform.

grouped as a set placed on a key ring or on an endless FIG. 4 is another side elevational view of the knife as

key chain which, for purposes of this application, is also illustrated in FIG. 3 shown with its latching means in a

considered to be a ring. 25 latched position holding a key ring.

Heretofore, devices have been conceived for holding FIG. 5 is a side elevational view with a side plate

a key or a set of keys together with another type of removed of a pocketknife embodying principles of the

article. For example, in U.S. Pat. Nos. 2,706,902 and invention in an alternative form.

2,982,454 combination devices for personal use are dis FIG. 6 is a side elevational view of a pocketknife with

closed that have sheathes in which both a key as well as 30 a side plate removed which embodies principles of the

a nail file and a knife blade may be positioned. U.S. Pat. invention in another alternative form.

No. 4,317,638 discloses a holder for holding both a key FIG. 7 is a side elevational view of a pocketknife

ring and a writing pen. In U.S. Pat. No. 4,312,128 a shown with a side plate removed which embodies prin

device is taught for attaching a key ring or key chain to ciples of the invention in yet another form.

a cutting blade. 35 FIG. 8 is a side elevational view of a pocketknife

Although some of the just described devices have shown with a side plate removed which embodies prin

been capable of coupling together useful tools, their ciples of the invention in still another form.

structural shapes have been quite different from those of FIG. 9 is an exploded view, in perspective, of a pock

conventional pocketknives. For example, they have etknife which embodies principles of the invention in

typically been of simple, light weight design having 40 still another preferred form.

small blades of specialized shape and duty. Their blades FIG. 10 is a fragmentary side elevational view of the

have often been constructed to be detachable from the pocketknife illustrated in FIG. 9 showing a latch por

holder for use. They have typically had no interlock tion thereof in a latch open position.

mechanism for holding their blades in either a sheathed FIG. 11 is a fragmentary side elevational view of the

or in an unsheathed position. Thus, their structure and 45 pocketknife illustrated in FIG. 9 showing a latch por

form has been designed at a sacrifice of attributes attrib tion thereof in a latch closed position.

utable to conventional pocketknife designs which today FIG. 12 is an exploded view, in perspective, of a

have reached a high degree of refinement. Therefore, it pocketknife embodying principles of the invention in

is seen that a need remains for a pocketknife of a gener yet another preferred form.

ally conventional construction that may be used with 50 FIG. 13 is a side elevational view of the pocketknife

out blade detachment and to which a key ring may be illustrated in FIG. 12 with a side plate removed in a

releasibly fastened securely and with facility. It is to the latch open position.

fulfullment of such need that the present invention is FIG. 14 is a side elevational view of the pocketknife

primarily directed. illustrated in FIG. 12, with a side plate removed, shown

SUMMARY OF THE INVENTION

55 in a latch closed position.

DETAILED DESCRIPTION

In a preferred form of the invention a combination

article comprises cutting means that includes a blade With reference to the drawings, there is shown in

pivotably mounted to a blade housing and latching FIGS. 1-4 a pocketknife having a blade 10 formed with

means for releasibly holding a key ring to the cutting 60 a cutting edge 11 and a tang 12 which is formed with a

means that includes cooperating catch and latch means. notch 13 and with a lobe 14 that serves as a blade stop.

In another form of the invention a pocketknife com The blade tang is pivotably mounted to one end of a

prises a housing that includes a pair of juxtaposed side pair of identical side plates 16, that form a housing or

plates, a blade having a tang pivotably mounted to one sheath for the blade as well as a handle, by means of a

end of the pair of side plates, interlock means for releasi 65 pin 17 that extends through aligned holes in the blade

bly holding the blade in an unsheathed position with tang and the side plates. An edge 18 of each side plate is

respect to the side plates, and latching means for releasi furrowed to provide a finger grip. A lockbar 20 is pivot

bly holding a key ring to the housing. ably mounted by another pin 21 to a midportion of the

4,570,341

3 4.

two side plates 16. A spacer 23 is mounted between ends lockbar as done in the previously described embodi

24 of the two side plates by means of two pins 25 that ment.

extend through aligned holes in the side plates end 24 The embodiment of FIG. 6 differs from those of

and in the spacer bar 23. The spacer bar is provided FIGS. 1-4 and FIG. 5 primarily in the location of the

with a notch 27 in which an end of a leaf spring 28 is key ring latching means. The pocketknife here com

mounted. The sloping orientation of the notch 27 is such prises a blade 60 having a tang 61 formed with a notch

as to place the leaf spring in spring biased engagement 62 which tang is pivotably mounted between a pair of

with an edge of the lock bar, as shown. A lower end of side plates 63. Two spacer bars 65 and 66 are mounted

the spacer extends out from between the two side plates to an end 67 of the side plates opposite the end 68 to

and is provided with a rounded notch 30 that provides 10 which the blade tang is pivotably mounted. A leaf

a catch member of a latch. An end 32 of the lock bar 20 spring 69 is secured within a notch formed in the spacer

is seen to be positioned adjacent the notch 30 and ex 65 in spring biasing engagement with a lockbar 70 that

posed to ambience within a cutout 19 formed in the is pivotably mounted by pin 71 between the two side

edge of the side plates opposite edge 18. The lockbar plates. The lockbar 70 is formed with a tooth 73 for

end 32 functions as a latch bar while the opposite end of 15 interlocking engagement within the notch 62 formed in

the lockbar 20 is provided with a tooth 33 that may be the blade tang. The other end of the lockbar is formed

seated within the notch 13 formed in the blade tang to with a hook 75 which is shown substantially closing a

provide an interlocking mechanism. notch or catch 76 formed in the end 67 of the side plates.

With the components of the knife assembled the blade Thus, the latching means provided by hook 75 and

may be stowed in the sheathed orientation shown in 20 notches 76 is shown here closed. When it becomes de

FIG. 4. When it becomes desirable to use the knife the sirable to open the latching means the spring biased

blade 10 may be pulled by placing a fingernail within a lockbar is rotated clockwise thereby causing the hook

grip recess 35 and by then rotating the blade clockwise. to move upward opening the exit of notch 76.

Once the blade has been rotated approximately a half The pocketknife of FIG. 7 is seen to include a blade

turn the spring biased lockbar tooth 33 becomes inter 25 80 having a tang 81 formed with a notch 96 pivotably

locked within the notch 13, as shown in FIG. 1, thereby mounted between two side plates 82. This embodiment

holding the blade firmly in its unsheathed position includes a segmented lockbar system which includes a

shown in FIG. 2. Once it is desired to return the blade first bar 83 and a second bar 84 each of which bears

10 to its sheathed position the exposed end 32 of the 30 against a leaf spring 85 which is mounted to the side

lockbar is depressed whereupon the lockbar tooth 33 is plates by a pin 88. One end of the spring 85 bears against

moved out of interlocking engagement with the blade bar 83 to the left of its pivot pin 87 while the other end

by being removed from notch 13. With the blade re of the spring bears against bar 84 to the right of its pivot

leased it may be easily rotated back to its stowed or pin 86. An end 90 of bar 83 and an end 91 of bar 84

sheathed position. adjacent thereto extend into a cut out area 98 in the two

It will also be seen that not only may the blade be

35 side plates. Another end 89 of bar 83 is formed with a

moved between sheathed and unsheathed positions, but

tooth which slides against the periphery of tang 81 with

rotation of the blade. The other end 92 of the bar 84 is

the latch means may also be moved between latched also in the form of a tooth which projects over a catch

and unlatched positions by operation of the lockbar, as or notch 94 formed in an end of the side plates beneath

most clearly shown in FIG. 3. With the lockbar manu 40 a spacer and stop 93 thereby blocking the exit of the

ally depressed as shown here, it is moved away from a catch. So configured, the blade interlock system pro

position closing the catch provided by notch 30 where vided by tooth 89 and tang notch 96 and the latch sys

upon a key chain or key ring, as indicated by ring R, tem provided by catch 94 and lockbar tooth 92 may be

may be passed between the end of the catch and the end operated simultaneously or separately by inserting a

of the lockbar and seated within the notch 30. The ring 45 finger within the cut out area 98 and depressing the bar

R itself may be used to depress the lockbar. Once finger ends 90 and 91 against spring 85. With the blade

pressure is removed from the lockbar, it returns under sheathed, as shown, only the latch system is, of course,

the bias provided by leaf spring 28 to a position closing actuated.

the catch or notch 30 as shown in FIG. 4. At all times In the embodiment illustrated in FIG. 8 a blade 101

the end 32 of the lockbar is prevented from rotating 50 has its tang 102 rotatably mounted to a pair of side

counterclockwise beyond a position in which the catch plates 103 that are formed with a cut out area 104 and a

or notch 30 is closed by the engagement of the end 33 of notch 105. Here too the pocketknife is provided with a

the lockbar with the tang 12 of the blade. Thus, in the segmented lock bar system having one bar 107 pivota

position shown in FIG. 4, the ring R may not be pulled bly mounted by pivot pin 108 to the side plates with an

free. Here the latching means for a key ring may be 55 end tooth 109 urged against the blade tang 102 for lock

opened at all times regardless of the position of the ing engagement with a notch 120 formed in the tang.

blade. The bar extends through the side plate cut out areas 104

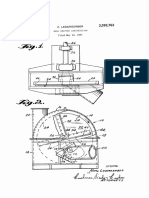

An alternative form of the pocketknife is illustrated in and terminates with a beveled end 110. A second bar

FIG. 5. Here a lobe or projection 40 is formed on a 112 is pivotably mounted by pin 113 to the side plates

blade 41 adjacent to the blade tang 42. When the blade 60 which bar also has a beveled end 114 overlying the

is sheathed between side plates 43 and manually de beveled end 110 of the bar 107. The bar 112 has a tooth

pressed, as shown, lobe 40 rotates a lockbar 44 clock or projection 116 that extends over the catch or notch

wise against a leaf spring 48 causing its end 45 to move 105 to serve as a latch bar. One end of a leaf spring 117

into contact with a stop 46 that projects outwardly from is mounted within a slot formed in a spacer 118 that is

a spacer 47 thereby opening a catch 48 formed in a 65 secured by pins 119 to the side plates. The leaf spring

lower, exposed portion of the spacer. Thus here the 117 is in spring biasing engagement with the bar 112 to

latching means for holding a key ring is opened by the right hand side of pin 113 as viewed in the figure

depression of the blade rather than by depression of the thereby urging it clockwise. In operation a user may

4,570,341 6

5

place a finger within the cut out area 104 and rotate the combination spacer and blade stop 160 is mounted be

bar 107 clockwise against the force of the leaf spring to tween the two side plates. With this embodiment the

remove bar tooth 109 from its interlocked position latching means provided by the combination of blade

within the tang notch 120. In doing so, the bar 107 tang notch 159 and the side plate notches 157 is seen to

rotates bar 112 counterclockwise thereby clearing hook be open or unlatched in all rotary positions of the blade

116 from its position blocking the exit of notch 105, except that of its closed or sheathed position as illus

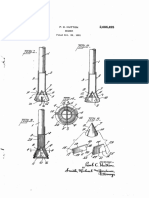

thereby enabling a key ring to be removed from or trated in FIG. 14. Therefore, in this embodiment, quite

placed within the notch. Of course, if the blade is in its contrary to the embodiment of FIGS. 9-11, a ring R

sheathed position, as shown in FIG. 8, tooth 109 is may be releasibly latched to the pocketknife when it is

already dislodged from notch 120. Nevertheless, with 10 in its closed position but inserted into the notch 157

this embodiment one manual motion may again serve to when in all unsheathed positions. The locking members

perform two functions, namely that of releasing the 152 and 153 serve to releasibly lock the blade in either

interlock as well as that of operating a key ring latch the open or closed position. When the blade is locked in

mechanism. the closed position illustrated in FIG. 14, the captured

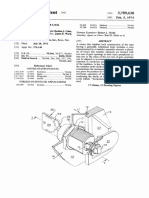

With reference next to FIGS. 9-11 the pocketknife 15 ring R may not be pulled free of the latching means.

here is seen to comprise a blade 130 having a tang 131 It thus is seen that a pocketknife is provided to which

pivotably mounted by a pin 132 to two side plates 133 a key ring or key chain or similar type article may be

which are formed with a catch provided by aligned releasibly attached. Though several different embodi

slots 135 in the ends thereof to which the blade tang is ments have been illustrated it should be understood that

pivotably mounted. The blade 130 is formed with a lobe 20 these merely illustrate preferred forms of the invention.

137 and a slot 138. A single lockbar 140 is pivotably Many modifications, additions and deletions may there

mounted by a pivot pin 141 between the two side plates fore be made thereto without departure from the spirit

so as to have an end 142 accessible to ambience for and scope of the invention as set forth in the following

manual depression as by a finger inserted into a cut out claims.

area 143 formed along an edge of the two side plates. 25 I claim:

The other end 144 of the lockbar is in the shape of a 1. An article of manufacture comprising, in combina

tooth configured for seating engagement within the tion, cutting means that includes a blade pivotably

tang slot 138. A spacer 146 is mounted by pins 147 to the mounted to a blade housing and latching means for

side plate adjacent the cut out area 143. The spacer 146 releasibly holding a key ring to said cutting means that

is provided with a slot in which one end of the leaf 30 includes cooperating catch means and latch means with

spring 148 is press fitted. The other end of the spring is said catch means defining a catch exit and said latch

in biasing engagement with an edge of the lockbar 140. means being mounted for movement relative to said

The manner in which latching is achieved here is catch means into and out of positions restricting said

illustrated in FIGS. 10 and 11. In FIG. 10, it is seen that exit, said latch means including a lockbar pivotably

the slots 135 and 138 are sufficiently aligned by the 35 mounted to said blade housing for movement of a first

relative rotary positions of the blade tang and the side lockbar end between a position closing said catch means

plates so as to provide access to the bottom of the slot exit to a position opening said catch means exit, and

138 and ambience for a ring R to be passed freely into wherein a second end of said lockbar is spring biased

and out thereof. This is achieved with the blade gener into engagement with the tang of said blade.

ally in the position illustrated in FIG. 10. Once the blade 2. The article of claim 1 wherein said blade tang is

is sheathed, as illustrated in FIG. 11, the exit of the slot formed with a notch and wherein said second end of

135 is closed by a portion of the tang 131. In the fully said lockbar is formed with a tooth for releasibly inter

open position the blade completely blocks off the slot locking engagement with said tang notch.

135. Thus here the latch is open for ring insertion in 3. A foldable knife comprising a sheath that includes

only the specific position of the blade shown in FIG. 10 45 a pair of side plates spaced apart by a bar pivotably

and the latch is closed to capture a ring in only the mounted to said side plates, a blade pivotably mounted

specific position of the blade shown in FIG. 11. By to said sheath for movement between a sheathed posi

continuously pulling on a latched ring as the blade is tion with a blade cutting edge located within the sheath

swung, the ring will, of course, become detached as the and an unsheathed position with the blade cutting edge

blade passes through the position of FIG. 10. 50 located outside said sheath, and latching means for

Finally, with reference to FIGS. 12-14, still another releasibly latching a key ring to said sheath that includes

embodiment of the invention is shown which does not catch means defining a catch exit and latch means

include a lockbar and spring as do the other embodi mounted for movement relative to said catch means into

ments. Here, the pocketknife includes a blade 150 and out of positions restricting said exit, and wherein

mounted between two side plates 151 by cylindrical, 55 said latch means includes a latch on an end of said bar

telescoping locking members 152 and 153 which pass and a catch on said sheath adjacent said latch.

through aligned holes 154 in the side plates and hole 155 4. The knife of claim 3 further comprising spring

in the blade tang 156. These locking members may be of means for biasing one end of said bar into engagement

the same structure as of those detailed in the previously with the tang of said blade and for biasing said latch on

mentioned Patent No. 4,148,140. Each side plate has a 60 the bar end opposite said one end into a position latch

catch or notch 157 adjacent its hole 154. The blade tang ing said catch closed.k k se it k

is formed with a latch-like or hook-shaped notch 159. A

65

You might also like

- US5421114 DerringerDocument12 pagesUS5421114 Derringeruntersberg91% (11)

- Tunnel Thru The Air Correct Starting PointDocument2 pagesTunnel Thru The Air Correct Starting Pointkhit wong54% (13)

- Denso Mitsubishi L200 Common Rail PDFDocument53 pagesDenso Mitsubishi L200 Common Rail PDFAlex Renne Chambi100% (8)

- US3448518Document4 pagesUS3448518liebersax8282No ratings yet

- US4893426Document7 pagesUS4893426Jean DelaronciereNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2006/0174490 A1Document12 pagesPatent Application Publication (10) Pub. No.: US 2006/0174490 A1Слэйтер Строительная компанияNo ratings yet

- Us4252504 PDFDocument7 pagesUs4252504 PDFAhmed EltemsahNo ratings yet

- March 9, 1971 - F. G. Smith 3,568,315: Filed Oct. 2, 1968Document4 pagesMarch 9, 1971 - F. G. Smith 3,568,315: Filed Oct. 2, 1968Barmak CheraghiNo ratings yet

- Us 4689908Document6 pagesUs 4689908djsfNo ratings yet

- United States Patent: Vodinh (10) Patent N0.: (45) Date of PatentDocument12 pagesUnited States Patent: Vodinh (10) Patent N0.: (45) Date of PatentJames LindonNo ratings yet

- United States Patent (19) : ReinschreiberDocument6 pagesUnited States Patent (19) : ReinschreiberBarmak CheraghiNo ratings yet

- United States Patent (19) : Filed: July 27, 1976 57Document3 pagesUnited States Patent (19) : Filed: July 27, 1976 57Alexandre Magno Bernardo FontouraNo ratings yet

- Sling GunDocument7 pagesSling GunMinh100% (1)

- United States Patent (19) : Felix-DalichowDocument5 pagesUnited States Patent (19) : Felix-DalichowBarmak CheraghiNo ratings yet

- Title - Wood Chipper ConstructionDocument4 pagesTitle - Wood Chipper Constructionمحمد عبدالدايمNo ratings yet

- United States Patent (19) : (75) Inventor: Nahemia Sirkis, King County, WashDocument7 pagesUnited States Patent (19) : (75) Inventor: Nahemia Sirkis, King County, WashSandeep SNo ratings yet

- United States Patent (19) : GullettDocument7 pagesUnited States Patent (19) : GullettMaJoy GarciaNo ratings yet

- United States Patent (19) : HoenigDocument5 pagesUnited States Patent (19) : HoenigminiselNo ratings yet

- "A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Document7 pages"A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Guillermo Avila RiveraNo ratings yet

- Us3789638 PDFDocument13 pagesUs3789638 PDFjdanacayaNo ratings yet

- Vernier Caliper PatentDocument9 pagesVernier Caliper Patentmeinard angelesNo ratings yet

- US4335764Document7 pagesUS4335764Jorge ArbelaezNo ratings yet

- US4483464Document6 pagesUS4483464Joao LemesNo ratings yet

- U.S. Patent 6,797,871, Entitled "Pick and Method", To Adkin, Dated 2004.Document14 pagesU.S. Patent 6,797,871, Entitled "Pick and Method", To Adkin, Dated 2004.Anonymous a7S1qyXNo ratings yet

- United States PatentDocument6 pagesUnited States PatentLucian CostacheNo ratings yet

- Us 6131519Document4 pagesUs 6131519dgfhjsdg hfsdhyjNo ratings yet

- Dec. 14, 1948. O. G. Reske 2,456,446: - 2Z 2. 77zzvezzoDocument4 pagesDec. 14, 1948. O. G. Reske 2,456,446: - 2Z 2. 77zzvezzoAngelica Mae LargaNo ratings yet

- Foldable Boat FlierDocument5 pagesFoldable Boat FlierRakeshNo ratings yet

- Q Loader PatentsDocument20 pagesQ Loader Patentssjdarkman1930No ratings yet

- H!!!!! - EEHHE) : Nonononononon Niinin 'Document4 pagesH!!!!! - EEHHE) : Nonononononon Niinin 'Hadi KoraniNo ratings yet

- Us 6394517Document5 pagesUs 6394517Ezekiel BarreraNo ratings yet

- QZZZZZZZZZZZZ: PATENTED AUG, 21, 1906. No. 829,327Document3 pagesQZZZZZZZZZZZZ: PATENTED AUG, 21, 1906. No. 829,327Galo YambayNo ratings yet

- Filed Oct. 22, 1951: P. C. HuttonDocument5 pagesFiled Oct. 22, 1951: P. C. HuttonGalo YambayNo ratings yet

- Pants5 9Document14 pagesPants5 9Choo Wei shengNo ratings yet

- Us 3688484Document4 pagesUs 3688484James LindonNo ratings yet

- Us 6357155Document5 pagesUs 6357155edef345No ratings yet

- 撞针选择的枪 PDFDocument9 pages撞针选择的枪 PDFJin SongNo ratings yet

- Adjustable Cutting JigDocument10 pagesAdjustable Cutting JigFakrul HakimieNo ratings yet

- (Patente 1) US1489458Document3 pages(Patente 1) US1489458diegoNo ratings yet

- Post 6 36083 SA Repeating DerringerDocument18 pagesPost 6 36083 SA Repeating Derringerbadlabmouse0% (1)

- Us 5117735Document14 pagesUs 5117735sdfsdf333No ratings yet

- Revolver PatentDocument5 pagesRevolver PatentdududadamikeNo ratings yet

- Vernier DesignDocument9 pagesVernier DesignRakeshNo ratings yet

- Us3757634 PDFDocument6 pagesUs3757634 PDFagustinzmNo ratings yet

- Wadi-Xi? I: United States PatentDocument5 pagesWadi-Xi? I: United States PatentRamos GabeNo ratings yet

- United States Patent (19) : Assistant Examiner-Charles L. WillisDocument5 pagesUnited States Patent (19) : Assistant Examiner-Charles L. WillisJagannathan ArumugamNo ratings yet

- 2010-1151 SJ OrderDocument11 pages2010-1151 SJ OrderPATracerNo ratings yet

- US Patent 4677897Document8 pagesUS Patent 4677897Mosin-NagantNo ratings yet

- Description: (OCR Text May Contain Errors)Document6 pagesDescription: (OCR Text May Contain Errors)geeNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2002/0153034 A1Document25 pagesPatent Application Publication (10) Pub. No.: US 2002/0153034 A1Paballo MontleNo ratings yet

- O/ie/7 Covaz: Nov. 4, 1941. O. H. Cottingham 2,261,231Document5 pagesO/ie/7 Covaz: Nov. 4, 1941. O. H. Cottingham 2,261,231VyacheslavNo ratings yet

- 偏心枪支噪音抑制器和组装方法定位装置 PDFDocument6 pages偏心枪支噪音抑制器和组装方法定位装置 PDFJin SongNo ratings yet

- United States Patent 19Document9 pagesUnited States Patent 19Claudinei MayerNo ratings yet

- United States Patent (16) Patent N6. US 6,564,491 B2Document5 pagesUnited States Patent (16) Patent N6. US 6,564,491 B2edef345No ratings yet

- G. Ft. Saved. /6/27% Az: No. 591,525. Patented Oct. 12, 1897Document7 pagesG. Ft. Saved. /6/27% Az: No. 591,525. Patented Oct. 12, 1897Слэйтер Строительная компанияNo ratings yet

- United States PatentDocument13 pagesUnited States Patent63No ratings yet

- Jain. 1U, 1939. T.'4 Harris ': MW Gßz/:ÁwDocument4 pagesJain. 1U, 1939. T.'4 Harris ': MW Gßz/:Áwmoch rizki darmawanNo ratings yet

- Fitz 22.é.-Years: A 4-SeriesDocument3 pagesFitz 22.é.-Years: A 4-SeriesAlexandre Magno Bernardo FontouraNo ratings yet

- Diagrama Electrico de ControlDocument7 pagesDiagrama Electrico de ControlemernelsonmanNo ratings yet

- Patented Dec. I7, I90".: ' WH NesseszDocument3 pagesPatented Dec. I7, I90".: ' WH NesseszPayal MinochaNo ratings yet

- United States "Patents PDFDocument17 pagesUnited States "Patents PDFTien Nguyen VanNo ratings yet

- Fredkin Introduction To Digital PhilosophyDocument59 pagesFredkin Introduction To Digital PhilosophyEdoardo MatteiNo ratings yet

- Mud Pump CourseDocument88 pagesMud Pump CourseZeeshan SharifNo ratings yet

- Ascend P7: Huawei SchematicDocument51 pagesAscend P7: Huawei SchematicCarlos Andres EscamillaNo ratings yet

- Reference Manual - Model 6487 Picoammeter/Voltage SourceDocument338 pagesReference Manual - Model 6487 Picoammeter/Voltage SourceRanilson AngeloNo ratings yet

- Worksheet - Work and Power ProblemsDocument2 pagesWorksheet - Work and Power ProblemsDaisy Soriano PrestozaNo ratings yet

- Assignment 2 MKT 411Document3 pagesAssignment 2 MKT 411Farhad HossainNo ratings yet

- List of ROs Under VODocument74 pagesList of ROs Under VOvivek mishraNo ratings yet

- Surface Vehicle Standard: Rev. AUG1997Document6 pagesSurface Vehicle Standard: Rev. AUG1997anupthattaNo ratings yet

- Computer Aided ManufacturingDocument3 pagesComputer Aided ManufacturingVivek PatelNo ratings yet

- OutputDocument5 pagesOutputCarlos FazNo ratings yet

- List of Engineering Colleges in PakistanDocument7 pagesList of Engineering Colleges in PakistanFahad Bin ImtiazNo ratings yet

- 04-68350A Manual CCN DM01-DI01 PDFDocument47 pages04-68350A Manual CCN DM01-DI01 PDFtaha50% (2)

- Political Discourse A Critical Discourse Discourse A Critical Discourse AnalysisDocument13 pagesPolitical Discourse A Critical Discourse Discourse A Critical Discourse AnalysisJennina MazoNo ratings yet

- Graphic OrganizerDocument2 pagesGraphic OrganizerLex TalionesNo ratings yet

- Chap 3Document40 pagesChap 3eshbliNo ratings yet

- SECTION 33 05 13 Manholes: Revised 03/2012Document52 pagesSECTION 33 05 13 Manholes: Revised 03/2012FAISAL NAZEERNo ratings yet

- 015 Sami ZubaidaDocument2 pages015 Sami ZubaidaJuan Manuel CarriónNo ratings yet

- 2b FLUID STATIC - Pressure MeasurementDocument27 pages2b FLUID STATIC - Pressure Measurement翁绍棠No ratings yet

- Phy12l E301Document5 pagesPhy12l E301Arvn Christian Santicruz FloresNo ratings yet

- DT Unit2Document11 pagesDT Unit2riyafsharma2013No ratings yet

- Penurunan Waktu Tunggu Operasi Elektif Dengan Membuat Standar Prosedur Operasional Di Rumah Sakit Umum Karsa Husada BatuDocument8 pagesPenurunan Waktu Tunggu Operasi Elektif Dengan Membuat Standar Prosedur Operasional Di Rumah Sakit Umum Karsa Husada BaturirisNo ratings yet

- BLUE COLLAR JOBS Vs WHITE COLLAR JOBS.Document2 pagesBLUE COLLAR JOBS Vs WHITE COLLAR JOBS.Nelson VersozaNo ratings yet

- BAH Series 6000 Manguard - 113534-91Document40 pagesBAH Series 6000 Manguard - 113534-91AhmedNo ratings yet

- Evaluation Exam 1 Math Algebra and Trigonometry SET ADocument2 pagesEvaluation Exam 1 Math Algebra and Trigonometry SET AEngr. HLDCNo ratings yet

- Woldia University: The Role of Effective Communication in Resolving ConflictDocument17 pagesWoldia University: The Role of Effective Communication in Resolving ConflictMerry Hiyab100% (1)

- Valtra A114 HitechDocument31 pagesValtra A114 Hitechhicev32274No ratings yet

- Ground Effect Aerodynamics PDFDocument12 pagesGround Effect Aerodynamics PDFChegrani Ahmed100% (1)

- Sustainable Livelihood Security Index in A Developing Country: A Tool For Development PlanningDocument11 pagesSustainable Livelihood Security Index in A Developing Country: A Tool For Development PlanningTundeNo ratings yet